Cement-based material compression creep testing device

A cement-based material and testing device technology, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of low measurement accuracy, low measurement efficiency, poor voltage stabilization effect, etc., and achieve accurate measurement data and automation. High, high-efficiency measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

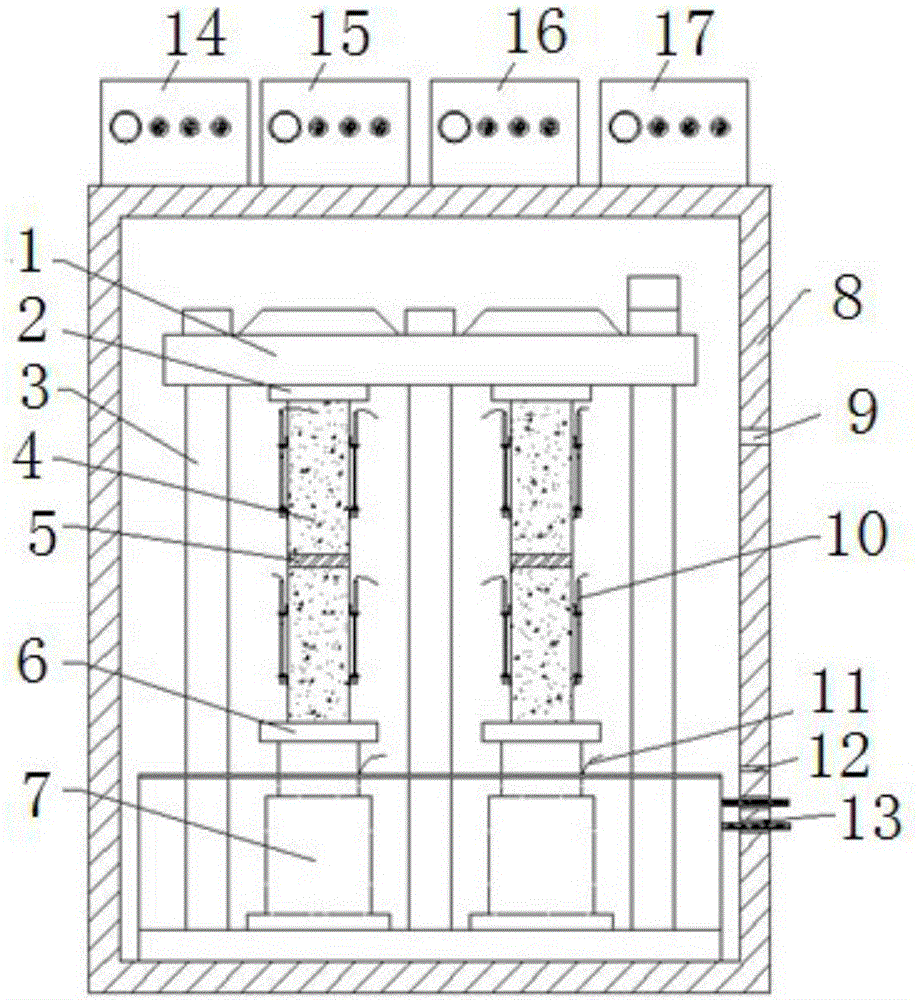

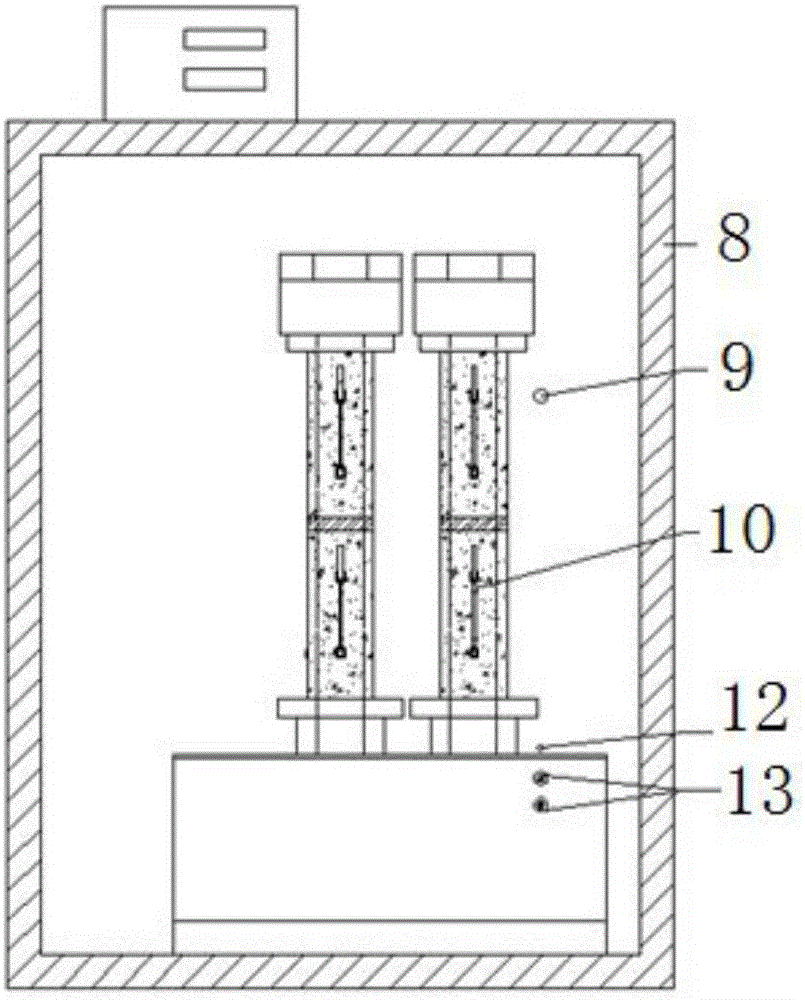

[0017] Referring to Figure 1, figure 2 and image 3 , a cement-based material compression creep test device, including a double-station gantry loader 3, a hydraulic drive part 7 is connected to the bottom of the double-station gantry loader 3, and a lower pressure plate 6 is fixed on the hydraulic drive part 7, The top of the double-station gantry loader 3 is a gantry reaction beam 1, the lower surface of the gantry reaction beam 1 is fixed with an upper platen 2, and an intermediate metal plate is clamped between the upper platen 2 and the lower platen 6. The cement-based material pouring test piece 4 connected in series with the connection plate 5;

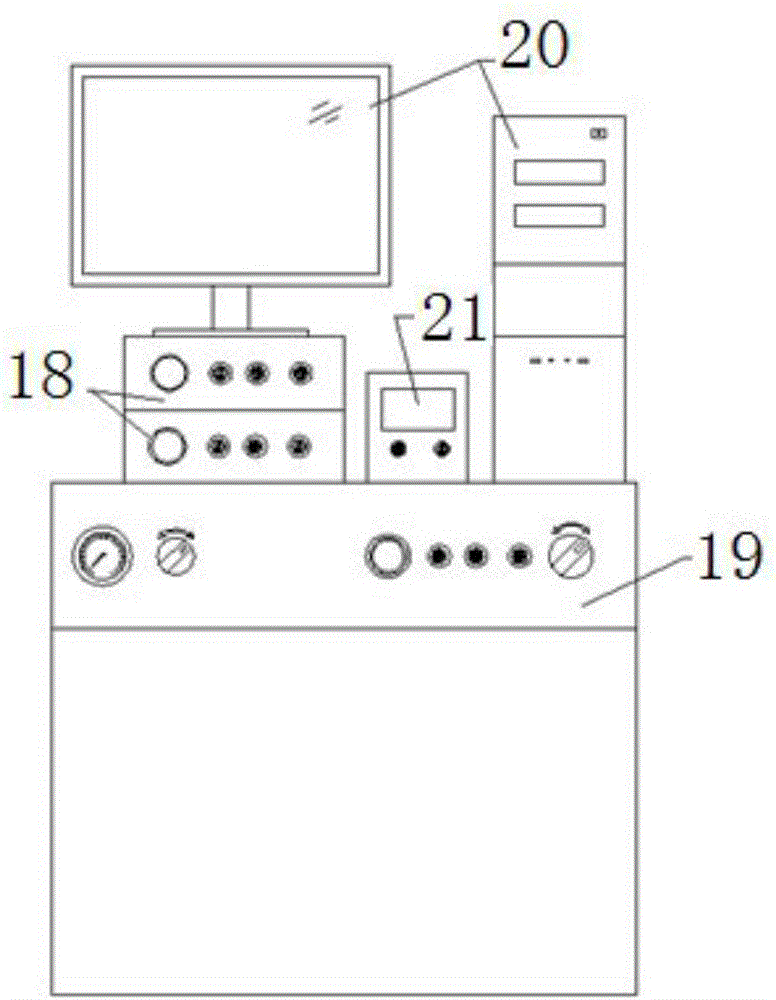

[0018] Described lower platen 6 is connected with load cell 11, and the signal output end of load cell 11 is connected with the input end of computer 20, and the output end of computer 20 is connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com