High-temperature creep property testing method based on section-variable test sample

A technology of high temperature creep and testing methods, applied in the direction of applying stable tension/pressure to test material strength, measuring devices, strength characteristics, etc. Insufficient long-term creep performance of materials and other issues, achieving high work efficiency, easy observation and handling, and saving test cycle and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0028] A high-temperature creep performance testing method based on a variable-section sample, comprising the steps of:

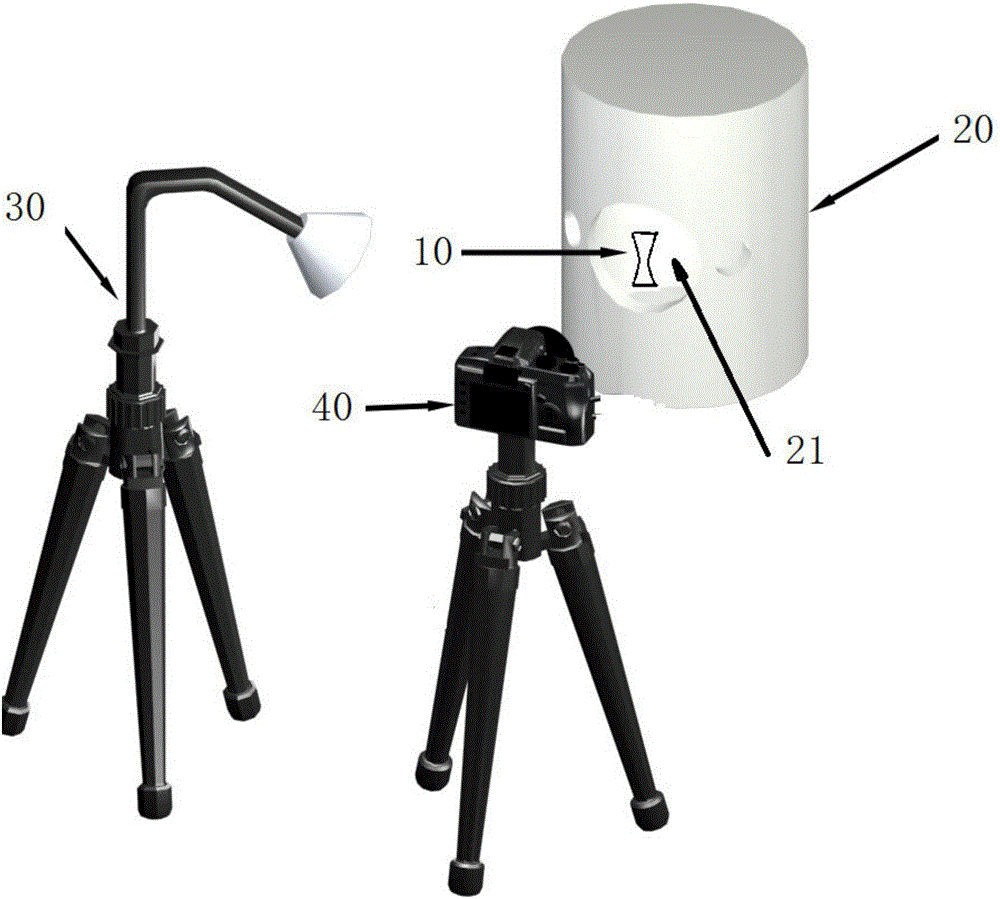

[0029] S1, spraying high-temperature paint on the surface of variable-section sample 10 to generate speckles.

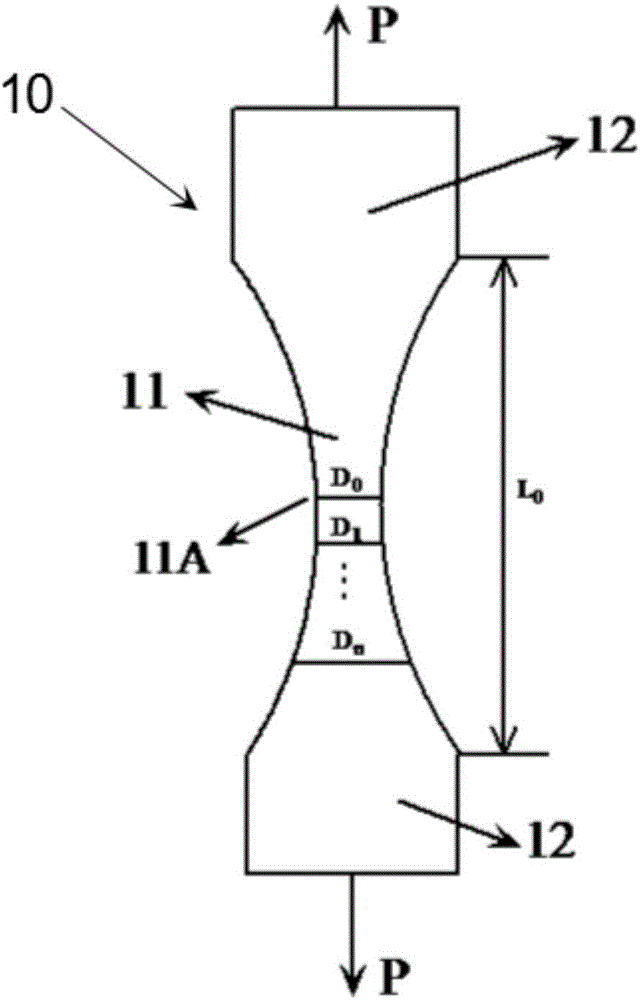

[0030] like figure 2 As shown, the variable cross-section sample 10 is rod-shaped, and the two ends of the variable cross-section sample 10 are set as clamping ends 12, and between the two clamping ends 12 is set as a sample segment 11 to be tested, and the sample segment 11 to be tested is The length is L 0 ; The cross-sectional diameter of the sample section to be tested 11 smoothly and gradually changes along the sample axis, and the diameter D of the middle cross section 11A of the sample section to be tested 11 0 Minimum, the diameter of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com