Patents

Literature

42results about How to "Short manufacturing period" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

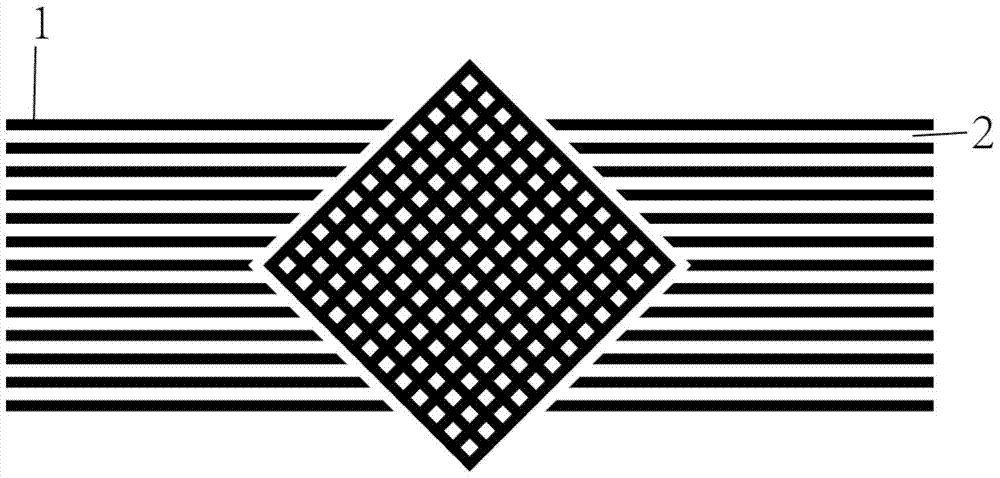

Manufacturing method of simulation fracture for fractured rock mass seepage test

InactiveCN105158039AOvercome limitationsHigh precisionPreparing sample for investigationPermeability/surface area analysisComputer Aided DesignSurface roughness

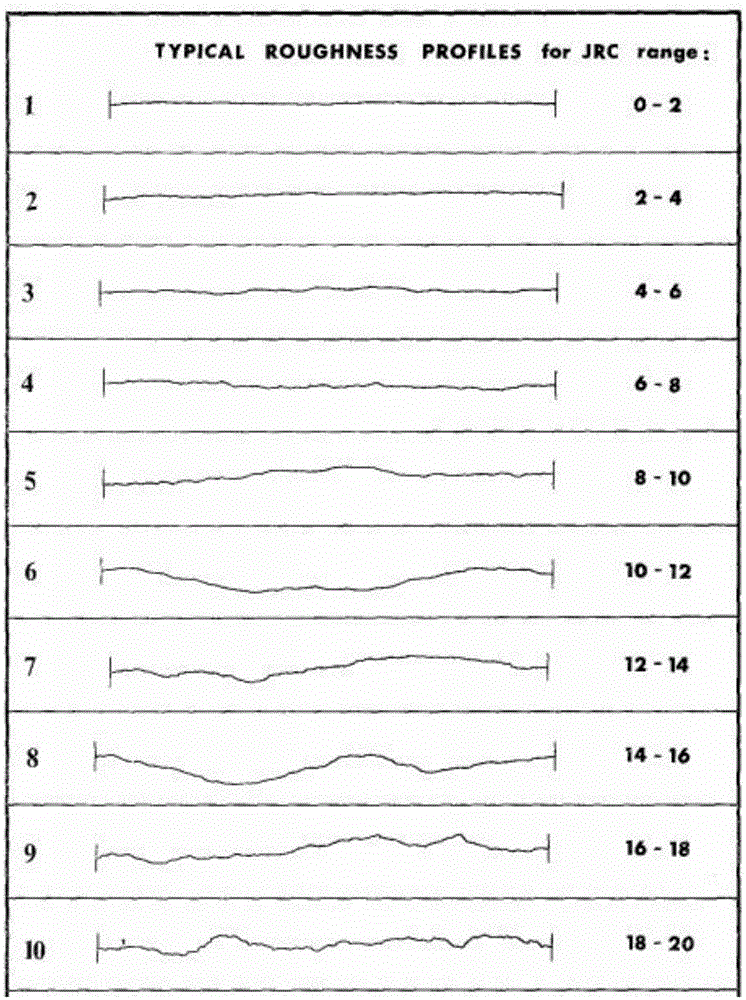

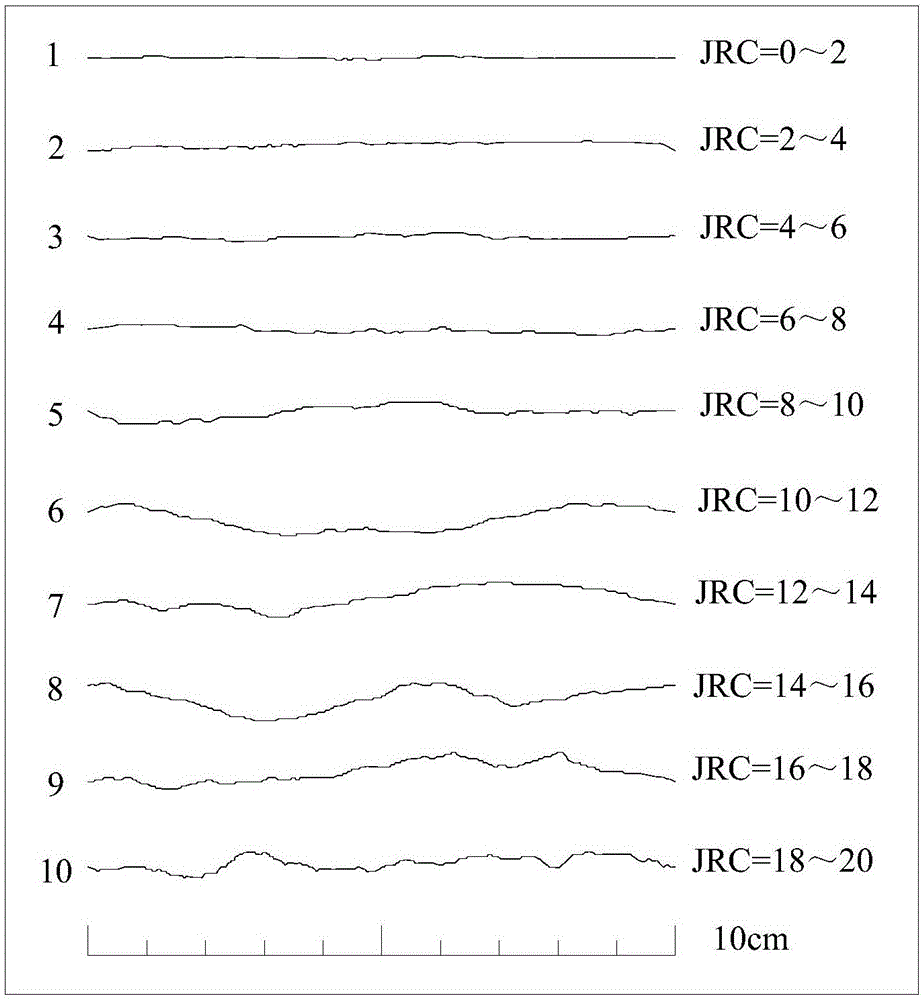

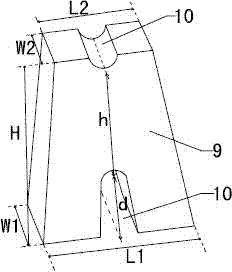

The invention discloses a manufacturing method of a simulation fracture for a fractured rock mass seepage test. The manufacturing method comprises the steps of drawing a fracture digitized profile curve, constructing a fracture three-dimensional model, making a fracture plate through 3D (three-dimensional) printing, making a fracture test piece casting model and performing casting and maintenance of a fracture test piece, specifically, through digitizing a rock structural surface joint roughness profile curve, drawing the fracture three-dimensional model on the basis of CAD (Computer Aided Design) software, making the fracture plate satisfying JRC value fluctuation by adopting a 3D printing technology, making the fracture test piece casting model by combining the fracture test piece, forming by using cement mortar to cast, and making the fracture test piece by performing maintenance in a cement test piece maintenance box for 28 days. The manufacturing method has the beneficial effects: the manufacturing method of rock rough fracture analogue simulation which is easy in observing, simple in manufacturing, convenient in testing, convenient for adjusting fracture opening, and capable of truly and accurately reflect rock mass fracture structural surface roughness is provided, the working procedures are simple and clear, the manufacturing duration is short, economy and efficiency are realized, the accuracy is high, and the adaptability is good.

Owner:HOHAI UNIV

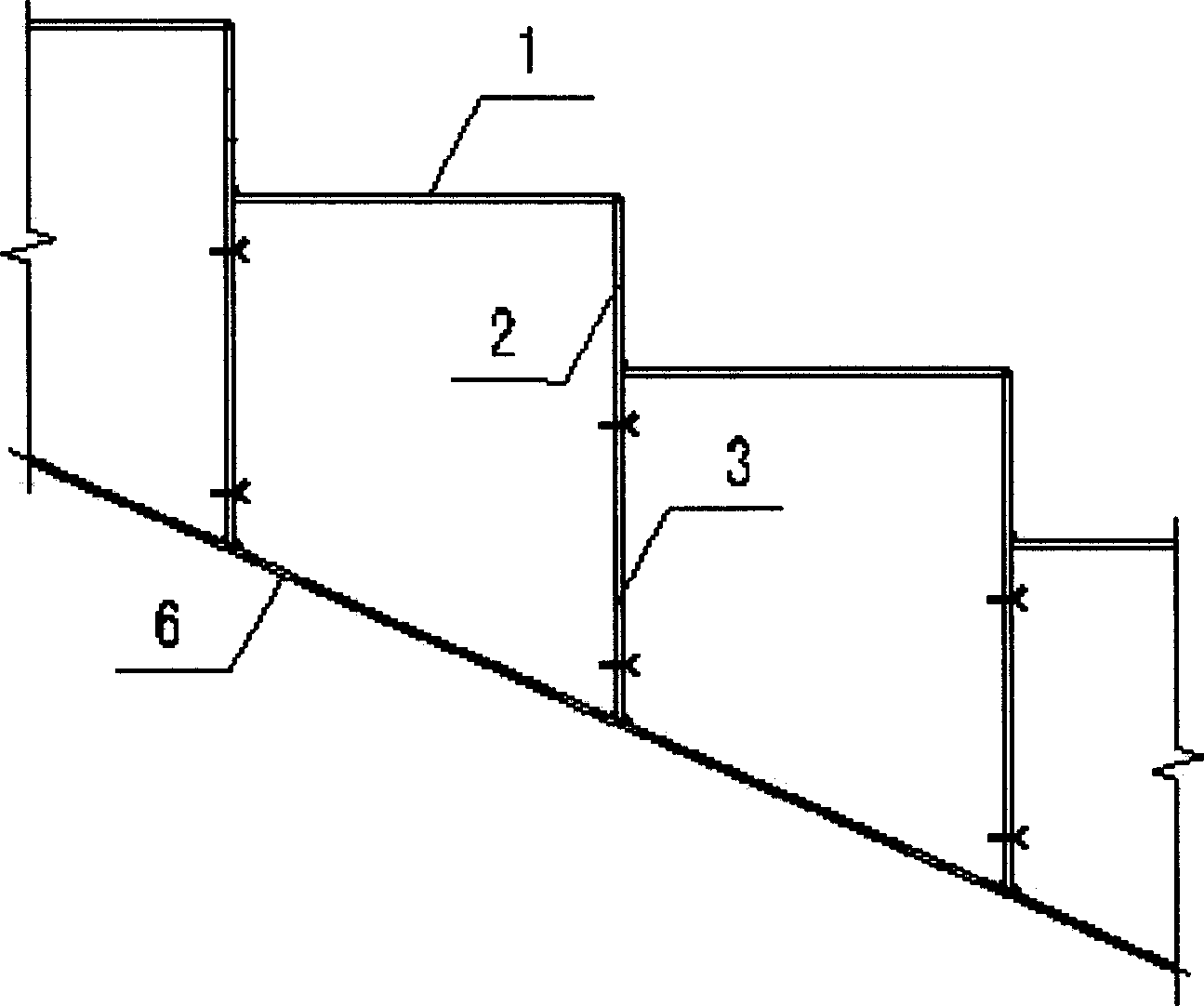

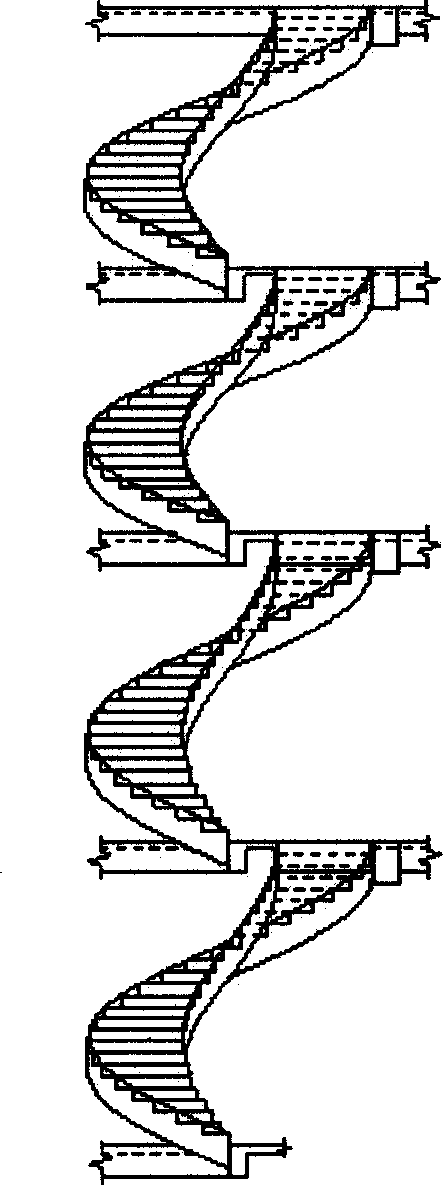

Integrally assembling staircase and method for fabricating same

The invention discloses an installation entire stair and the manufacturing method, especially an installation entire helix stair. The process is that: making every step to box structure and joining the steps into an entire stair by the method of bolt or joint. The shape of the stair could be straight stair or helix stair. The invention sharply decreases the time limit for a project and the cost. Moreover, it has advantages of simple structure, low cost and easy to realize mass production.

Owner:GUIZHOU UNIV

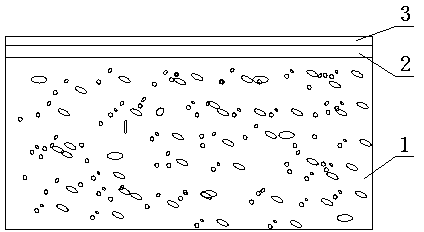

Sintered shale micropore building block and manufacturing method thereof

The invention discloses a sintered shale micropore honeycomb glaze building block and a manufacturing method thereof. The manufacturing method includes: stirring and mixing raw materials comprising shale, building spoil, sludge, rubbish, straw (such as tree branches, leaves, rotten wood or tree), coal gangue, water, and the like to obtain a viscous mixture, extruding and forming to obtain a workblank of the building block, coating at least one side surface of the workblank of the building block with a clay layer and a glaze layer, sintering and forming. The building brick is manufactured by the method. The building block and the manufacturing method have advantages of low cost, short production period, low energy consumption, high building block strength, light unit weight, low heat conductivity coefficient, and good energy-conservation, heat insulation, sound insulation effects. The building block is provided with the glaze layer and can be directly used as a wall surface, thus shortening the building period, reducing cement consumption, reducing environment pollution, and avoiding hazards of dropping of external tiles. In addition, the building block and the manufacturing method achieve processing of the agriculture straw, the coal gangue, the rubbish, and other waste and turn the waste into things of value, thus achieving effects of energy conservation and environmental protection.

Owner:晏兴洪

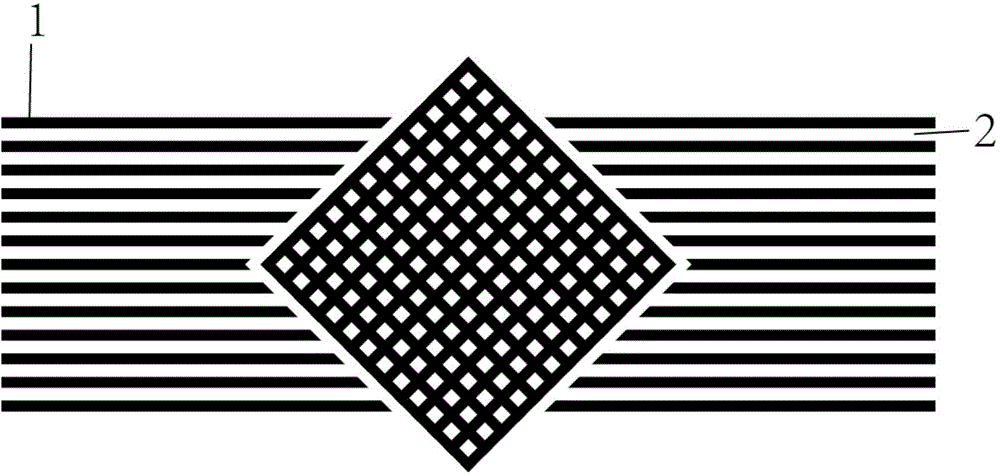

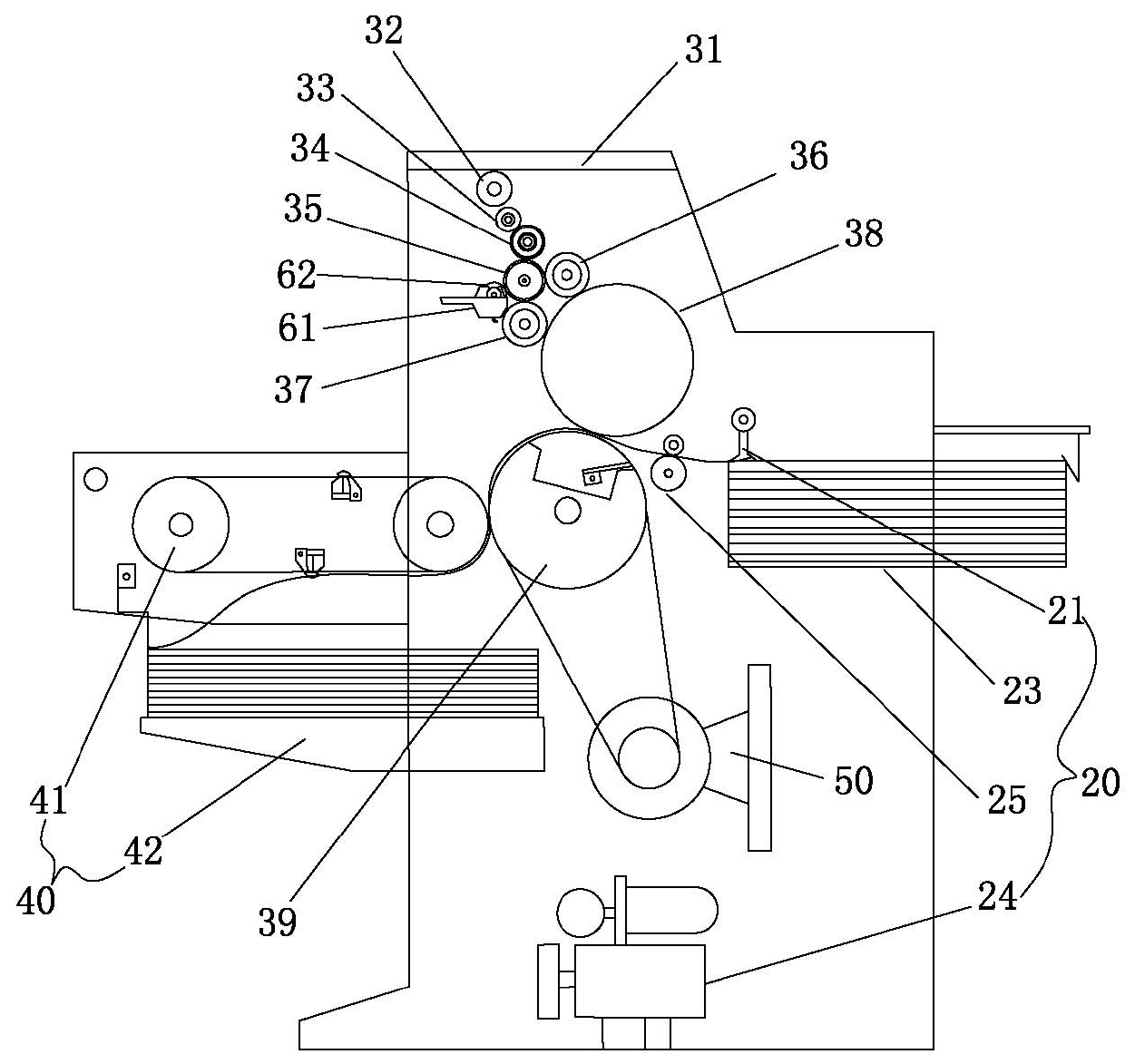

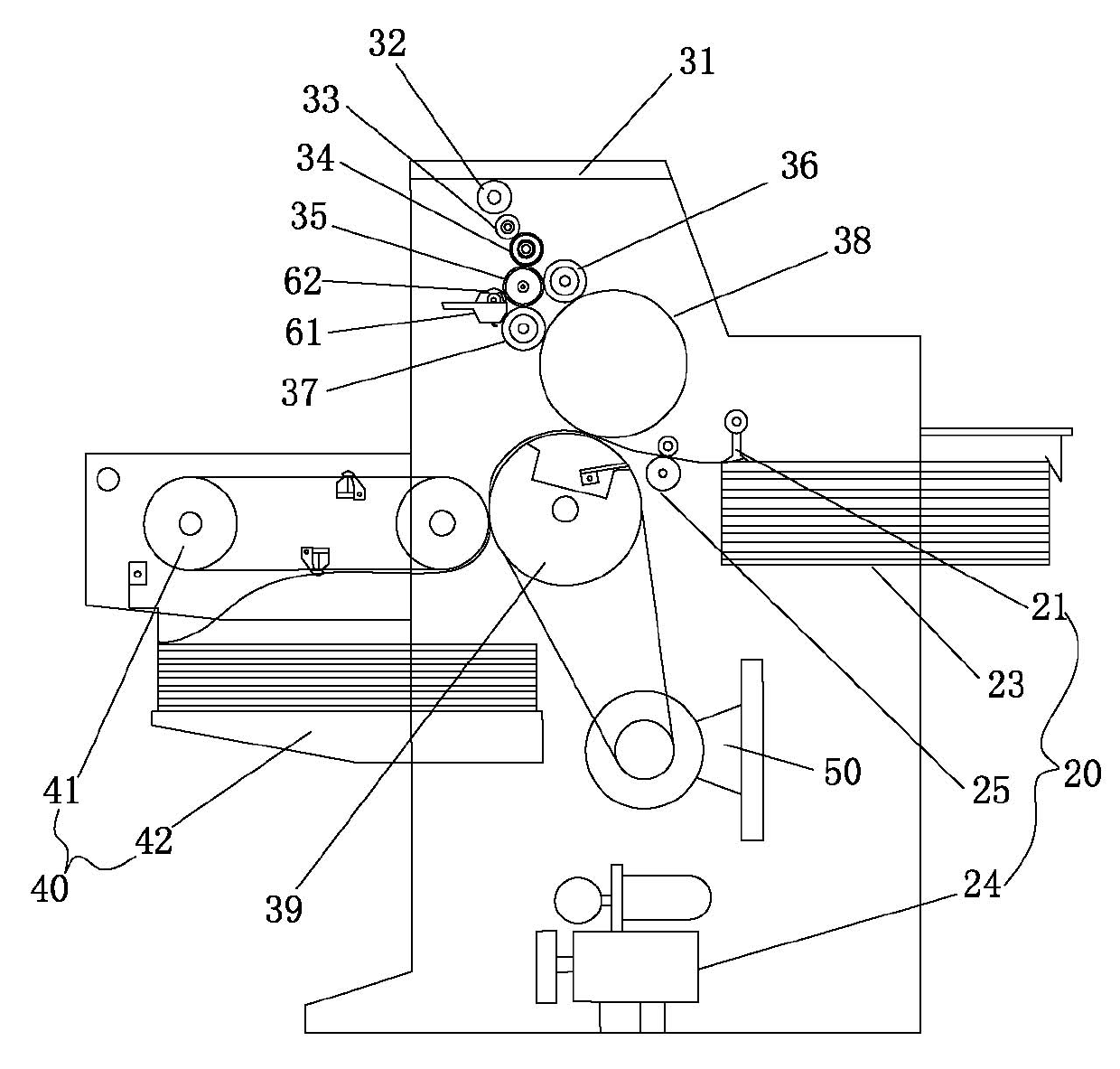

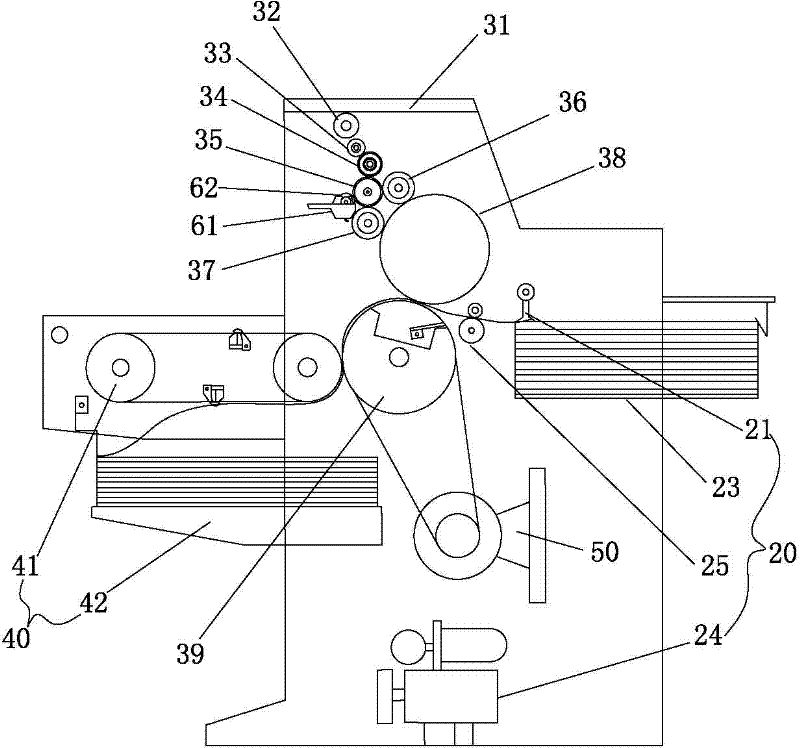

Three-dimensional effect glossing method of offset press

ActiveCN105082747AIncrease contrastImprove the three-dimensional effectPrinting press partsEngineeringHigh contrast

The invention discloses a three-dimensional effect glossing method of an offset press. The method includes the following steps that a product needing design of concave and convex space patterns is selected, graphic design software of a computer is utilized for making a manuscript with the needed concave and convex space patterns, the color value of the locations, needing a matte effect, of the patterns in the manuscript is set to be 100 k, and the color value of the rest is set to be 0 k; a CTP for UV printing is used for making formes; a color sequence is designed; each printing unit of the offset press is provided with one forme; oil ink of various colors is added to ink containers according to the sequence of the printing process, and reverse glossing ink is added to the corresponding last ink container in the printing process; a UV lamp in the offset press is turned on; the formes are subjected to sammeld ruck after being registered; and printed products are wholly coated with UV gloss oil through an anilox roller of the offset press. By means of the three-dimensional effect glossing method of the offset press, partial image-text has a high-contrast effect, a high three-dimensional effect is achieved, and printed products are delicate and have high quality.

Owner:LANGFANG BEIFANG JIAKE PRINTING

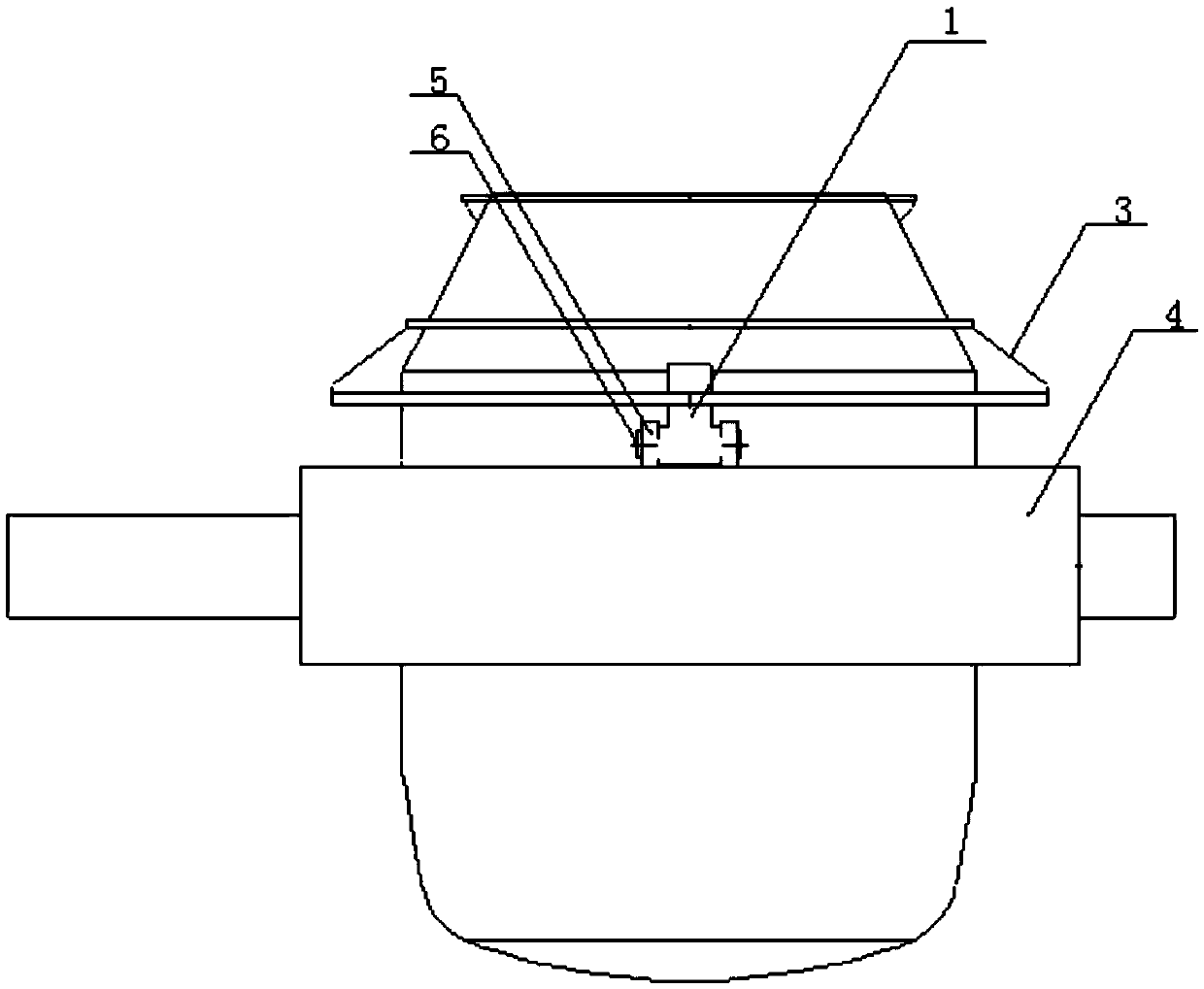

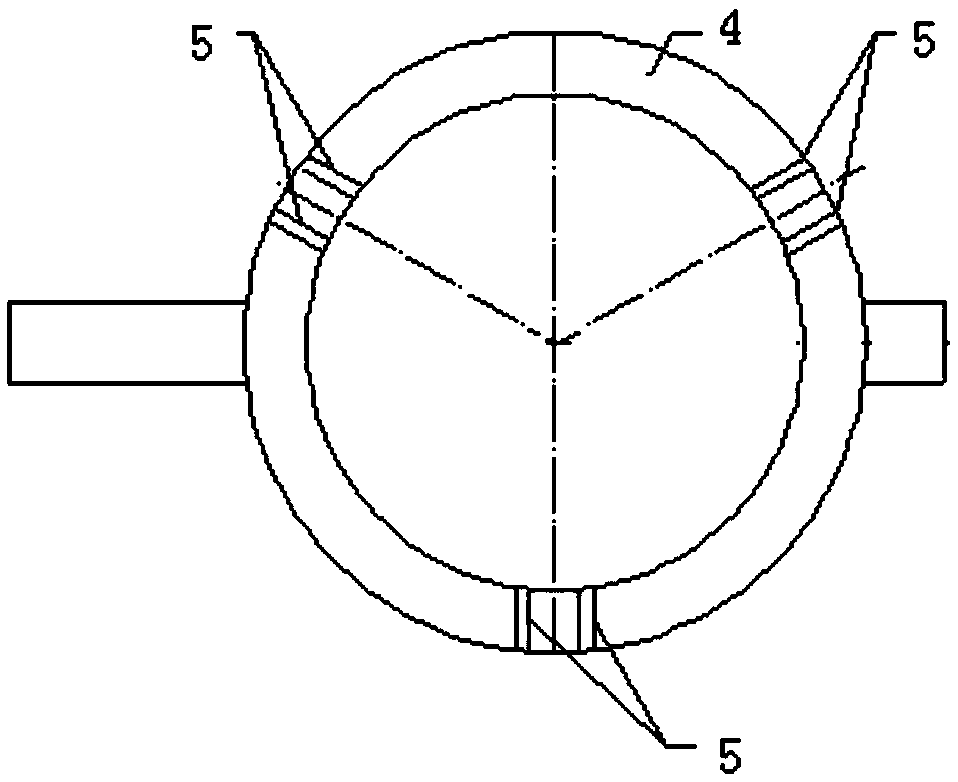

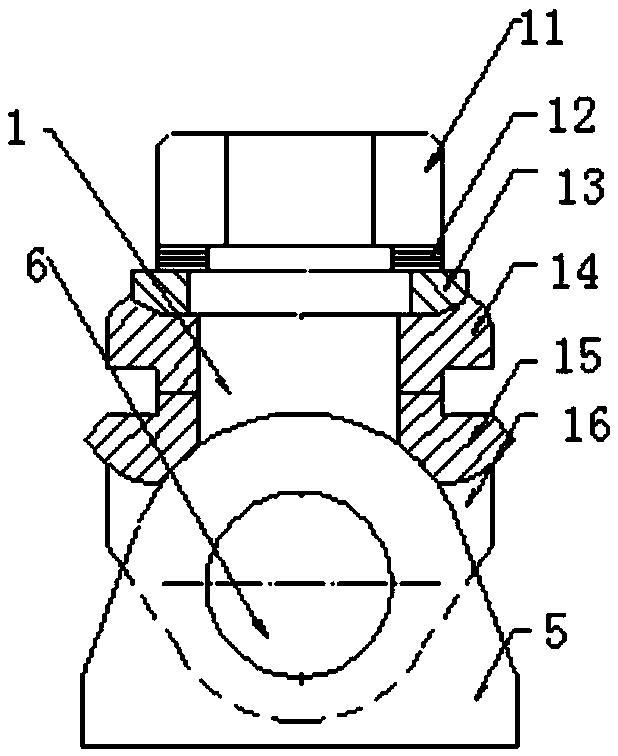

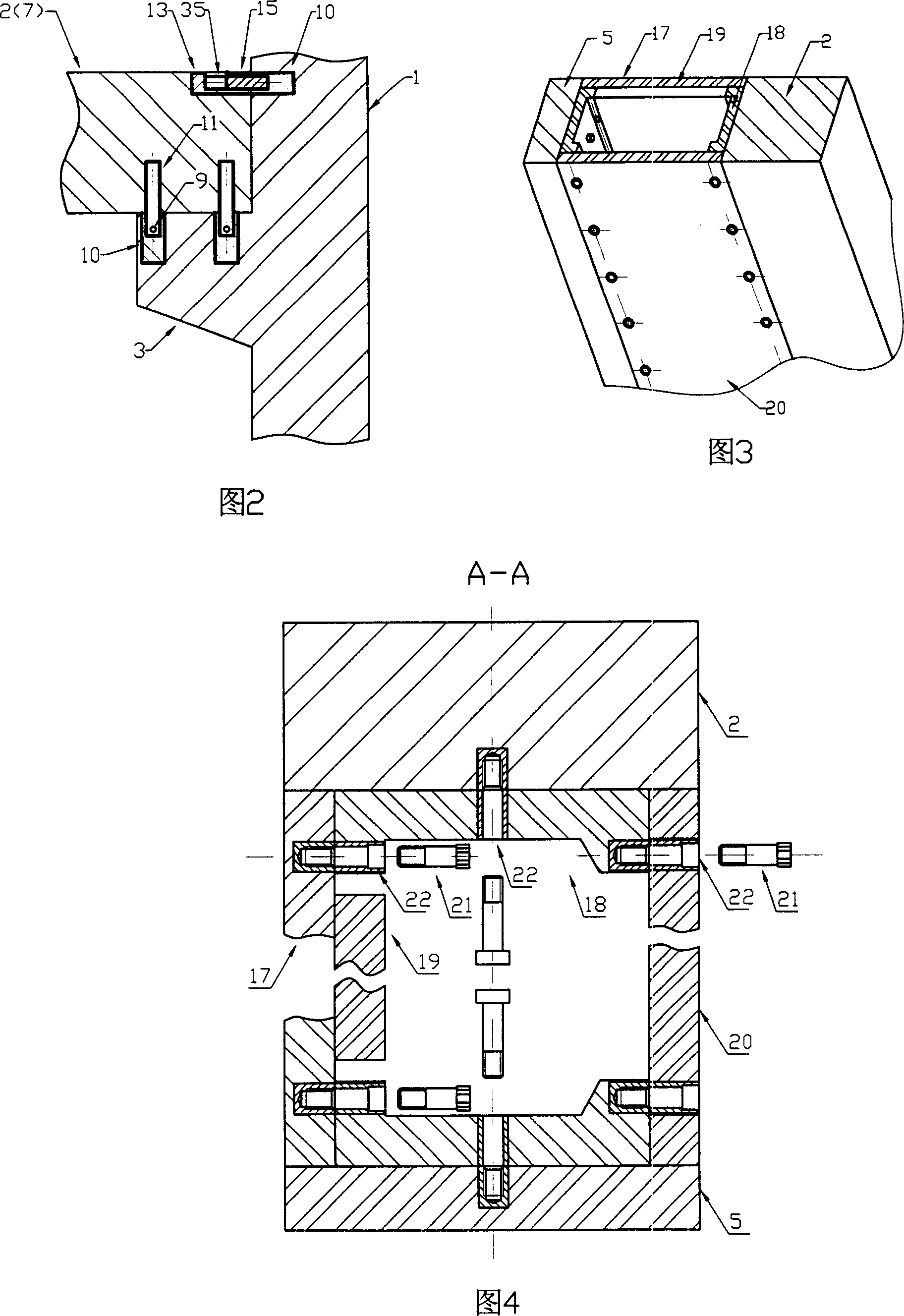

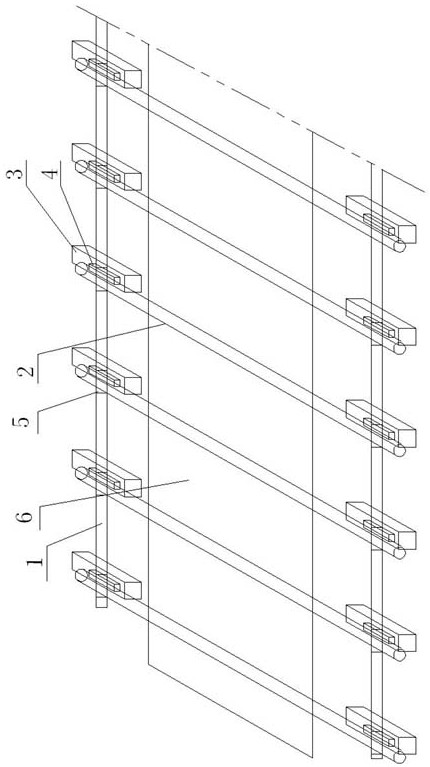

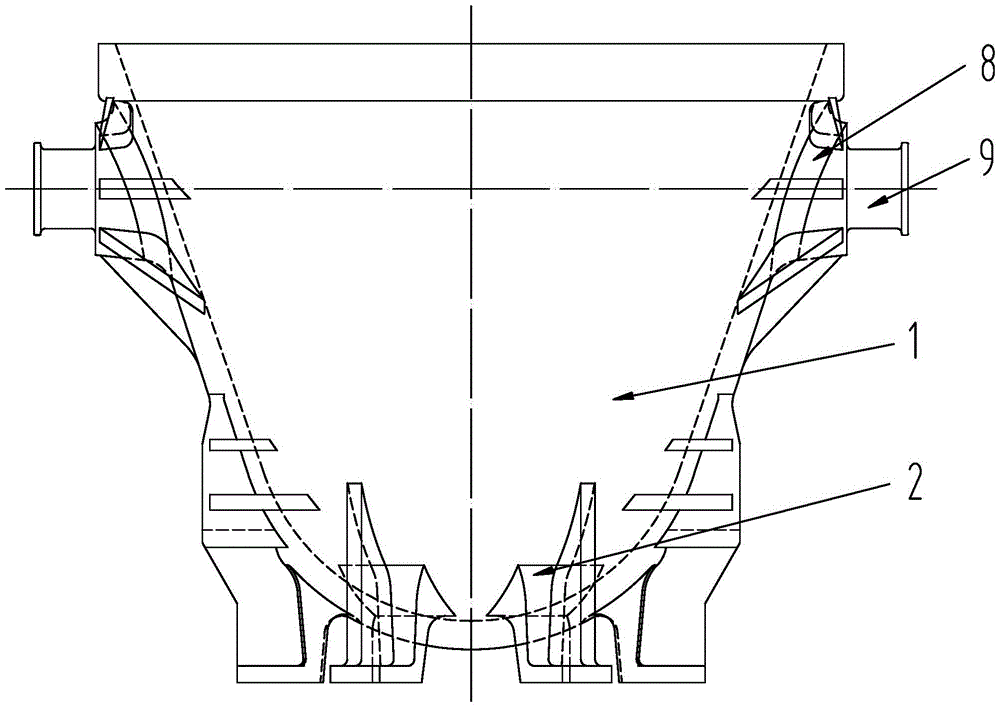

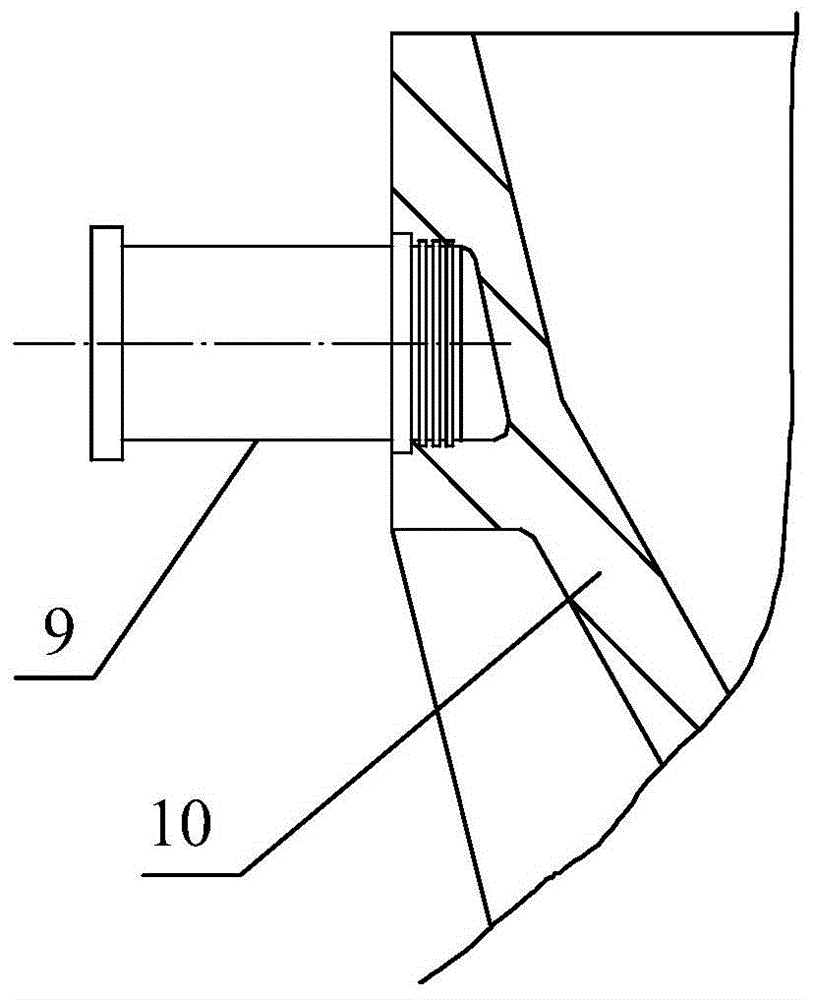

Mounting assisting device for three-point spherical bearing and mounting-welding method of mounting assisting device

ActiveCN105499891AReduce manufacturing costShorten the production periodWelding/cutting auxillary devicesArc welding apparatusSpherical bearingEngineering

The invention discloses a mounting assisting device for a three-point spherical bearing and a mounting-welding method of the mounting assisting device. The mounting assisting device comprises three-point support seats, a dummy shaft pin and temporary rigid supports II, wherein three points are uniformly formed at intervals of 120 degrees along the peripheral direction of a support ring, two three-point support seats are respectively symmetrically arranged on two sides of the center line of the three points, and the dummy shaft pin is located between the inner sides of the two mutually symmetric three-point support seats; and the temporary rigid supports II are symmetrically arranged relative to the center line outside the two mutually symmetric three-point support seats. Two sides of the three-point support seats are supported by the temporary rigid supports II, the dummy shaft pin is arranged between the three-point support seats to maintain the required mounting size, the temporary rigid supports II and the dummy shaft pin act together to enable the axial direction of the three-point support seats to be parallel to the plane on which the support ring is located, so that the side surfaces of the three-point support seats are vertical to the plane on which the support ring is located, the distances from the upper parts to the lower parts of the inner sides of the two three-point support seats are equal, and the mounting and the welding are prepared.

Owner:ANHUI MASTEEL ENG & TECH GRP

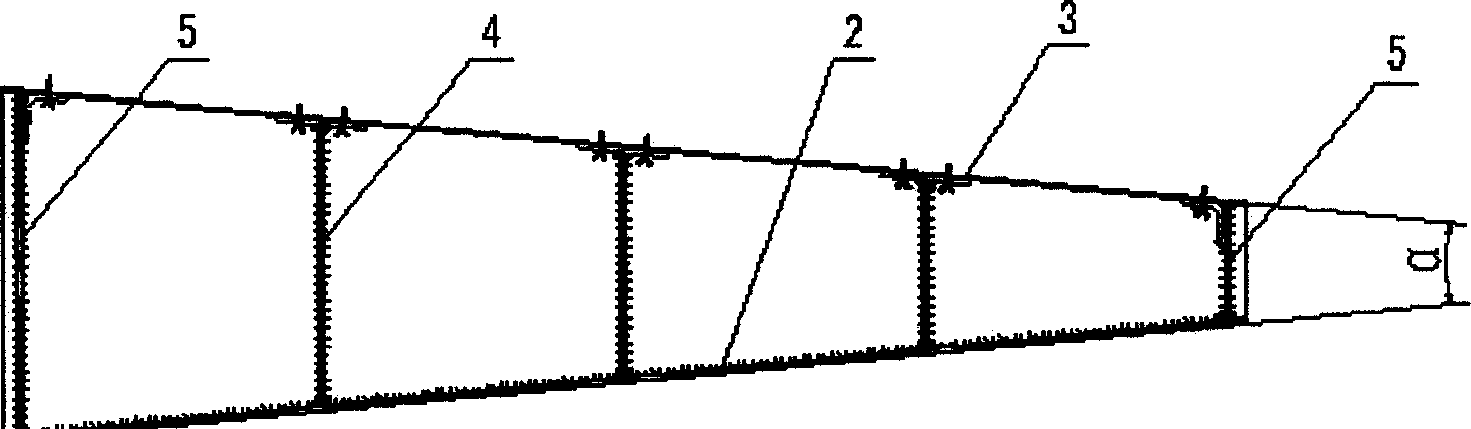

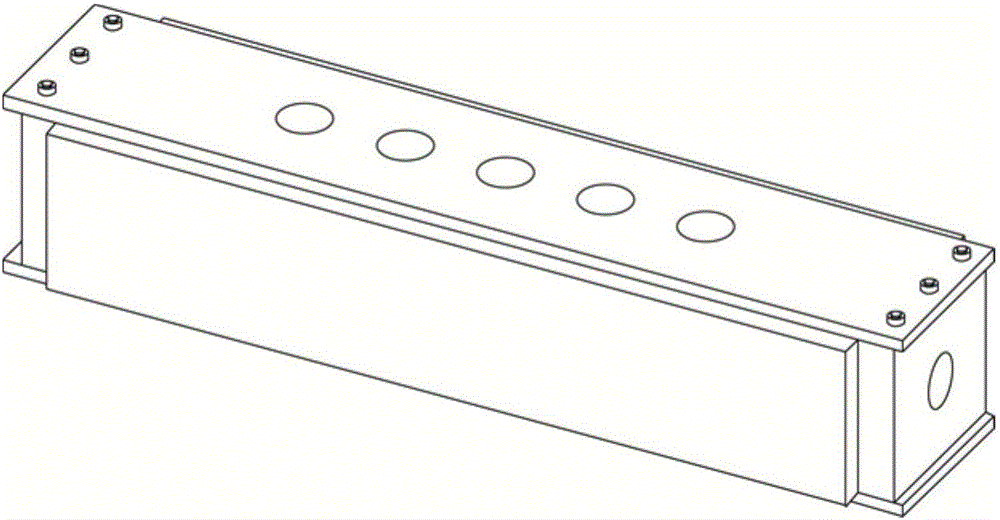

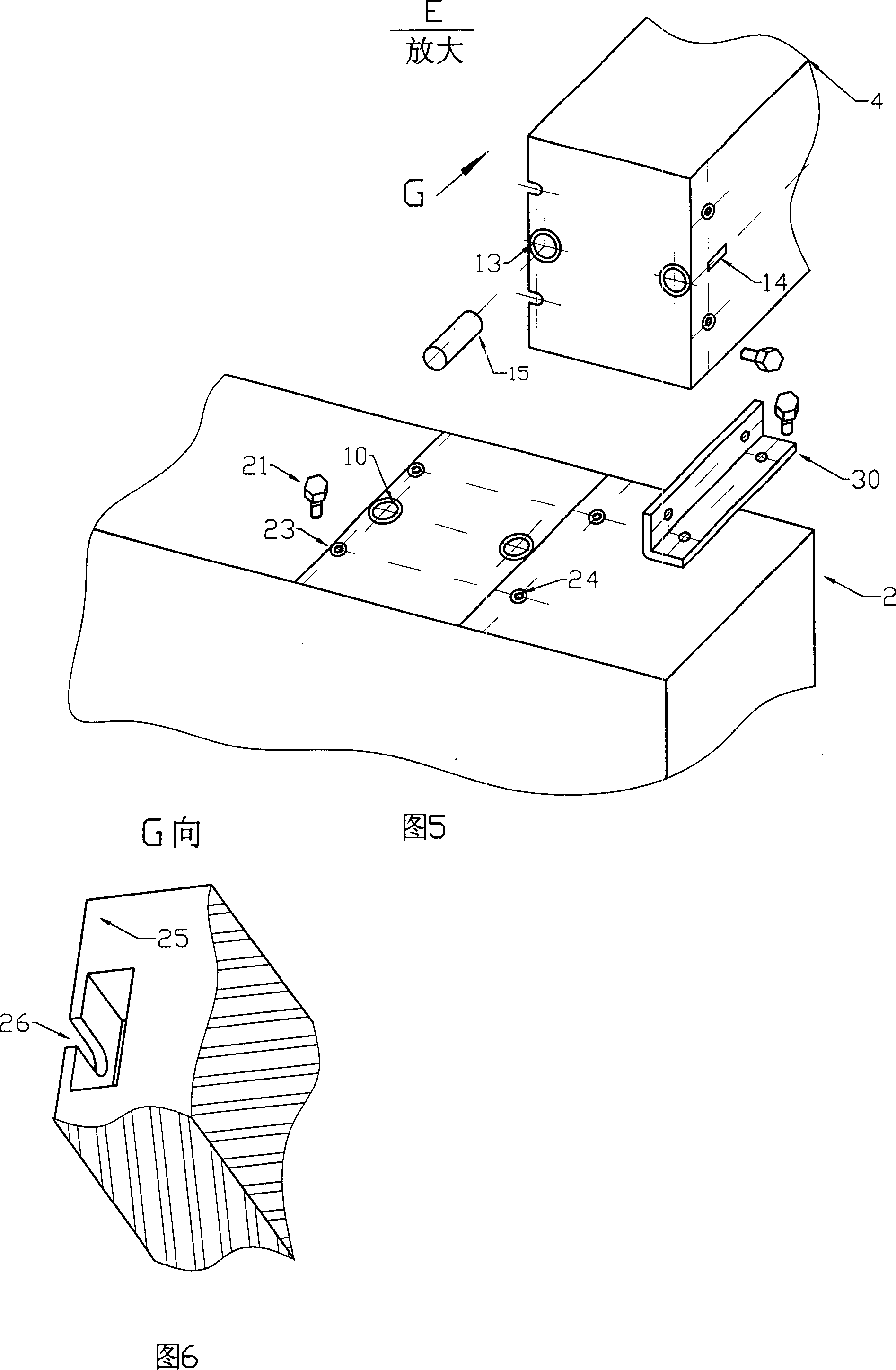

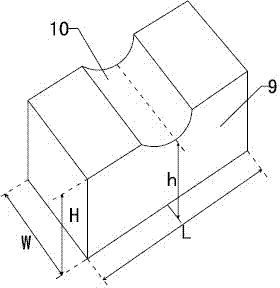

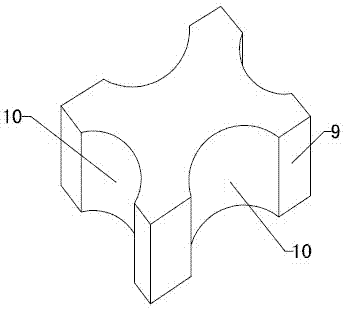

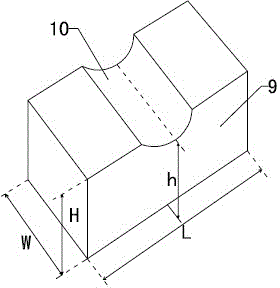

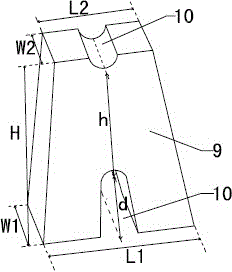

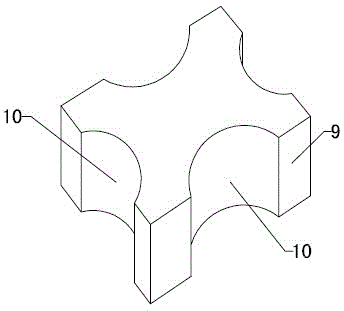

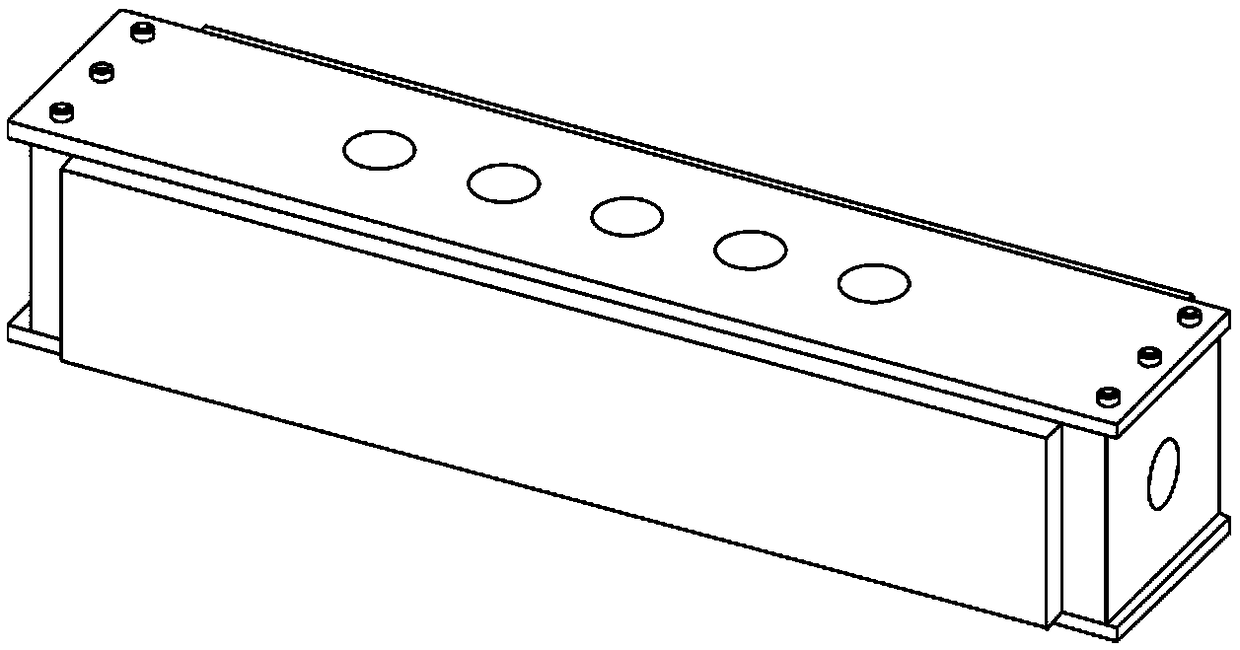

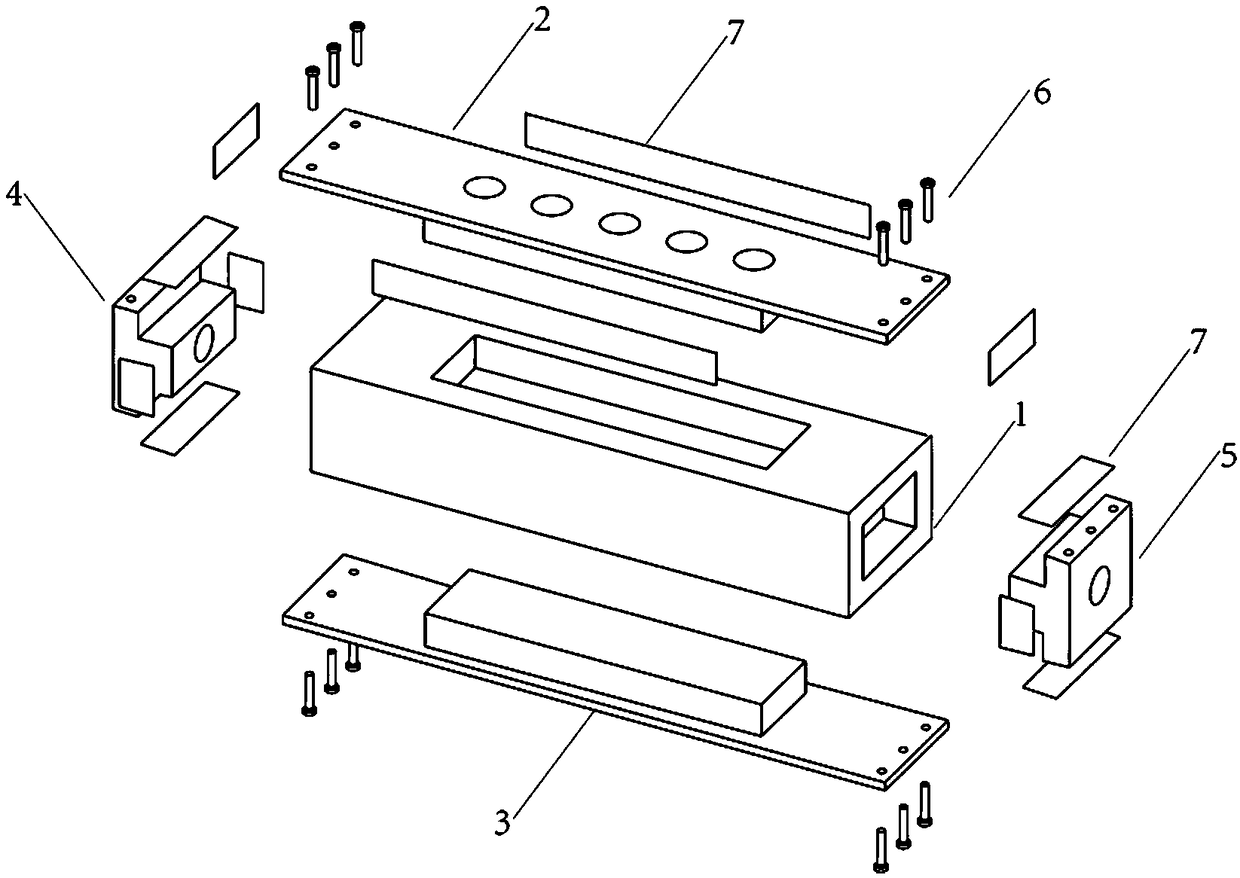

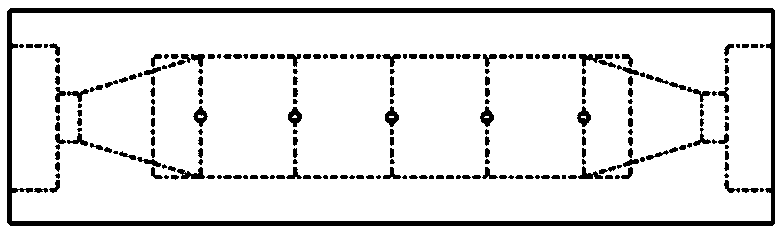

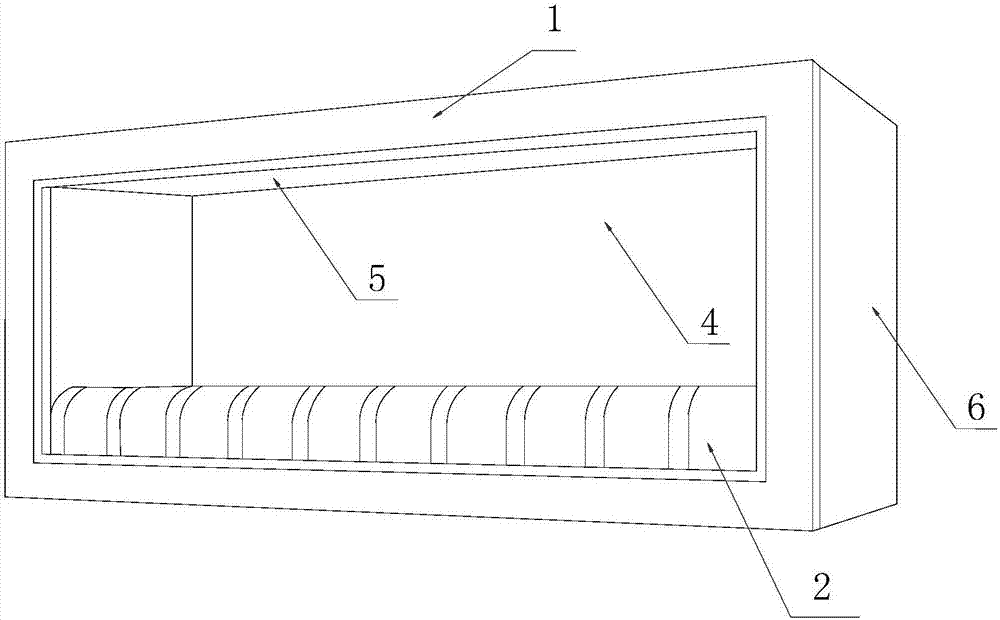

Rock coarse fracture seepage simulation model and making method

ActiveCN106353233AReduce intensityOvercome the disadvantage of low strengthPermeability/surface area analysisEngineeringWater pressure

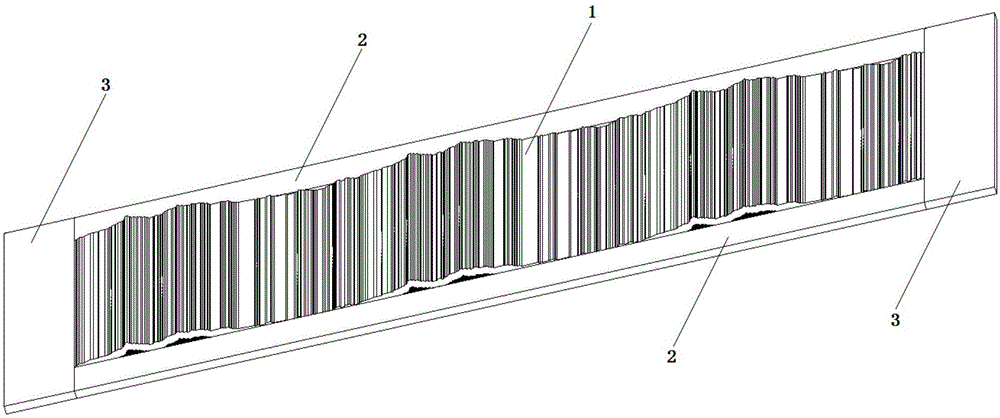

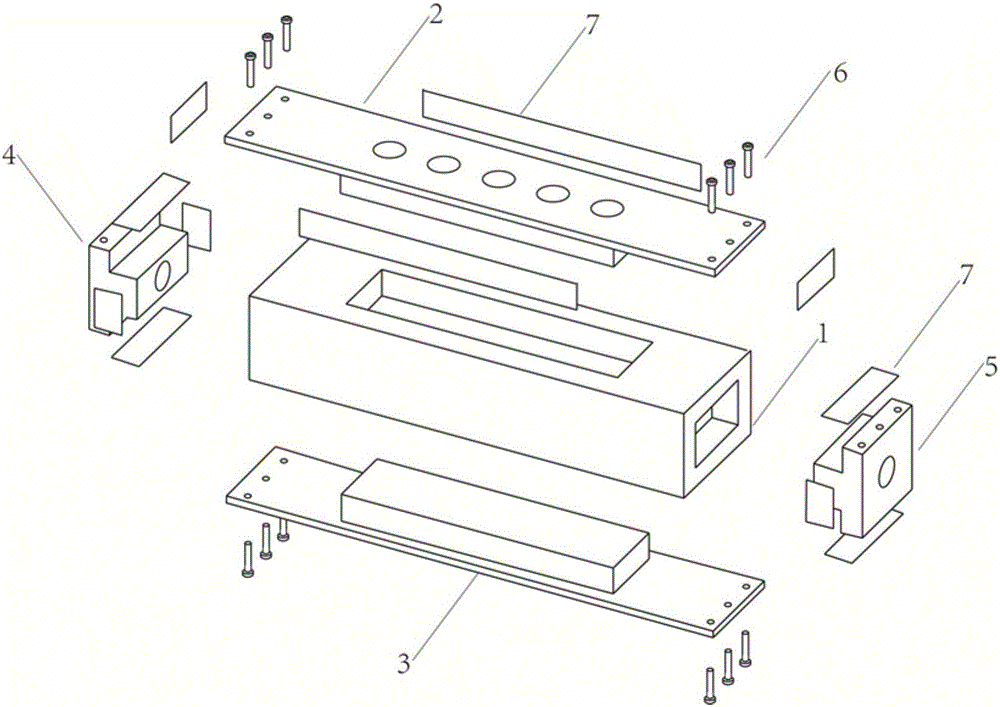

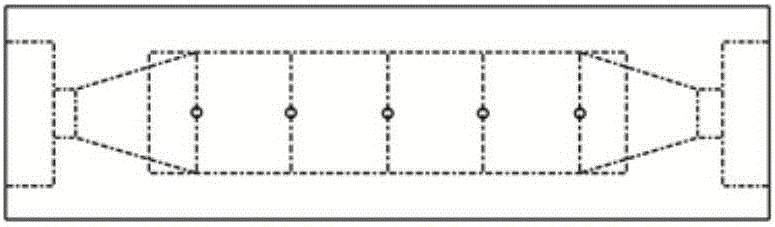

The invention discloses a rock coarse fracture seepage simulation model and a making method. The rock coarse fracture seepage simulation model comprises a fracture main board, a left mounting board, a right mounting board, an upper mounting board and a lower mounting board, the fracture main board is of a cuboid structure, a hydrophobic area is arranged on one side of the cuboid structure, a water gathering area is arranged on the other opposite side, the hydrophobic area is communicated with the water gathering area, the outer side of the hydrophobic area is matched with the left mounting board, and the outer side of the water gathering area is matched with the right mounting board; the upper surface and the lower surface of the cuboid structure are respectively matched with the upper mounting board and the lower mounting board, and a pressure measuring hole communicated with a communicating area between the hydrophobic area and the water gathering area is formed in the upper mounting board. 3D printing technology is adopted to manufacture the fracture main board which is fixed through the upper, lower, left and right mounting boards, and a bolt or a water pressure sensor is mounted on each mounting board, so that the making method of the rock coarse fracture seepage simulation model is simple to make, convenient to experiment and capable of reflecting rock fracture seepage characteristics more really and more accurately.

Owner:SHANDONG UNIV

An offset press UV varnishing method

InactiveCN107310263AIncrease contrastSimple structureLithographyPrinting press partsPulp and paper industryUV coating

The invention relates to the field of printing, in particular to a UV glazing method for an offset printing machine. It includes the following steps: selecting the liner paper and the original, cutting off the area of the liner paper corresponding to the non-image part of the printed matter to form a hollow, installing the color sequence printing plate, and laying the cut liner paper in a corresponding manner On the printing area on the blanket, install the liner paper together with the blanket on the blanket cylinder and fix and lock it, then set the light ink, UV lamp, adjust the offset printing machine and print, UV on the printed matter Varnish. The invention provides a high-efficiency glazing method for performing UV three-dimensional effect of an offset printing machine by hollowing out the liner paper, and solves the problems that the existing offset printing machine glazing method has complicated procedures and cannot print three-dimensional effects.

Owner:郑州华美彩印纸品有限公司

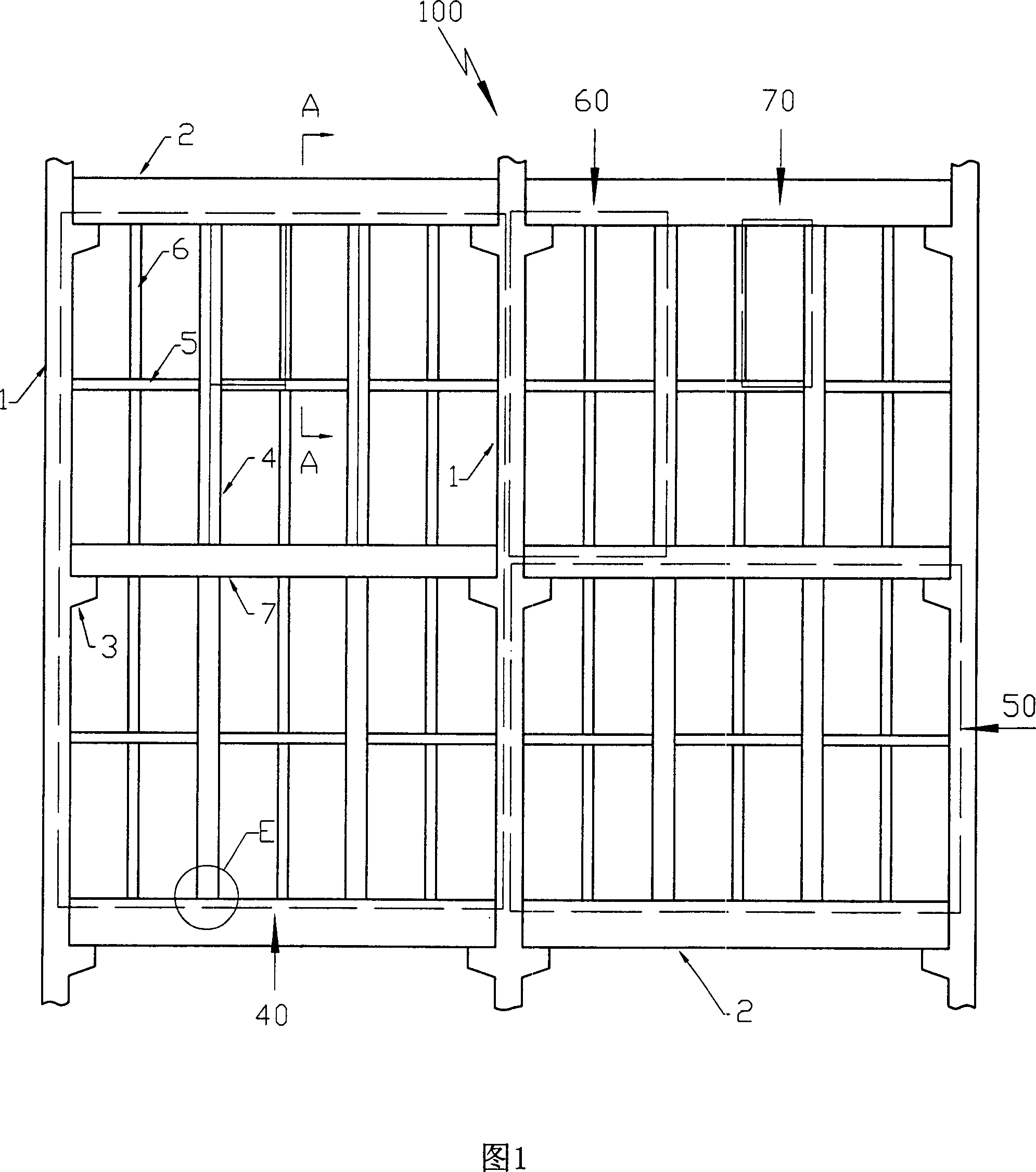

Wall body for building

The invention relates to a building wall. The rectangle main framework of wall is formed by at least two vertical poles and two horizontal beams set on up-down ends of two poles. N horizontal beams I in the main framework divides the main framework to N+1 rectangle frameworks. In main framework without layer frame or layer frame there is a vertical secondary pillar I at least to divide that to two secondary frames. In each secondary frame there are a horizontal secondary beam and two vertical secondary pillars II. Two secondary pillars II are set on up-down sides of secondary beam respectively and are formed to cross structure with it so as to divide the secondary frame to four rectangle basis frames. Outer and inner sides of each basis frame are connected with outer and inner walls. If it is one layer building there is no need of transverse beam, namely N=0, here there is no layer frame in the transverse beam, namely the main frame is the layer frame. The merit is that low building cost, short building period, high building efficiency, easy fabrication and good heat insulation performance.

Owner:张山峰

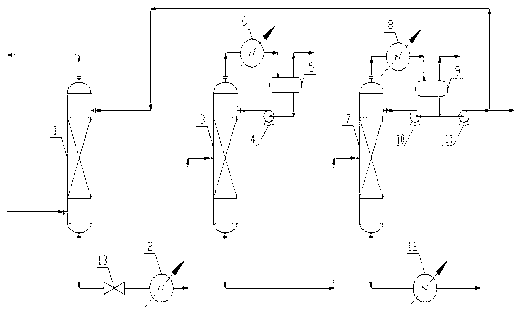

Process device and method for removing heavy hydrocarbon in natural gas by adopting LPG (Liquefied Petroleum Gas)

InactiveCN103265987AReliable sourceImprove removal effectGaseous fuelsLiquid hydrocarbon mixture recoveryProcess engineeringPre treatment

The invention discloses a process device and a process method for removing heavy hydrocarbon in natural gas by adopting LPG (Liquefied Petroleum Gas) in a natural gas liquefying process. The process device comprises a heavy hydrocarbon washing tower, a deethanization tower and a debutanization tower, wherein the heavy hydrocarbon washing tower is connected with a throttle valve, a cooler, the deethanization tower and the debutanization tower in sequence; the top outlet of the debutanization tower is connected with a debutanization tower condenser, a debutanization tower reflux tank, a debutanization tower reflux pump and a debutanization tower upper inlet in sequence; and the debutanization tower reflux tank is connected with an upper inlet of the heavy hydrocarbon washing tower by an LPG booster pump. The process device and the process method for removing heavy hydrocarbon in natural gas by adopting LPG have the positive effects that the LPG products produced in the device are utilized to wash, and the LPG product source is stable and reliable; the heavy hydrocarbon removing effect is good, so that the heavy hydrocarbon components in the natural gas are removed as much as possible for facilitating a liquefying process and effectively preventing the heavy hydrocarbon from being frozen and blocked; and the heavy hydrocarbon removing process by adopting the LPG is simple, so that the deep pre-treatment needs of the natural gas liquefaction can be achieved by absorbing and transferring mass, and therefore, the natural gas liquefaction needs are satisfied.

Owner:CHINA GASOLINEEUM ENG

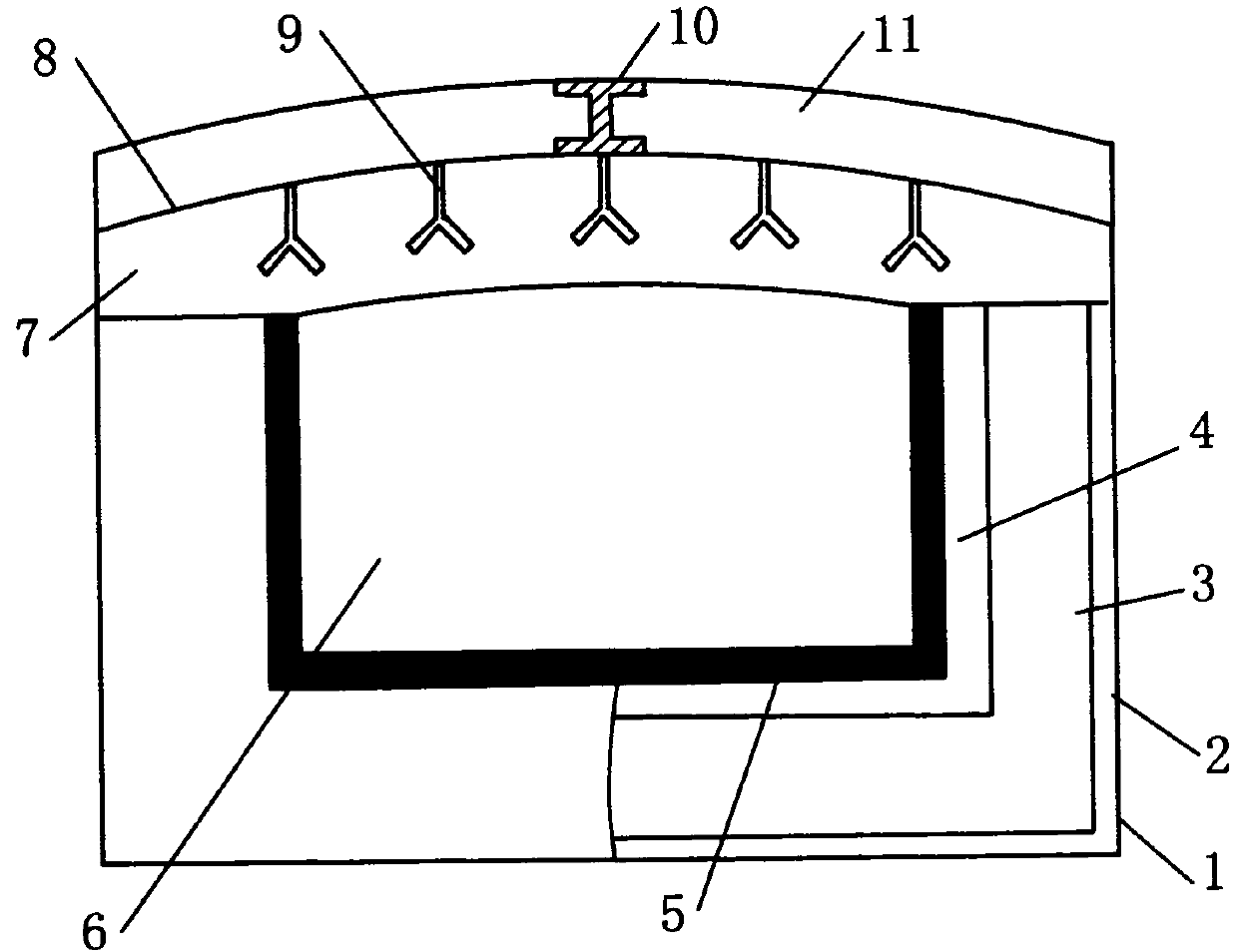

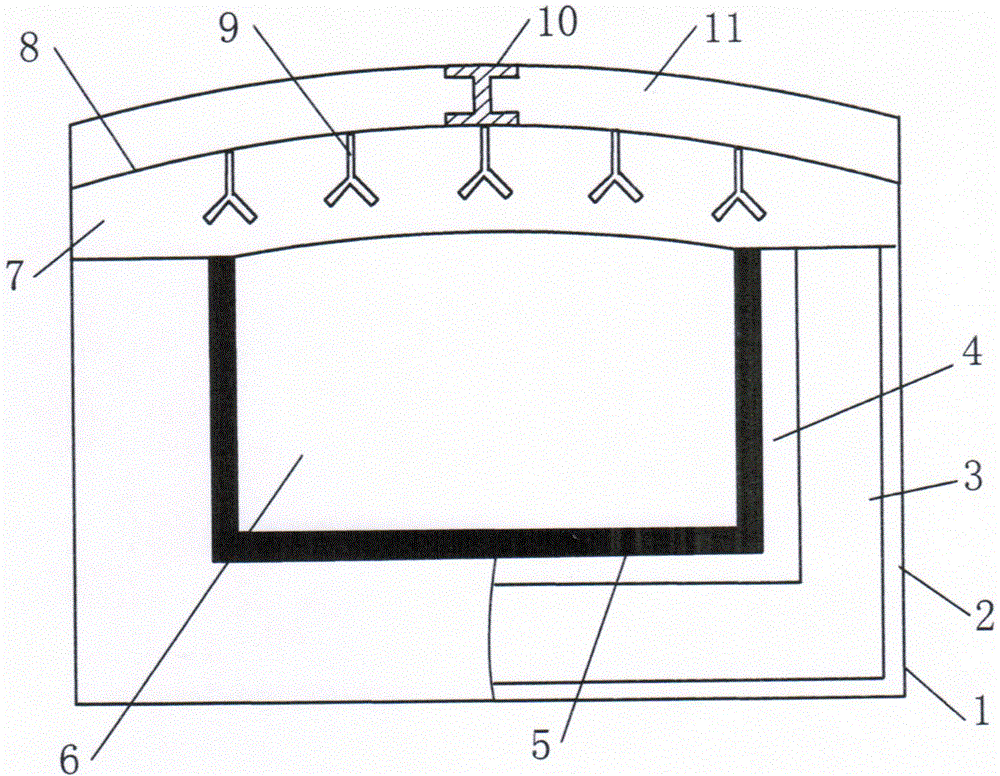

Construction method for aluminum alloy smelting furnace with high-nitrogen composite ceramic lining layer

ActiveCN104197717AGood energy saving effectQuality improvementLinings repairComposite ceramicAluminum silicate

The invention provides a construction method for an aluminum alloy smelting furnace with a high-nitrogen composite ceramic lining layer. The method comprises the steps of arrangement of an aluminum silicate wool felt layer, a light silicon-calcium insulation board layer, an aluminum silicate insulating brick masonry layer, an oxide cement gum impervious layer and a high-nitrogen composite ceramic tile masonry layer on the outer portion of a furnace body with a furnace chamber respectively, arrangement of the furnace chamber, pouring of a furnace top high-aluminum castable insulating layer, arrangement of a stainless steel grid framework, arrangement of anchoring parts, arrangement of an I-steel beam and laying of a furnace top aluminum silicate insulating layer; in this way, the smelting furnace is constructed. The smelting furnace is provided with the high-nitrogen composite ceramic tile lining layer, thereby having the advantages of heat preservation, a good energy-saving effect, metal corrosion resistance, good molten aluminum quality, easy furnace cleaning, long service life and a short manufacturing period; he construction method is suitable for construction of an aluminum ingot smelting furnace.

Owner:LIAONING YIFEI TECH

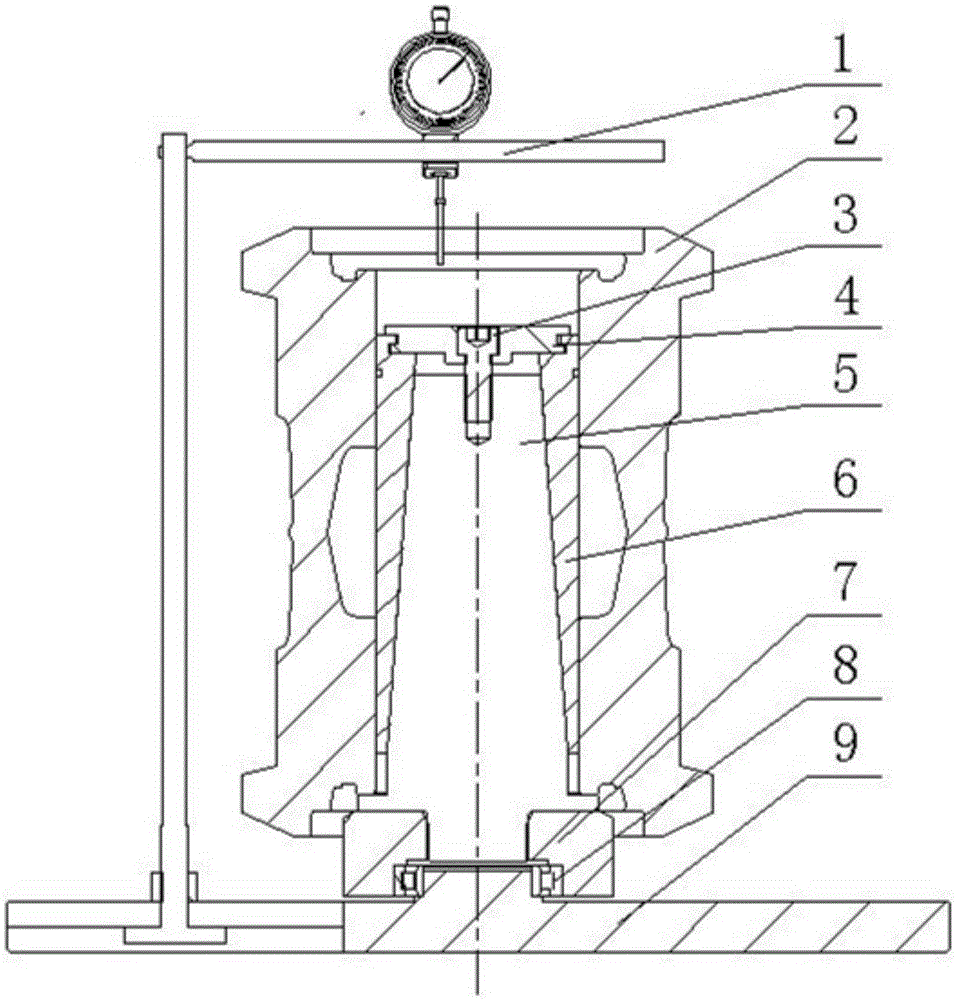

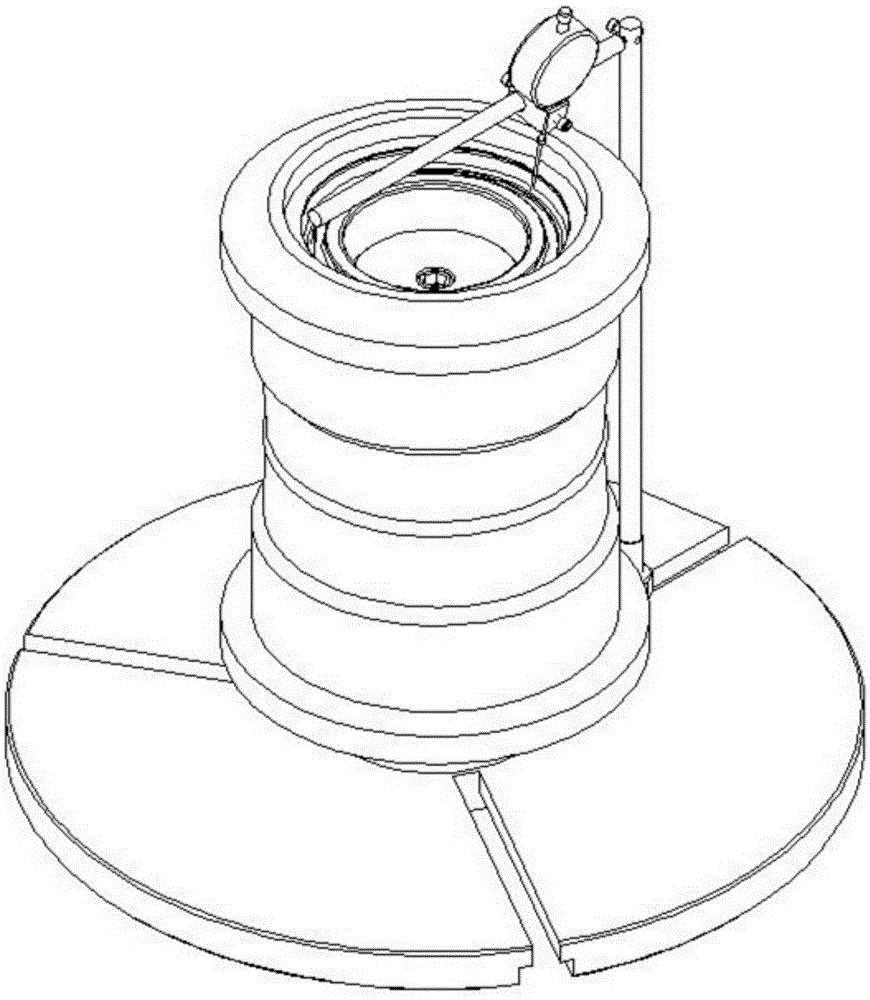

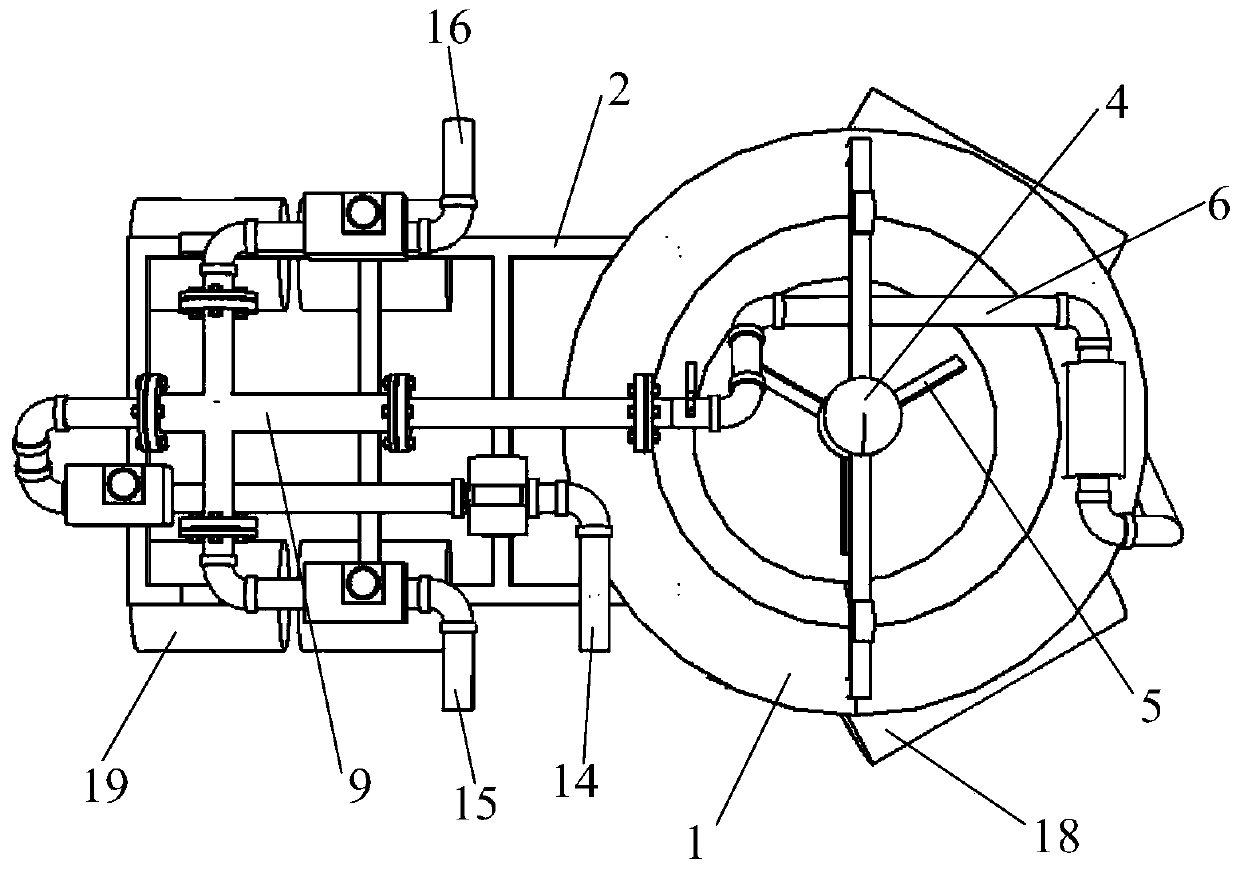

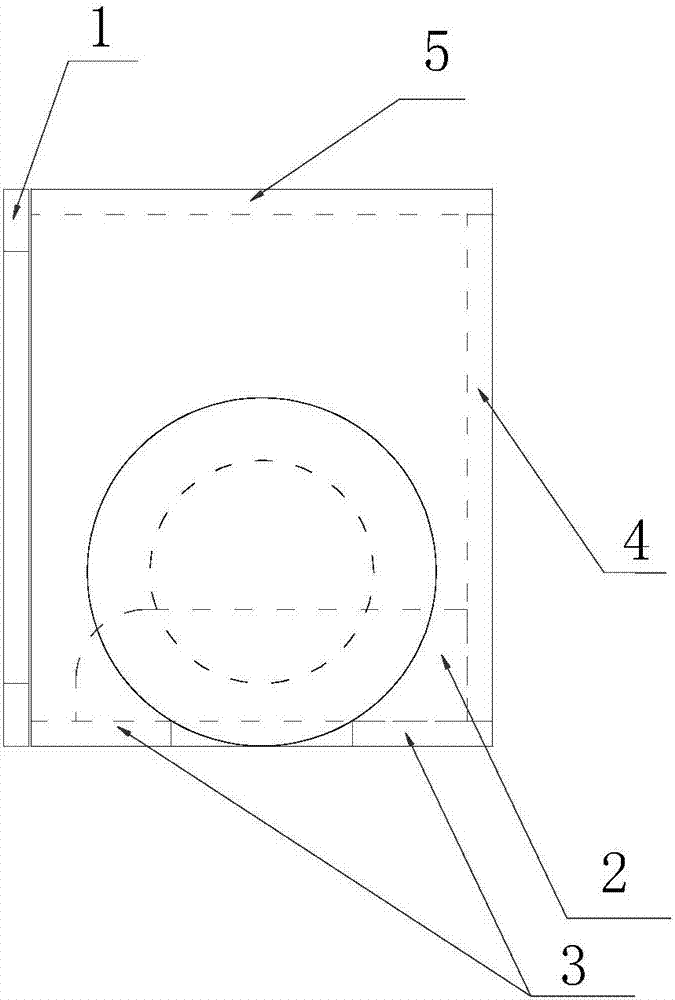

Self-centering rotary detection table

InactiveCN105352462AImprove the shortcomings that cannot be removedFlexible useMeasurement devicesEngineeringUtilization rate

The invention discloses a self-centering rotary detection table which comprises a gauge stand, an opening gland, a tensioning column, a tensioning cover and a chassis, wherein the tensioning column is rotationally arranged in the middle of the chassis and has a conical structure; the tensioning cover is arranged outside the tensioning column in a sleeving manner and has a cylindrical cavity structure; the cavity is conical and is matched with the appearance of the tensioning column; the opening gland is arranged on the top of the tensioning cover and is in threaded connection with the tensioning column by virtue of a tightening screw; the gauge stand is arranged on the chassis in a sliding manner; and a gauge head is arranged on the gauge stand. The self-centering rotary detection table disclosed by the invention is flexible to use, and the detection efficiency and accuracy of each location degree of the wheel are greatly improved; the detection table is convenient to manufacture, low in cost and high in utilization rate and can be matched with multiple common check measuring tools; and complicated detection is simplified, multiple sizes and form and location tolerances needing to be detected in a rotating state are unified together, one-time detection is realized, and the result is obtained.

Owner:DALIAN SHENGLONG MACHINERY

Manufacturing method of concrete prefabricated column molding bed

InactiveCN111730726AEasy to makeSave spaceStrutsMould separation apparatusArchitectural engineeringPipe

The invention relates to the field of prefabricated column manufacturing, in particular to a manufacturing method of a concrete prefabricated column molding bed. The manufacturing method comprises thefollowing steps that a cushion layer is manufactured, specifically, a manufacturing site is firstly leveled and tamped, and then the concrete cushion layer is manufactured; a mold is manufactured, specifically, a plurality of long scaffold steel pipes are placed on the cushion layer in the length direction of a prefabricated column, short scaffold steel pipes are placed above the long scaffold steel pipes in the width direction of the prefabricated column, the intersection positions between the short scaffold steel pipes and the long scaffold steel pipes are connected through fasteners, and battens are arranged below the intersection positions between the short scaffold steel pipes and the long scaffold steel pipes in a cushioned mode correspondingly; the mold is leveled, specifically, observing is carried out through a gradienter after the erection is completed, and line drawing leveling is carried out; and after leveling is completed, a bottom mold is laid on the mold for prefabricated column manufacturing construction. The manufacturing method of the concrete prefabricated column molding bed is easy to manufacture, the construction period can be effectively shortened, and manufacturing materials can be recycled, so that cost is saved.

Owner:CHINA 22MCC GROUP CORP

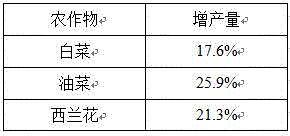

Environmental-friendly organic fertilizer capable of preventing diseases and insect pests

InactiveCN106187483ALow costReasonable useSuperphosphatesBio-organic fraction processingDiseasePhosphate

The invention relates to an environmental-friendly organic fertilizer capable of preventing diseases and insect pests, and belongs to the technical field of fertilizers. The environmental-friendly organic fertilizer is prepared from the following raw materials in parts by weight: 28-35 parts of eupatorium adenophorum, 15-25 parts of mushroom residues, 5-13 parts of melon seed shells, 10-15 parts of corn cobs, 8-15 parts of walnut shells, 20-28 parts of chicken manure, 25-35 parts of coconut bran, 8-15 parts of tobacco leaf, stem and stalk residues, 13-20 parts of calcium superphosphate, 8-15 parts of sodium hydroxide, 4-10 parts of cyanoacrylate, 10-18 parts of potassium dihydrogen phosphate, 12-25 parts of ammonium nitrate and 30-45 parts of water. According to the environmental-friendly organic fertilizer disclosed by the invention, the cost of the raw materials is low, resources are reasonably utilized, the making period is short, the soil vitality can be improved, the environmental-friendly organic fertilizer can be used for preventing diseases and insect pests, the production increase of crops can be promoted, nutrient elements in soil can be rich, domestic garbage can be turned into wealth from waste, environmental pollution is improved, and the environmental-friendly organic fertilizer is environmental-friendly and efficient.

Owner:KUNMING UNIV OF SCI & TECH

Concrete cushion block and preparation technology thereof

The invention relates to a concrete cushion block and a preparation technology thereof, belonging to the technical field of a strutting piece for a building. The concrete cushion block is characterized in that a cushion block body comprises the following raw materials in parts by weight: 100 parts of cement, 460-520 parts of aggregate chips, and 42-61 parts of water, wherein the aggregate chips and water are mixed according to the ratio of 1:0.2-0.12, and according to the difference of particle sizes D of aggregate chips, the mass percentages are as follows: the aggregate chips with D of no more than 0.1cm accounts for 40-50%, the aggregate chips with D of more than 0.1cm and no more than 0.2cm accounts for 20-25%, the aggregate chips with D of more than 0.2cm and no more than 0.3cm accounts for 15-20%, and the aggregate chips with D of more than 0.3cm and no more than 0.5cm accounts for 12-15%. According to the technology, a reinforcement steel bar slot is formed in the side surface, and demolding and maintenance are immediately conducted after pressing is conducted for 1-4s. The cushion block is short in maintenance time, high in early strength, adaptive to concrete of buildings, convenient and fast in technological process, firm and difficult to loose, short in preparation period and convenient to use.

Owner:曹连涛

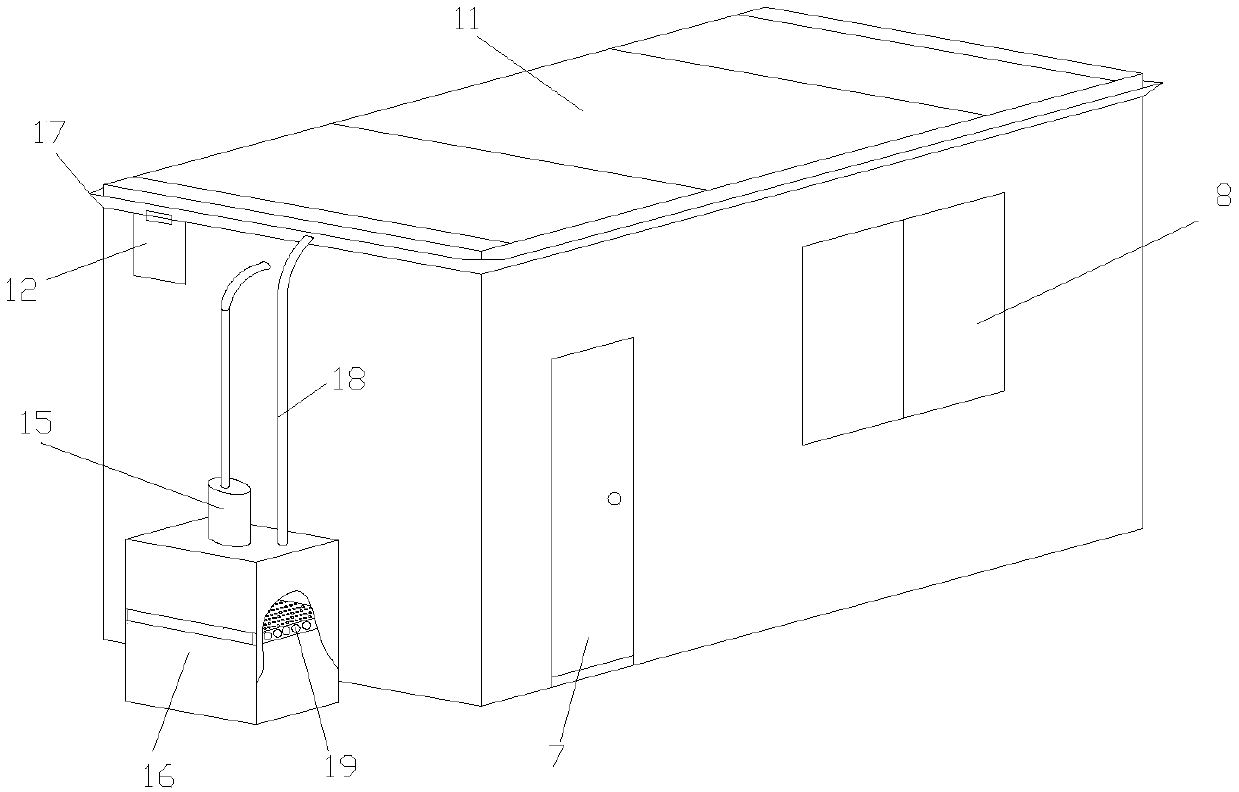

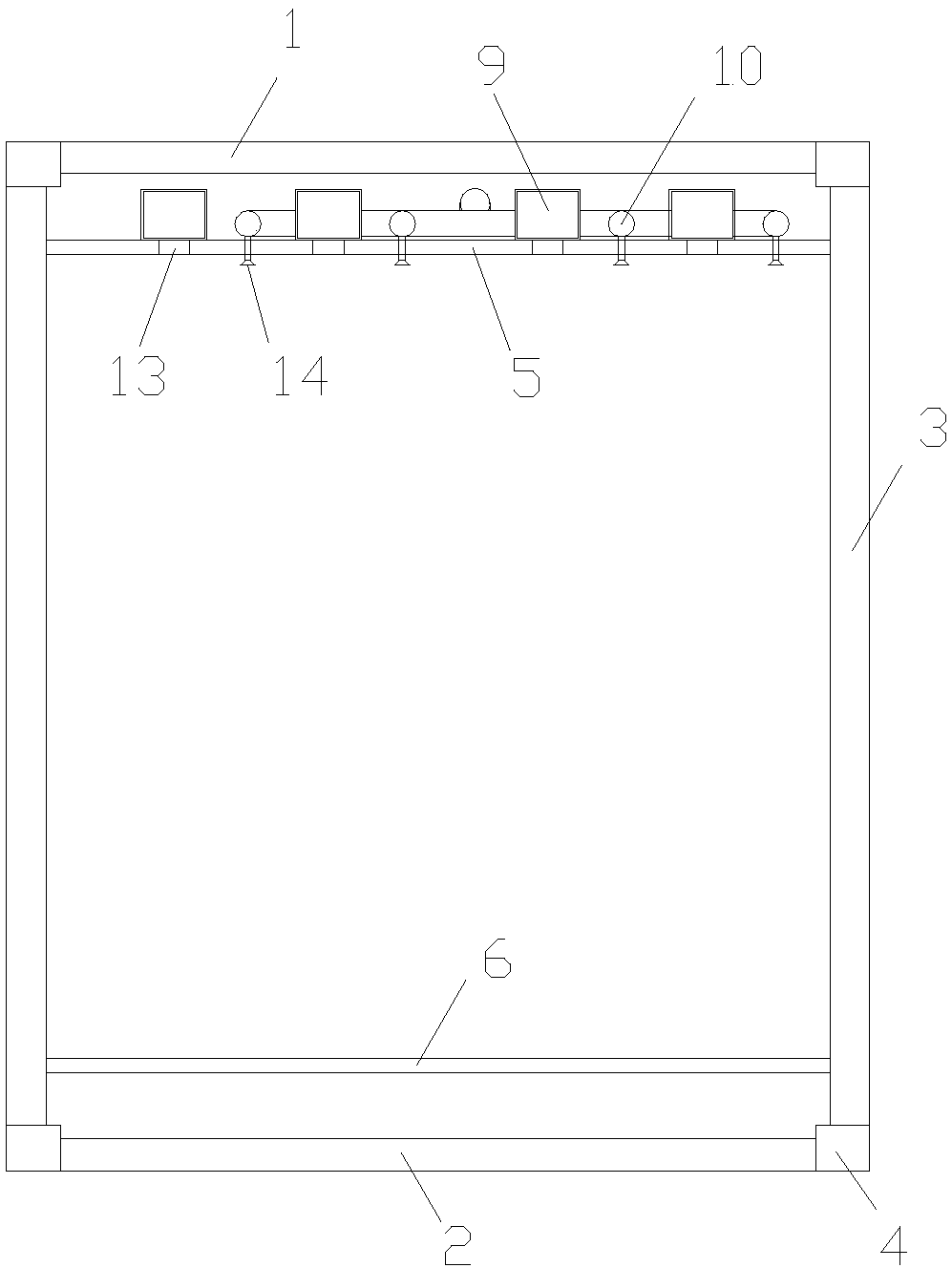

Colored steel removable house

InactiveCN107605046AImprove the effect of activitiesEasy to install and disassembleFatty/oily/floating substances removal devicesSewerage structuresActivated carbonVentilation tube

The invention provides a colored steel removable house, including a frame main body formed by riveting a series of sections, and colored steel wallboards wrapped out of the frame main body. The framemain body is provided with a top beam, a ground beam, and connecting columns connected between the top beam and the ground beam. The top beam is provided with a ceiling floor. The ground beam is laidwith a floor. A wall surface on one side of the frame main body is provided with a door opening and a window opening. The top beam is also coiled with a vent pipe and a fire service pipe. Two ends ofthe vent pipe are communicated with the external of the colored steel house. The vent pipe is provided with a plurality of ventilating openings abutting against the surface of the ceiling floor. The fire service pipe is provided with an induction sprayer. The fire service pipe and a water tank out of the colored steel house are connected through a pressure pump. A top colored steel wall board of the colored steel removable house is provided with an eave used to drain. One end of the eave is provided with a discharge pipe. The discharge pipe is communicated with the water tank. The water tank is internally provided with a water filtering layer. A water filtering layer bag is arranged in a filter screen on the middle part of the water tank in a drawer manner. Activated carbon is uniformly laid on the filter screen.

Owner:SUZHOU TIANDI COLORBOND MFG

Concrete cushion block and preparation technology thereof

The invention relates to a concrete cushion block and a preparation technology thereof, belonging to the technical field of a strutting piece for a building. The concrete cushion block is characterized in that a cushion block body comprises the following raw materials in parts by weight: 100 parts of cement, 460-520 parts of aggregate chips, and 42-61 parts of water, wherein the aggregate chips and water are mixed according to the ratio of 1:0.2-0.12, and according to the difference of particle sizes D of aggregate chips, the mass percentages are as follows: the aggregate chips with D of no more than 0.1cm accounts for 40-50%, the aggregate chips with D of more than 0.1cm and no more than 0.2cm accounts for 20-25%, the aggregate chips with D of more than 0.2cm and no more than 0.3cm accounts for 15-20%, and the aggregate chips with D of more than 0.3cm and no more than 0.5cm accounts for 12-15%. According to the technology, a reinforcement steel bar slot is formed in the side surface, and demolding and maintenance are immediately conducted after pressing is conducted for 1-4s. The cushion block is short in maintenance time, high in early strength, adaptive to concrete of buildings, convenient and fast in technological process, firm and difficult to loose, short in preparation period and convenient to use.

Owner:曹连涛

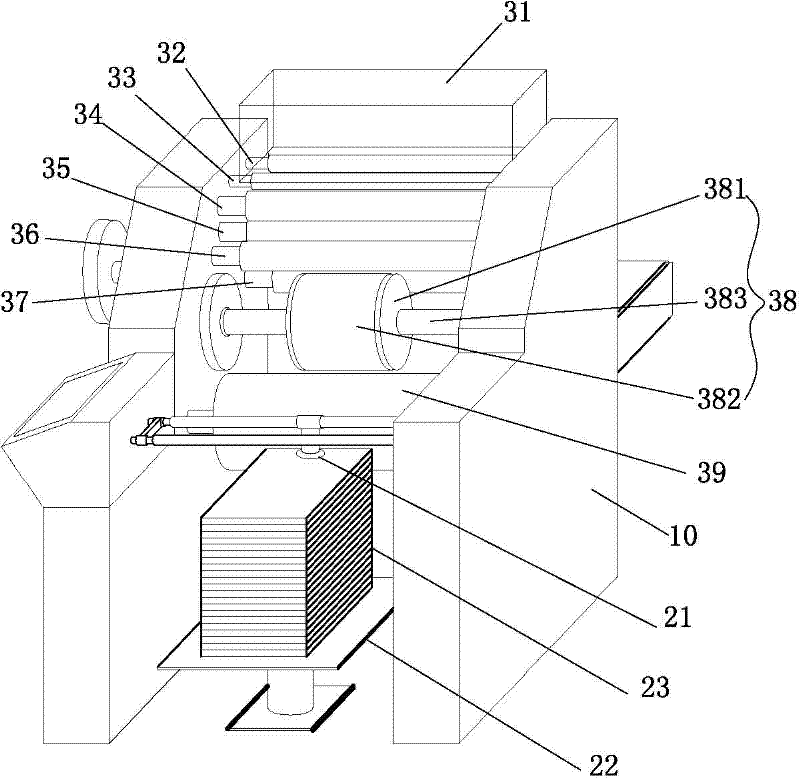

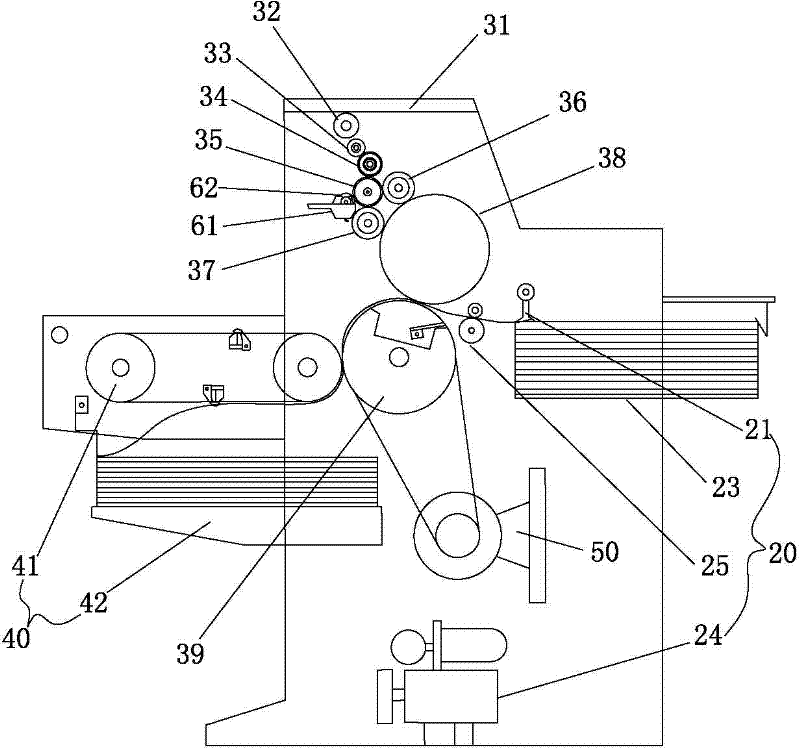

White water printing paper preparation machine and preparation method

InactiveCN101905560ASimple processLess investmentRotary letterpress machinesTransmittancePrinting ink

The invention relates to the technical field of water printing paper preparation devices and preparation methods, in particular to a white water printing paper preparation machine and a preparation method. White water printing ink permeates paper by stamping to change the light transmittance of the paper, and predetermined white water printing patterns with different brightness are generated during visual inspection of light transmittance, so primary textures and characteristics of the paper are basically not damaged, and any influence on reprinting, writing, printing and the like after printing is not caused.

Owner:深圳市华德防伪技术开发有限公司

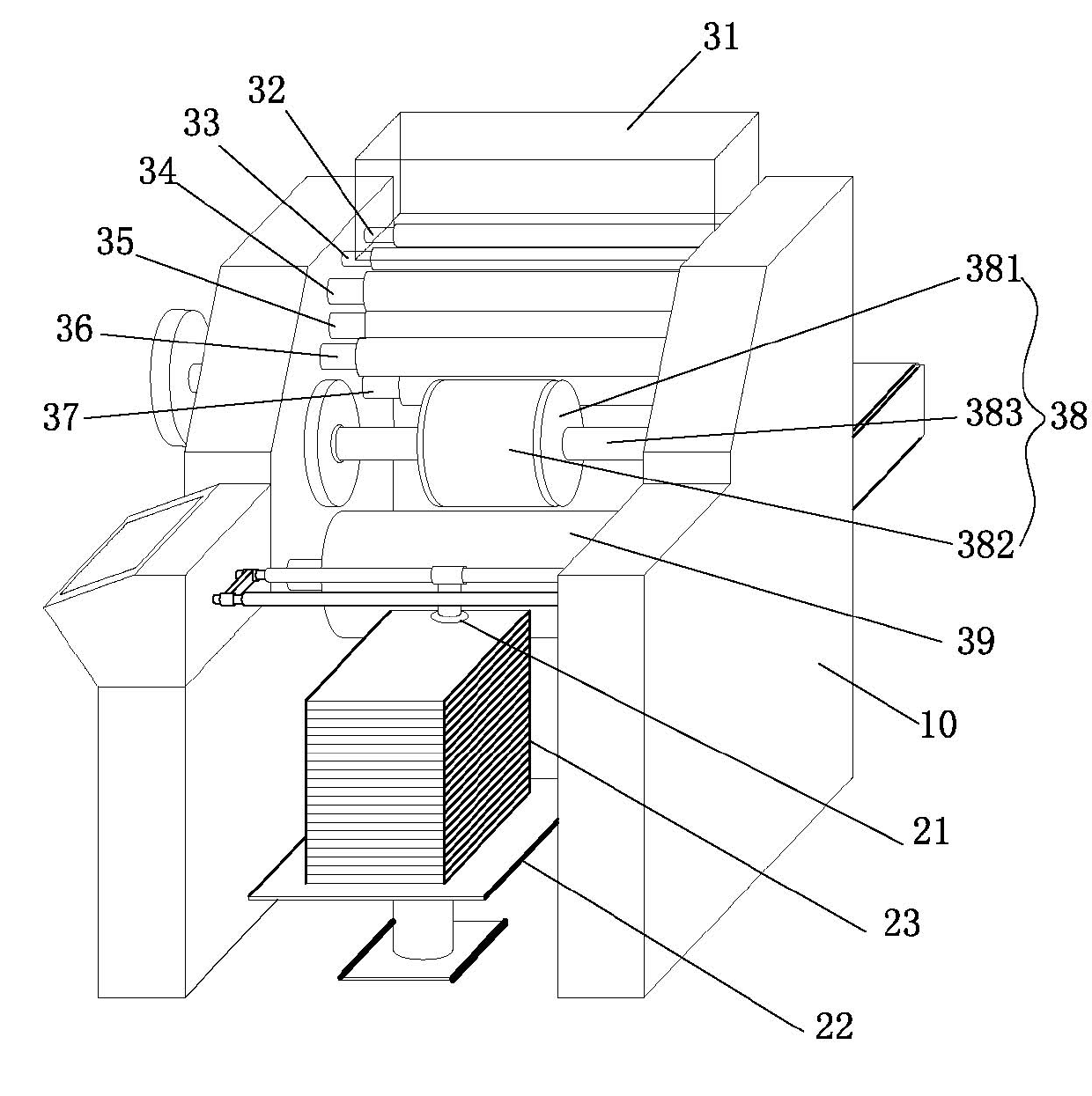

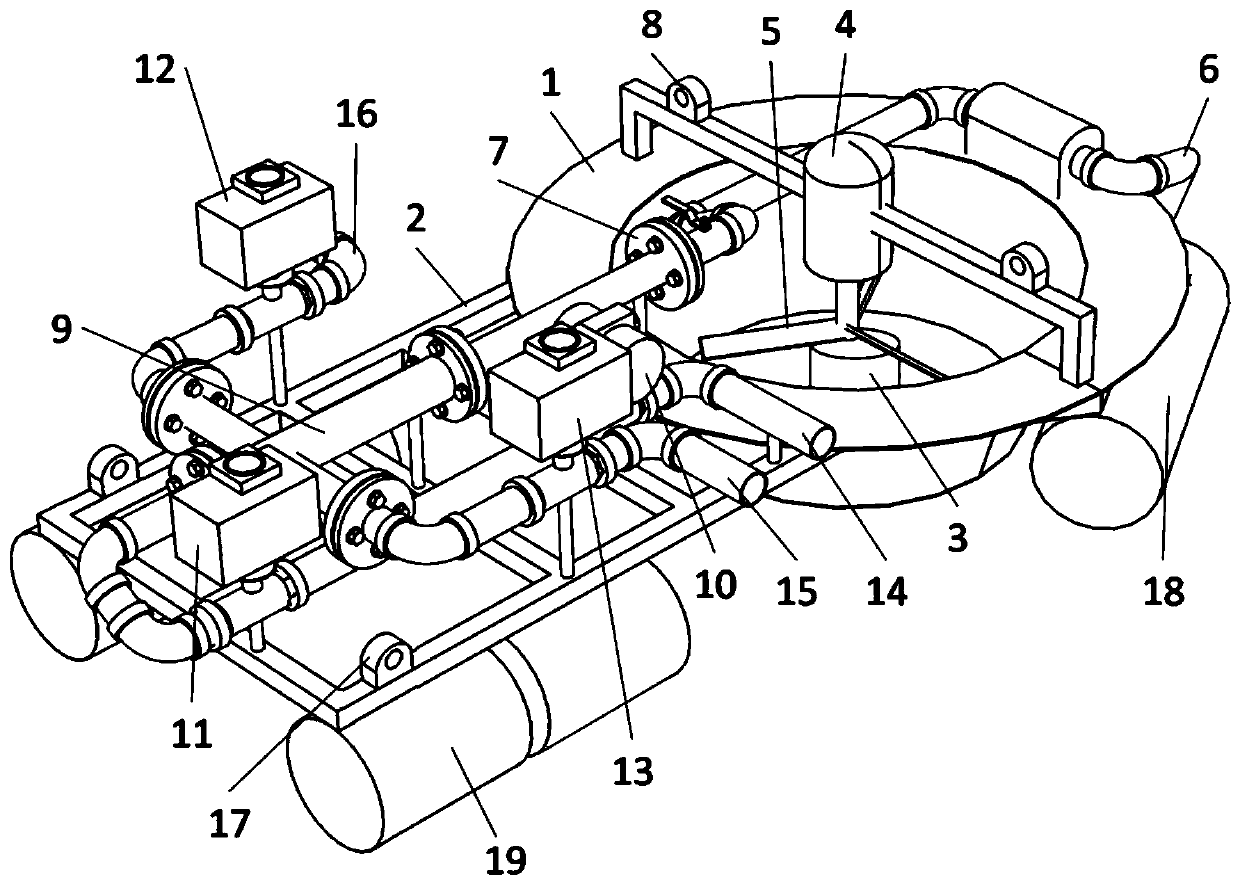

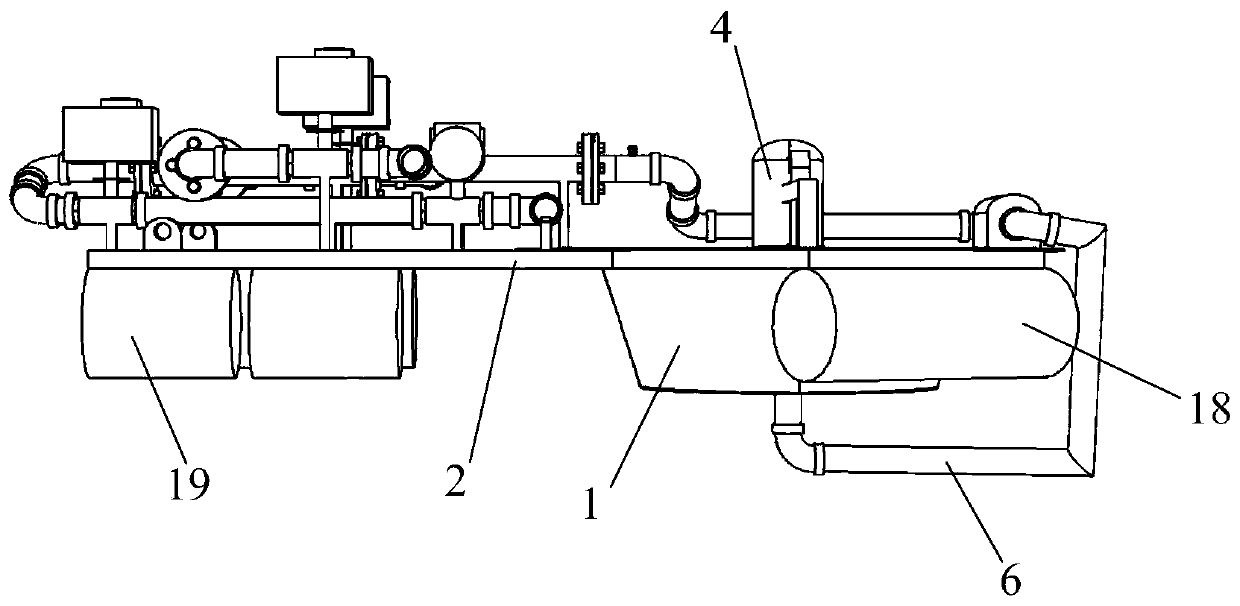

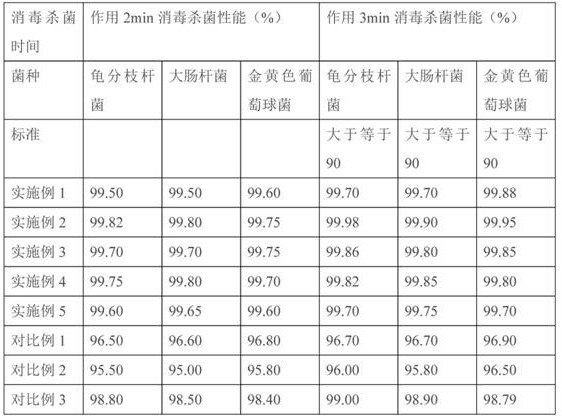

Sea surface spilled oil rapid separation and recovery device

PendingCN111167169ALow running costShort manufacturing periodLiquid separationElectric machineMechanics

The invention relates to a sea surface spilled oil rapid separation and recovery device which comprises a support frame, a vortex-making recovery tank, vortex-making blades, a motor, a submersible pump and a primary vortex separator. Float bowls are connected to the head and tail ends of the lower part of the support frame. The vortex-making recovery tank is fixed on the support frame, and the vortex-making blades are positioned in the vortex-making recovery tank. The motor is vertically fixed to the middle position over the vortex-making recovery tank through the support frame. The motor is connected with the vortex-making blades located under the motor. A hole is formed in the center of the bottom of the vortex-making recovery tank, and the submersible pump vertically penetrates throughthe hole and is fixed to the hole. A liquid inlet of the submersible pump is located at the height of an oil layer formed after liquid in the vortex-making recovery tank forms Rankine combined vortexes, and a liquid outlet of the submersible pump is connected with the primary vortex separator through a primary mixed liquid pipeline. The device is small in size, low in weight and convenient to transport and install, and can be quickly hauled to an oil leakage site. Compared with a traditional direct extraction method, mixed liquid with higher oil phase content can be conveyed into the separation device, and the separation efficiency is further improved.

Owner:CNOOC ENERGY TECH & SERVICES +2

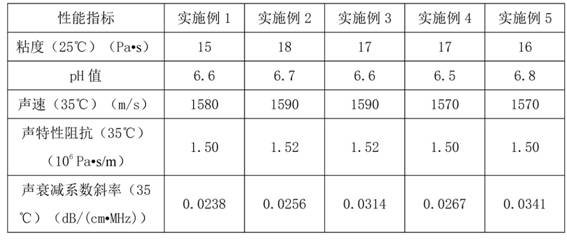

Medical ultrasonic coupling agent with disinfection function and preparation method

InactiveCN113069561AModerate degree of polymerizationModerate molecular weightHydroxy compound active ingredientsAerosol deliveryCellulosePolyethylene glycol

The invention relates to a medical ultrasonic coupling agent with a sterilization function and a preparation method, and belongs to the technical field of coupling agent processing. The medical ultrasonic coupling agent is prepared from the following components in parts by weight: 8-10 parts of carbomer, 0.08-0.11 part of o-phthalaldehyde, 0.1-0.5 part of chlorhexidine gluconate, 0.1-0.3 part of polyethylene glycol, 0.04-0.07 part of propylene glycol, 50-70 parts of glycerol, 1-5 parts of sodium hydroxide, 1-4 parts of menthol, 0.1-0.5 part of hydroxypropyl methyl cellulose and 900-1000 parts of purified water. The medical ultrasonic coupling agent has good biocompatibility, coupling property and stability, and can effectively ensure the definition and accuracy of ultrasonic instrument inspection and use; and the medical ultrasonic coupling agent is mild in performance, does not irritate the skin, can kill the growth of bacteria, avoids cross infection, and is easy to clean. According to the medical ultrasonic coupling agent with the sterilization function, o-phthalaldehyde and chlorhexidine gluconate are compounded for use, so that a synergistic interaction effect is achieved. The menthol can promote the contact between the o-phthalaldehyde and the chlorhexidine gluconate and disinfection substances, so that the disinfection and sterilization effects are improved.

Owner:广州市一杰医药科技有限公司

Three-dimensional effect glazing method for offset printing machine

ActiveCN105082747BIncrease contrastImprove the three-dimensional effectPrinting press partsEngineeringHigh contrast

Owner:LANGFANG BEIFANG JIAKE PRINTING

A simulation model of seepage in rough cracks of rock mass and its manufacturing method

ActiveCN106353233BReduce intensityOvercome the disadvantage of low strengthPermeability/surface area analysisEngineeringMotherboard

The invention discloses a rock coarse fracture seepage simulation model and a making method. The rock coarse fracture seepage simulation model comprises a fracture main board, a left mounting board, a right mounting board, an upper mounting board and a lower mounting board, the fracture main board is of a cuboid structure, a hydrophobic area is arranged on one side of the cuboid structure, a water gathering area is arranged on the other opposite side, the hydrophobic area is communicated with the water gathering area, the outer side of the hydrophobic area is matched with the left mounting board, and the outer side of the water gathering area is matched with the right mounting board; the upper surface and the lower surface of the cuboid structure are respectively matched with the upper mounting board and the lower mounting board, and a pressure measuring hole communicated with a communicating area between the hydrophobic area and the water gathering area is formed in the upper mounting board. 3D printing technology is adopted to manufacture the fracture main board which is fixed through the upper, lower, left and right mounting boards, and a bolt or a water pressure sensor is mounted on each mounting board, so that the making method of the rock coarse fracture seepage simulation model is simple to make, convenient to experiment and capable of reflecting rock fracture seepage characteristics more really and more accurately.

Owner:SHANDONG UNIV

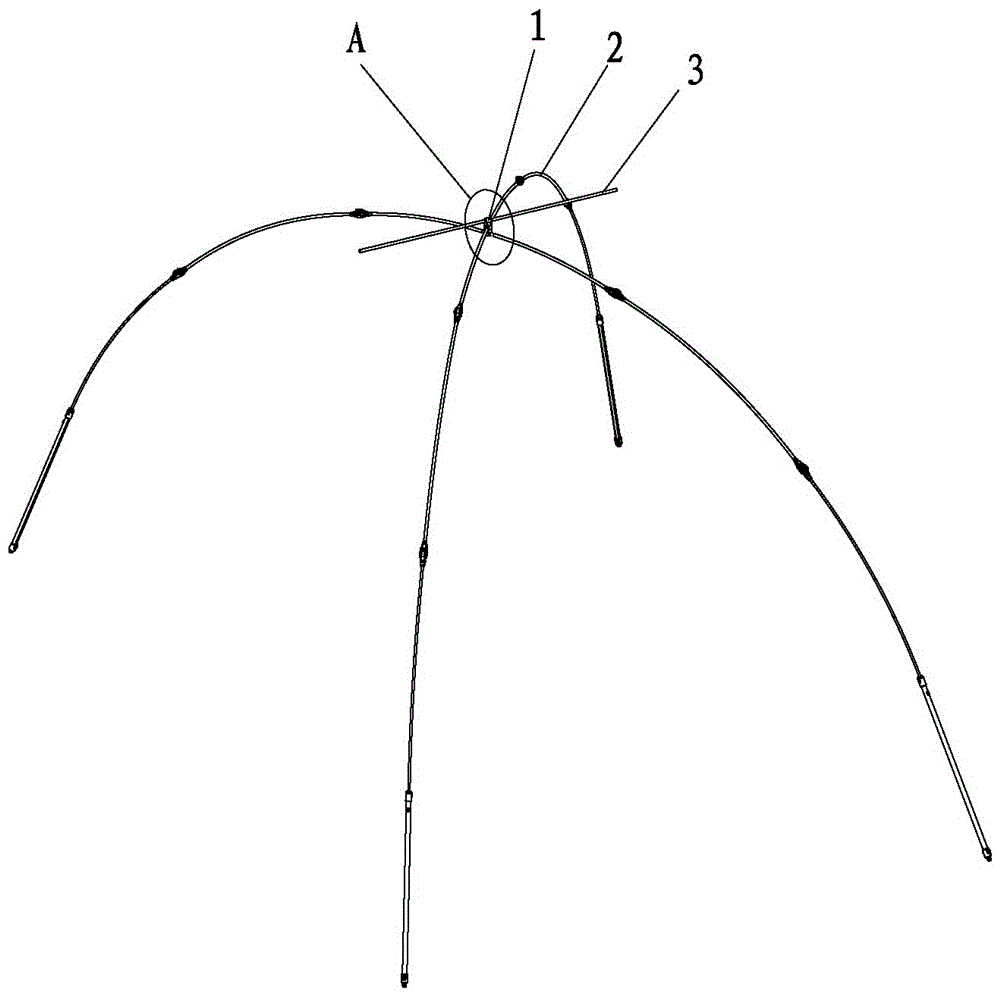

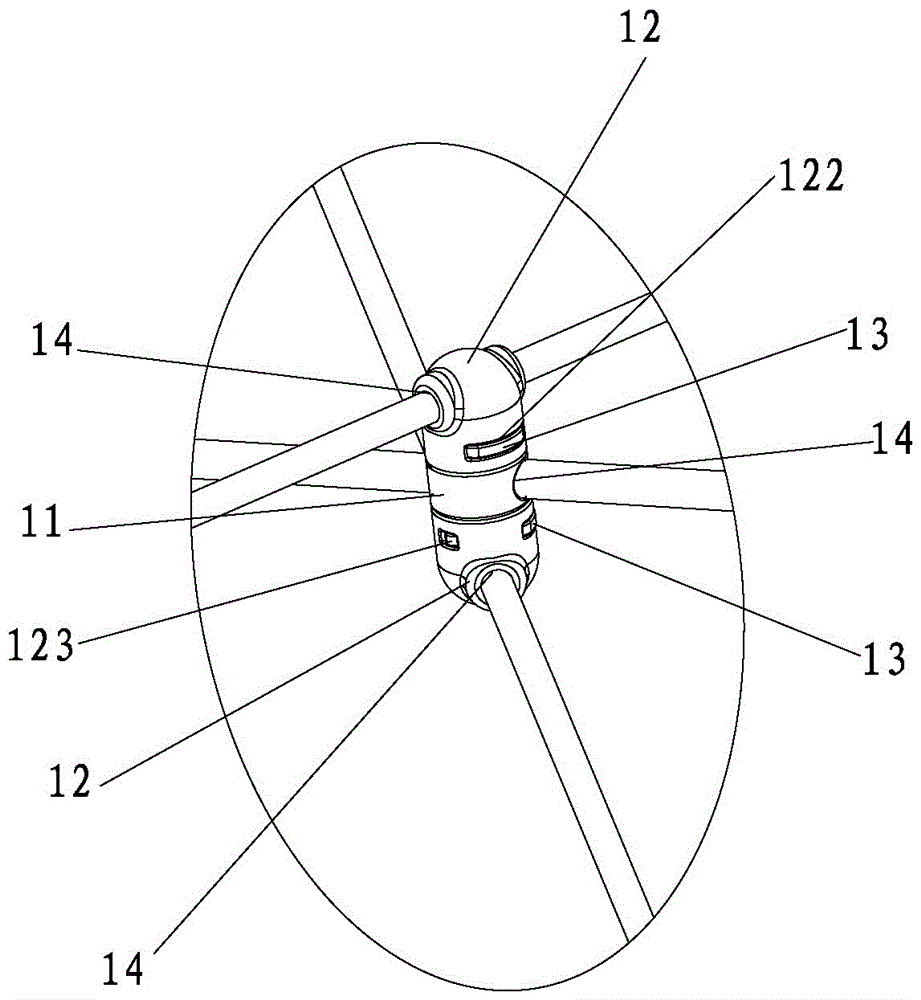

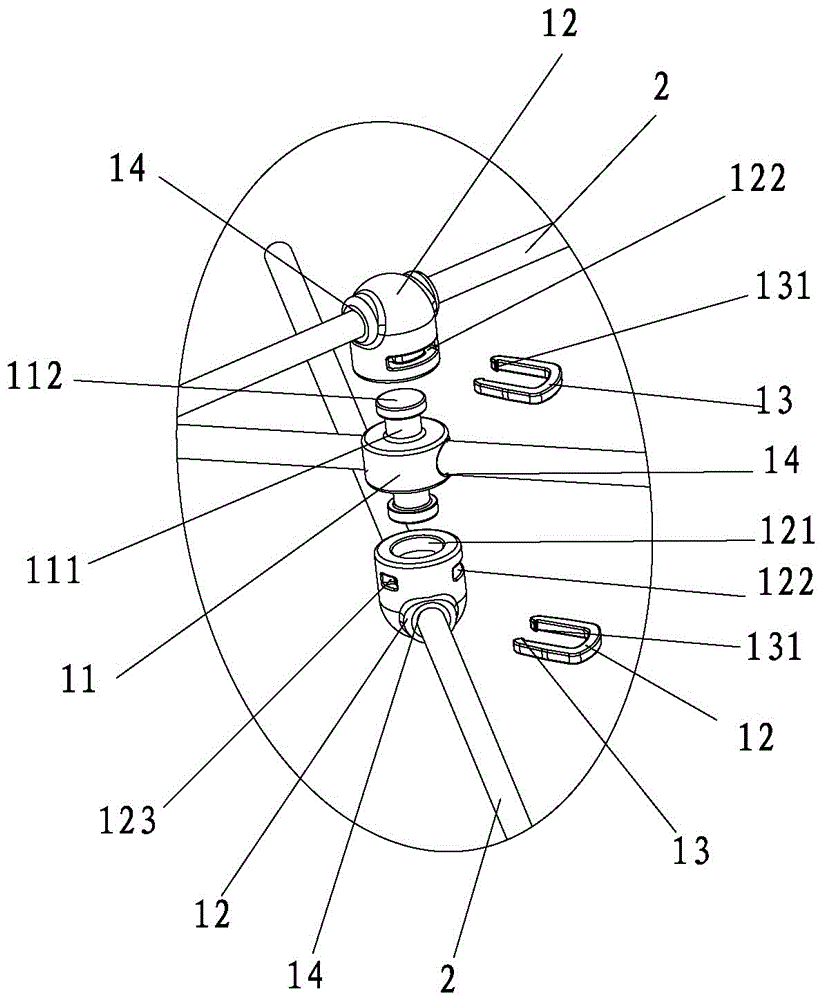

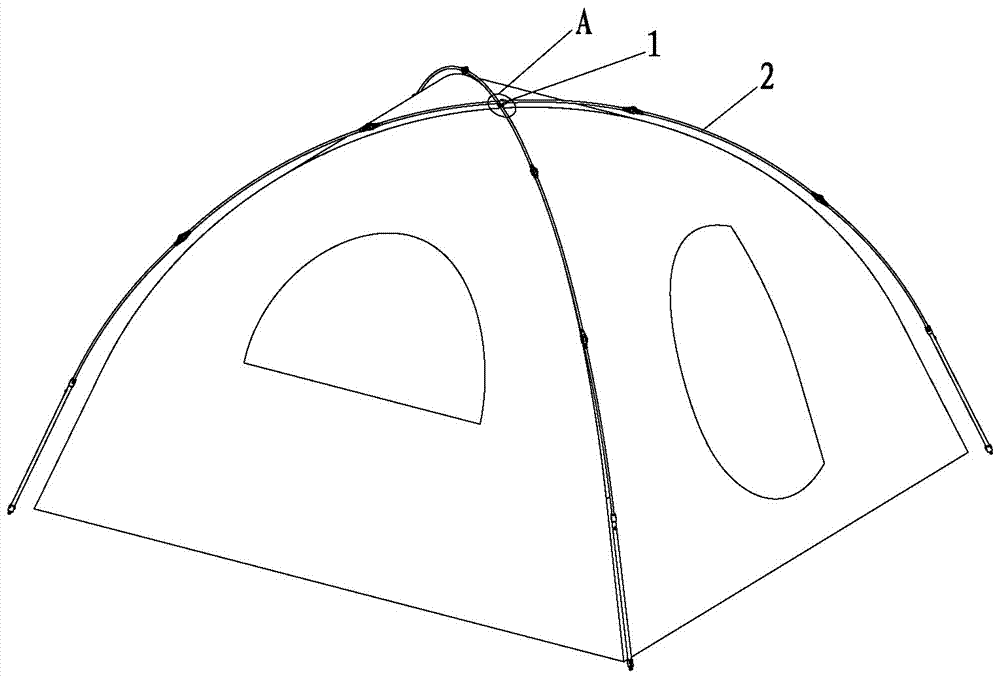

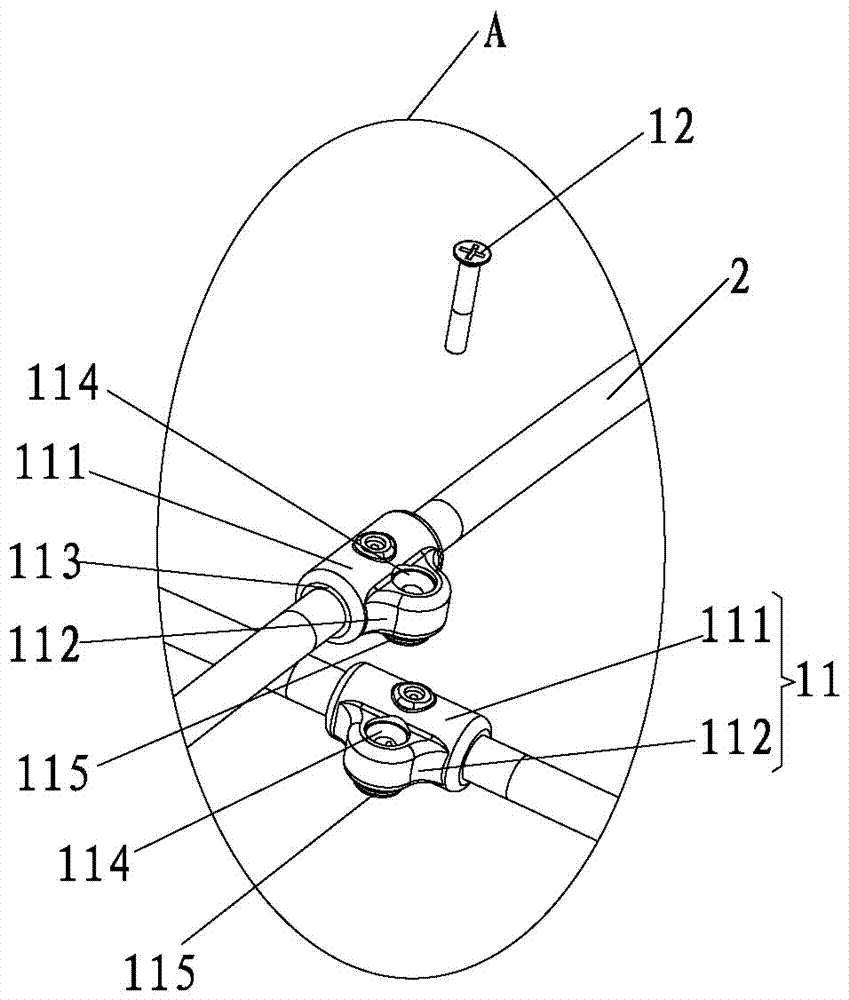

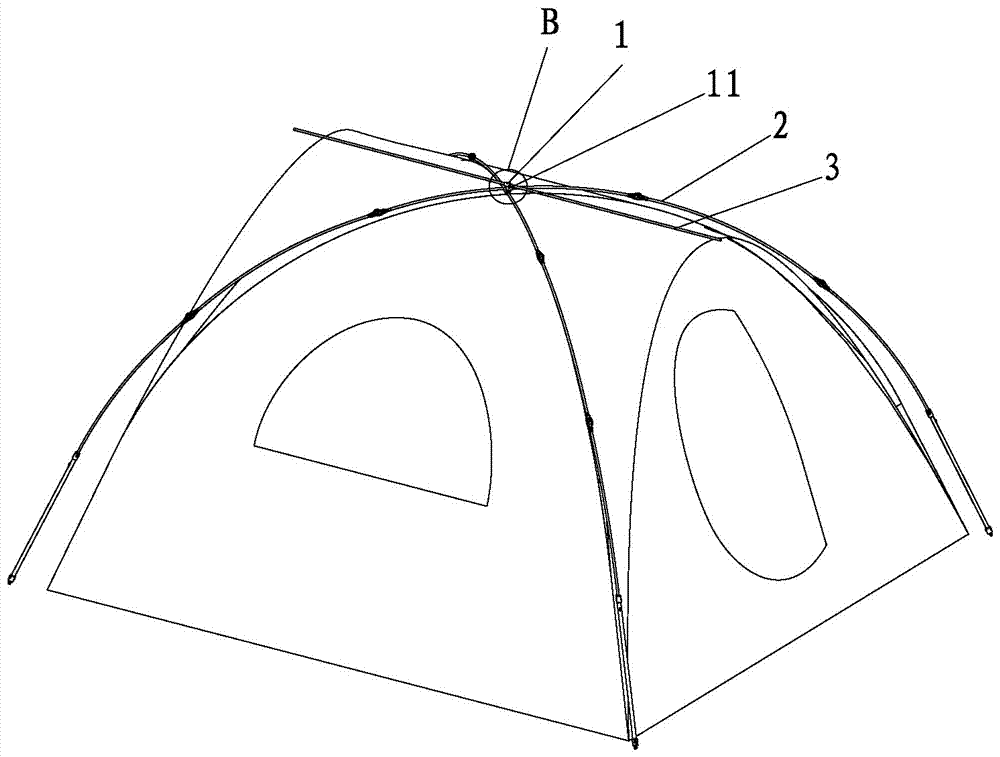

a tent stand

InactiveCN104100128BPrevent slipping outAvoid problems caused by airtightnessTents/canopiesEngineering

The invention provides a tent support, comprising a top connecting piece and a plurality of frame bars, wherein the top connecting piece comprises a first connecting part, at least one end of the upper end and the lower end of the first connecting part is provided with a cylindrical bulge, the end part of the cylindrical bulge outwards extends to form a circle of horizontal table, the top connecting piece also comprises a second connecting part with the quantity corresponding to that of the cylindrical bulge, the second connecting part is provided with a groove corresponding to the cylindrical bulge and the horizontal table, the side wall of the groove is provided with a horizontal hollow groove, the second connecting part also comprises a U-shaped limiting buckle, the two ends of the U-shaped limiting buckle are provided with barbs, the cylindrical bulges are embedded into the corresponding grooves, the two ends of the U-shaped limiting buckle extend into the hollow groove and are clamped on the cylindrical bulge, the first connecting part and the second connecting part are provided with a through hole respectively, and the frame bars cut across the corresponding through holes. The tent support is simple in structure, high in stability, very convenient to fold and unfold and low in production cost.

Owner:CAMPVALLEY XIAMEN LEISURE PRODS

Concrete building support component and preparation technology thereof

The invention provides a concrete building support component and a preparation technology thereof and belongs to the technical field of building support parts. The concrete building support component is characterized by comprising the following raw materials in parts by weight: 100 parts of cement, 460-600 parts of stone chips and 42-70 parts of water, wherein the ratio of the stone chips and water is 1 to 0.09-0.12; the stone chips comprise the stone chips different in particle diameters D by the following quality percentage: stone chips with particle diameters equal to or larger than 0.1 cm account for 30-60% of the total quantity of the stone chips; stone chips with particle diameters within the range of being larger than 0.1 cm and equal to or less than 0.3 cm account for 25-55% of the total quantity of the stone chips; stone chips with particle diameters within the range of being larger than 0.3 cm and equal to or smaller than 0.5 cm account for 10-18% of the total quantity of the stone chips. The preparation technology for the concrete building support component adopts side molded steel grooves. Moreover, after 1-4 seconds of pressing, demolding and maintenance are carried out immediately. The concrete building support component is short in maintenance time, high in strength at the initial stage and is adapted to the concrete of the building; the technological process is convenient and fast; the concrete building support component is firm and is not prone to looseness; the preparation construction period is short; the utilization is convenient.

Owner:曹连涛

White water printing paper preparation machine

InactiveCN101905560BSimple processLess investmentRotary letterpress machinesTransmittanceVisual inspection

The invention relates to the technical field of water printing paper preparation devices and preparation methods, in particular to a white water printing paper preparation machine and a preparation method. White water printing ink permeates paper by stamping to change the light transmittance of the paper, and predetermined white water printing patterns with different brightness are generated during visual inspection of light transmittance, so primary textures and characteristics of the paper are basically not damaged, and any influence on reprinting, writing, printing and the like after printing is not caused.

Owner:深圳市华德防伪技术开发有限公司

A method for constructing an aluminum alloy melting furnace with a high-nitrogen composite ceramic inner lining

ActiveCN104197717BGood energy saving effectQuality improvementLinings repairComposite ceramicAluminum silicate

The invention provides a construction method for an aluminum alloy smelting furnace with a high-nitrogen composite ceramic lining layer. The method comprises the steps of arrangement of an aluminum silicate wool felt layer, a light silicon-calcium insulation board layer, an aluminum silicate insulating brick masonry layer, an oxide cement gum impervious layer and a high-nitrogen composite ceramic tile masonry layer on the outer portion of a furnace body with a furnace chamber respectively, arrangement of the furnace chamber, pouring of a furnace top high-aluminum castable insulating layer, arrangement of a stainless steel grid framework, arrangement of anchoring parts, arrangement of an I-steel beam and laying of a furnace top aluminum silicate insulating layer; in this way, the smelting furnace is constructed. The smelting furnace is provided with the high-nitrogen composite ceramic tile lining layer, thereby having the advantages of heat preservation, a good energy-saving effect, metal corrosion resistance, good molten aluminum quality, easy furnace cleaning, long service life and a short manufacturing period; he construction method is suitable for construction of an aluminum ingot smelting furnace.

Owner:LIAONING YIFEI TECH

Concrete building support component and preparation technology thereof

The invention provides a concrete building support component and a preparation technology thereof and belongs to the technical field of building support parts. The concrete building support component is characterized by comprising the following raw materials in parts by weight: 100 parts of cement, 460-600 parts of stone chips and 42-70 parts of water, wherein the ratio of the stone chips and water is 1 to 0.09-0.12; the stone chips comprise the stone chips different in particle diameters D by the following quality percentage: stone chips with particle diameters equal to or larger than 0.1 cm account for 30-60% of the total quantity of the stone chips; stone chips with particle diameters within the range of being larger than 0.1 cm and equal to or less than 0.3 cm account for 25-55% of the total quantity of the stone chips; stone chips with particle diameters within the range of being larger than 0.3 cm and equal to or smaller than 0.5 cm account for 10-18% of the total quantity of the stone chips. The preparation technology for the concrete building support component adopts side molded steel grooves. Moreover, after 1-4 seconds of pressing, demolding and maintenance are carried out immediately. The concrete building support component is short in maintenance time, high in strength at the initial stage and is adapted to the concrete of the building; the technological process is convenient and fast; the concrete building support component is firm and is not prone to looseness; the preparation construction period is short; the utilization is convenient.

Owner:曹连涛

Novel four-sealing-edge dish rack and manufacturing method thereof

PendingCN107048771ADoes not affect appearanceLow costFurniture joining partsDismountable cabinetsEngineeringMechanical engineering

The invention relates to the technical field of kitchen cabinet functions, in particular to a novel four-sealing-edge dish rack and a manufacturing method thereof. The novel four-sealing-edge dish rack comprises a surface frame, partition plates, bottom plate strips, a back plate, a top plate and side plates. The surface frame, the back plate, the top plate and the side plates are fixedly connected into a box body without a lower bottom face. The bottom plate strips are parallel to the long sides of the box body, three side faces of one bottom plate strip are fixedly connected with the surface frame and the two side plates respectively, and three side faces of the other bottom plate strip are fixedly connected with the back plate and the two side plates respectively. The partition plates are fixedly connected to the upper surfaces of the bottom plate strips in parallel, and meanwhile the partition plates are fixedly connected with the back plate. The product can be used for mating of different kitchen cabinet material door sheet elements, the cost is reduced, and terminal design application is improved. Meanwhile, the dish rack is manufactured from double veneers, the cost is low, the manufacturing period is short, certain abrasion resistance and corrosion resistance are achieved, and various problems of a dish rack in daily life can be fully solved.

Owner:ZBOM HOME COLLECTION CO LTD

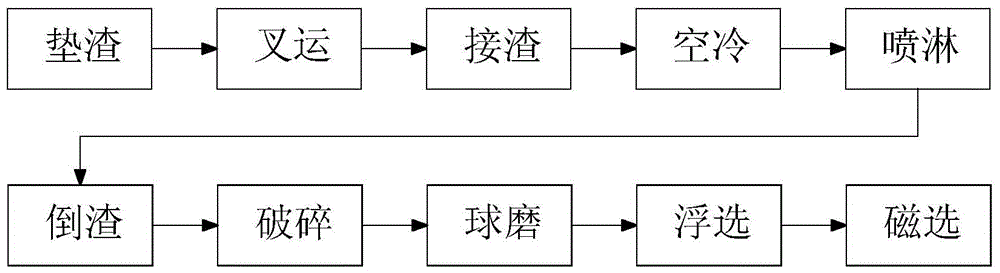

Welding slag package suitable for copper slag slow cooling process

The invention provides a novel welding slag ladle suitable for a slow cooling process of copper slag. The novel welding slag ladle comprises a ladle body, a ladle bottom and a plurality of ladle feet, wherein the ladle body is pressed into a whole; the ladle bottom is welded at the bottom of the ladle body; the ladle feet are welded at the bottom of the ladle bottom; a radiating space is formed between the two adjacent ladle feet; the ladle body, the ladle bottom and the ladle feet are all made of low-alloy high-strength plates. The novel welding slag ladle does not have any structural change during a using process and is particularly suitable for the slow cooling process of the copper slag; the service life of the welding slag ladle is greatly prolonged, so that the recycling cost of the copper slag is reduced.

Owner:MCC BAOSTEEL TECH SERVICE

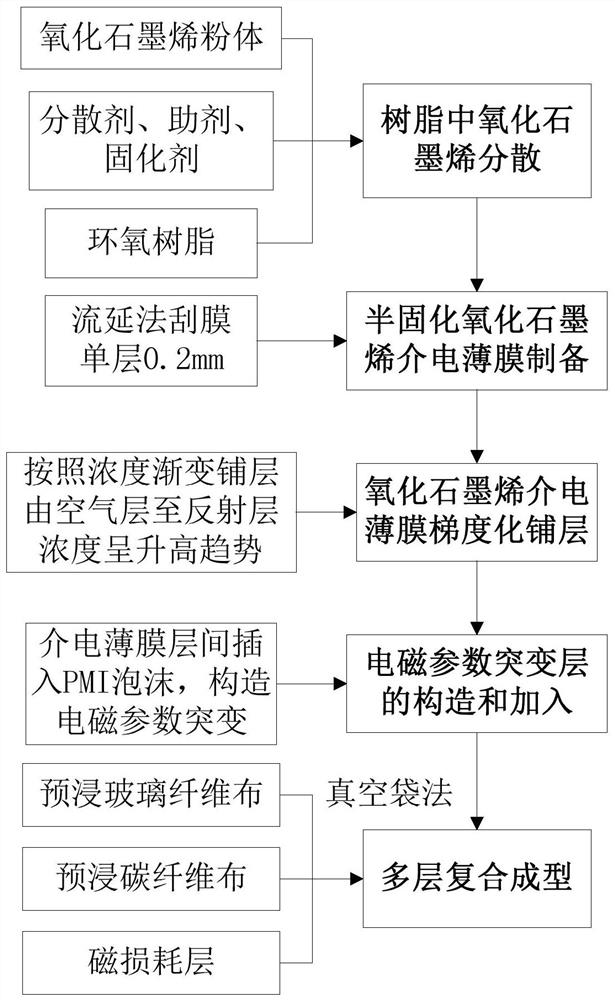

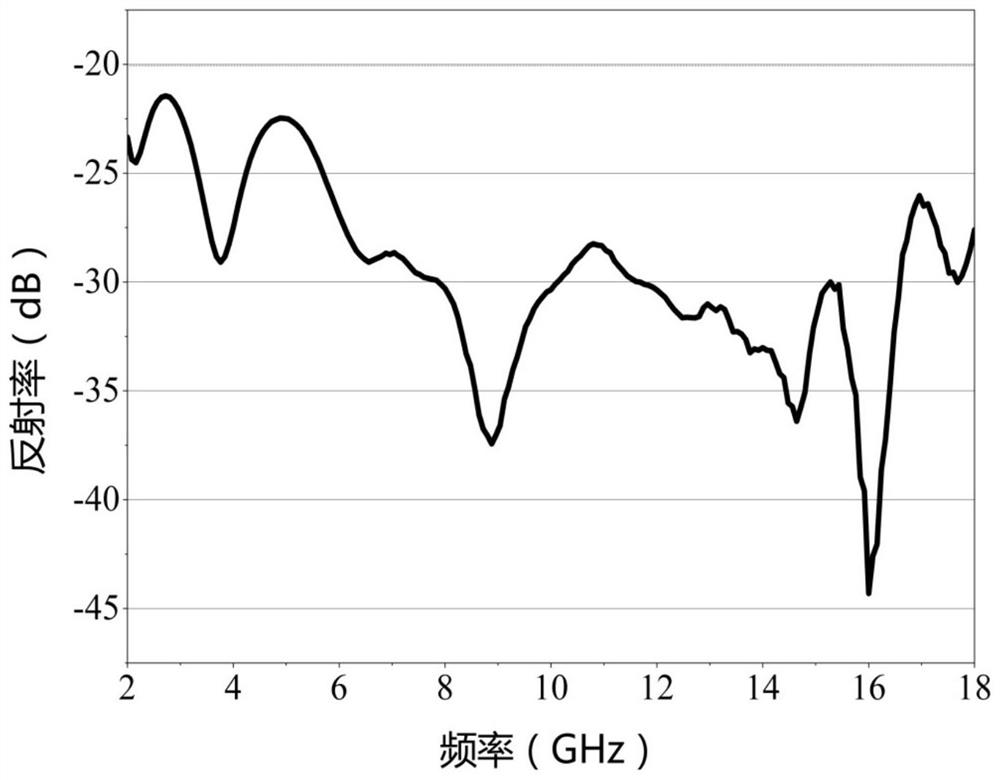

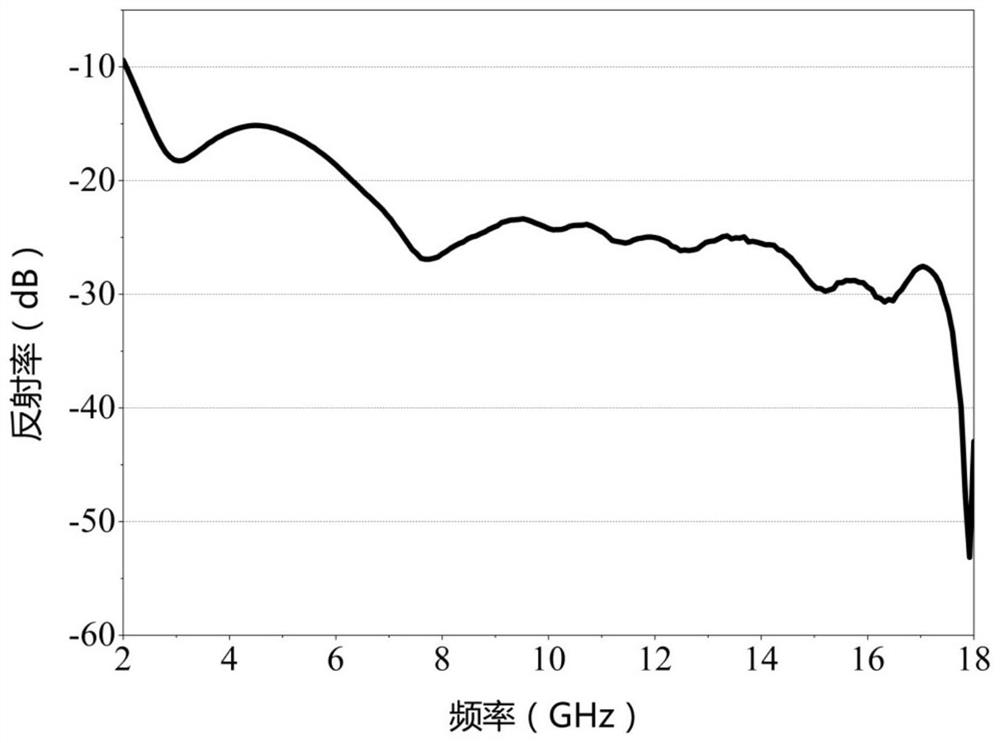

A kind of gradient graphene oxide-based structure wave-absorbing material and its preparation method

ActiveCN109648952BAbsorption BandwidthReduce reflectionSynthetic resin layered productsVehicle componentsEpoxyPhysical chemistry

The invention relates to a gradient type graphene oxide-based structure wave-absorbing material and a preparation method thereof. The method comprises: using a dispersant to prepare graphene oxide, auxiliary agent, curing agent and epoxy resin into various mixed slurries with different graphene oxide mass percentages; The materials were casted on the release paper to form a film to obtain a plurality of graphene oxide dielectric films in a semi-cured state with different graphene oxide mass percentages; The method of increasing or decreasing the content is alternately bonded to the rigid foam material layer in sequence to obtain a layered structure; the obtained layered structure is cured to obtain a gradient graphene oxide-based structure wave-absorbing material. The gradient type graphene oxide-based structure wave-absorbing material prepared by the method of the invention has a lower surface density while improving the radar wave absorption bandwidth and absorption depth, and can realize the stealth integration of various weapon equipment components.

Owner:BEIJING INST OF ENVIRONMENTAL FEATURES

A simple tent support

Owner:CAMPVALLEY XIAMEN LEISURE PRODS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com