Process device and method for removing heavy hydrocarbon in natural gas by adopting LPG (Liquefied Petroleum Gas)

A process device and natural gas technology, which is applied in the petroleum industry, gas fuel, liquid hydrocarbon mixture recovery and other directions, can solve the problems of unfavorable energy saving and consumption reduction, complex process, large investment, etc., and achieves short manufacturing period, simple process and low investment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

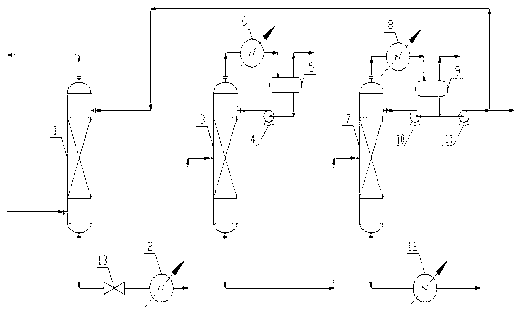

[0009] A process device for LPG to remove heavy hydrocarbons in natural gas, such as figure 1 As shown, it includes: heavy hydrocarbon scrubber 1, cooler 2, deethanizer 3, deethanizer reflux pump 4, deethanizer reflux tank 5, deethanizer condenser 6, debutanizer 7 , debutanizer condenser 8, debutanizer reflux tank 9, debutanizer reflux pump 10, LPG booster pump 11, debutanizer bottom condenser 12 and throttle valve 13. in:

[0010] Heavy hydrocarbon scrubber 1 is connected with throttle valve 13, cooler 2, deethanizer 3, debutanizer 7 and debutanizer bottom condenser 12 in sequence; the top outlet of deethanizer 3 is connected with deethanizer in turn The tower condenser 6, the deethanizer reflux tank 5, the deethanizer reflux pump 4 and the upper inlet of the deethanizer 3 are connected; The tower reflux tank 9, the debutanizer reflux pump 10 are connected to the upper inlet of the debutanizer 7; the debutanizer reflux tank 9 is connected to the upper inlet of the heavy hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com