All-closed zero-emission household refuse energy regeneration and comprehensive utilization production process

A technology of domestic waste and production technology, which is applied in the field of fully enclosed zero-emission domestic waste energy regeneration and comprehensive utilization production technology, can solve the problems of complex separation of products, long process cycle, high cost of biological treatment, etc., and achieve high output value and energy efficiency. Consumption of reasonable, significant economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

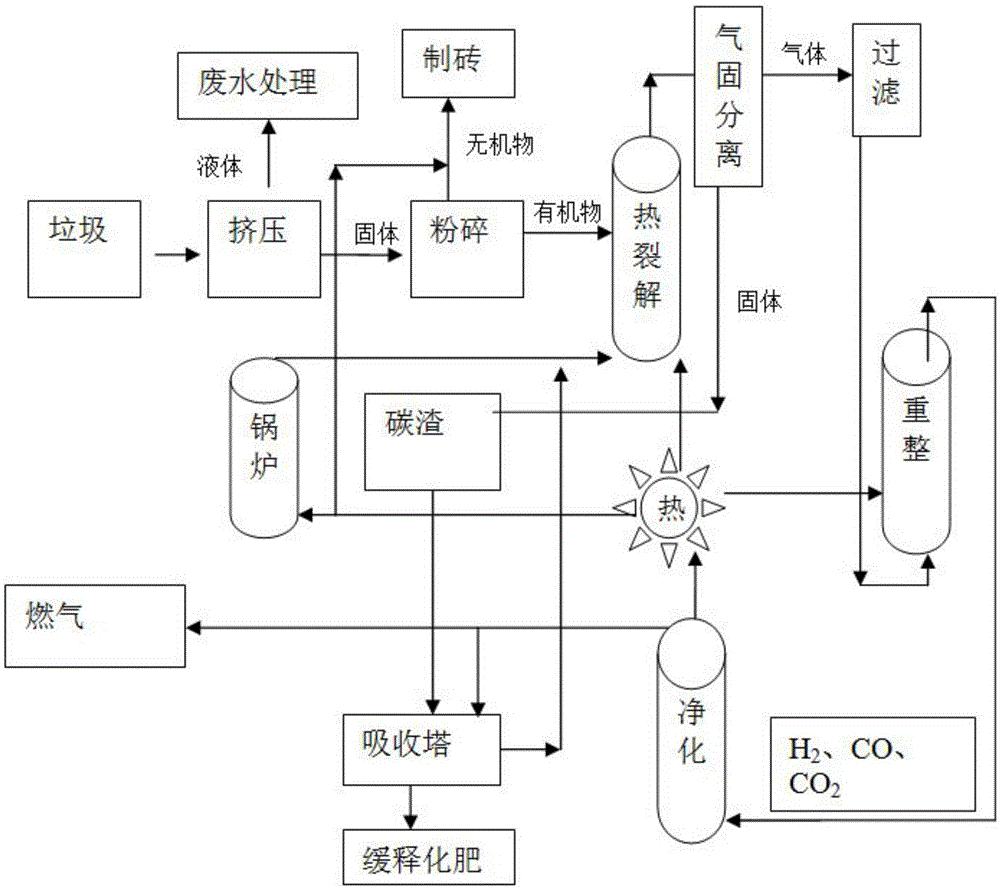

[0037] The garbage composition in a certain area is: paper: 3.9%, kitchen waste / wood: 17.6%, plastic: 16.1%, fiber products: 2.7%, solid residue: 40.3%, metal: 0.2%, water: 19.3%.

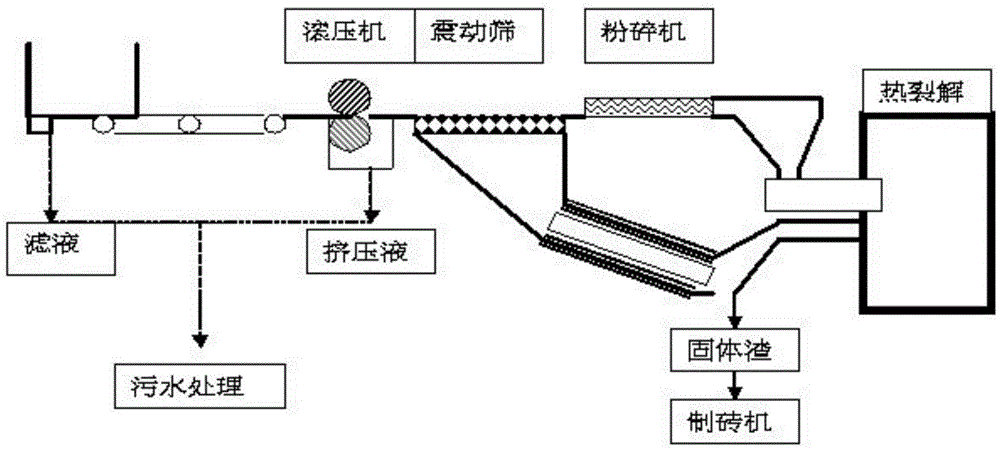

[0038] According to the treatment capacity of 4 tons / hour, 200 kg / hour (5%) of waste water will enter the sewage treatment after being squeezed, and then be conveyed through the vibrating screen bed after rolling, and the 1600 kg / hour soil residue will be separated and heated. After modification (dehydration at 400°C, crushing, modification at 850°C), it can be mixed with 160 kg / h of cement and other additives to make various unburned bricks; After the mud is pressed by the plate, it is sent to the thermal modification device for brick making; while the organic matter part is collected and sent to the thermal cracking device.

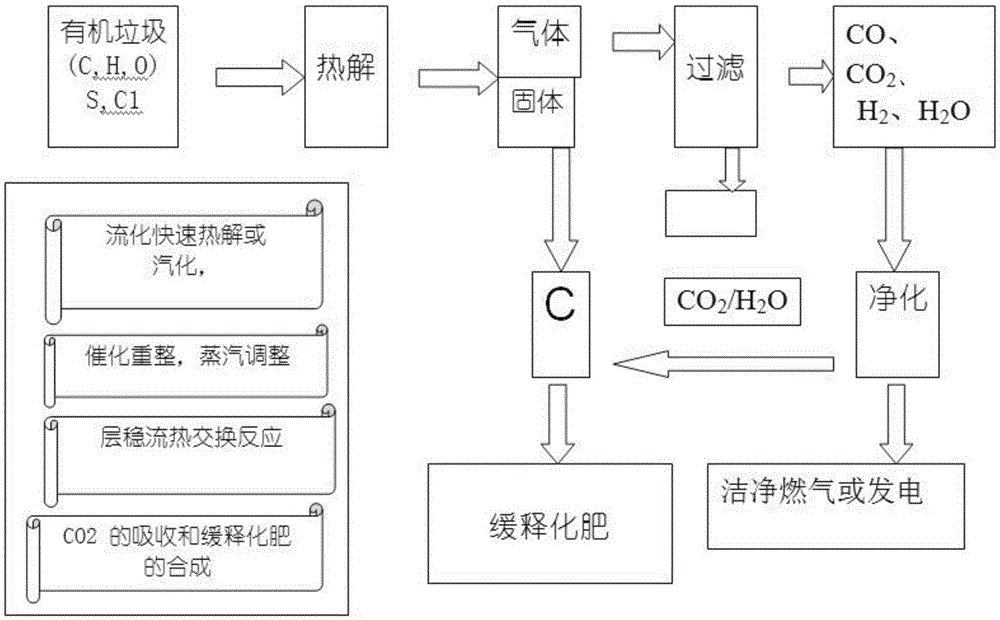

[0039] The rest of the organic matter is about 2200 kg / h (water content 15%), and enters the thermal cracking furnace after shearing and crushing (size 2cm), where the fluid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com