White water printing paper preparation machine and preparation method

A preparation machine and white water technology, which is applied to printing presses, rotary printing machines, rotary printing machines, etc., can solve the problems of high cost, complex technology of watermark anti-counterfeiting paper, and large batch requirements for paper production, so as to achieve small investment and high printing efficiency The effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

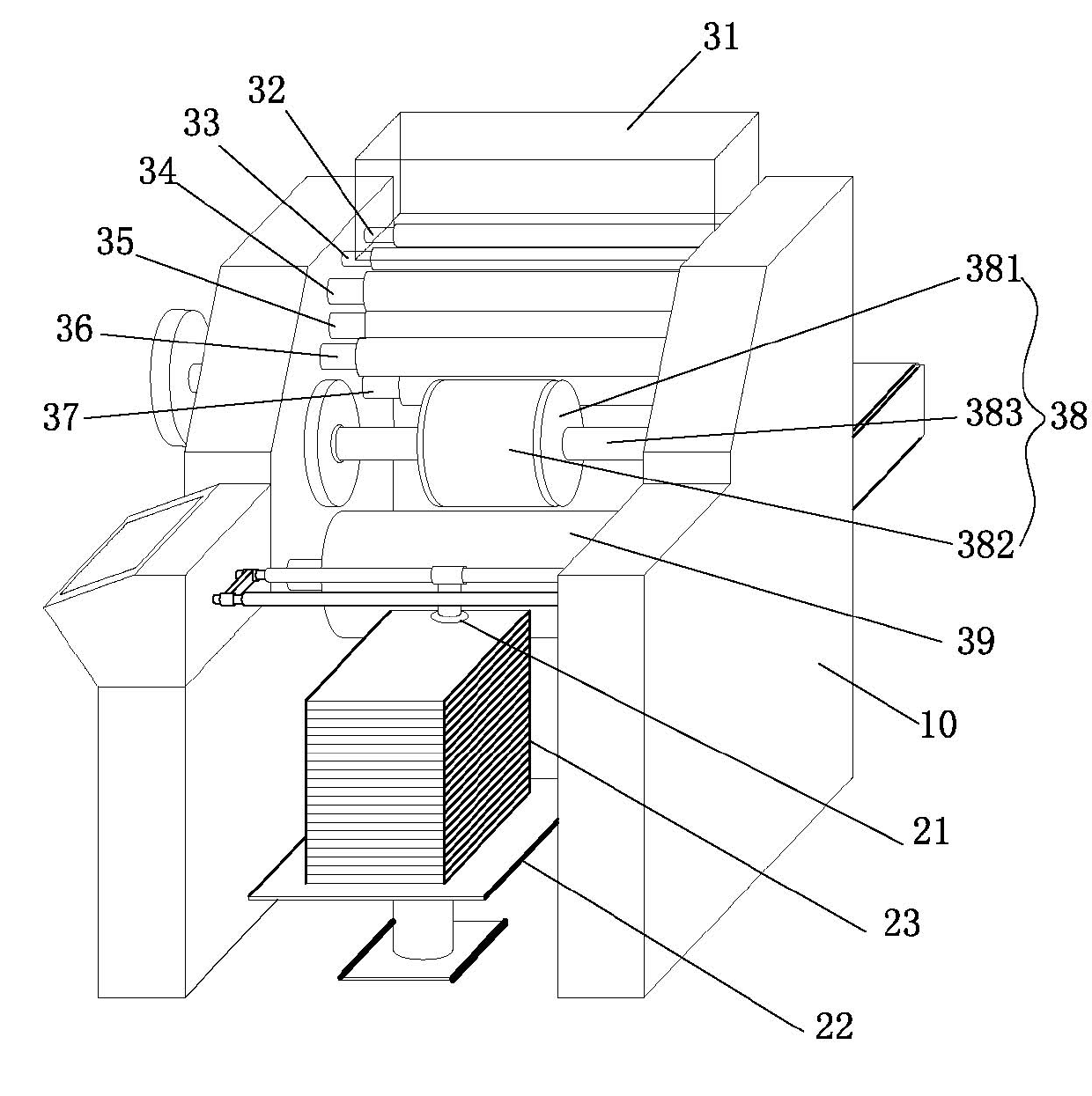

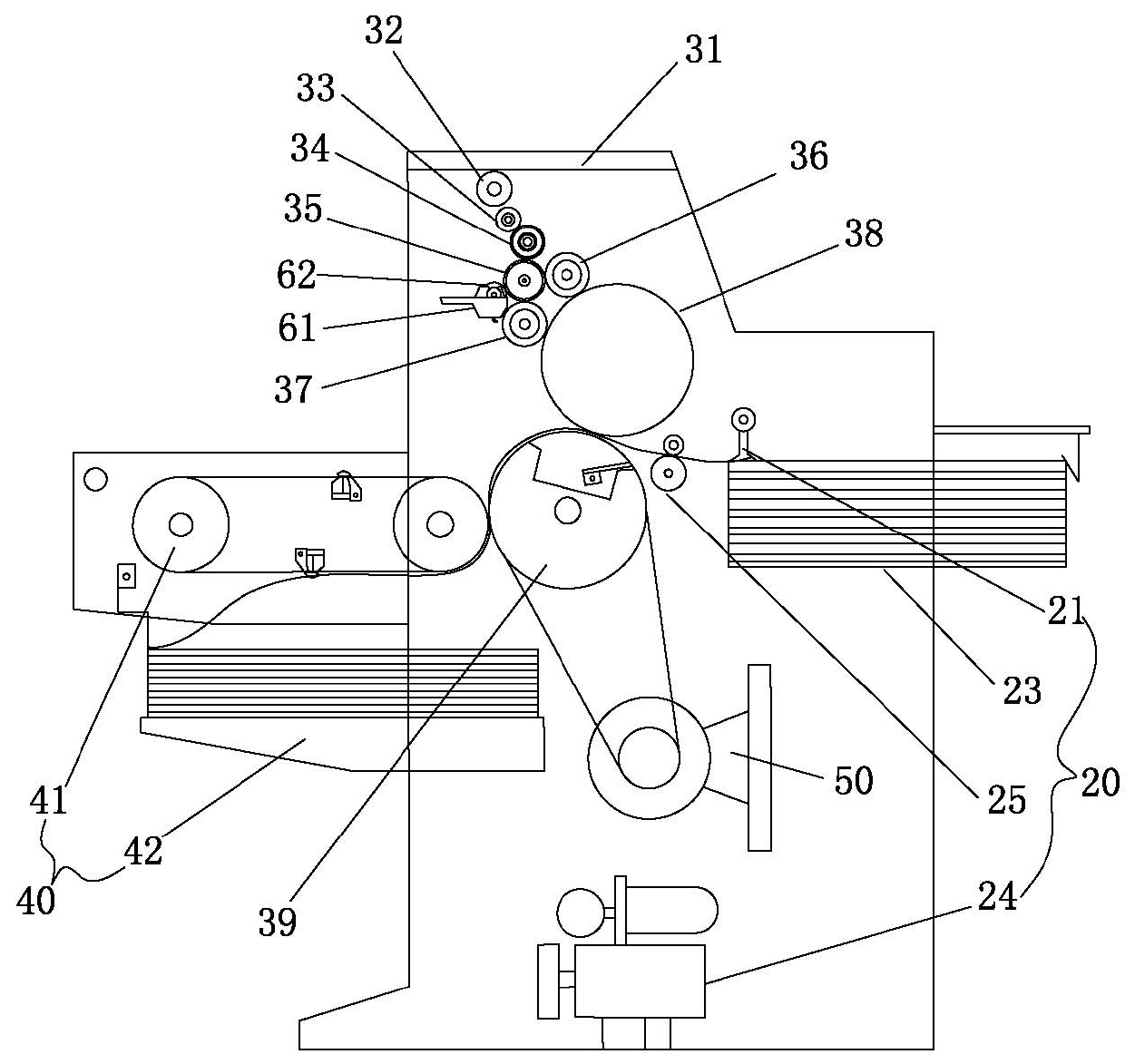

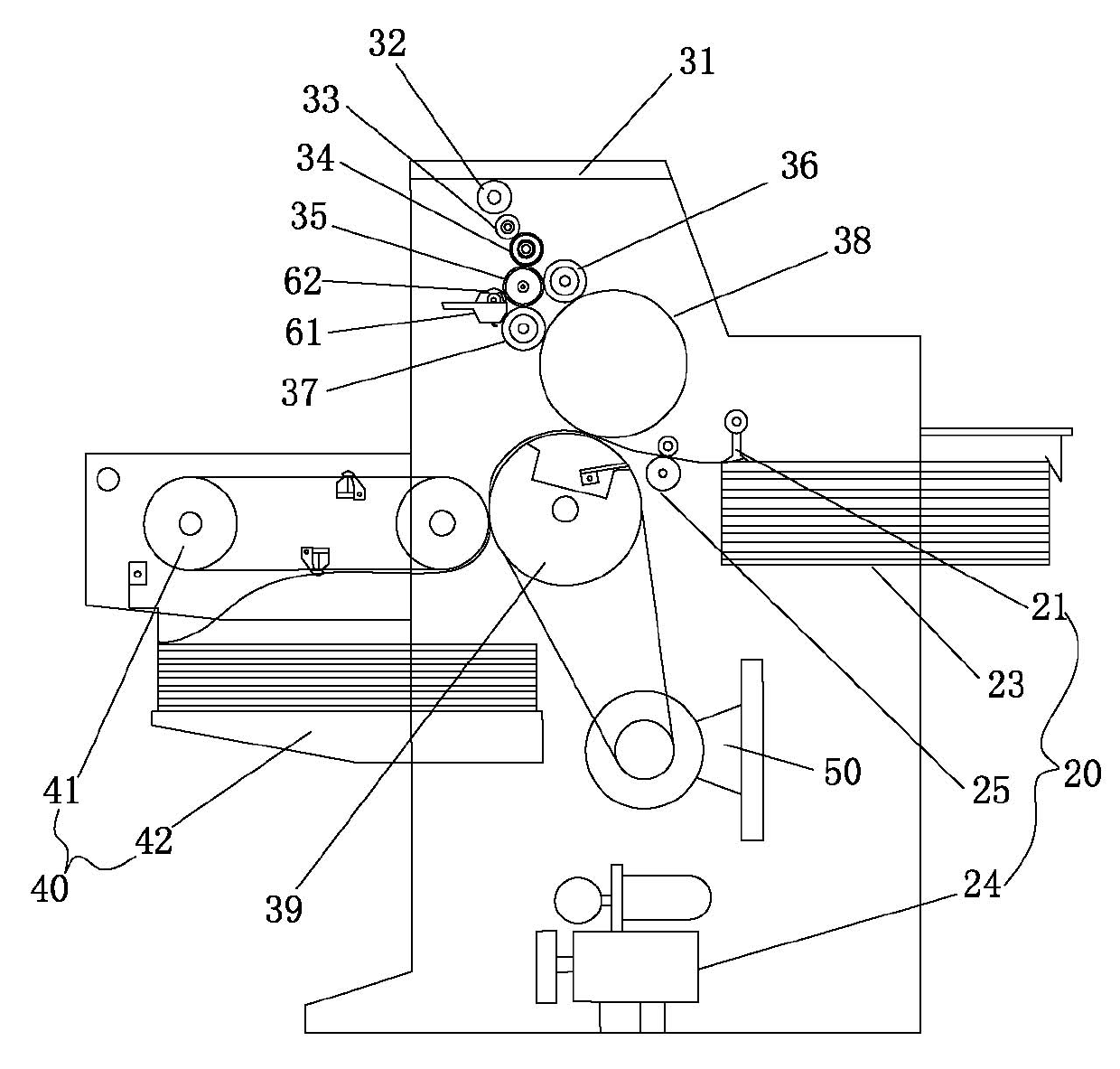

[0027] Such as Figure 1-2 As shown, a white watermark paper preparation machine includes a frame 10 on which a paper feeding mechanism 20, a printing mechanism 30 and a paper discharge structure 40 are respectively arranged, wherein the printing mechanism 30 includes a The upper ink supply tank 31 and the ink supply roller 32, the ink transfer roller 33, the ink equalizing roller 34, the ink shifting roller 35, the upper ink form roller 36, the lower ink form roller 37, Plate cylinder assembly 38, impression cylinder 39 and driving motor 50, drive motor 50 is connected with impression cylinder 39 to drive the rotation of impression cylinder 39 through transmission parts, and the outer circumferential surface of impression cylinder 39 is on the plate cylinder assembly 38 The printing plate 382 of the concave-convex pattern on the outer peripheral surface of the printing plate cylinder 381 is in conflict with each other, and the other side of the printing plate 382 is in confli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com