Wall body for building

A technology for buildings and walls, applied in the direction of building structures, buildings, building components, etc., can solve the problems of a large amount of construction waste, low construction efficiency, waste of resources, etc., and achieve beneficial utilization of resources, reduction of construction waste, construction The effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0020] This embodiment is a body of wall of a 2-storey house

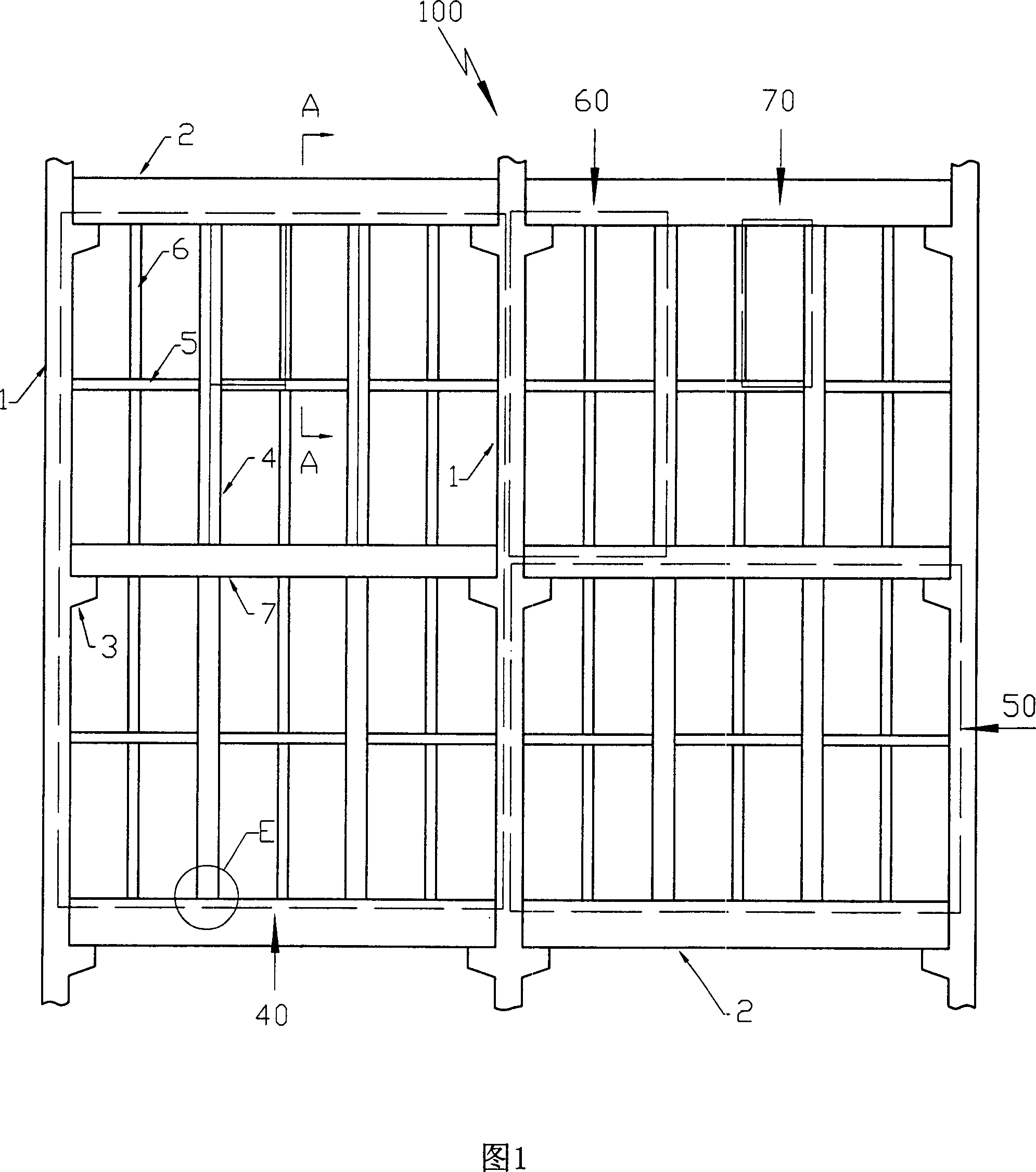

[0021] Fig. 1 is a body of wall of a 2-storey house, and it is built into the body of wall frame that comprises two main frames 40 by three columns 1 and four beams 2. Two main frames 40 are divided into four layer frames 50 by a beam I7 in the middle, and each layer frame 50 is divided into three sub-frames 60 by two secondary columns II6, and each secondary frame 60 is composed of a secondary beam 5 and The two secondary columns II6 are divided into four basic frames 70 . The column 1 is provided with a corbel 3 on one side or its symmetrical sides along the column length direction, and the two ends of the beam 2 and the beam I7 are built on the corbel 3 at the corresponding position of the column 1.

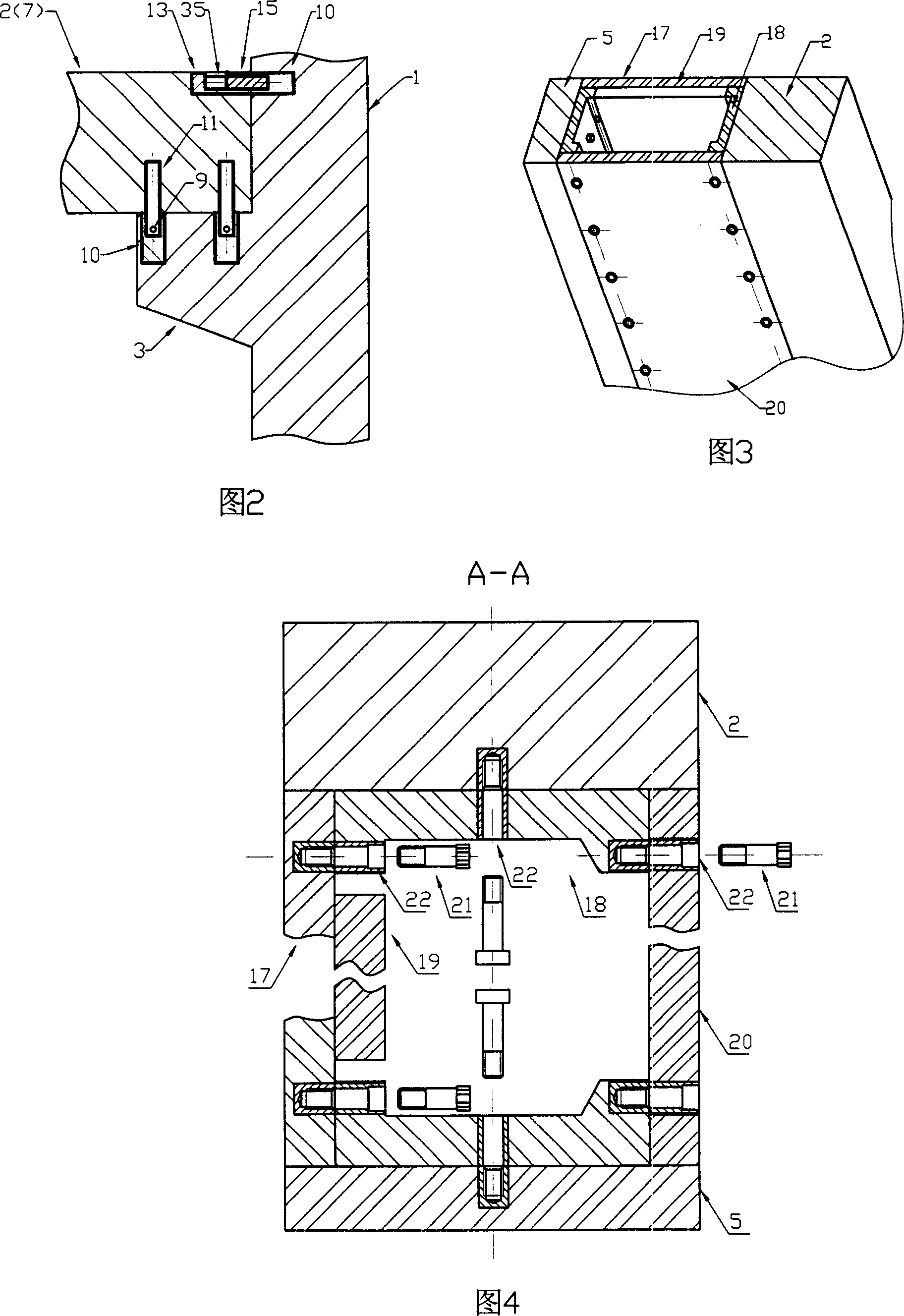

[0022] Fig. 2 is a schematic diagram of the connection structure between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com