Manufacturing method of simulation fracture for fractured rock mass seepage test

A fissured rock mass and a technology for making it, which is applied in the fields of simulated fissure making and fissure rock mass seepage test simulation fissure making, can solve the problem of not being able to fully and accurately reflect the structural surface characteristics of rock mass fissures, the gap between test simulation results and actual seepage characteristics, Limited test conditions and other issues, to achieve rapid integrated molding, improve production efficiency, and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

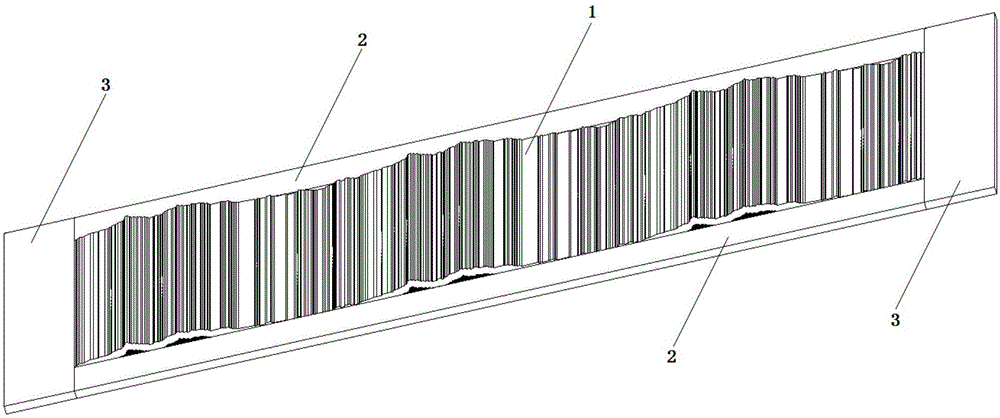

[0041] Below in conjunction with accompanying drawing of description, the present invention will be further described.

[0042] The invention provides a method for fabricating a simulated crack for a seepage test of a cracked rock mass, comprising the following steps:

[0043] 1) Draw digital contour curves of cracks;

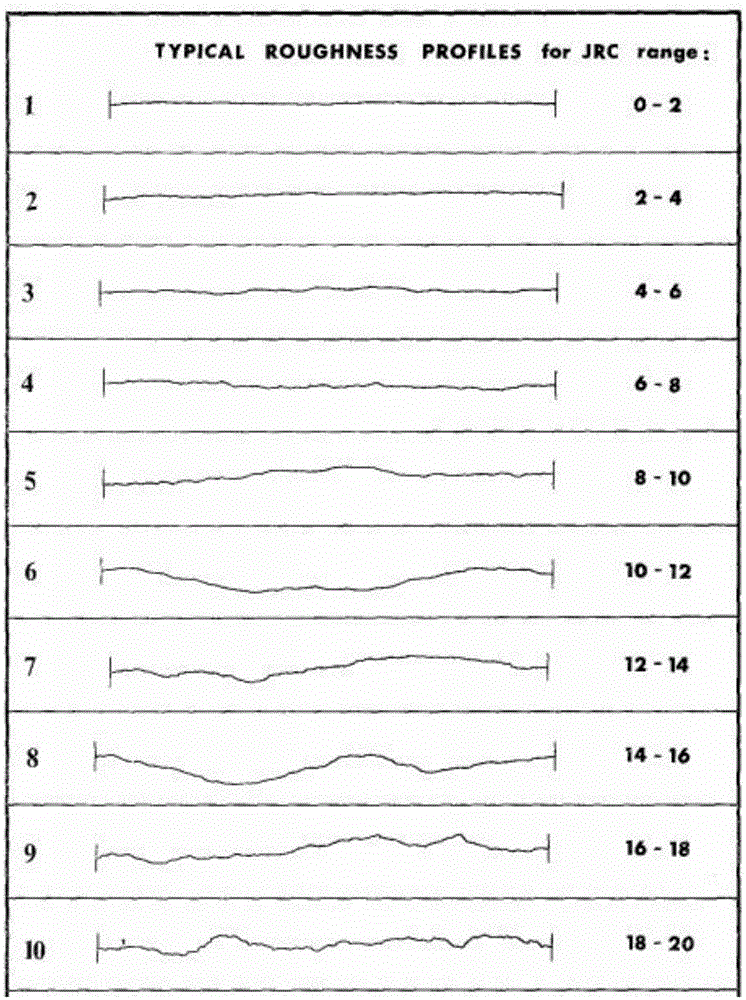

[0044] The joint roughness profile curve of the rock structure surface proposed by Barton is used as the prototype of the undulation curve of the crack, and the ten JRC profile curves are scanned sequentially according to the size of the original image to obtain ten curve pictures, as shown in figure 1 shown.

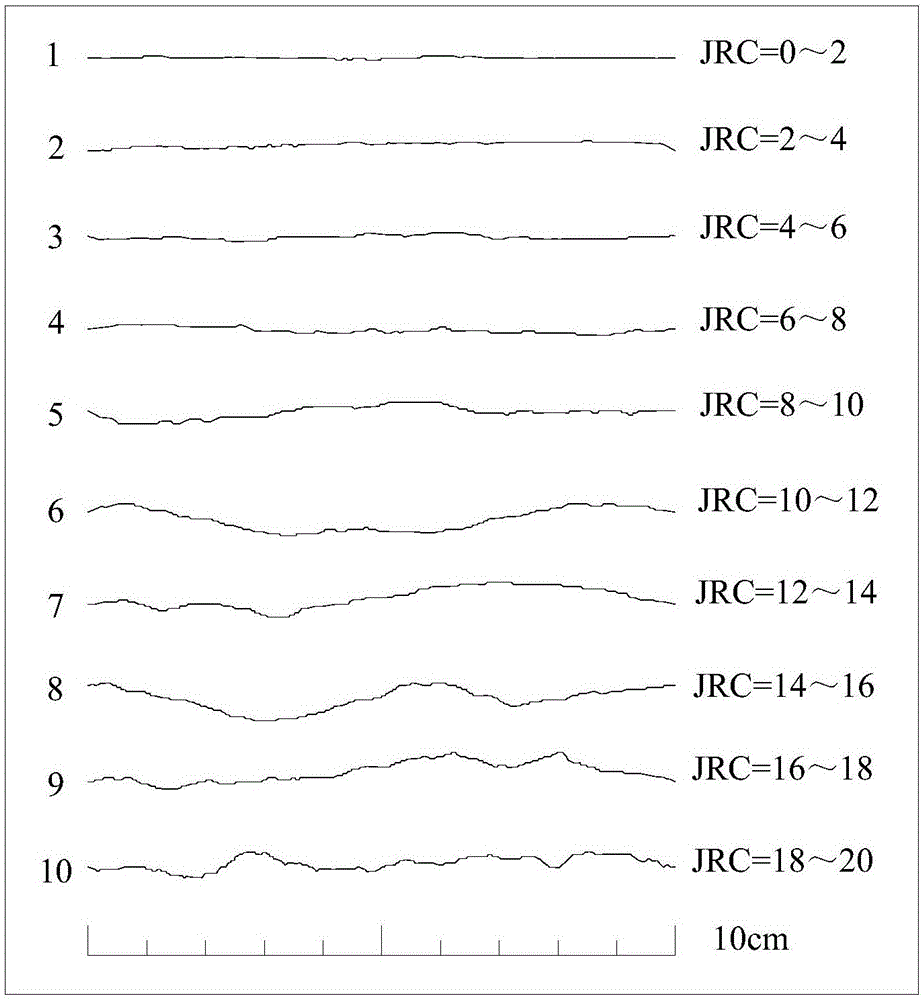

[0045] Import the pictures of ten curves into the CAD software, enlarge the picture, use the polyline drawing function in the CAD drawing interface to draw ten digital contour curves of cracks, as shown in figure 2 As shown, each fissure digitized contour curve is composed of multiple straight line segments, the horizontal length is 10cm, and the accu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com