Sea surface spilled oil rapid separation and recovery device

A technology for separation and recovery of oil spilled on the sea surface, applied in the direction of separation methods, liquid separation, chemical instruments and methods, etc., can solve problems such as pipeline leakage, crude oil leakage, floating, etc., and achieve the effects of short manufacturing period, improved efficiency, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

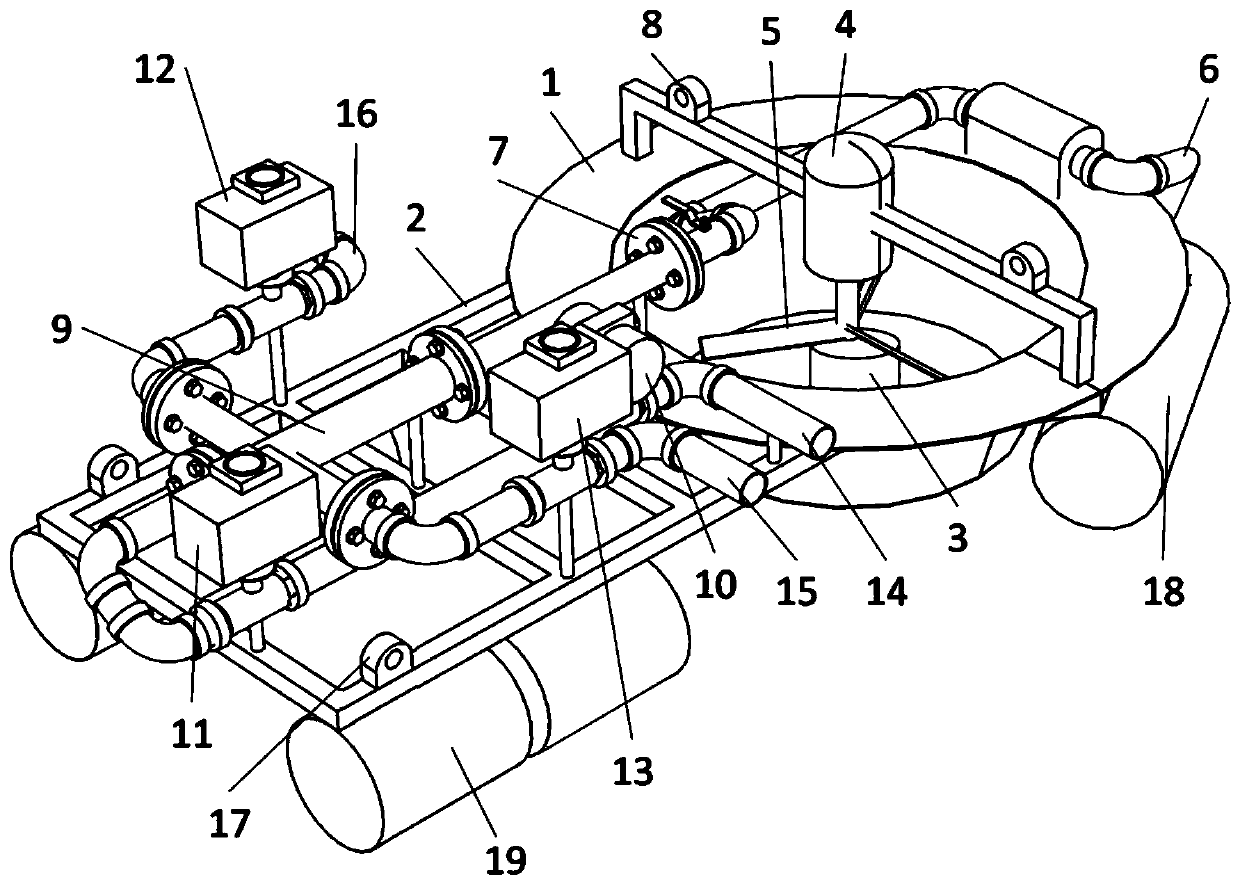

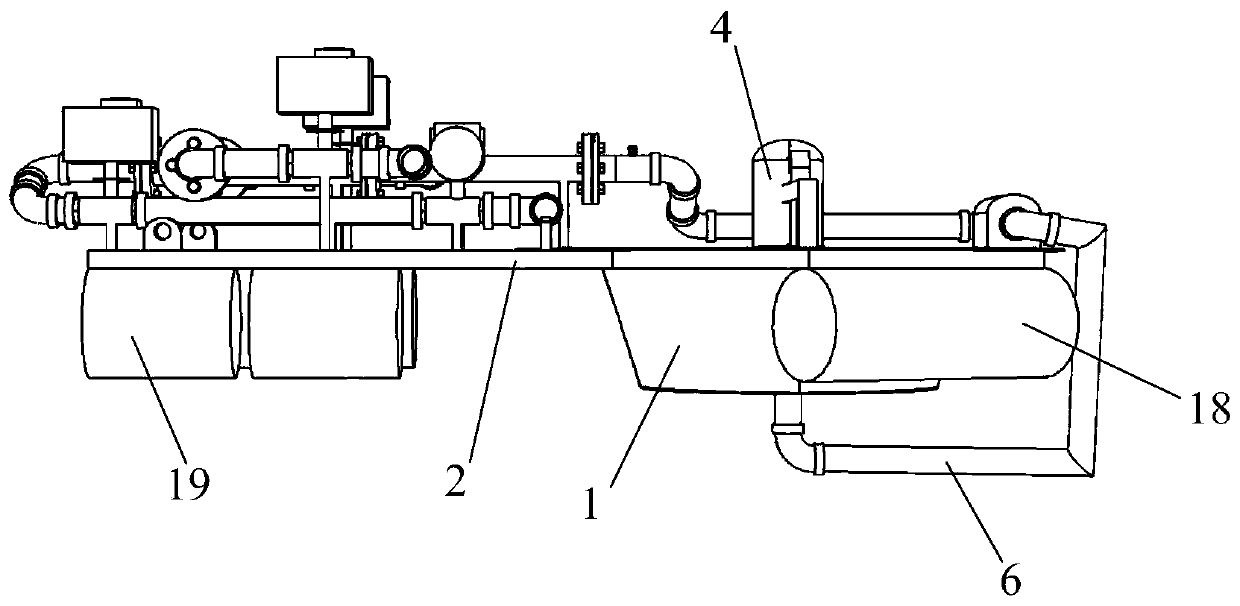

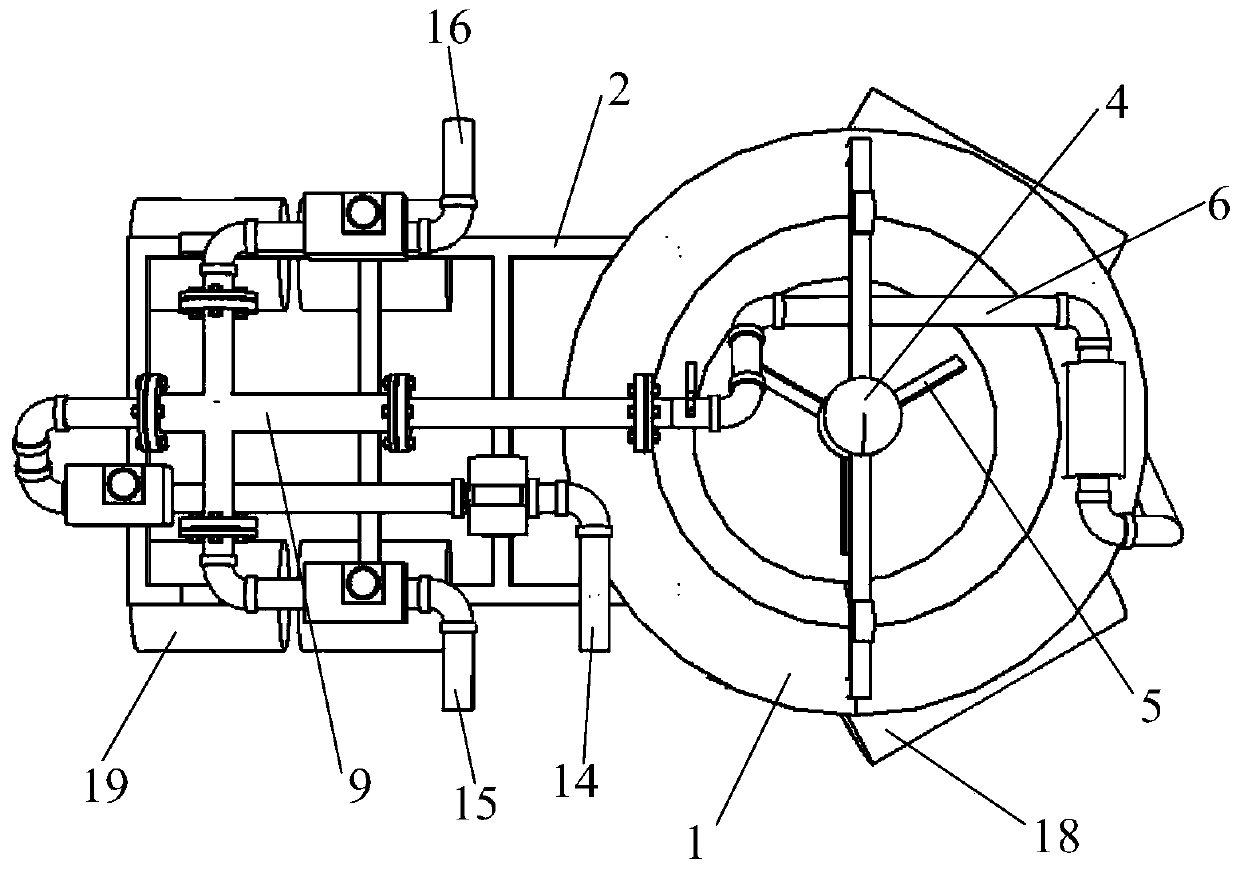

[0039] see Figure 1~3 , the present embodiment provides a rapid separation and recovery device for sea surface oil spill, comprising a support frame 2, a vortex-making recovery tank 1, a vortex-making blade 5, a motor 4, a submersible pump 3 and a primary vortex separator 9, the support frame 2 The first and last ends of the lower part are connected with buoys. Specifically, the support frame 2 is connected with six buoys at its first and last ends, wherein two long buoys 18 are fixed at the left and right ends of the head, and four are fixed at the left and right ends of the tail. A short buoy 19. The vortex-making recovery tank 1 is fixed on the head of the support frame 2, the vortex-making blade 5 is located in the vortex-making recovery tank 1, and the motor 4 is vertically fixed at the middle position directly above the vortex-making recovery tank 1 through the support frame 2 , the motor 4 is connected to the vortex-making blade 5 directly below, the bottom center of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com