Three-dimensional effect glossing method of offset press

A three-dimensional effect, offset press technology, applied in printing presses, general parts of printing machinery, printing and other directions, can solve the problems of prolonged construction period, increased process cost, single process effect, etc., to achieve short production period, low cost, strong three-dimensional effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0021] The invention discloses a three-dimensional effect glazing method for an offset printing machine, which comprises the following steps:

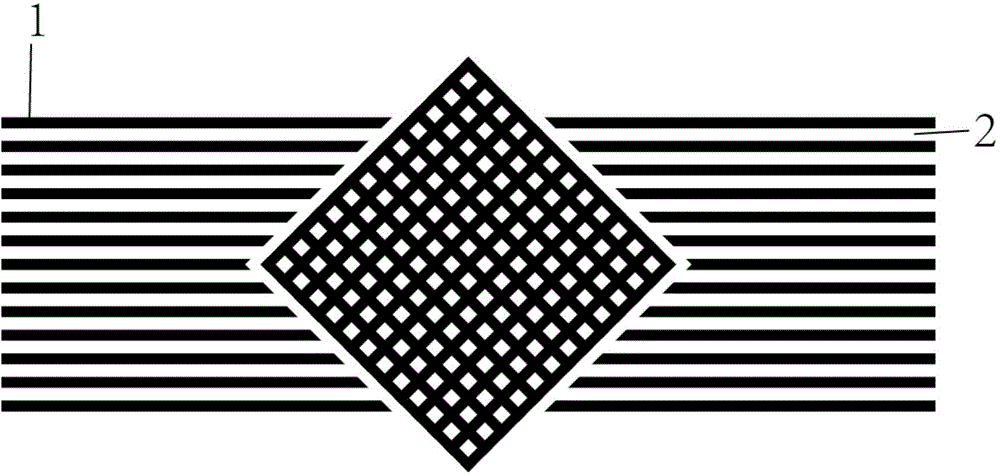

[0022] 1) Select a product that needs to be designed with a concave-convex three-dimensional pattern, use the graphic design software of the computer to make an original with the required concave-convex three-dimensional pattern, and set the color value at the position of the pattern that needs a matte effect in the original. Set it to 100k, and set the color value to 0k for the rest. that is, if figure 1 The part marked 1, that is, all the black parts in the figure, has its color value set to 100k. figure 1 The part marked 2, namely figure 1 For all white parts in , set its color value to 0k;

[0023] 2) Input the prepared manuscript into the direct plate-making machine, the manuscript is an electronic piece, and the man...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com