Sintered shale micropore building block and manufacturing method thereof

A production method and block technology are applied in the field of building wall blocks, which can solve the problems of easy falling off of external wall bricks, inability to handle, complicated block production methods, etc. Excellent thermal insulation and sound insulation, and the effect of avoiding dust and carbon dioxide pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

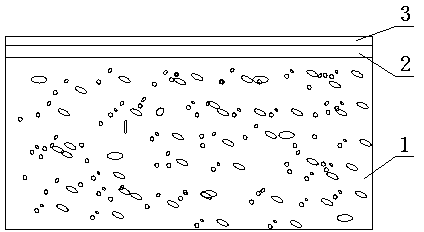

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0035] During specific implementation, a method for manufacturing a sintered shale microporous block comprises the following steps:

[0036] a. According to parts by mass, 40-60 parts by mass of one or more of shale, construction spoil and silt, 30-50 parts by mass of garbage and / or straw, 10-35 parts by mass of coal gangue, of which shale , construction spoil and coal gangue are required to pass through 80-100 mesh after being crushed, and sludge is required to pass through 80-100 mesh after drying and crushing, and straw and garbage should be squeezed and crushed until the particle diameter is less than 2cm;

[0037]b. After adding 10-25 parts by mass of water and stirring to form a viscous shape, extrude to form a block blank;

[0038] c. Apply a layer of clay layer on at least one side surface of the block blank, and then apply a layer of glaze on the su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com