Preparation method of thin-film solar cell absorption layer with gradient gallium-indium atomic ratio distribution

A solar cell and gradient distribution technology, applied in the field of solar power generation, can solve the problems of difficult control of the evaporation process, difficulty in large-area uniformity and continuous production, and strict equipment requirements, so as to achieve large-area uniformity and continuity. The effect of production, improving conversion efficiency and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

[0021] Example.

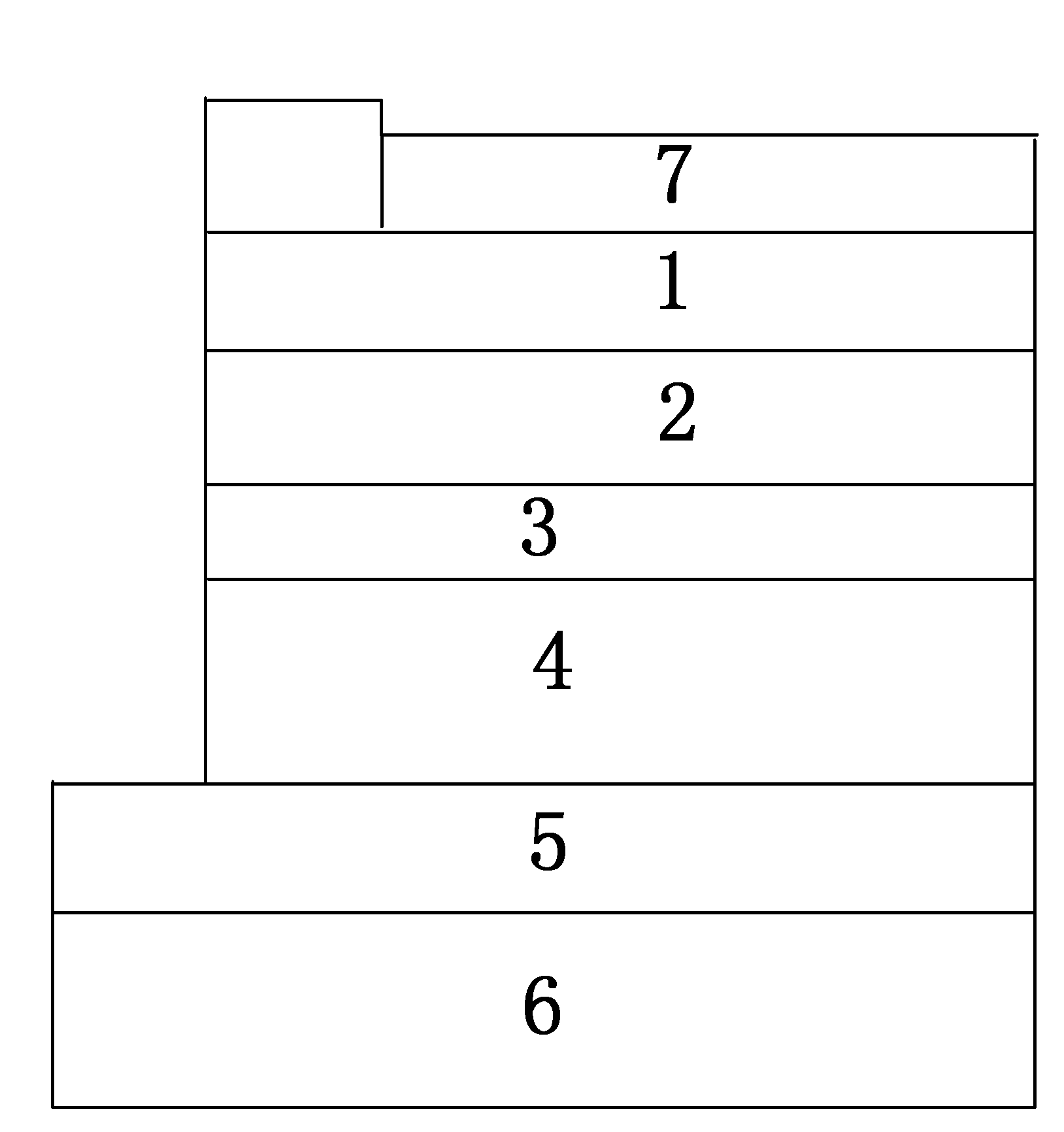

[0022] The copper indium gallium selenium solar cell is followed by the substrate 6, the back electrode layer 5 (Mo), the absorber layer 4 (CIGS), the buffer layer 3 (ZnS or CdS), the transparent conductive film layer 2 and the transparent window layer 1 and the reverse electrode from the bottom to the top. Reflective layer 7 (MnF 2 ). Such as figure 1 shown.

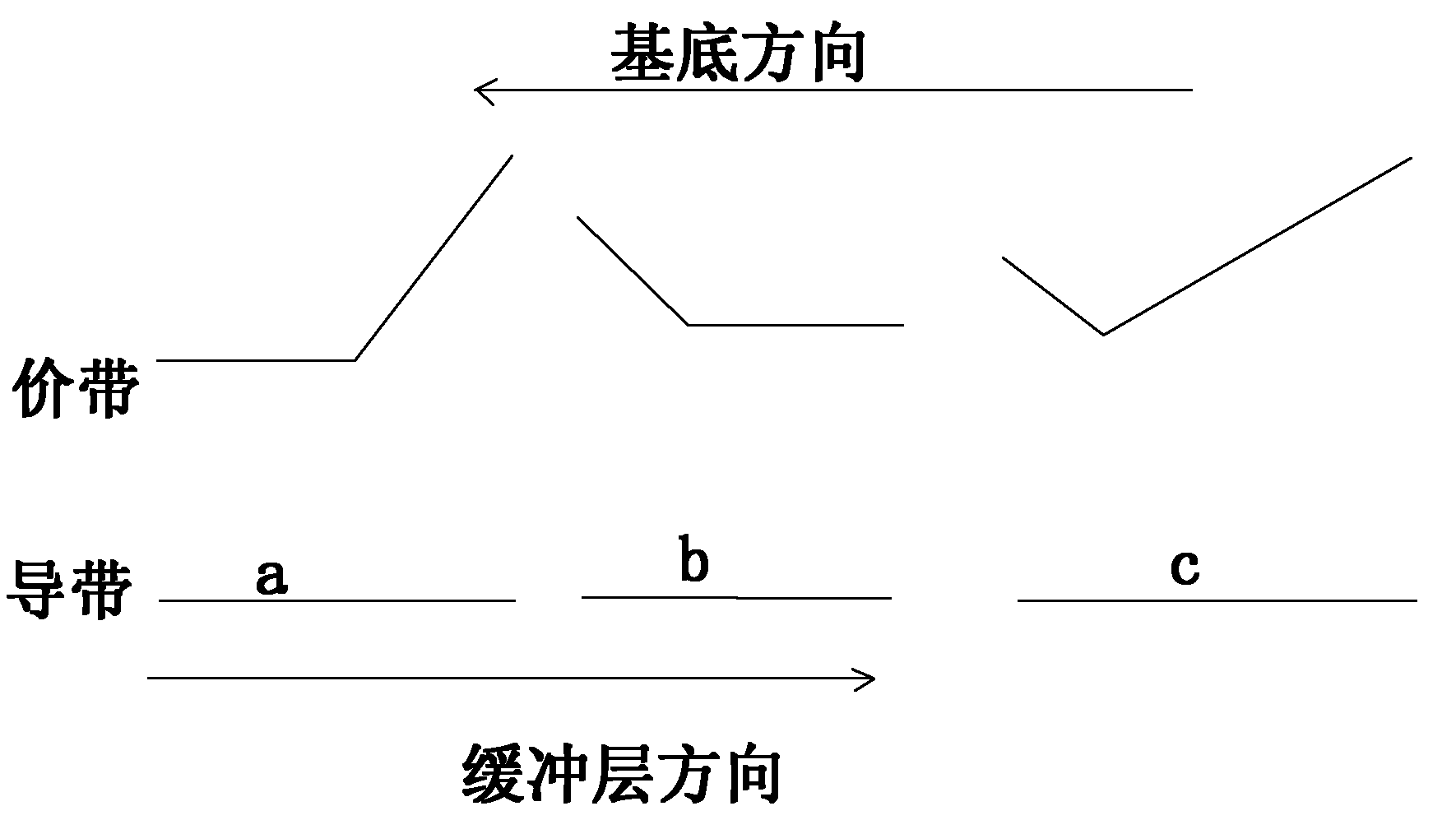

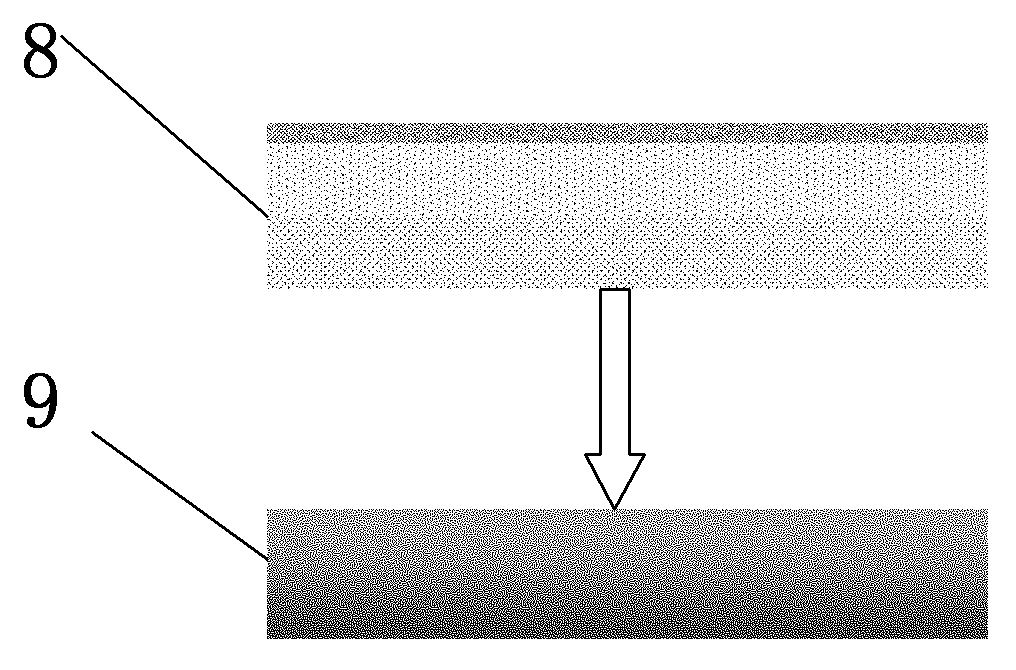

[0023] Preparation method of thin film solar cell absorber layer with gallium indium atomic ratio gradient distribution: using copper indium gallium selenide nanoparticles containing different gallium indium content ratios, using a simple multi-layer jet printing method to prepare thin film solar cell copper indium gallium selenide absorber layer . Specific steps are as follows:

[0024] a. Prepare water-soluble precur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com