Preparation method for iron-coated ceramic composite powder of core-shell structure

A technology of ceramic composite and core-shell structure, which is applied in transportation and packaging, gaseous chemical plating, metal processing equipment, etc., can solve the problems of complex process, easy introduction of impurity salt, and high price, and achieve simple preparation process, The effect of high coating integrity and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

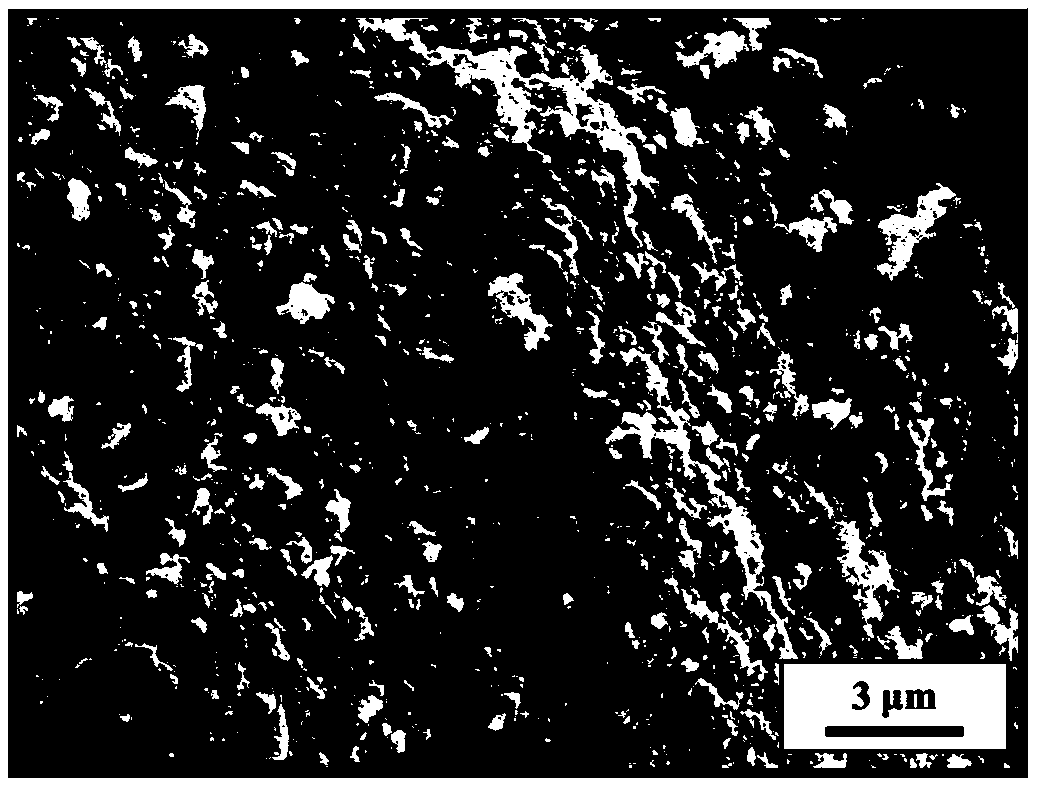

[0042] Titanium carbide particles with a particle size of 50 μm were selected and placed in the designed fluidized bed. The mixed gas of hydrogen and argon with a volume ratio of 2:5 was used as the fluidizing gas, and the gas velocity was 0.07m / s to make the titanium carbide particles In a fluidized state, titanium carbide is mainly fluidized in the reaction section of the fluidized bed. Put the fluidized bed into a vertical tubular heating furnace with a heating temperature of 750°C to heat the titanium carbide particles in a fluidized state. Heating the ferric chloride in the vaporizer at a heating temperature of 300°C, using argon as the carrier gas, the gas flow rate is 0.01m / s, entraining chloride vapor into the fluidized bed reaction zone. The deposition time is 0.5h, and the deposition reaction is carried out in the reaction zone of the fluidized bed. After the reaction was completed, it was cooled to room temperature under the protection of argon to obtain a metal ir...

Embodiment 2

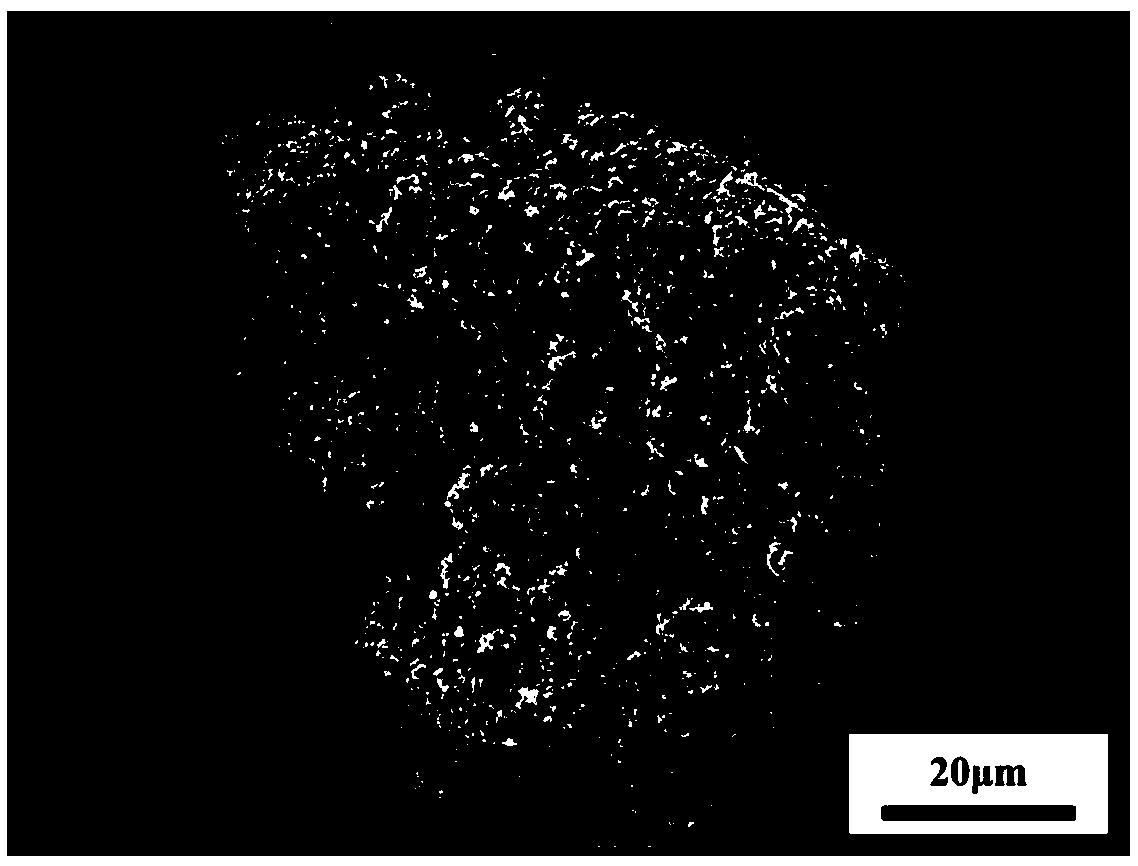

[0045]Select tungsten carbide particles with a particle size of 75 μm, place them in the designed fluidized bed, use the mixed gas of hydrogen and argon with a volume ratio of 3:5 as the fluidizing gas, and the gas velocity is 0.1m / s to make the tungsten carbide particles In a fluidized state, tungsten carbide is mainly fluidized in the reaction section of the fluidized bed. Put the fluidized bed into a vertical tubular heating furnace with a heating temperature of 700°C to heat the tungsten carbide particles in a fluidized state. Heat the ferric chloride in the vaporizer at a heating temperature of 500°C, use argon as the carrier gas, and the gas flow rate is 0.015m / s, entraining chloride vapor into the fluidized bed reaction zone. The deposition time is 1 h, and the deposition reaction is carried out in the reaction zone of the fluidized bed. After the reaction was completed, it was cooled to room temperature under argon protection to obtain a metal iron-coated tungsten car...

Embodiment 3

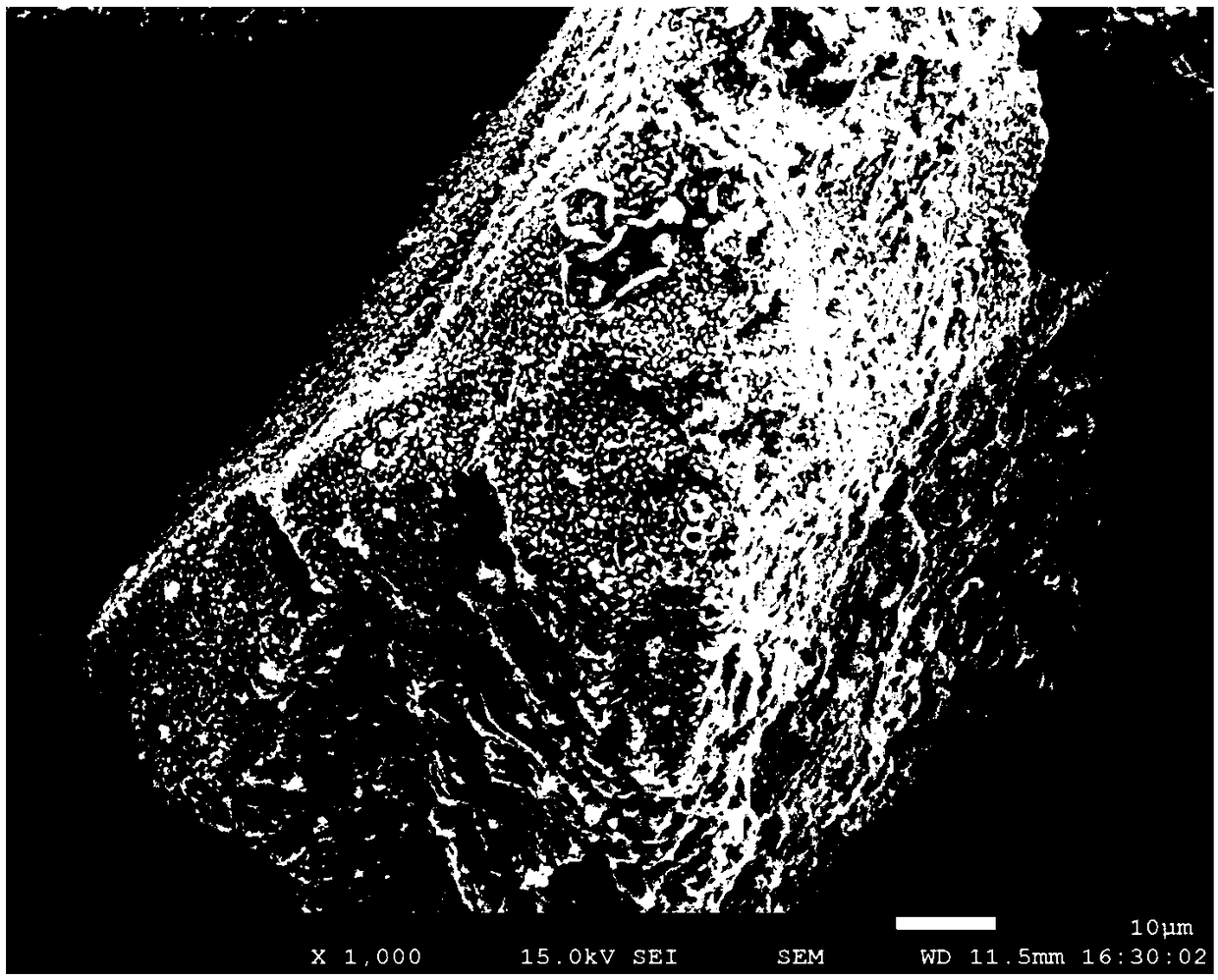

[0048] Alumina particles with a particle size of 100 μm were selected and placed in a designed fluidized bed. The mixed gas of hydrogen and argon with a volume ratio of 0.5:5 was used as the fluidizing gas, and the gas velocity was 0.2m / s to make the alumina particles In a fluidized state, alumina is mainly fluidized in the reaction zone of the fluidized bed. Put the fluidized bed into a vertical tubular heating furnace with a heating temperature of 700°C to heat the alumina particles in a fluidized state. Heat the ferric bromide in the vaporizer at a heating temperature of 550°C, use argon as the carrier gas, and the gas flow rate is 0.015m / s, entraining the bromide vapor into the fluidized bed reaction zone. The deposition time is 10 min, and the deposition reaction is carried out in the reaction section area in the fluidized bed. After the reaction was completed, it was cooled to room temperature under the protection of argon to obtain a metal iron-coated alumina composite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com