Silica sand inkstone and preparation method thereof

A technology of inkstone and silica sand, which is applied in the field of silica sand inkstone and its preparation, can solve the problems of large-scale and modern production, high raw material requirements, and high cost, and achieve the effects of low material cost, simple production process, and short curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

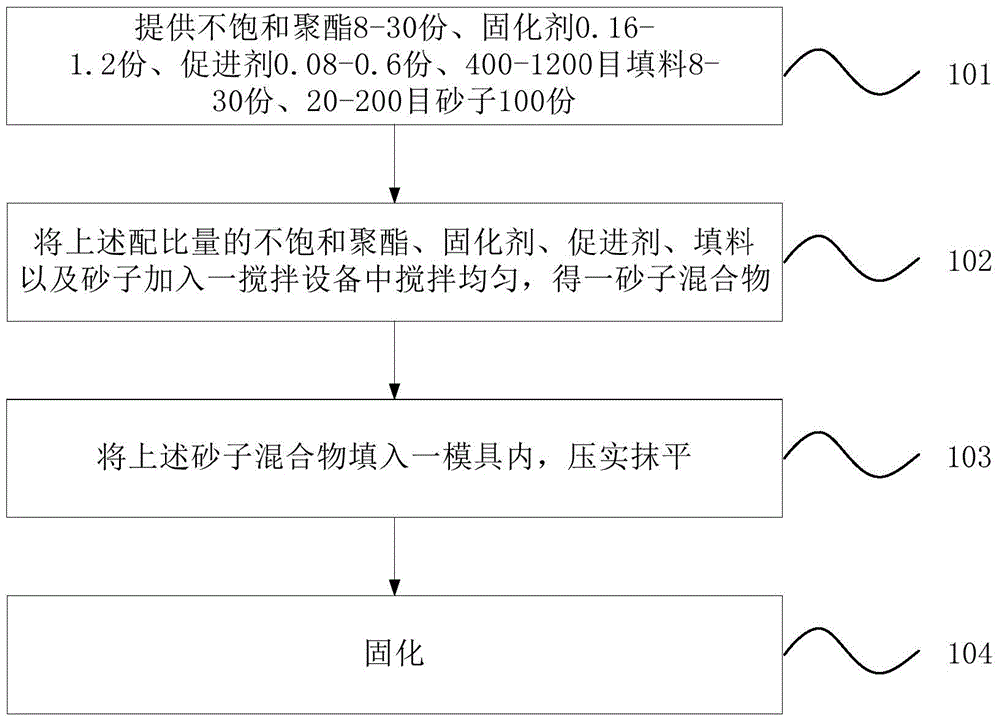

Method used

Image

Examples

Embodiment 1

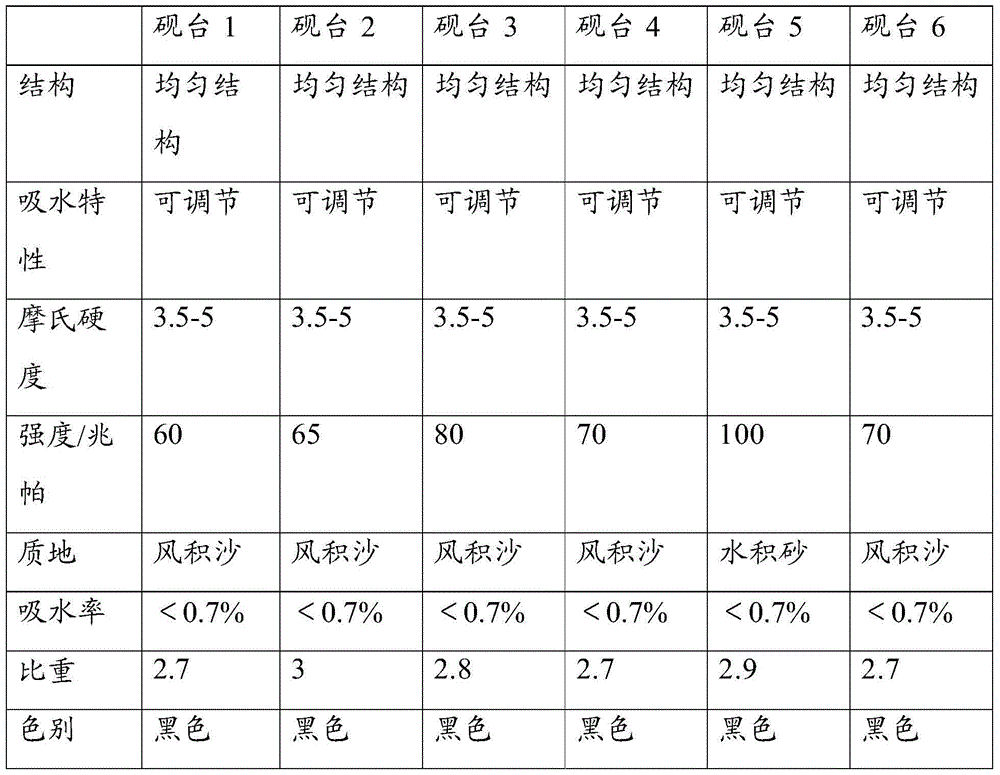

[0040] Embodiment 1. Inkstone 1

[0041] 8 parts of 191 unsaturated polyester, 1.2 parts of curing agent methyl ethyl ketone peroxide, 0.6 parts of accelerator cobalt naphthenate, 30 parts of 400-800 mesh filler fumed silica, 140-200 mesh sand ( Add 100 parts of desert aeolian sand to the cement mortar mixer and stir evenly, the sand used is desert aeolian sand;

[0042] Fill the sand mixture processed through the above steps into an inkstone mold, and compact it evenly, then smooth the surface with a trowel, place it on a flat surface, and cure it at 15°C for 30 minutes to obtain the inkstone 1 of the present invention.

Embodiment 2

[0043] Example 2. Inkstone 2

[0044] 30 parts of 192 unsaturated polyester, 0.16 parts of curing agent benzoyl peroxide, 0.08 parts of accelerator dimethylbenzene, 1000-1200 mesh filler fumed silica, 8 parts of talcum powder, Add 300 parts of 20-70 mesh sand into the cement mortar mixer and stir evenly;

[0045] Fill the sand mixture processed through the above steps into an inkstone mold and compact it evenly, then smooth the surface with a trowel, put it on a flat surface, and cure it at 20°C for 25 minutes to obtain the inkstone 2 of the present invention.

Embodiment 3

[0046] Example 3. Inkstone 3

[0047] 2 parts of 191 unsaturated polyester, 8 parts of 192 unsaturated polyester, 0.2 part of curing agent benzoyl peroxide, 0.08 part of accelerator diethylaniline, 10 parts of 400-600 mesh filler talcum powder in the following proportions by weight 200 parts, 70-140 mesh sand and 200 parts are added to the cement mortar mixer and stirred evenly;

[0048] Fill the sand mixture processed through the above steps into an inkstone mold, and compact it evenly, then smooth the surface with a trowel, place it on a flat surface, and cure it at 25°C for 20 minutes to obtain the inkstone 3 of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com