Large-scale preparation method for stably-doped large-area graphene transparent conductive films

A transparent conductive film and graphene technology, which is applied in the direction of cable/conductor manufacturing, circuits, electrical components, etc., can solve the interaction and high-efficiency doping environment that is not conducive to large-scale graphene large-scale doping processing, limiting electron transfer, etc. Poor stability and other issues, to achieve the effect of promoting electron transfer and interaction, simple and controllable process, and improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

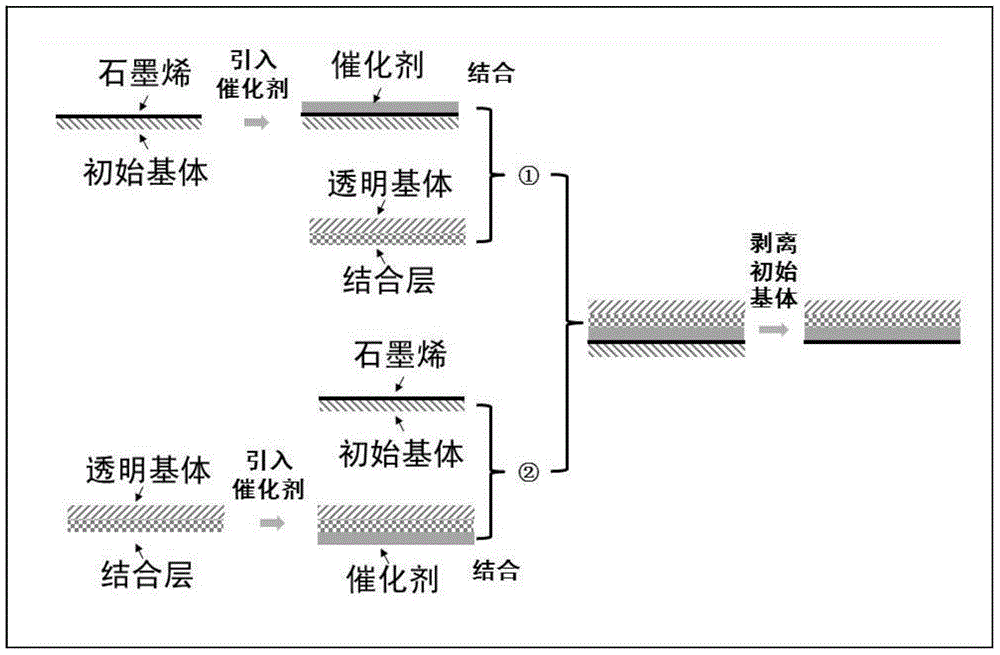

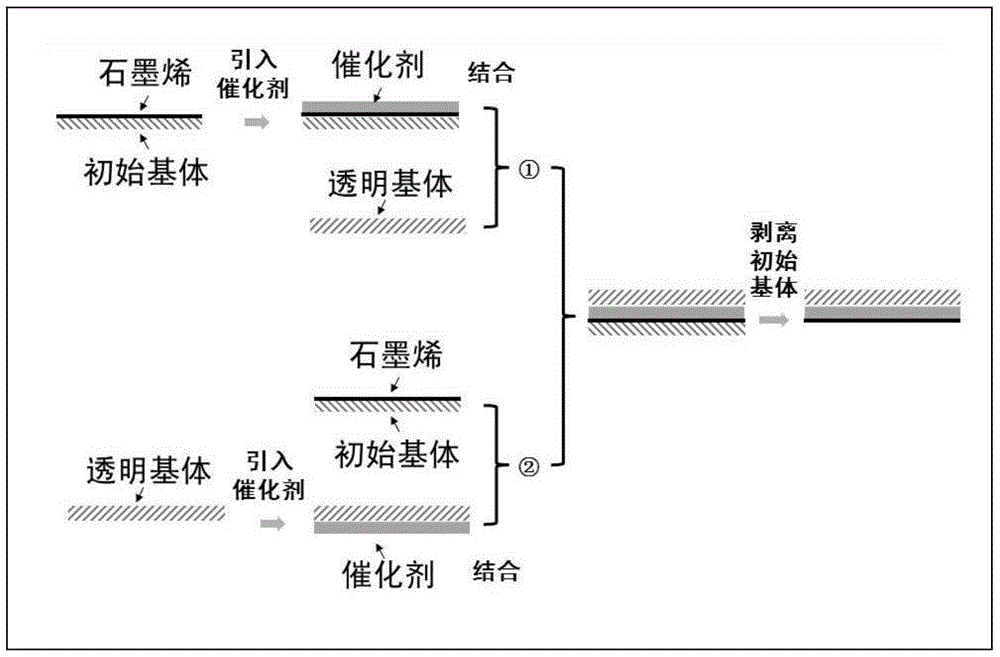

Method used

Image

Examples

Embodiment 1

[0035] Metal copper foil is used as the initial matrix, molybdenum oxide is used as the dopant, polyethylene terephthalate film is used as the target matrix, and the method of thermal compression bonding is adopted. Use CVD method to grow graphene on metal copper foil (in this embodiment, metal copper foil can be replaced with copper sheets or copper plates of different specifications, single crystal or polycrystalline, thickness greater than 10 μm, this embodiment is 25 μm). After the copper foil grown with graphene is cooled, a molybdenum oxide film with a thickness of 3 nm is formed on the surface of the graphene / copper foil by evaporation coating. This thin film was treated in an argon atmosphere at 300° C. for 1 hour. Graphene, molybdenum oxide and polyethylene terephthalate film grown on the copper foil are directly pressed together by the method of roll-to-roll hot roll pressing (or hot plate pressing), and the pressure is less than 2MPa (this embodiment) 1MPa), the ho...

Embodiment 2

[0038] The difference from Example 1 is:

[0039] Electrostatic force is used as binding force. Utilize electrostatic generator to generate electrostatic force (the voltage that produces static electricity is not less than 0.1kV, the present embodiment is 15kV) at " molybdenum oxide / graphene / copper foil " (or on the surface of polyethylene terephthalate film), The "molybdenum oxide / graphene / copper foil" and the polyethylene terephthalate film are pressed together by electrostatic force (pressure less than 1MPa, 0.1MPa in this embodiment) by rolling or plate pressing, A "polyethylene terephthalate / molybdenum oxide / graphene / copper foil" composite material is formed.

[0040] In this embodiment, the electrolyte is 8 mol / L NaOH aqueous solution, the operating temperature of the electrolysis process is 35-40° C., the voltage used in the electrolysis process is 45-50 volts, the current is 7 amperes, and the gas generated by the electrolysis is hydrogen.

[0041] In the present emb...

Embodiment 3

[0043] The difference from Example 1 is:

[0044] Different initial matrix materials are used. In this embodiment, the metal copper foil can be replaced with metals such as nickel, cobalt, molybdenum and alloys thereof (copper-nickel alloy, molybdenum-nickel alloy, gold-nickel alloy, etc.) or a metal film stably combined on a silicon chip, and Titanium carbide, molybdenum carbide, tungsten carbide and other metal carbides, or other semiconductors such as Si) are used as the initial substrate, and single-layer or multi-layer graphene is grown on the surface by different methods.

[0045] In this embodiment, the electrolyte is 3 mol / L NaOH aqueous solution, the operating temperature of the electrolysis process is 20-30°C, the voltage used in the electrolysis process is 10-12 volts, and the current is 4 amperes; the gas generated by the electrolysis is hydrogen.

[0046] In the present embodiment, the performance of the doped graphene transparent conductive film is as follows: t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com