Method for batch green synthesis of nitrogen and phosphorus doped fluorescent carbon dots

A technology of fluorescent carbon dots and green synthesis, which is applied in multi-cross research fields, can solve the problems not related to the cost and yield of preparation of carbon dots, and achieve the effects of reducing synthesis costs, good repeatability, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

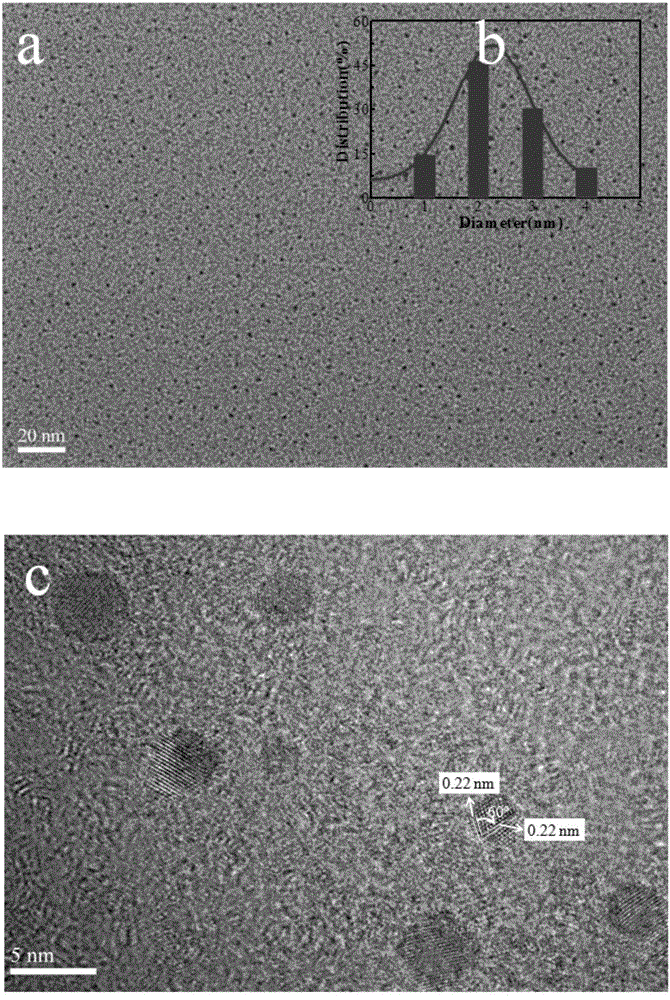

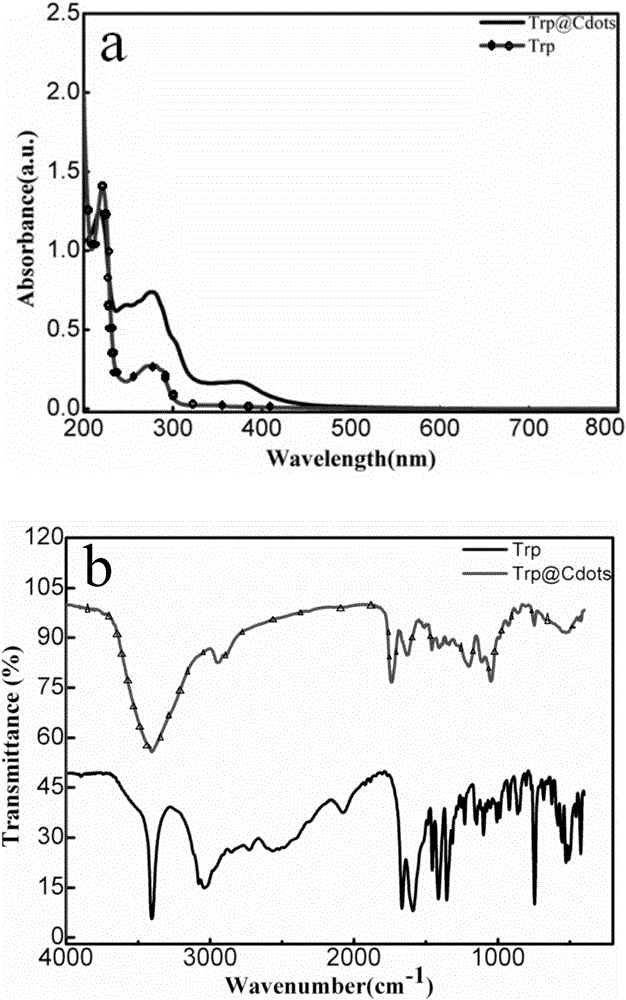

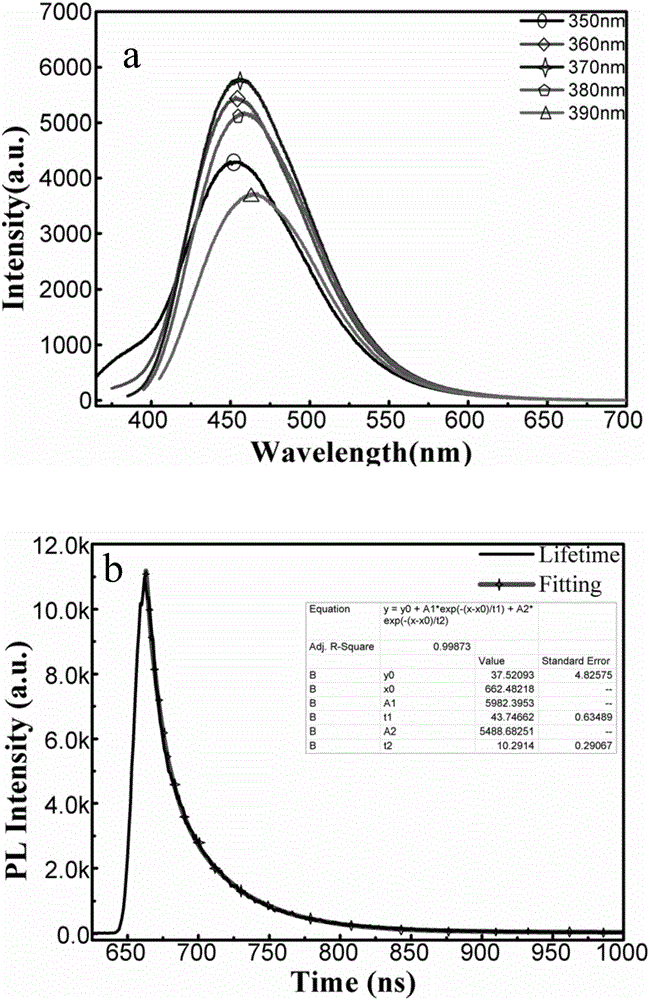

[0047] This embodiment relates to a method for batch synthesis of doped nitrogen and phosphorus fluorescent carbon dots, the method comprising the following steps:

[0048] Using glucose as carbon precursor, tryptophan as nitrogen source and co-combination reagent, phosphoric acid as co-oxidant and P source, react in ethylene glycol medium to prepare fluorescent carbon dots doped with nitrogen and phosphorus, specifically:

[0049] (1) At room temperature, weigh 0.5g of glucose and 0.25g of tryptophan, and dissolve them in a 25mL 15% phosphate glycol round-bottomed flask under magnetic stirring. After the reactants are completely dissolved, heat to reflux for reaction After the temperature was maintained at 160°C for 80 minutes, the concentration of the reaction solution changed from colorless and transparent to a dark brown solution, the reaction was stopped, and cooling was performed for purification and separation.

[0050] (2) centrifuge the mixed solution obtained in step...

Embodiment 2

[0055] Using citric acid as a carbon precursor, glutamic acid as an auxiliary combination reagent, phosphoric acid as an auxiliary oxidant and phosphorus source, react in a glycerol medium to prepare fluorescent carbon dots doped with nitrogen and phosphorus, specifically:

[0056] (1) At room temperature, weigh 0.5g of citric acid and 0.5g of glutamic acid, and dissolve them in a round-bottomed flask with 25mL of 25% phosphoric acid and 25mL of glycerol in advance under magnetic stirring. After the temperature was maintained at 180° C. for 120 minutes, the concentration of the reaction solution turned from colorless and transparent to a dark brown solution, the reaction was stopped, and the reaction was cooled, purified and separated.

[0057] (2) centrifuge the mixed solution obtained in step (1) at 5000r / min, and discard the precipitate.

[0058] (3) For the supernatant in step (2), neutralize the unreacted phosphoric acid solution with sodium hydroxide, add 0.5M NaCl solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com