Flotation method of highly argillaceous alkaline gangue copper oxide ore

A technology of copper oxide ore and mud, which is applied in flotation, solid separation, etc., can solve the problems that the recovery rate of copper flotation cannot be greatly improved, and the effect is not significant, so as to achieve good driving force and demonstration, stable indicators, The effect of efficient recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Properties of high argillaceous alkaline gangue copper oxide ore: raw ore grade ≥ 0.8%, oxidation rate ≥ 88, mud content ≥ 30%, binding rate ≤ 10%.

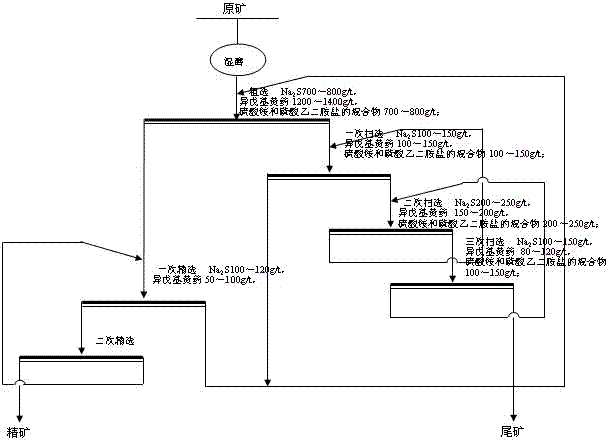

[0020] (1) Wet grind 1 ton of high muddy alkaline gangue copper oxide ore until the ore with a grinding fineness of 74 μm accounts for 85%, adjust the mass concentration of the pulp to 38%, add Na 2 S600g, adding 1400g of isoamyl xanthate, adding 800g of a mixture of ammonium sulfate and ethylenediamine phosphate salt with a mass ratio of 10:1, and roughing for 10 minutes after slurry mixing for 4 minutes;

[0021] (2) Adjust the mass concentration of the remaining pulp after roughing to 30%, and add Na 2 S120g, add isoamyl xanthate 100g, add the mixture 150g of ammonium sulfate and ethylenediamine phosphate salt with a mass ratio of 10:1, carry out a sweep for 10 minutes; the foam product of a sweep returns to the roughing operation;

[0022] The foam product obtained by roughing is adjusted to have a mass concentration ...

Embodiment 2

[0027] Properties of high argillaceous alkaline gangue copper oxide ore: raw ore grade ≥ 0.8%, oxidation rate ≥ 88, mud content ≥ 30%, binding rate ≤ 10%.

[0028] (1) Wet grind 1 ton of high muddy alkaline gangue copper oxide ore until the ore with a grinding fineness of 74 μm accounts for 95%, adjust the mass concentration of the pulp to 30%, add Na 2 S700g, adding 1200g of isoamyl xanthate, adding 700g of a mixture of ammonium sulfate and ethylenediamine phosphate salt with a mass ratio of 10:1, and roughing for 10 minutes after slurry mixing for 4 minutes;

[0029] (2) Adjust the mass concentration of the remaining pulp after roughing to 25%, and add Na 2 S150g, add isoamyl xanthate 120g, add the mixture 100g of ammonium sulfate and ethylenediamine phosphate salt with a mass ratio of 10:1, carry out a sweep for 10 minutes; the foam product of a sweep returns to the roughing operation;

[0030] The mass concentration of the foam product obtained by roughing is adjusted to ...

Embodiment 3

[0035] Properties of high argillaceous alkaline gangue copper oxide ore: raw ore grade ≥ 0.8%, oxidation rate ≥ 88, mud content ≥ 30%, binding rate ≤ 10%.

[0036] (1) Wet grind 1 ton of high muddy alkaline gangue copper oxide ore until the ore with a grinding fineness of 74 μm accounts for 90%, adjust the mass concentration of the pulp to 28%, add Na 2 S800g, adding 1300g of isoamyl xanthate, adding 750g of a mixture of ammonium sulfate and ethylenediamine phosphate salt with a mass ratio of 10:1, performing roughing for 10 minutes after slurry mixing for 4 minutes;

[0037] (2) Adjust the mass concentration of the remaining pulp after roughing to 28%, and add Na 2 S100g, add isoamyl xanthate 150g, add the mixture 120g of ammonium sulfate and ethylenediamine phosphate salt that mass ratio is 10: 1, carry out once sweeping 10 minutes; The foam product of once sweeping returns roughing operation;

[0038] Adjust the mass concentration of the pulp to 15% for the foam product ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com