Cylindricity measuring method and device for separating reference errors of cylindricity instrument

A technology of reference error and measuring device, applied in the direction of measuring device, mechanical counter/curvature measurement, instrument, etc., can solve the problem of inability to separate vertical guide rail straightness error guide rail and rotation axis parallelism error, etc., to achieve easy automatic execution, measurement Simple steps and the effect of satisfying measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The cylindrical shape measuring method and device which can completely separate the reference error of the cylindricity meter in conjunction with the embodiment and the accompanying drawings are described in detail as follows:

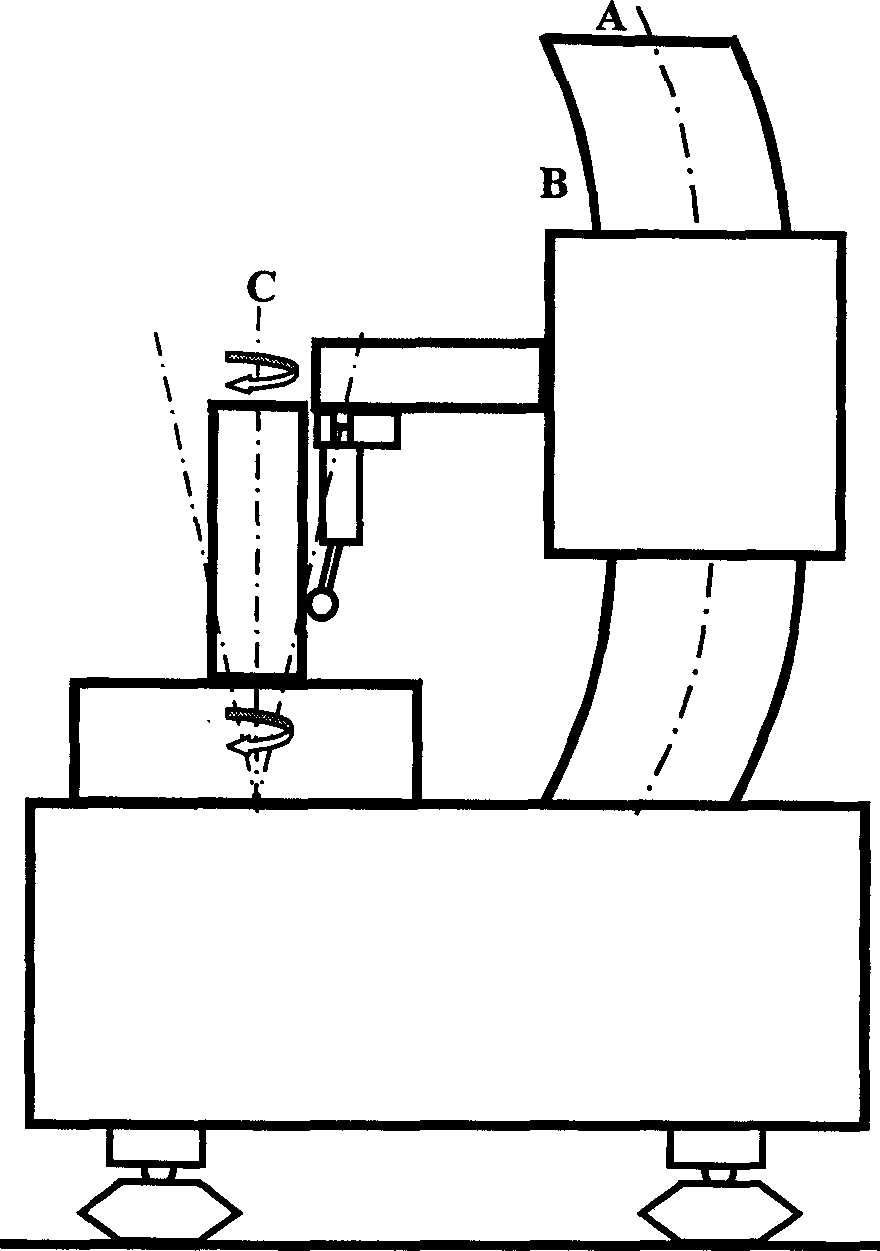

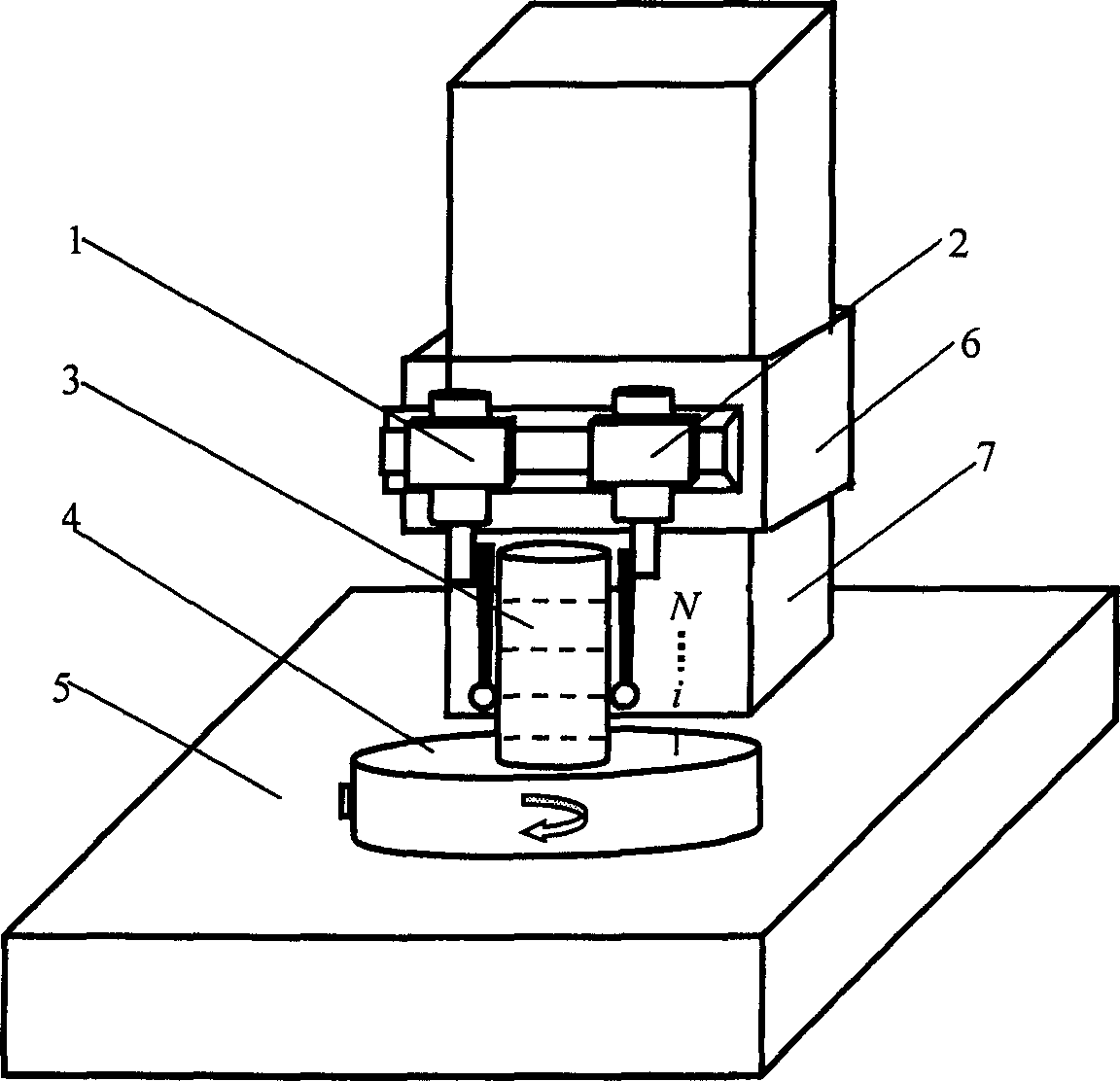

[0031] see Image 6 , Figure 7 , the test piece 3 is installed on the error separation turntable 8, and the error separation turntable 8 is placed on the rotary table 4. During design, the error separation turntable 8 can not only rotate with the rotary table 4, but also drive the test piece 3 to rotate ; The rotary table 4 is installed on the instrument base 5 and connected with the instrument main shaft 9, the instrument main shaft 9 and the bushing 10 form an air-floating rotary shaft system, the design and manufacture should ensure that the rotary table 4 is coaxial with the instrument main shaft 9 ; The sensor 1 and the sensor 2 are installed on the same height of the vertical guide rail system composed of the guide rail air bearing (slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com