Transmission and reversion table for automatic production by extrusion manipulator

A technology of turning table and manipulator, which is applied in metal processing equipment, feeding device, manufacturing tools, etc., to achieve the effect of facilitating automatic operation and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

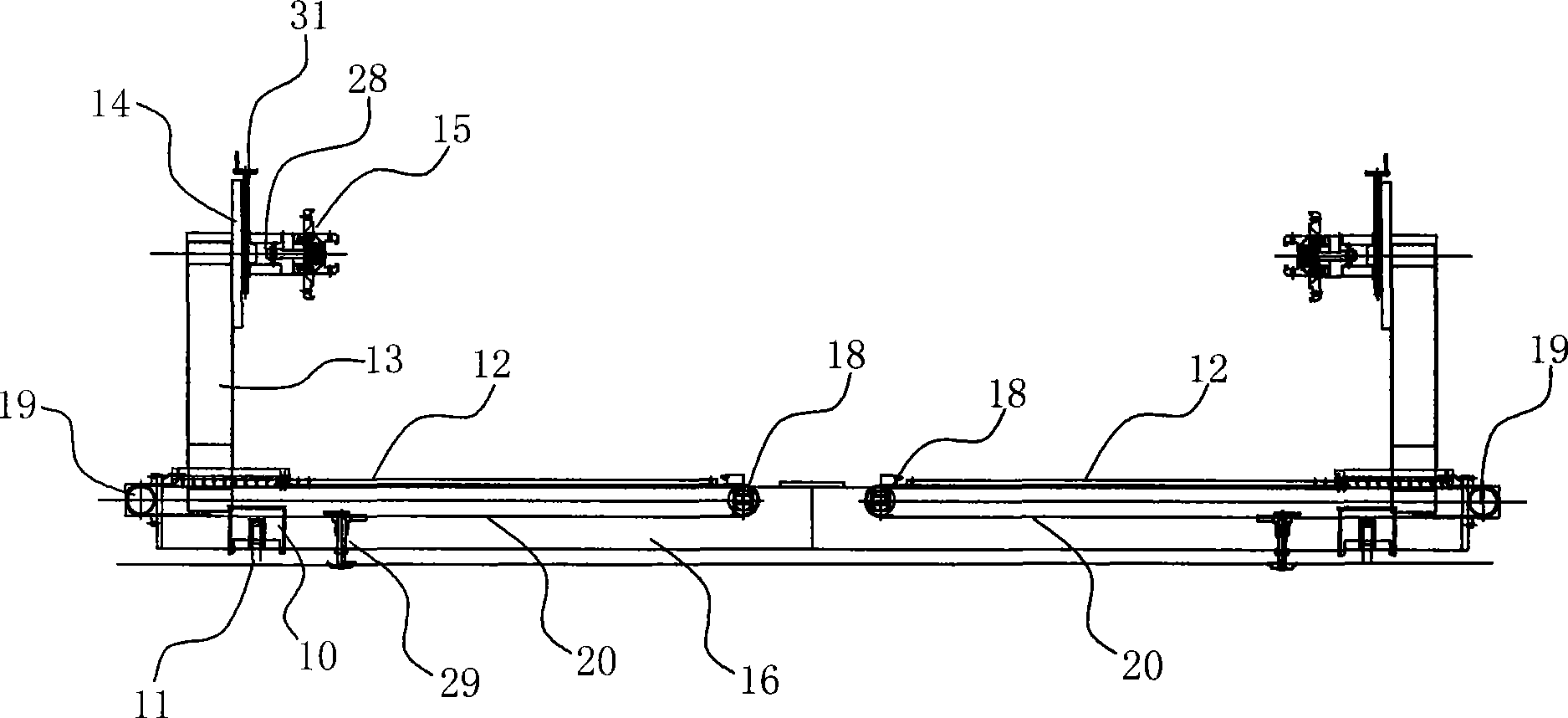

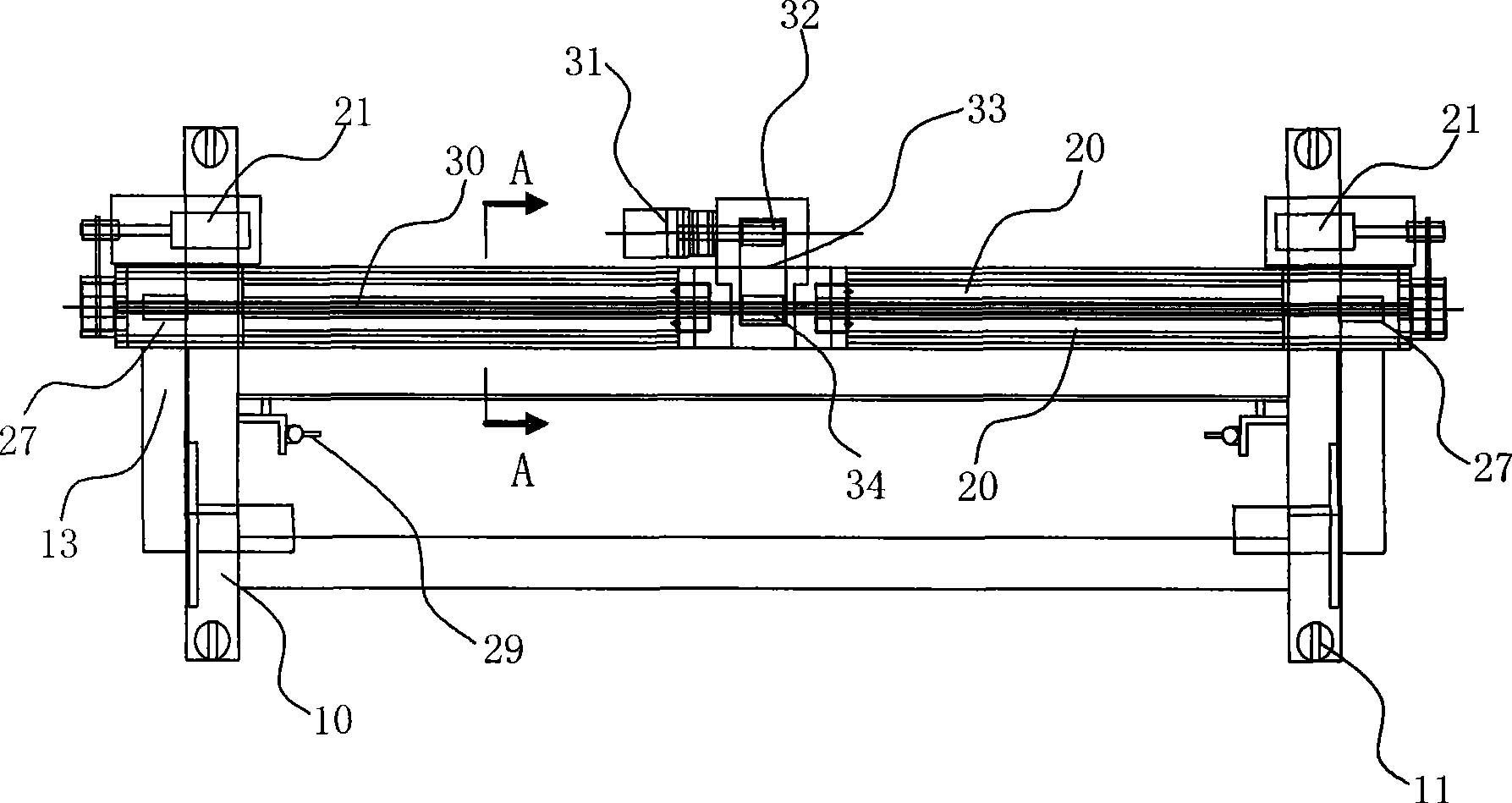

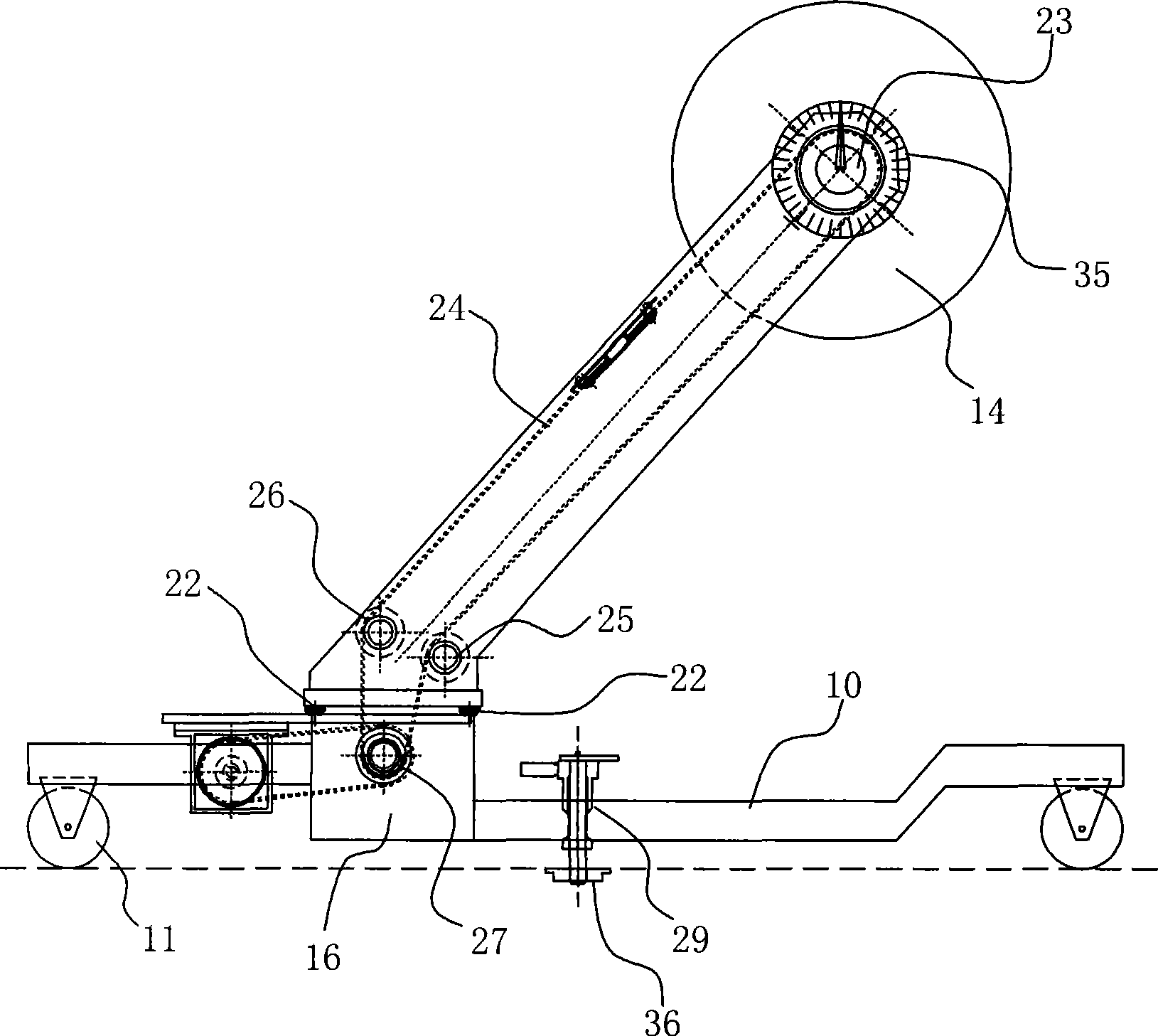

[0010] Such as figure 1 As shown, the transfer turning platform includes a frame base 10 made of profiles, under which the frame base 10 is provided with supporting and walking rollers 11, and on the upper part of the frame base 10 is provided with a guide rail 12 arranged horizontally, on which guide rails 12 are provided with A side-shifting frame 13 that moves in a limited direction. The side-shifting frame 13 is provided with an overturning frame 14 that rotates relative to the horizontal plane. The overturning frame 14 is provided with a workpiece clamping device 15, which is controlled by a cylinder. Putting action and can install different fixtures on it, its end is connected with the turning frame 14 on the side shifting frame 13, and a cylinder 28 is arranged between the clamping device 15 and the turning frame 14, and the cylinder of the cylinder 28 The body and the piston rod are connected with the flip frame 14 and the holding device 15 respectively.

[0011] comb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com