A kind of graphene/tetrapin zinc oxide whisker composite wave-absorbing material and its preparation method

A composite wave-absorbing material and zinc oxide whisker technology, which is applied in chemical instruments and methods, and other chemical processes, can solve the problems of small electromagnetic wave absorption peak, increase the density of wave-absorbing materials, and complicate the preparation process, and achieve wave-absorbing The effect of wide frequency band, reduced density, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

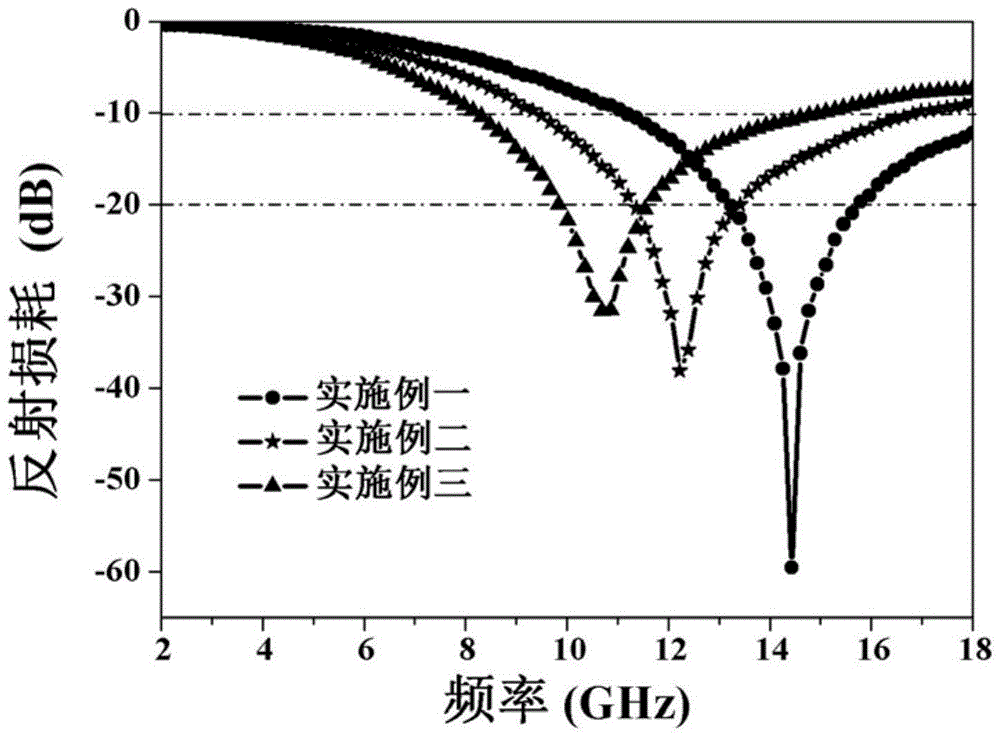

Embodiment 1

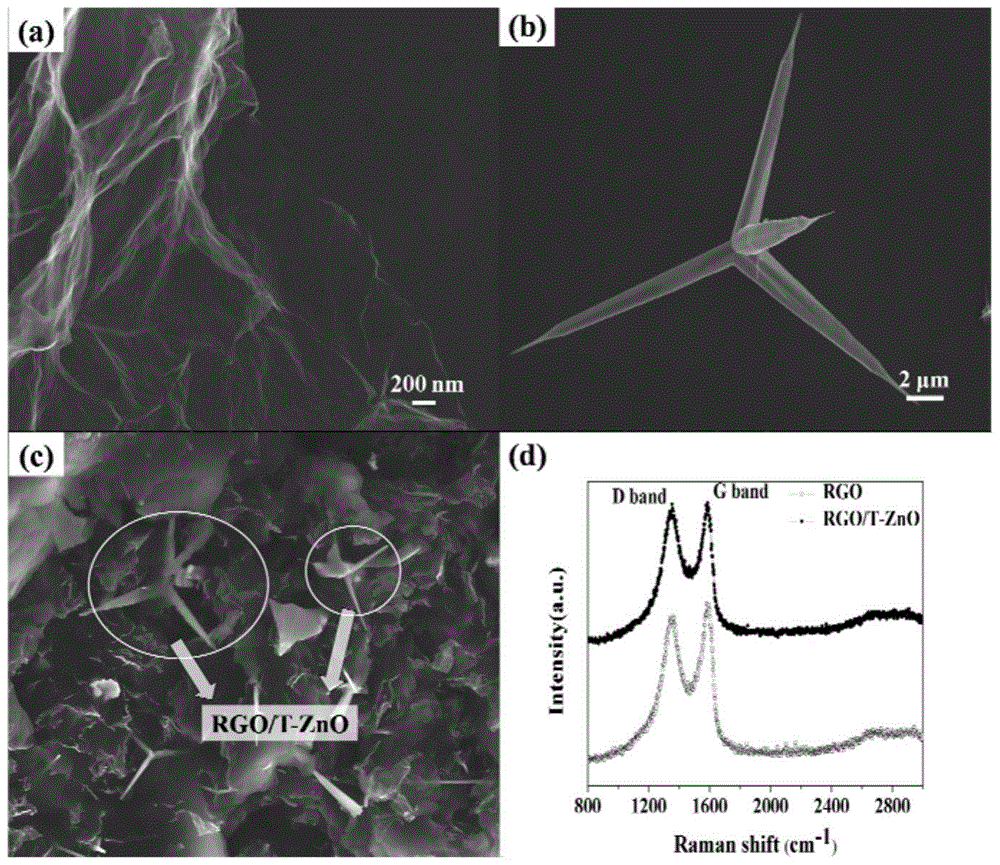

[0023] (1) take natural flake graphite as raw material, adopt Hummers method to prepare graphite oxide, then reduce graphite oxide to obtain reduced graphene oxide;

[0024] (2) Disperse the reduced graphene oxide in an alcohol solution, and ultrasonically treat it for 4 hours to obtain a dispersion of reduced graphene oxide with a concentration of 0.5 mg / ml, and then add four needle-shaped zinc oxide whiskers to the dispersion to ensure graphene The mass fraction of ZnO is 5%, and the mass fraction of four-needle zinc oxide whiskers is 10%. Then carry out magnetic stirring for 30min, control the rotation speed to be 500rpm / min, and the temperature to be 30℃;

[0025] (3) Put the mixed solution in an oven to dry, keep the temperature at 80°C for 6h, and ensure that the whole drying process is gently stirred until dry, and the obtained powder is graphene / four-needle zinc oxide whisker with strong absorption and wide frequency band. composite absorbing material;

[0026] (4) T...

Embodiment 2

[0028] (1) take natural flake graphite as raw material, adopt Hummers method to prepare graphite oxide, then reduce graphite oxide to obtain reduced graphene oxide;

[0029] (2) Disperse the reduced graphene oxide in an alcohol solution, and ultrasonically treat it for 4 hours to obtain a dispersion of reduced graphene oxide with a concentration of 0.5 mg / ml, and then add four needle-shaped zinc oxide whiskers to the dispersion to ensure graphene The mass fraction of ZnO is 5%, and the mass fraction of four-needle zinc oxide whiskers is 10%. Then carry out magnetic stirring for 30min, control the rotation speed to be 500rpm / min, and the temperature to be 30℃;

[0030] (3) Put the mixed solution in an oven to dry, keep the temperature at 80°C for 6h, and ensure that the whole drying process is gently stirred until dry, and the obtained powder is graphene / four-needle zinc oxide whisker with strong absorption and wide frequency band. composite absorbing material;

[0031](4) Th...

Embodiment 3

[0033] (1) take natural flake graphite as raw material, adopt Hummers method to prepare graphite oxide, then by reducing graphite oxide, obtain reduced graphene oxide;

[0034] (2) Disperse the reduced graphene oxide in an alcohol solution, and ultrasonically treat it for 4 hours to obtain a dispersion of reduced graphene oxide with a concentration of 0.5 mg / ml, and then add four needle-shaped zinc oxide whiskers to the dispersion to ensure the graphene The mass fraction is 5%, the mass fraction of the four-needle zinc oxide whiskers is 10%, and the others are adhesives. Then magnetic stirring was performed for 30min, the control speed was 500rpm / min, and the temperature was 30℃;

[0035] (3) Dry the mixed solution in an oven, keep the temperature at 80°C for 6 hours, and ensure that the whole drying process is gently stirred until dry, and the obtained powder is graphene / four-needle zinc oxide whisker with strong absorption and wide frequency band. composite absorbing materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com