Patents

Literature

393 results about "Mercaptobenzimidazol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

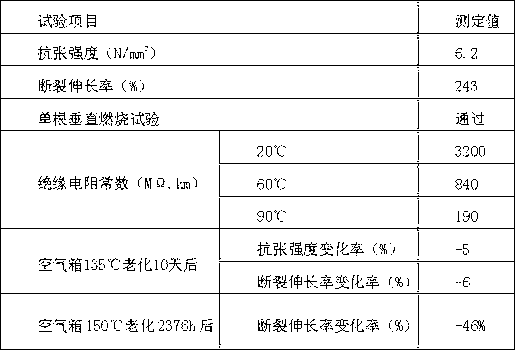

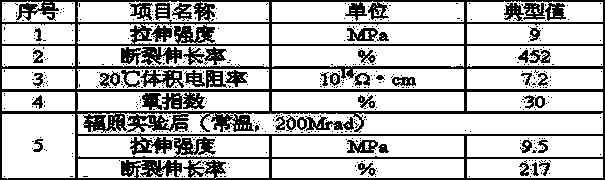

Radiation-resistant halogen-free low smoke flame retardant insulating material for cables of nuclear power plants and preparation method

ActiveCN101531789AImprove radiation resistanceThe ratio is scientific and reasonableRubber insulatorsSilanesNuclear power

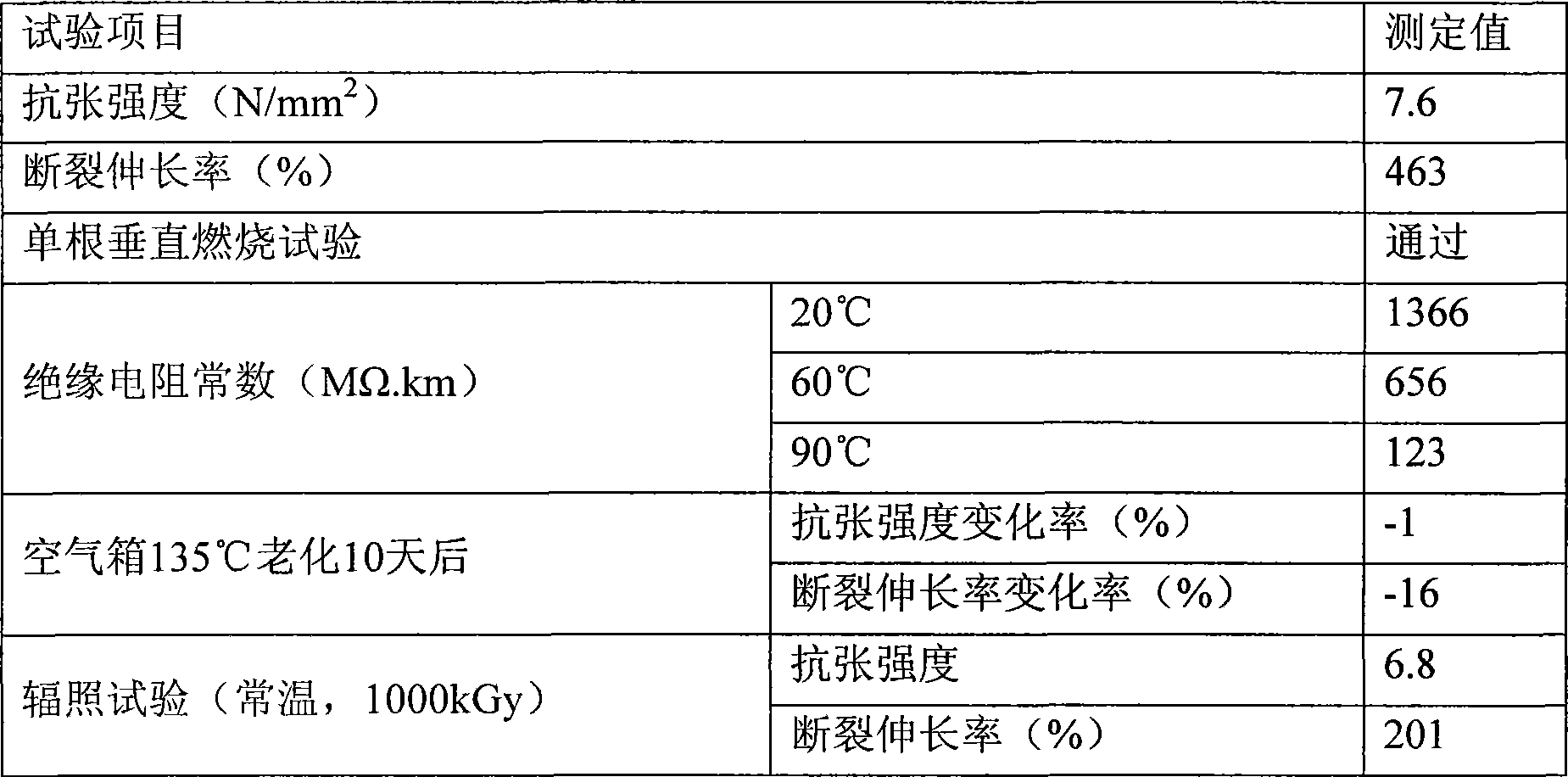

The invention discloses a radiation-resistant halogen-free low smoke flame retardant insulating material for cables of nuclear power plants and a preparation method. The radiation-resistant halogen-free low smoke flame retardant insulating material is prepared from the following raw materials: ethylene propylene diene rubber, phenyl siloxane rubber, magnesium hydrate, aluminium hydroxide, zinc borate, white carbon black, cerium dioxide, zinc oxide, Bis(tert-butyldioxyisopropyl)benzene, tri allyl cyanurate, 2-mercaptobenzimidazole, 2,2,4-trimethyl-1,2-dihydroquinoline, Aflux A-25, stearic acid, vinyl tris(beta-methoxyethoxy) silane, and paraffin oil by heating and mixing. The formulation and the mixture ratio are scientific and reasonable, and the process is advanced. The prepared insulating material has good radiation resistance, excellent mechanical property, good electrical property and long service life, and is a good radiation-resistant halogen-free low smoke flame retardant insulating material for manufacturing the cables of the nuclear power plants.

Owner:BAOSHENG SCI & TECH INNOVATION

Electroless copper plating solution

InactiveCN102051607ABright appearanceLow impurity contentLiquid/solution decomposition chemical coatingCopper platingPolyethylene glycol

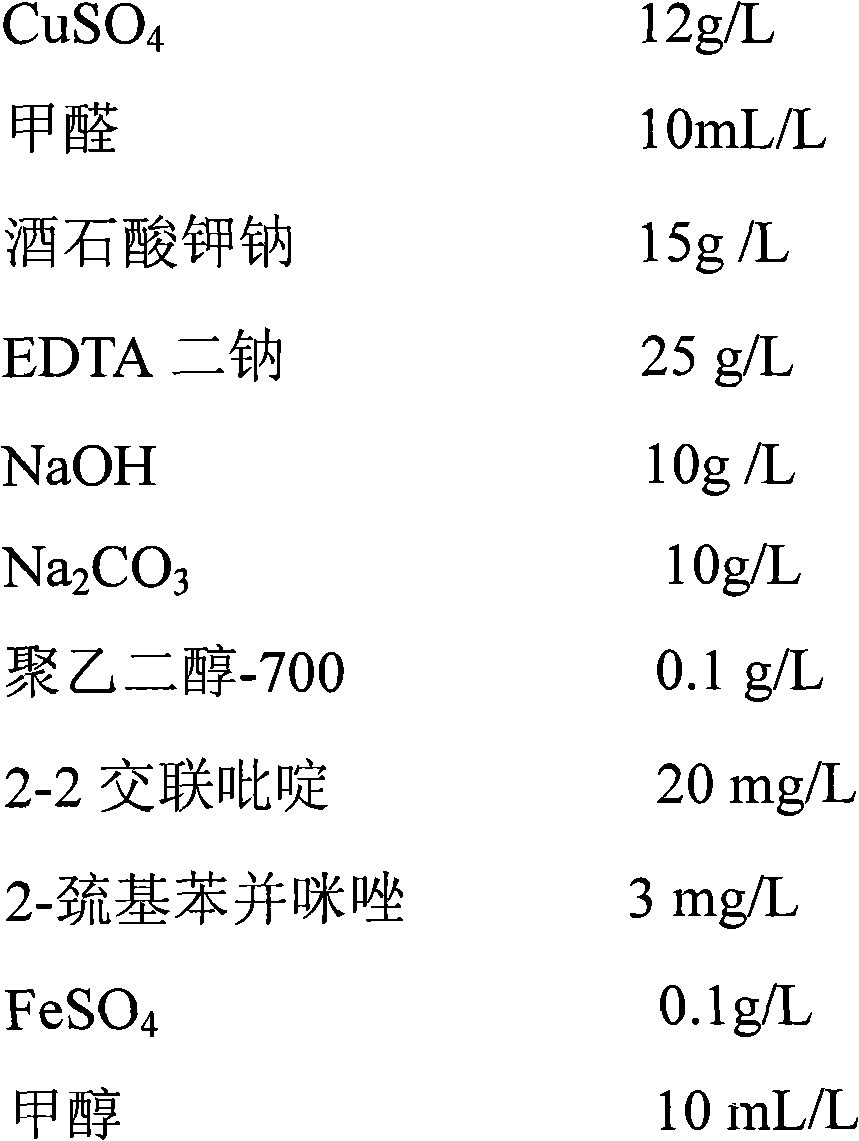

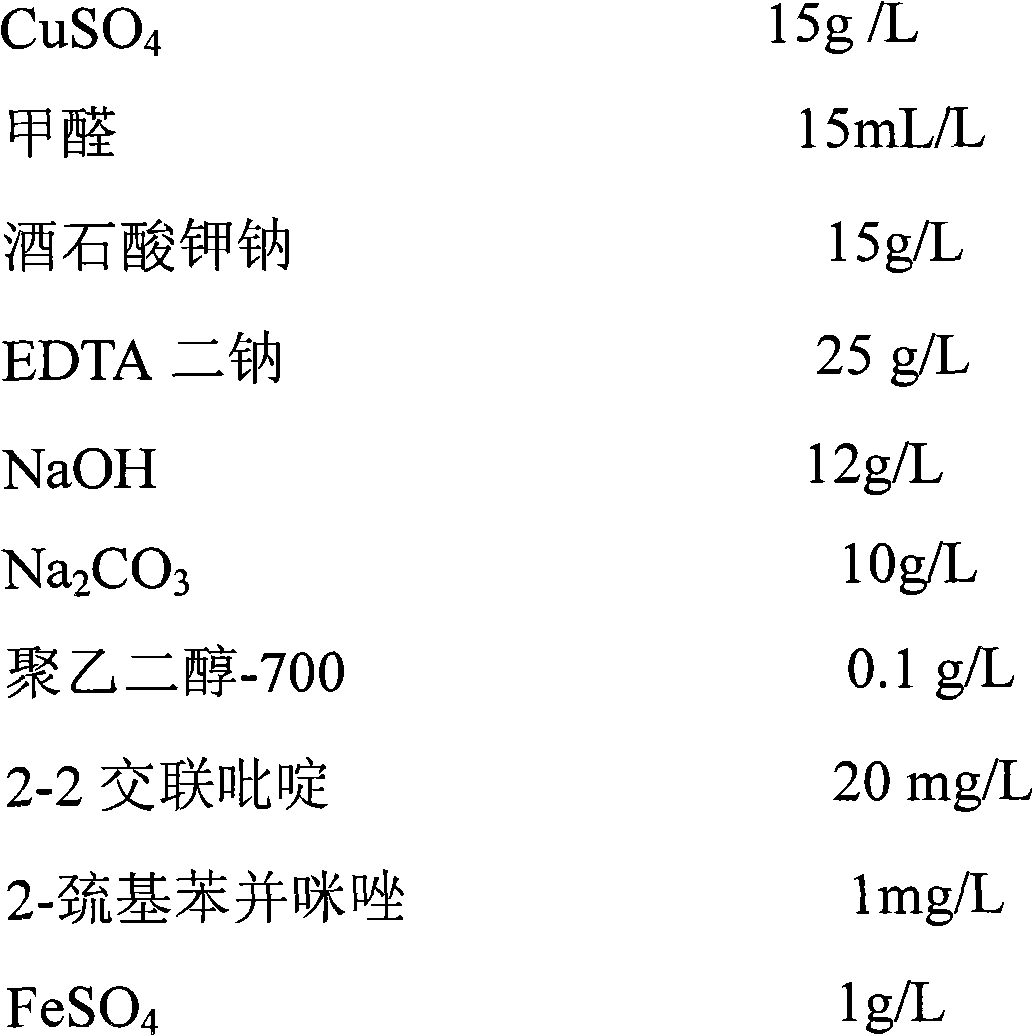

The invention belongs to the field of electroless copper plating, in particular to electroless copper plating solution. The electroless copper plating solution comprises the following components in concentration: 5 to 20 grams per liter of copper salt, 5 to 15 milliliters per liter of formaldehyde, 25 to 65 grams per liter of complexing agent, 8 to 20 grams per liter of pH regulator, 5 to 20 grams per liter of pH buffer, 0.05 to 1 gram per liter of polyethylene glycol, 10 to 60 milligrams of 2-2 cross-linked pyridinoline, 1 to 20 milligrams per liter of 2-mercapto benzimidazole, 0.05 to 1 gram per liter of ferrite and 5 to 50 milliliters per liter of methanol. The electroless copper plating solution provided by the invention is used in an electroless copper plating process for directly metalizing a circuit board, and the formed plating has a bright appearance color and a low impurity content. The thickness of the plating is improved greatly to over 20 micrometers. The electroless copper plating solution can accelerate plating speed to over 10 micrometers per hour.

Owner:深圳市新合富力科技有限公司

Aging-resistant and low-temperature-resistant EPDM (ethylene-propylene-diene monomer) rubber cable material

InactiveCN104610663AHigh strengthGood air aging resistanceRubber insulatorsPlastic/resin/waxes insulatorsCalcium silicateElastomer

The invention discloses an aging-resistant and low-temperature-resistant EPDM (ethylene-propylene-diene monomer) rubber cable material. The material comprises raw materials as follows: EPDM rubber, natural rubber, an ethylene-butene elastomer, superfine talc powder, nano calcium carbonate, modified superfine desulfurization ash, active calcium silicate, zinc methacrylate modified nano silicon nitride, pre-dispersed hollow phenolic microspheres, reinforcing fibers, zinc oxide, stearic acid, dicumyl peroxide, sulfur, N,N'-meta phenylene bismaleimide, diphenylmethane bismaleimide, DIPDIS, coumarone-indene resin, APP (ammonium polyphosphate), ADP, an MPE (metallocene polyethylene) elastomer, N-(4-anilino phenyl maleimide and 2-mercapto benzimidazole. The aging-resistant and low-temperature-resistant EPDM rubber cable material is high in strength, good in aging resistance and low-temperature resistance, excellent in insulating property and flame retardation and long in service life.

Owner:无为县华祥电缆材料有限公司

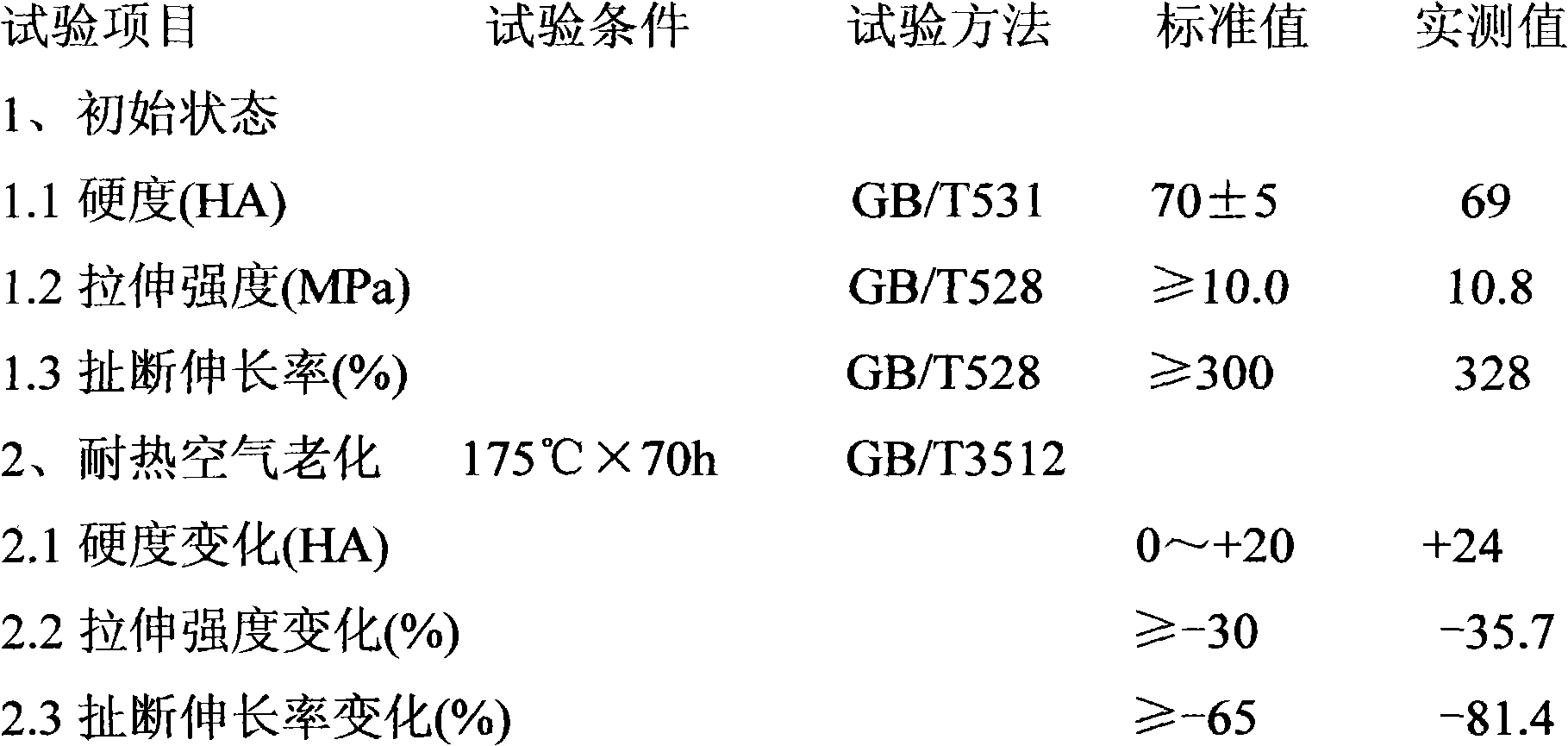

Preparation method of heat/ozone/compressive deformation resistant rubber material for automobile sealing element

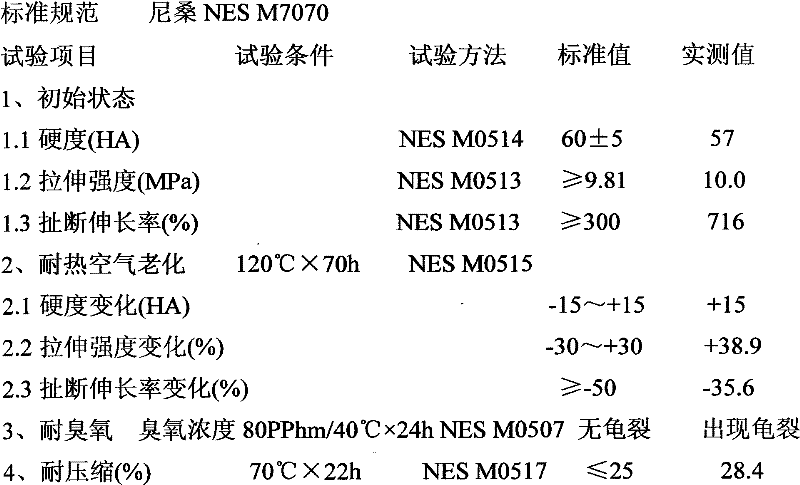

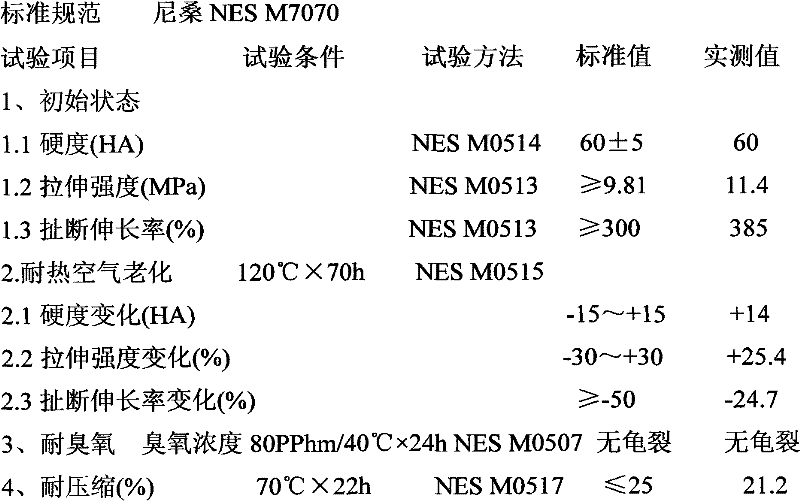

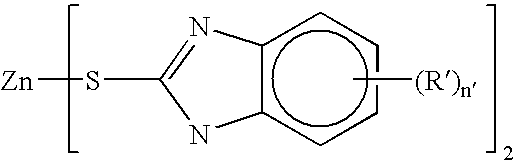

The invention discloses a preparation method of a heat / ozone / compressive deformation resistant rubber material for an automobile sealing element, and the method comprises a formula and a preparation process. In the invention, nitrile rubber / polyvinyl chloride resin and rubber are adopted; in the formula, a vulcanizing system of dicumyl peroxide and N,N'-m-phenylene dimaleimide is adopted, the anti-aging agents of 2,2,4-trimethyl-1,2-dihyaroquinoline polymer and 2-mercaptobenzimidazole are added, the anti-aging agent of N-isopropyl-N'-phenyl-p-phenylenediamine and a paraffin lubricating agent with ozone resistance are added, and the technical scheme of the corresponding preparation process is provided, thus the problems and defects of low temperature / ozone / permanent compressive deformation resistances in the prior art are overcome, and through the heat / ozone / compressive deformation resistant rubber material prepared by the method, the manufactured rubber article of an automobile oil tank pumping hole sealing element achieves the purpose of improving the heat / ozone / compressive deformation resistances to conform to the Nissan NES M707 standard.

Owner:宁波市天普橡胶科技股份有限公司

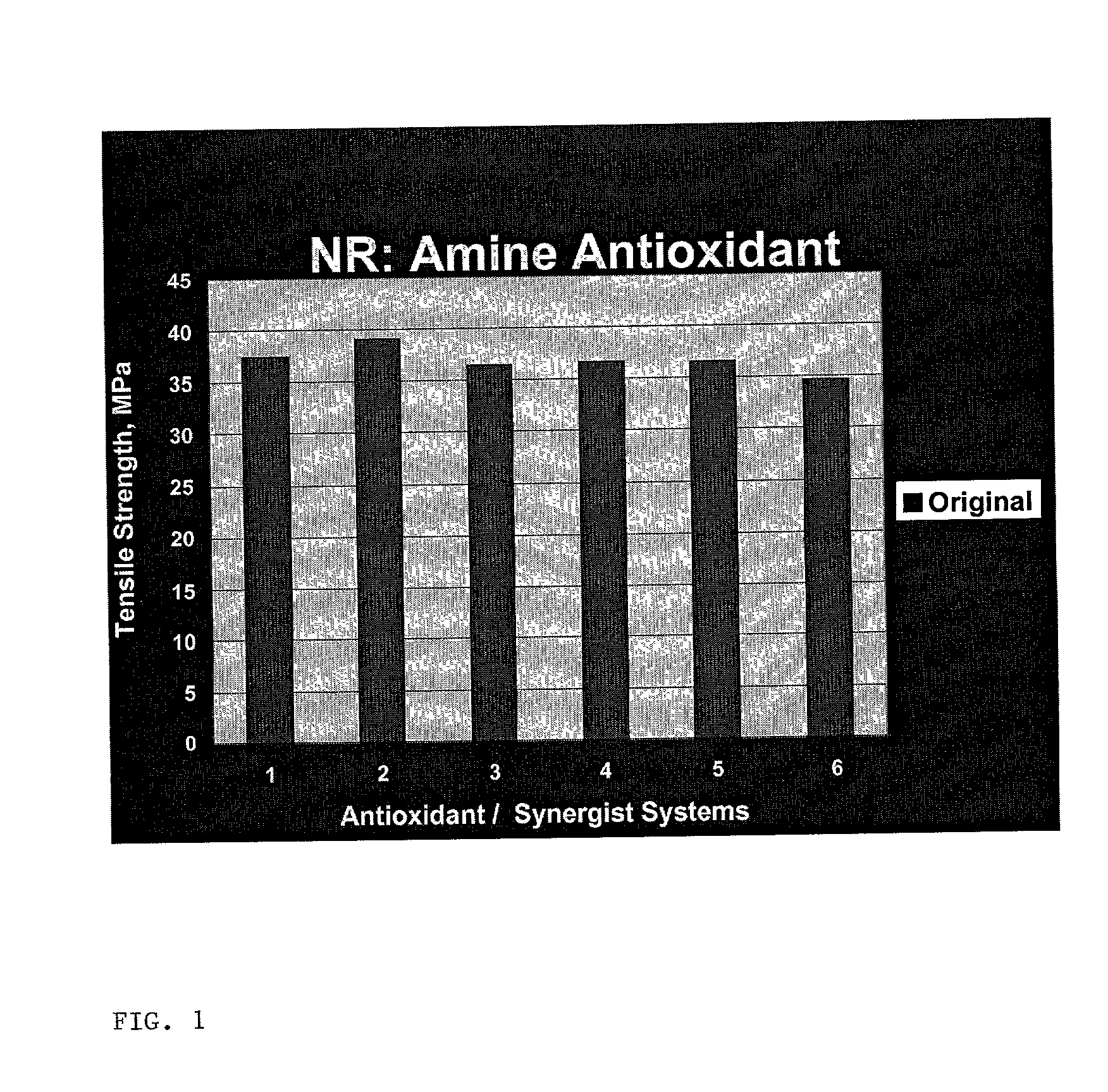

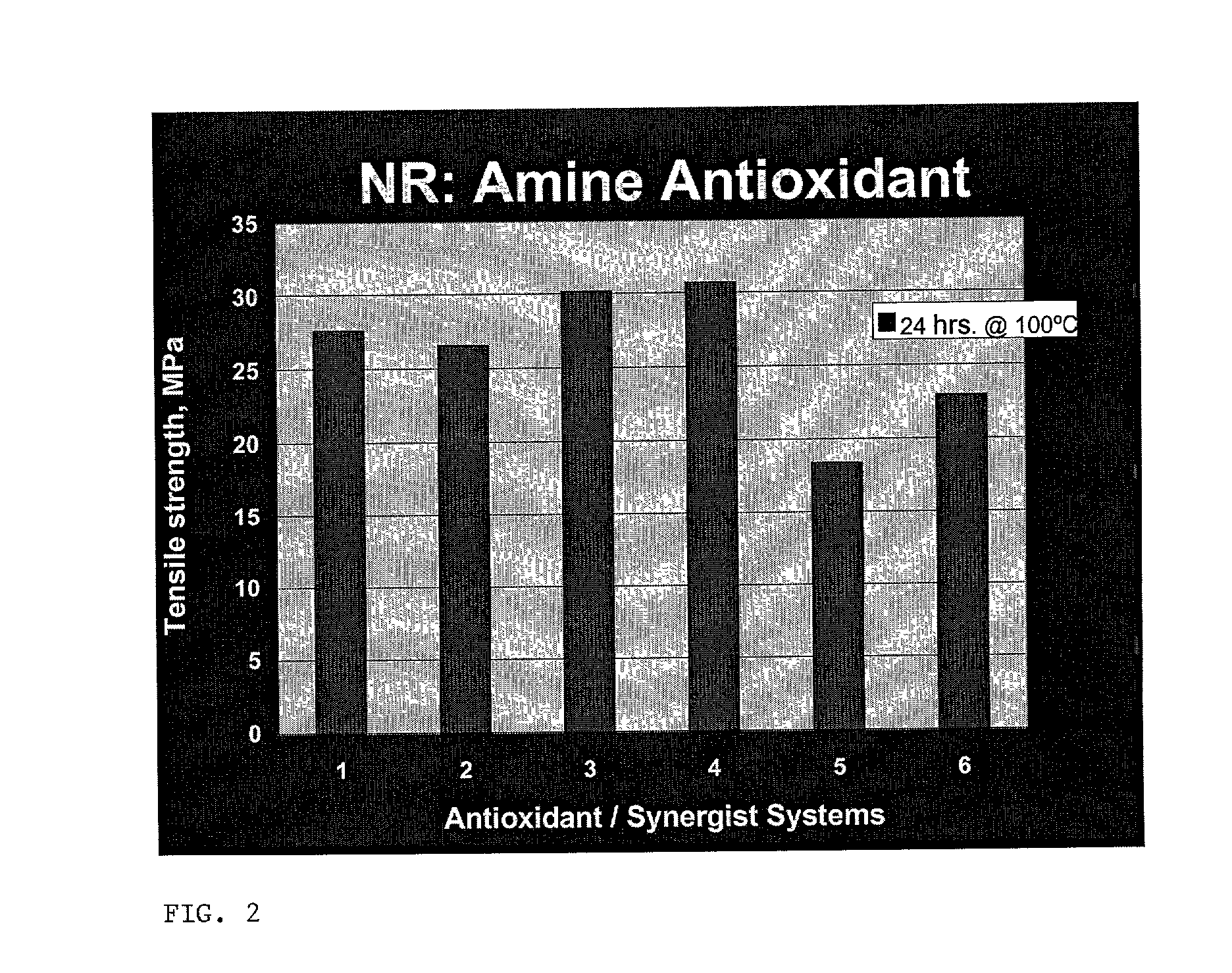

Latex film compound with improved tear resistance

InactiveUS7048977B2Increase elasticityIncrease resistanceClosuresClosure using stoppers2-mercaptobenzimidazoleAntioxidant

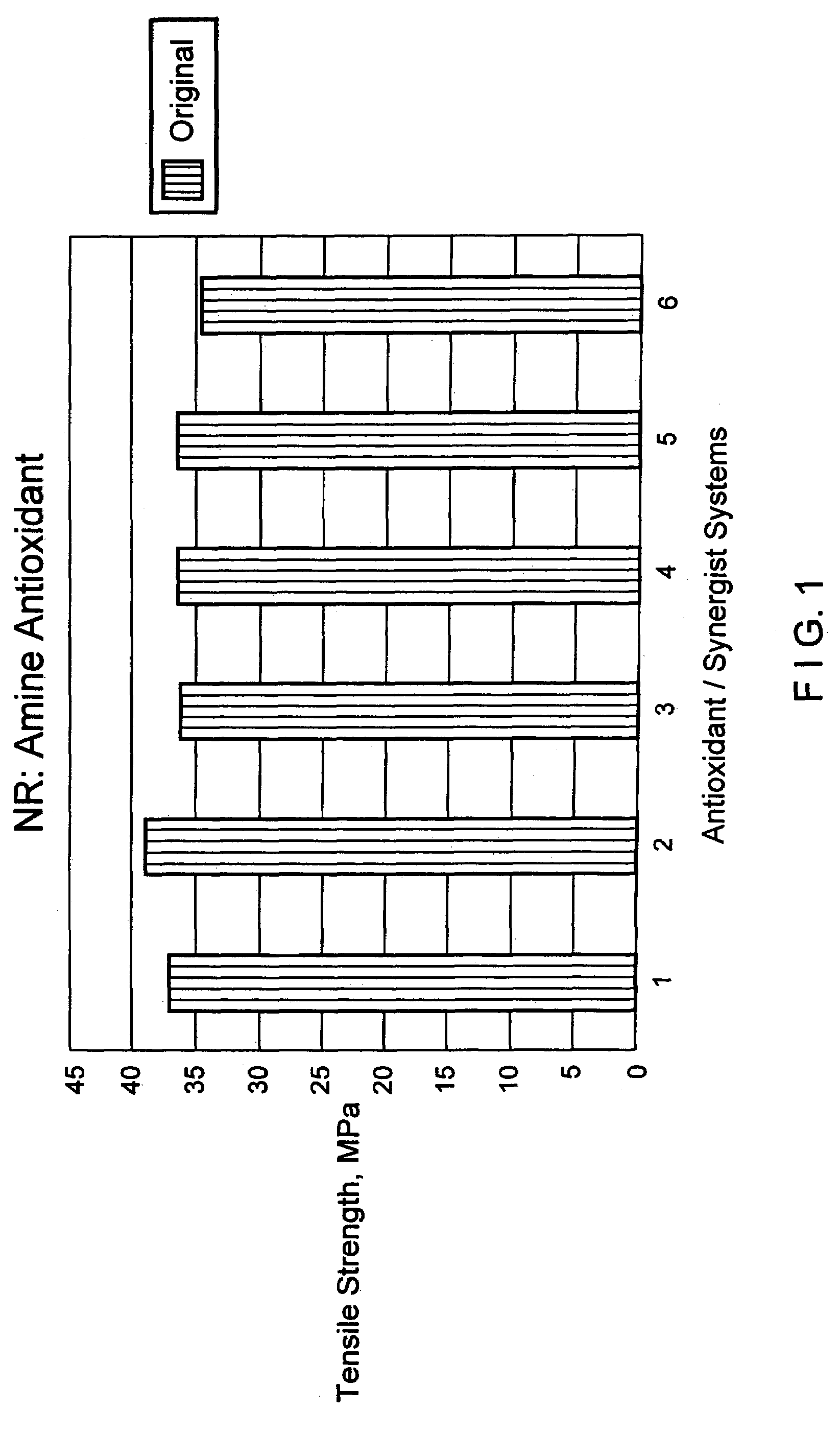

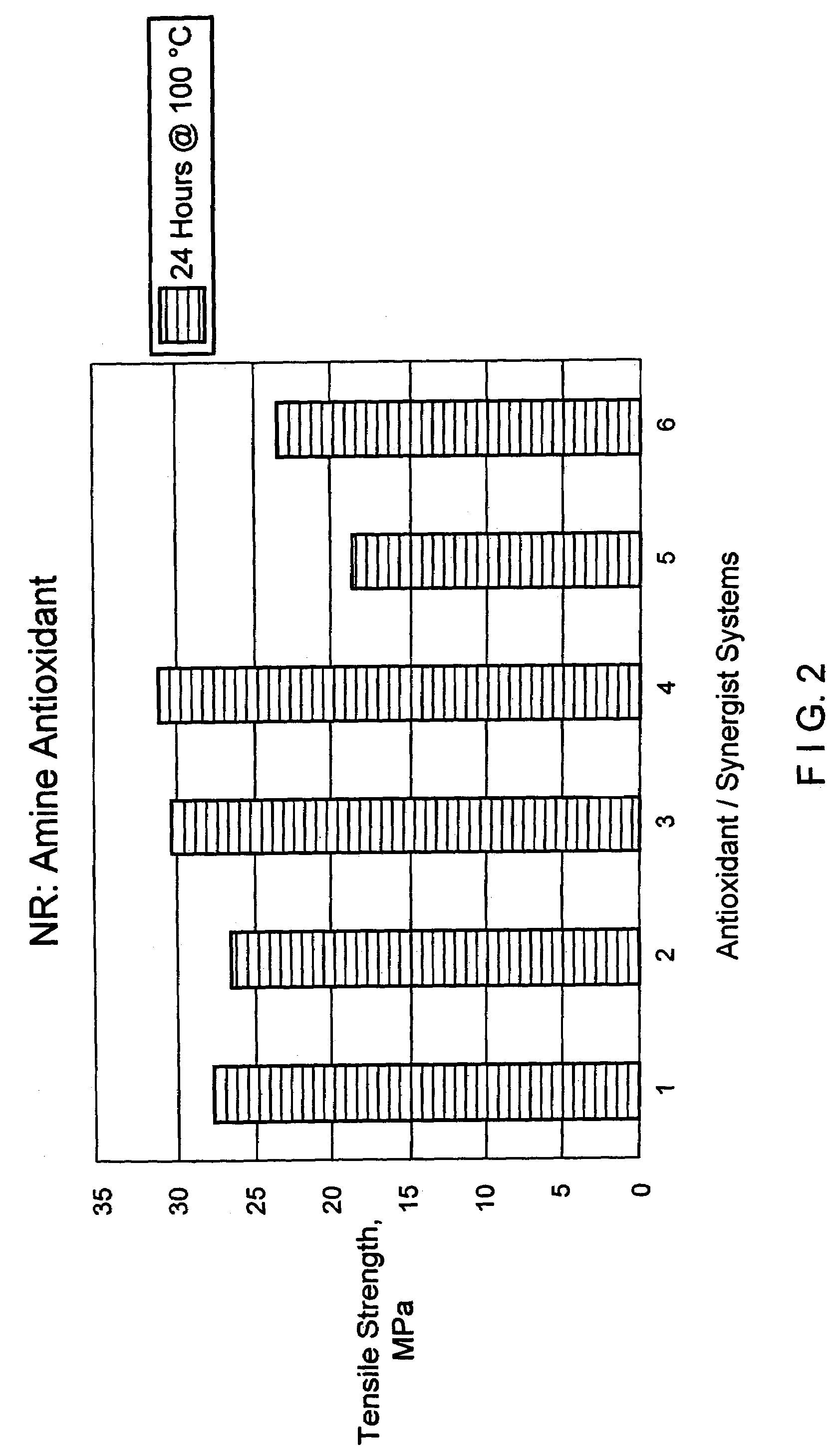

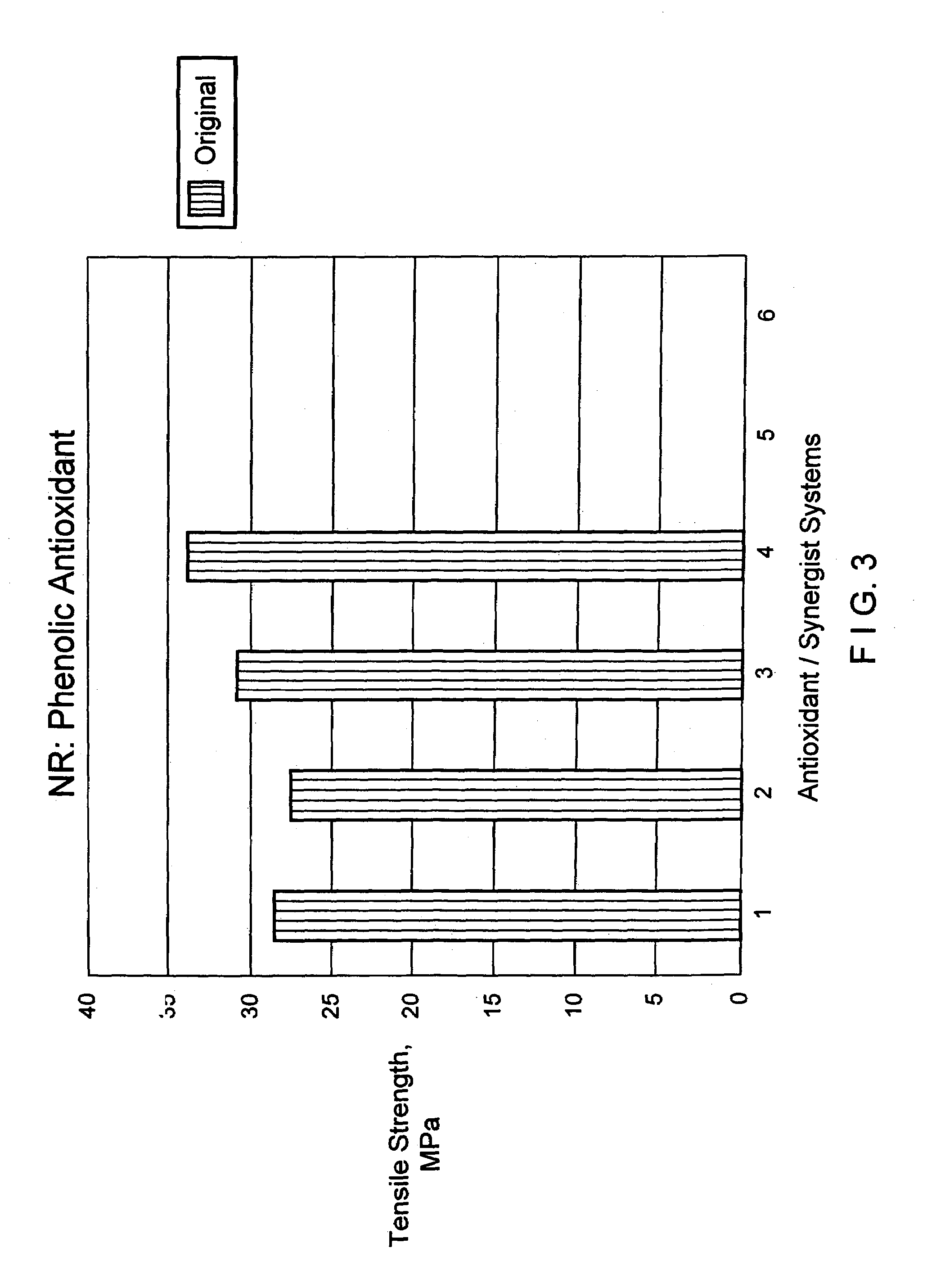

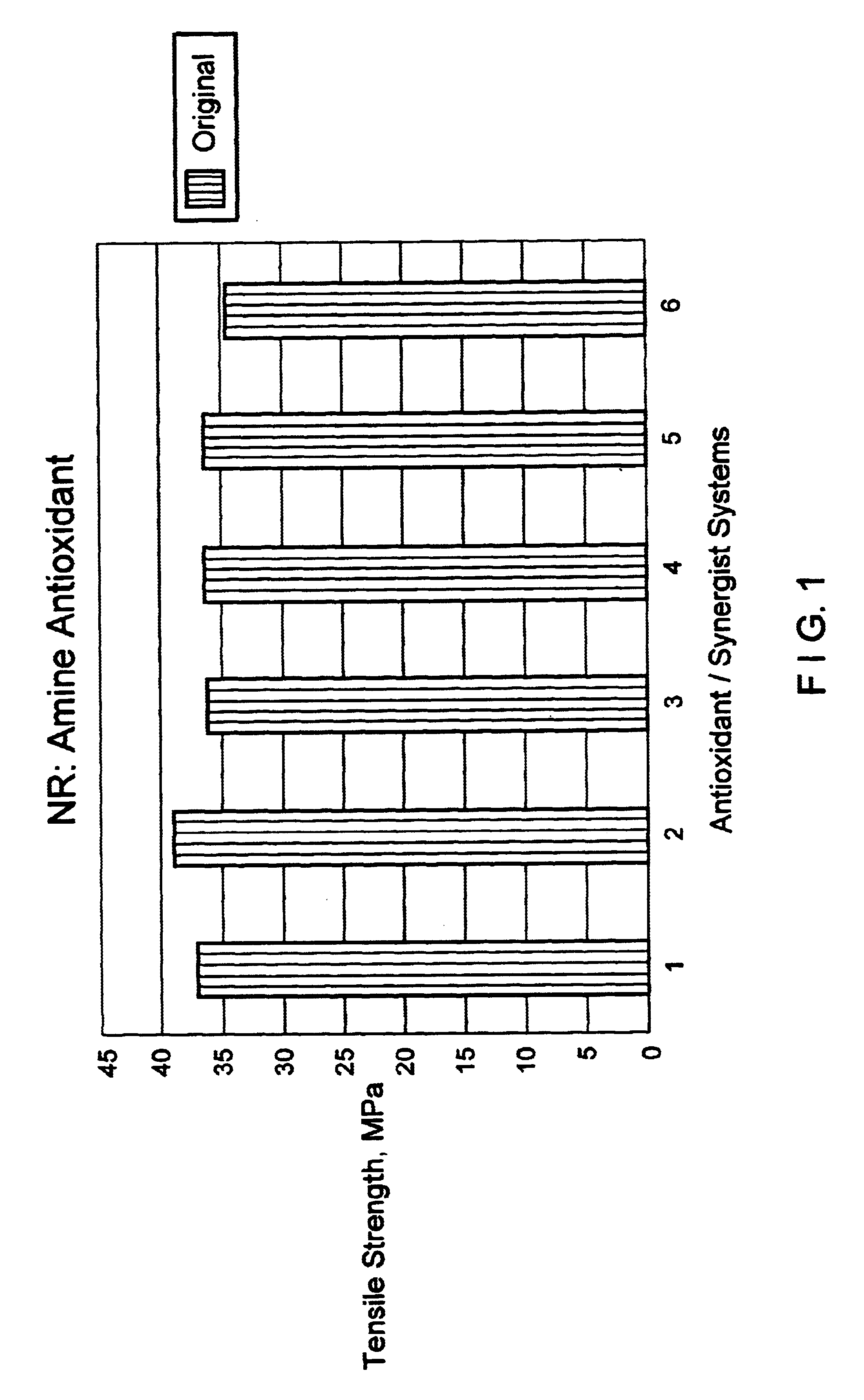

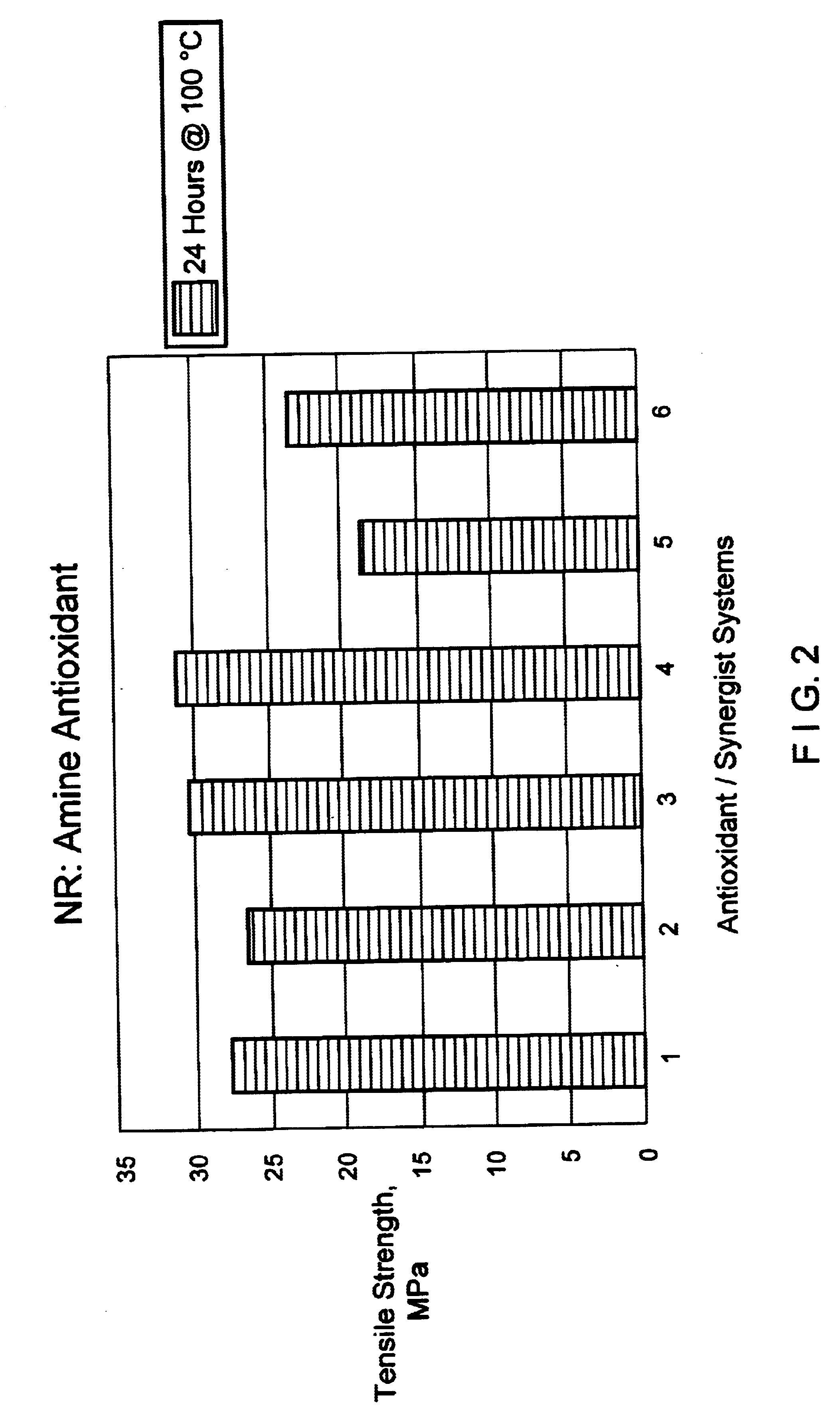

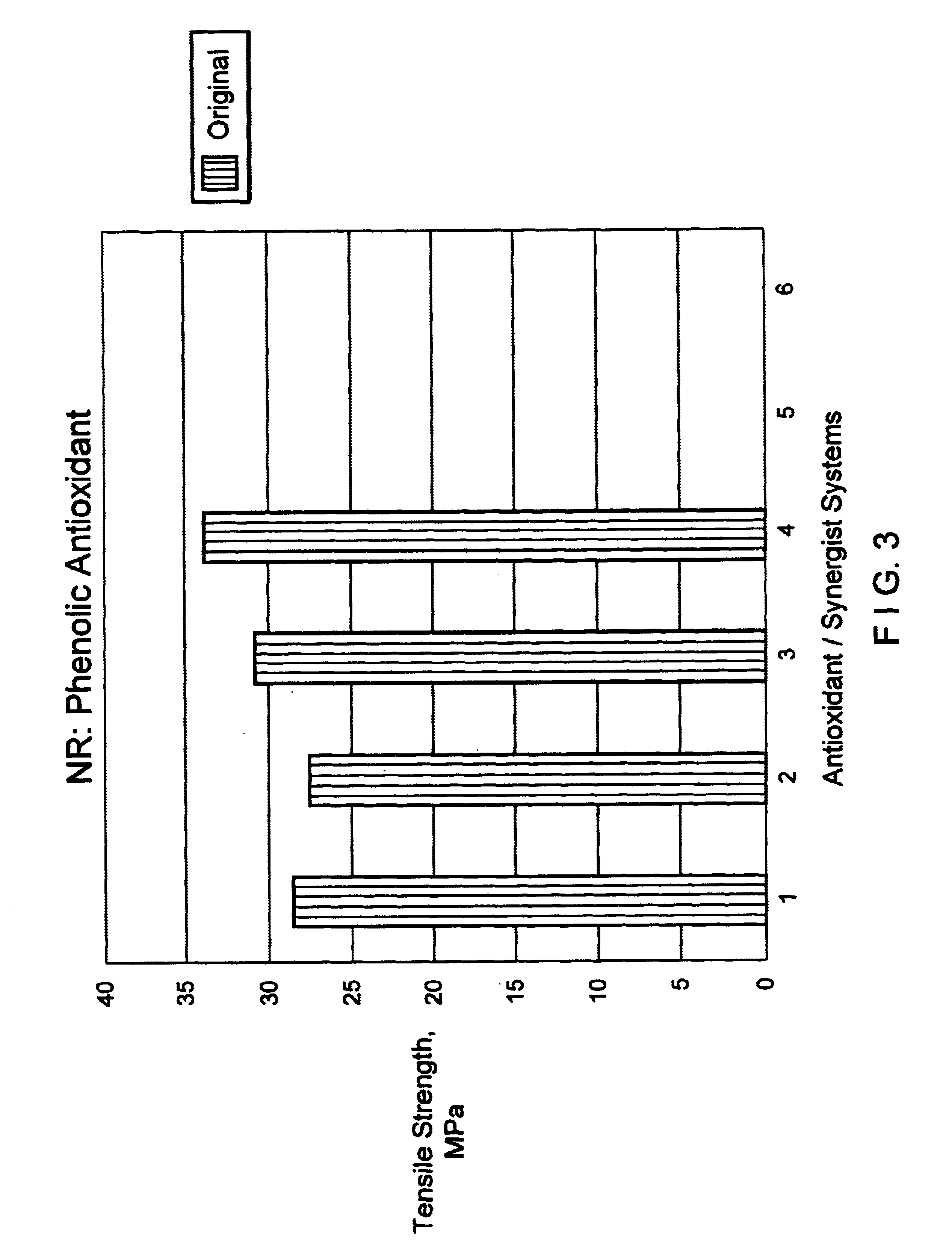

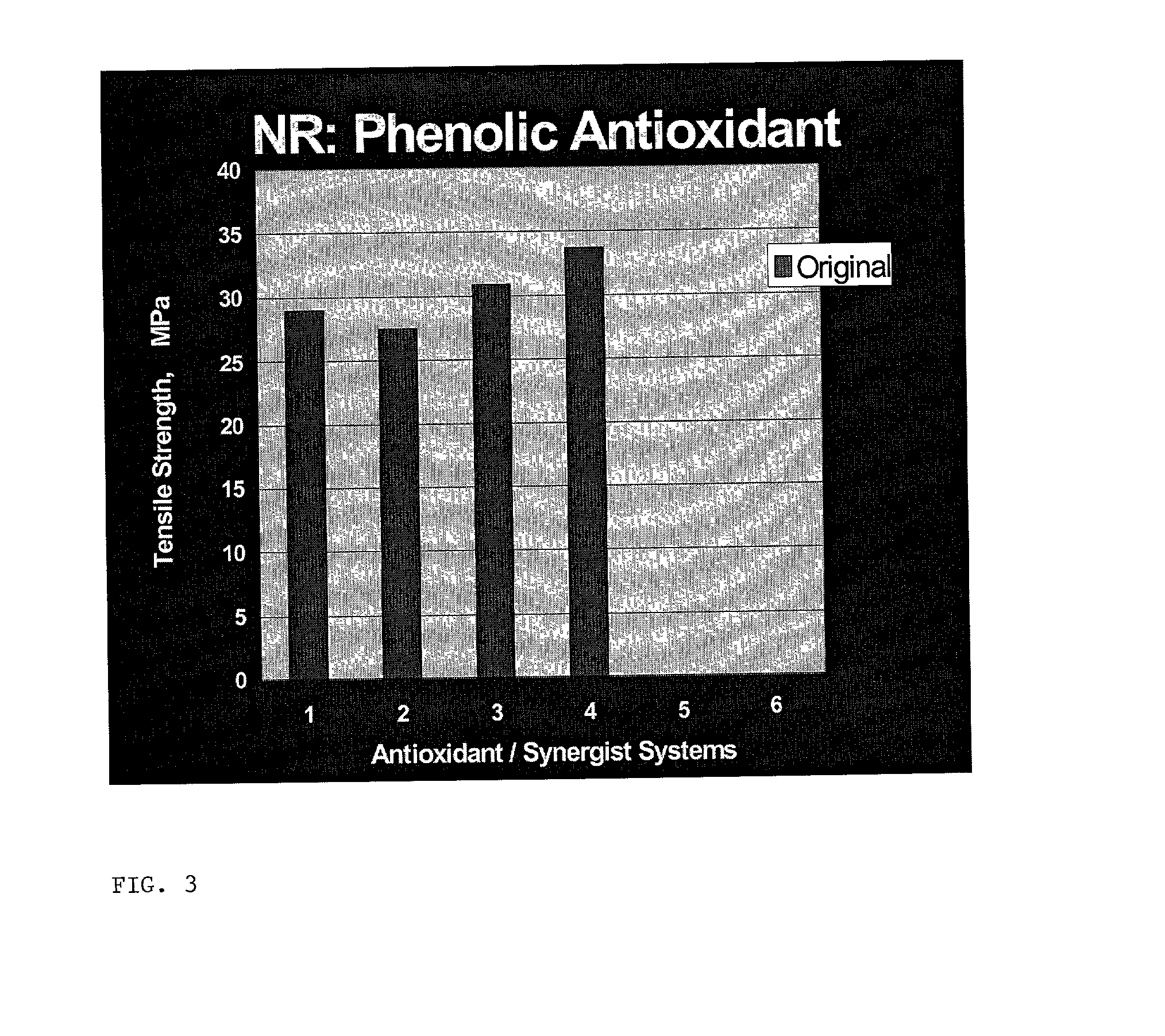

The invention relates to a method of enhancing the tear resistance, tensile strength, and the aging properties of a latex product by adding an antioxidant synergist with an antioxidant to a latex compound comprising of a polymer and a curing system comprised of an activator, crosslinker and accelerator and to the latex products formed therefrom. Antioxidant synergists which can be used with the present invention include 2-mercaptobenzimidazole (MBI), 2-mercaptotoluimidazole (MTI), zinc 2-mercaptobenzimidazole (ZMBI) and zinc 2-mercaptotoluimidazole (ZMTI). The latex products formed may be gloves but can also include threads, balloons and other latex-related products.

Owner:VANDERBILT CHEM LLC

Latex film compound with improved tear resistance

InactiveUS6653380B2Good effectDeterioration of propertyGranular deliverySolid balls2-mercaptobenzimidazoleAntioxidant

The invention relates to a method of enhancing the tear resistance, tensile strength, and the aging properties of a latex product by adding an antioxidant synergist with an antioxidant to a latex compound comprising of a polymer, a stabilizing system, a film surface conditioner and a curing system comprised of an activator, crosslinker and accelerator and to the latex products formed therefrom. Antioxidant synergists which can be used with the present invention include 2-mercaptobenzimidazole (MBI), 2-mercaptotoluimidazole (MTI), zinc 2-mercaptobenzimidazole (ZMBI) and zinc 2-mercaptotoluimidazole (ZMTI). The latex products formed may be gloves but can also include threads, balloons and other latex-related products.

Owner:VANDERBILT CHEM LLC

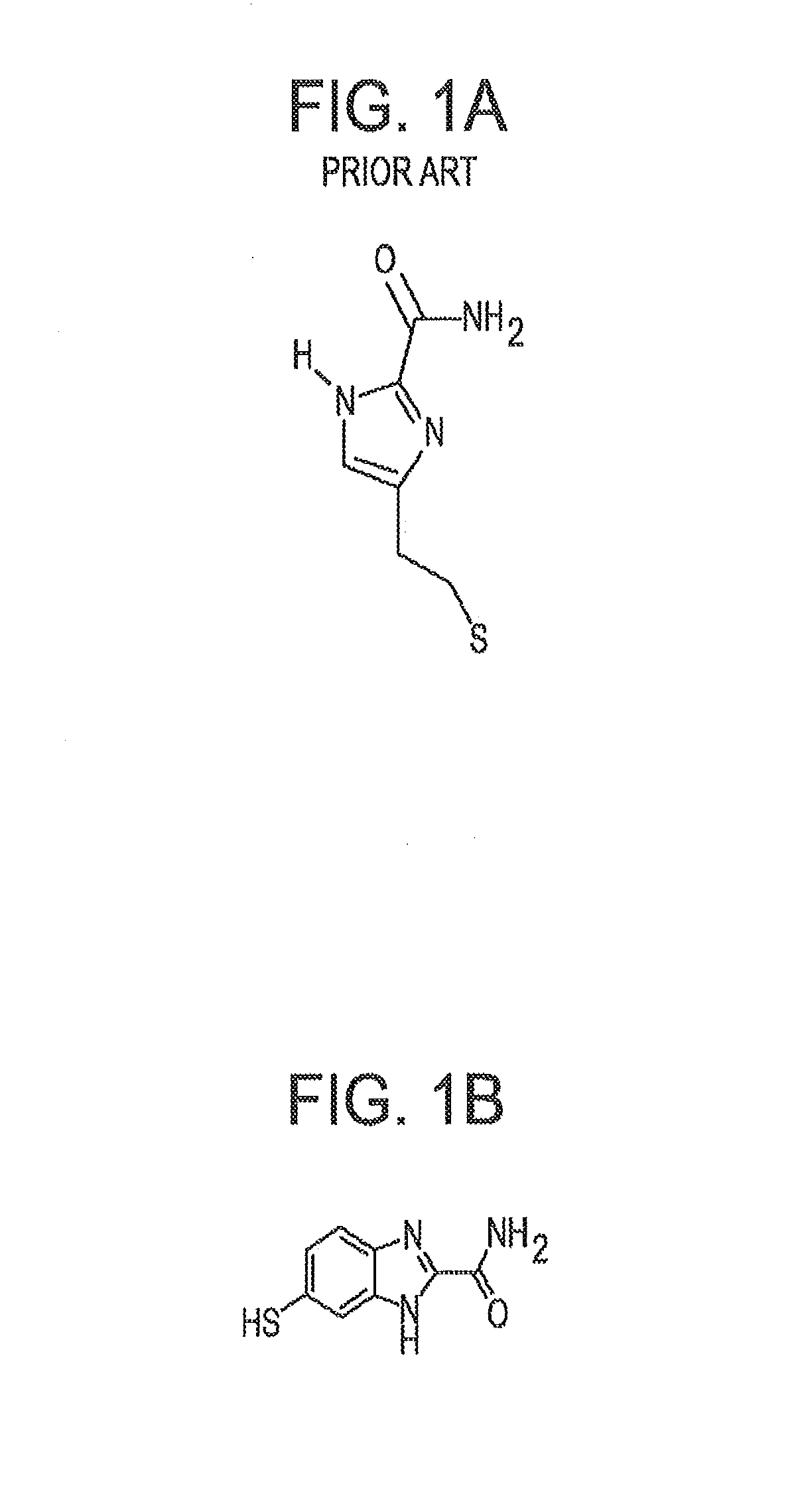

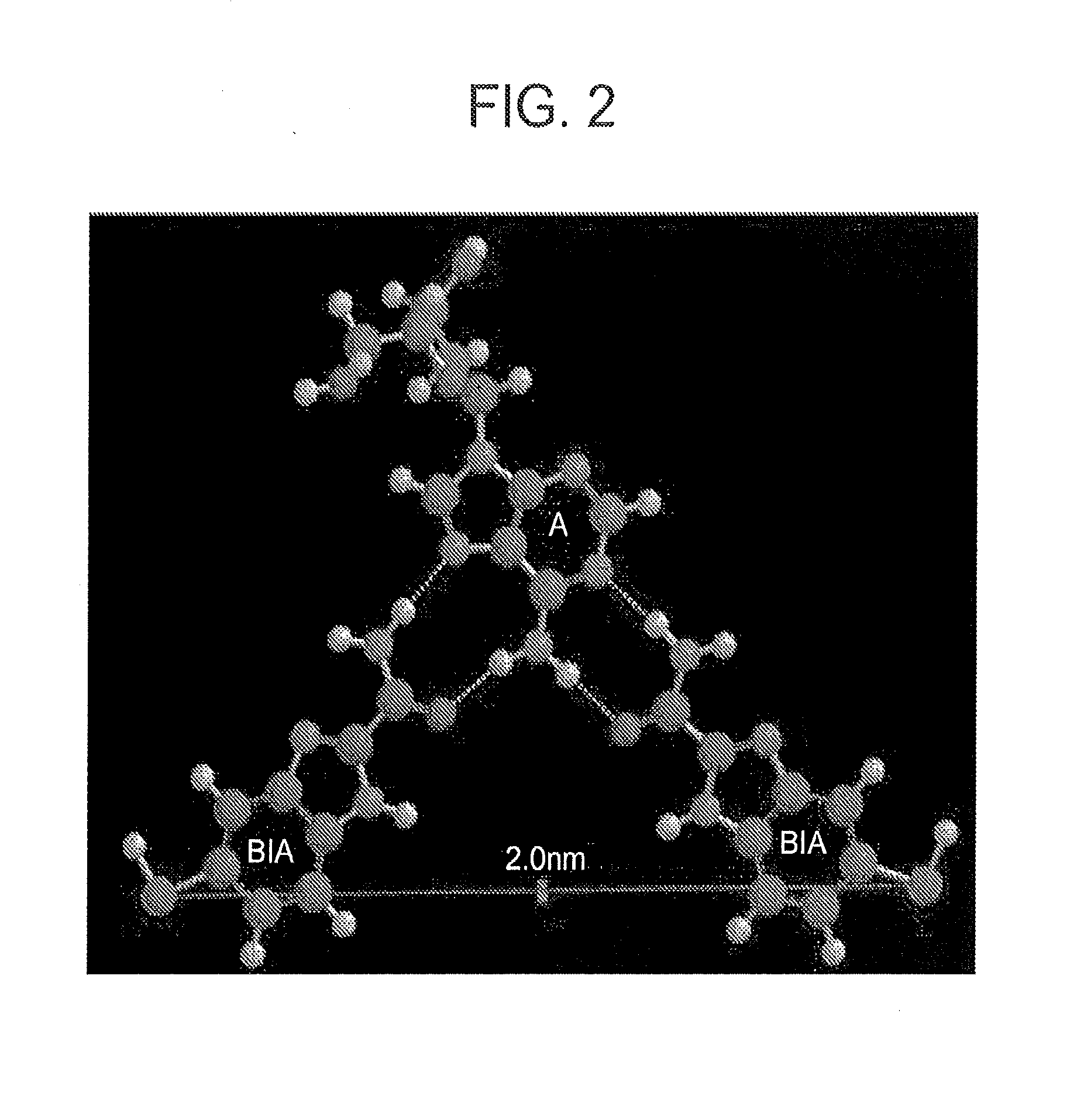

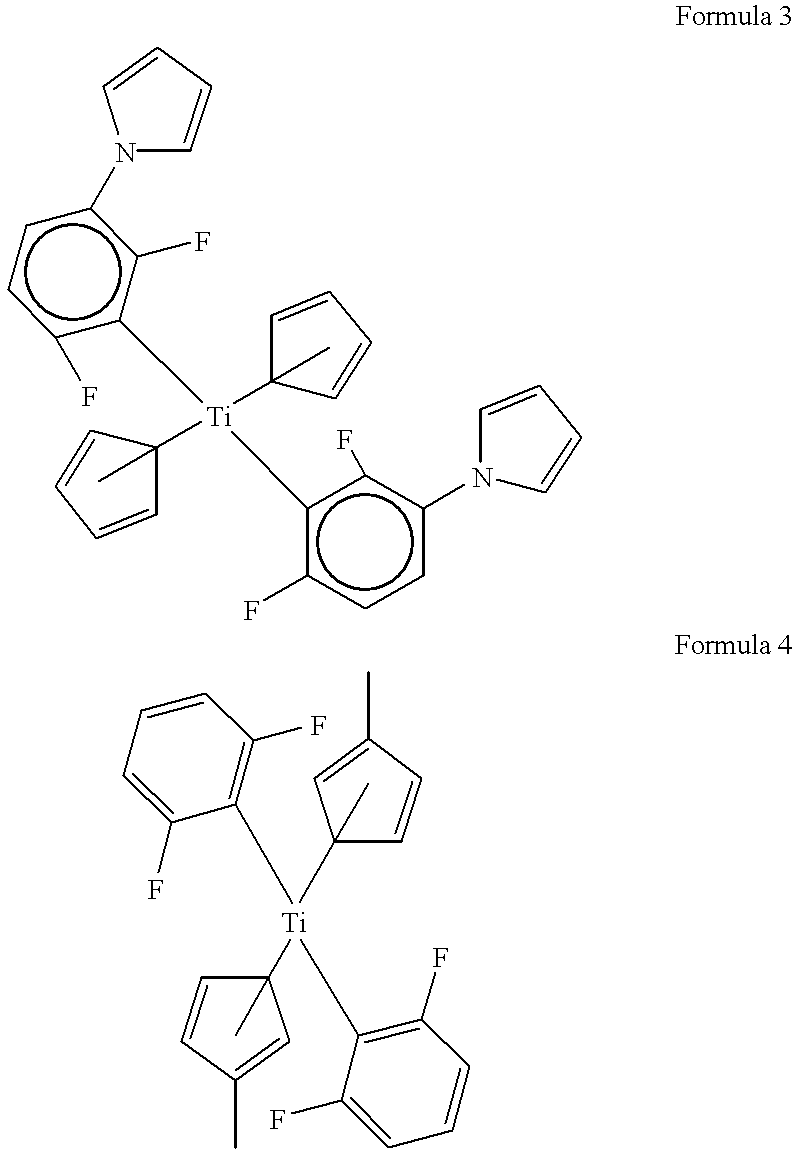

Universal reader molecule for recognition tunneling

InactiveUS20160108002A1Enhanced signalOrganic chemistryMaterial analysisMolecular identificationBenzene

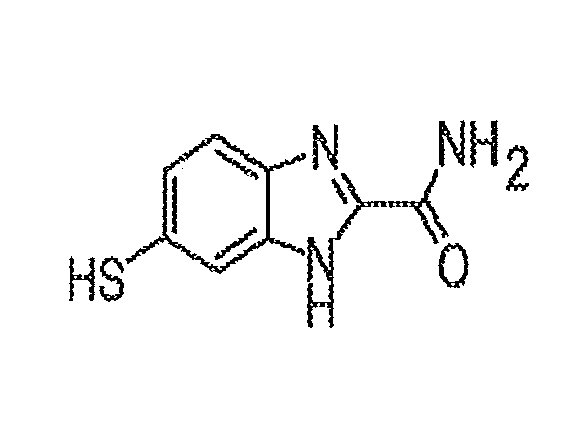

Some embodiments of the present disclosure are directed to a compound 5(6)-mercapto-1H-benzo[d]imidazole-2-carboxamide (“BIA”) which yields enhanced signals for recognition tunneling. Other embodiments are directed toward methods for producing such compounds as well as apparatuses and systems which utilize such compounds for recognition tunneling for molecule identification / sequencing (for example).

Owner:ARIZONA STATE UNIVERSITY

Cable insulating material for power station

ActiveCN1929039AImprove heat aging resistanceExcellent heat and humidity resistanceRubber insulatorsPlastic/resin/waxes insulatorsWaxPower station

This invention relates to nuclear station cable insulation materials, which comprises the following formula: EPT rubber-acrylic resin polymer for 100; aluminum hydroxide for 50 to 90; 2-mercaptobenzimidazole for 1 to 3; dysprosium oxide for 3 to 10; boron nitride for 10 to 20; wax for 1 to 6; dicumyl peroxide for 3 to 5; zinc bloom for 5 to 8.

Owner:JIANGSUSNGSHANG CABLE GROUP

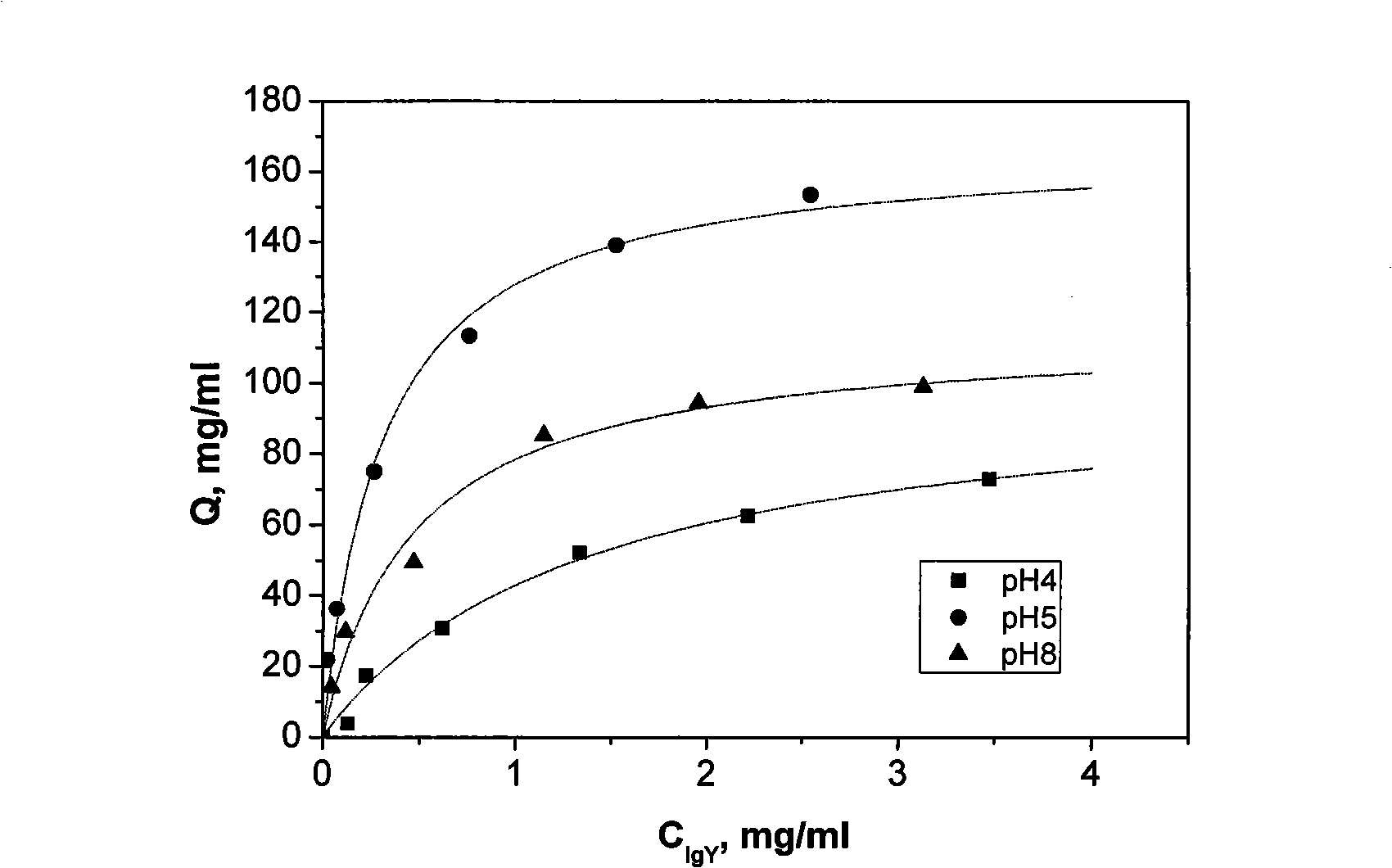

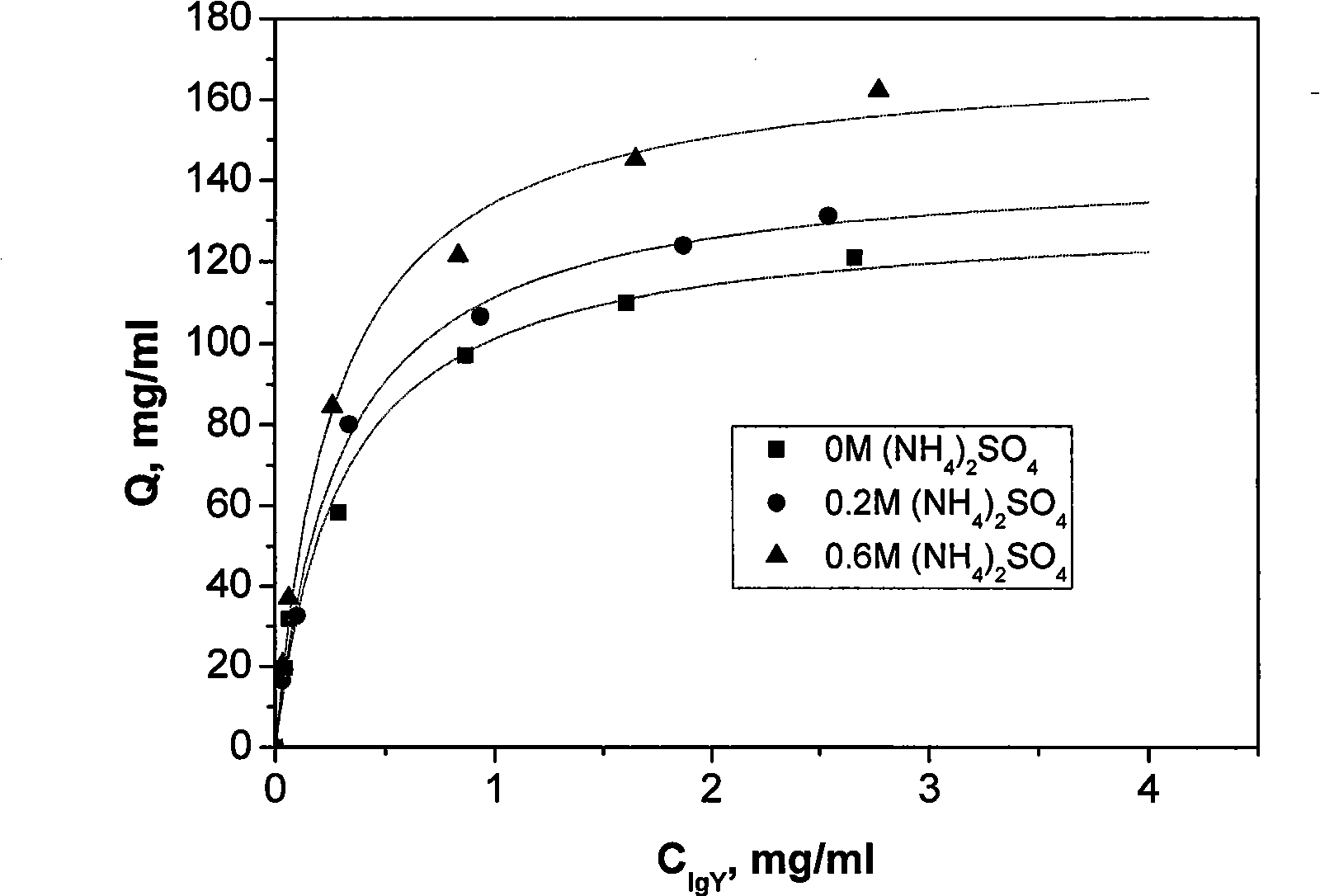

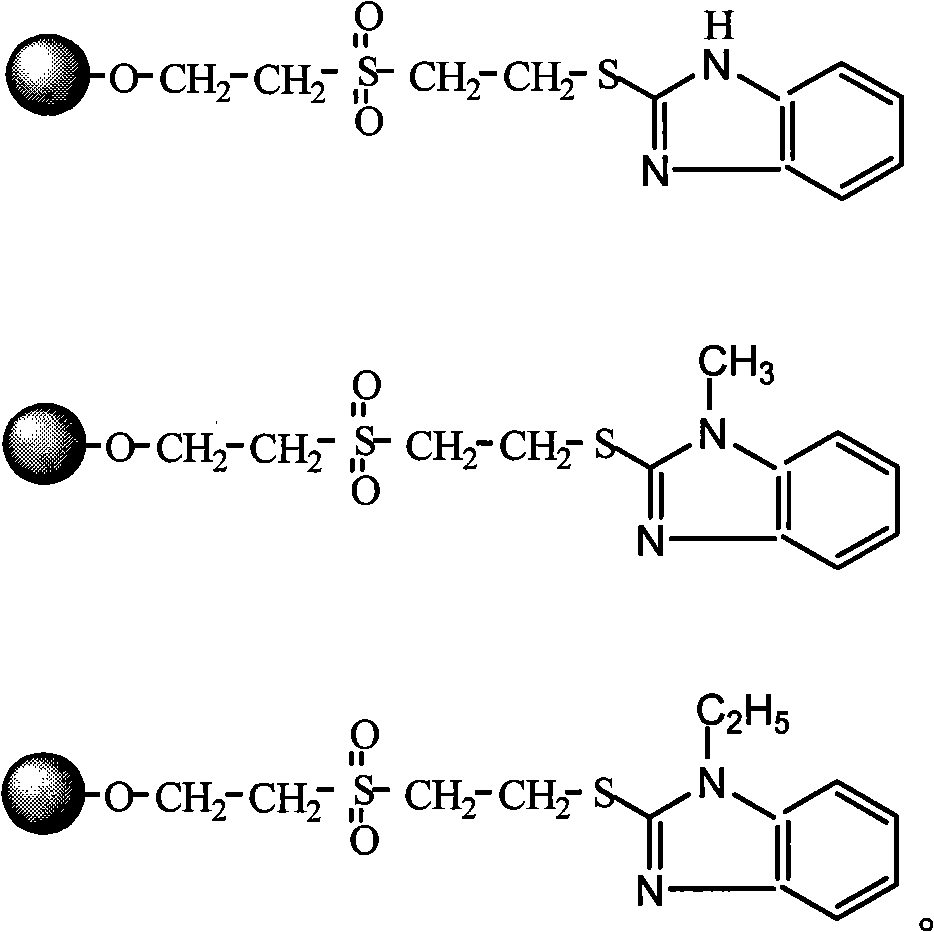

Mixing mode expanded adsorbent bed medium and method for producing the same

InactiveCN101279243ALarge adsorption capacityHigh selectivityOther chemical processesPeptide preparation methodsCelluloseMicrosphere

The invention discloses a mixed model expanded adsorbent bed medium and a preparation method thereof. In the composition of medium, matrix is a composite microsphere with fibrin / inorganic weighting agent, and petunidin is sulfonyl group and mercapto benzimidazole. The composite microsphere with fibrin / inorganic weighting agent is acquired by inverse suspension thermal regeneration and is taken as the matrix to mix divinyl sulfone, soda buffer solution and DMSO for activation, then swab-off activation matrix, the mercapto benzimidazole and sodium hydroxide containing ammonium persulfate are mixed for coupling, thus acquiring the mixed model expanded adsorbent bed medium taking the mercapto benzimidazole and the sulfonyl group as the petunidin. The novel expanded bed adsorbing medium developed by the invention combines with a plurality of petunidin-protein interaction mechanisms such as hydrophobic interaction, charge induction action, thiophilic action, etc, to form mixed model adsorption, which has the advantages of large adsorption capacity, high selectivity, etc., thus being used for high efficient separation and purification of bioactivators such as antibody, etc.

Owner:ZHEJIANG UNIV

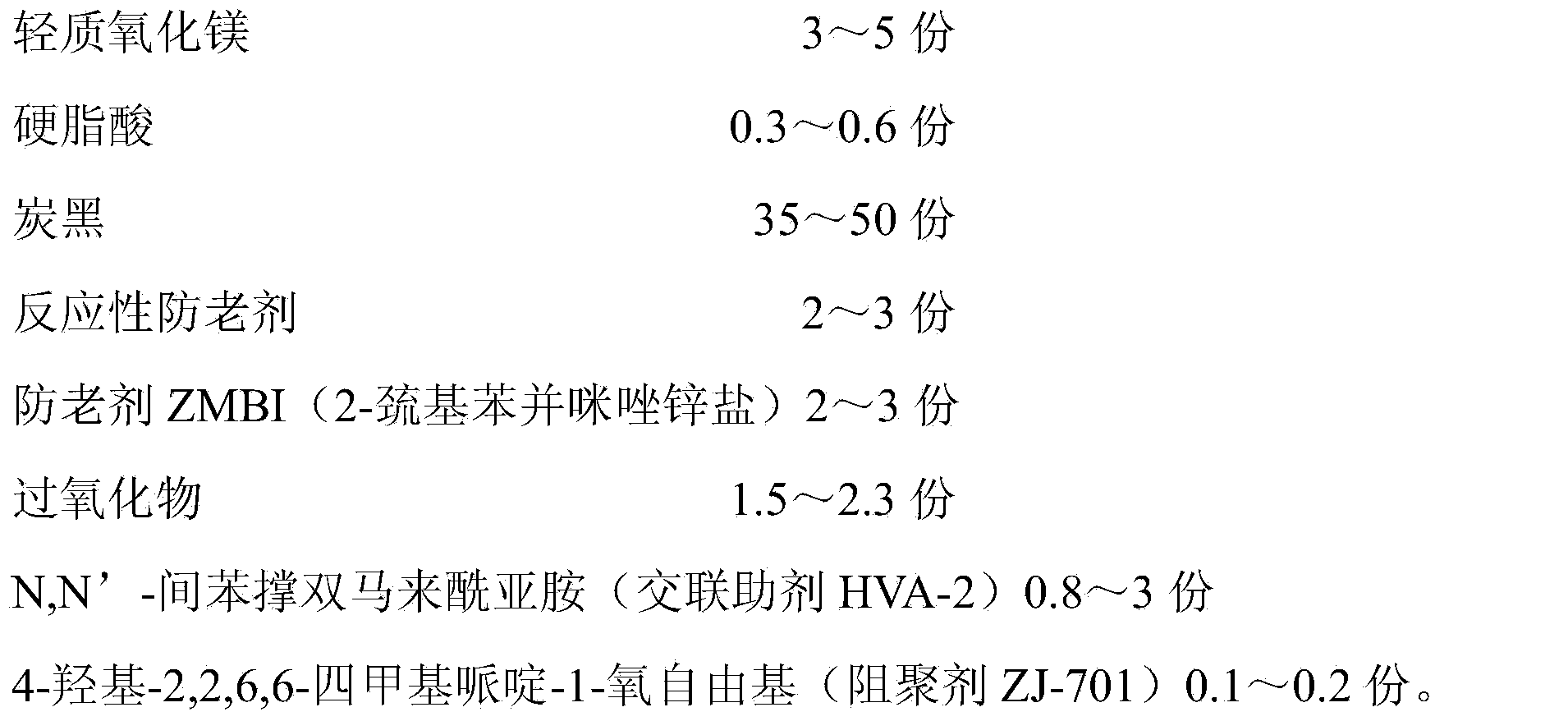

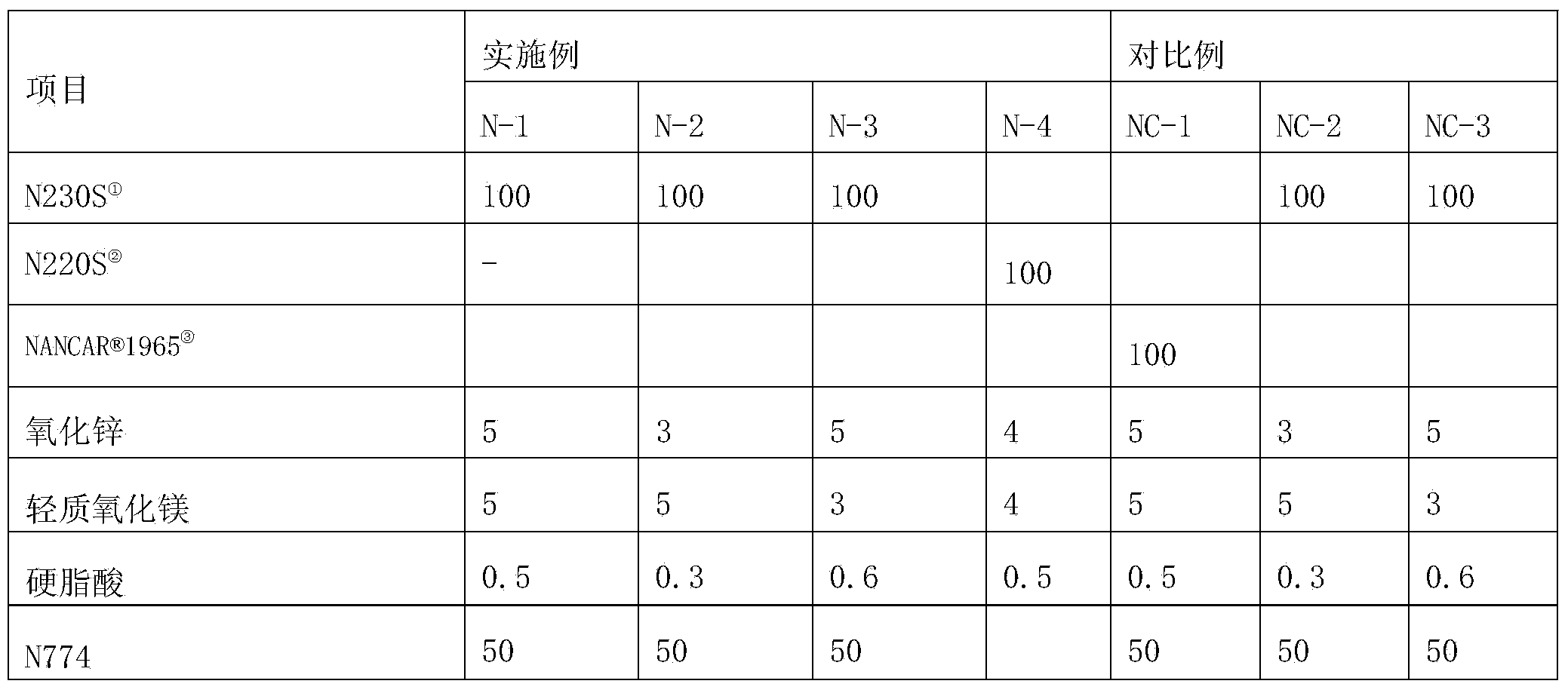

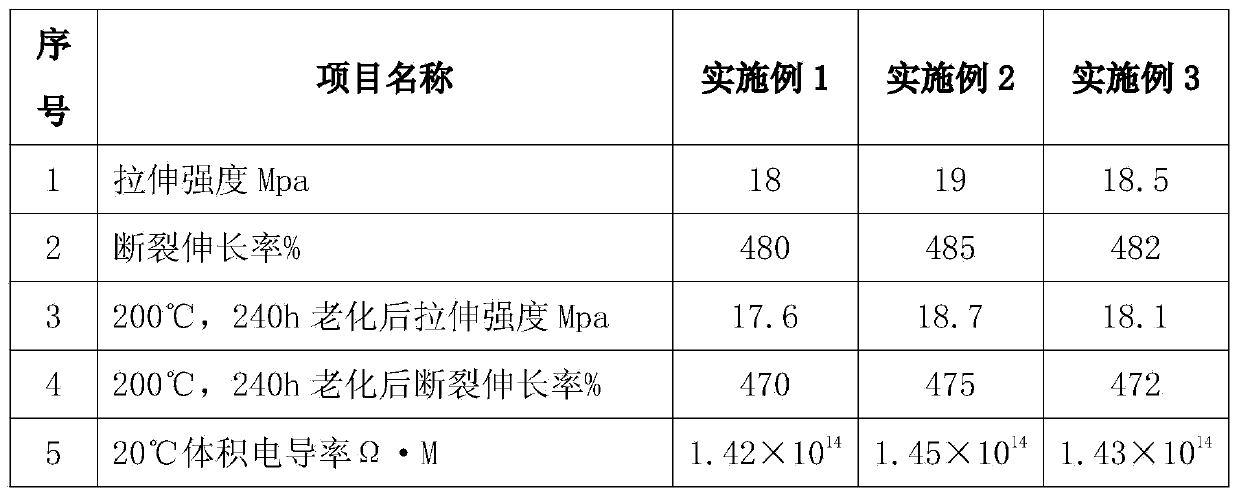

Heat-resistant and oil-resistant butadiene-acrylonitrile rubber material as well as preparation method and application thereof

The invention belongs to the technical field of rubber seal and discloses a heat-resistant and oil-resistant butadiene-acrylonitrile rubber material as well as a preparation method and application thereof. The butadiene-acrylonitrile rubber material comprises the following components in parts by mass: 100 parts of butadiene-acrylonitrile rubber,3-5 parts of zinc oxide, 3-5 parts of light magnesium oxide, 0.3-0.6 part of stearic acid, 35-50 parts of carbon black, 2-3 parts of a reactive antioxidant, 2-3 parts of 2-mercapto benzimidazole zinc salt, 1.5-2.3 parts of peroxide, 0.8-3 parts of N,N'-m-phenylene dimaleimide and 0.1-0.2 part of 4-hydroxy-2,2,6,6-tetramethylpiperidine-1-oxygen radical. After the rubber material is subjected to hot-air ageing at 120 DEG C for 70 hours, the permanent compression deformation rate (a type B sample) is not more than 18% and the break elongation rate and the retention rate are more than 90%. The rubber material is especially suitable for manufacturing oil-resistant static seal parts capable of being used at 100-120 DEG C for a long term, and can endow seal products with excellent durability.

Owner:GUANGZHOU MECHANICAL ENG RES INST

Fluorosilicone rubber cable material for coal mine cable and preparation method of cable material

The invention relates to a fluorosilicone rubber cable material for a coal mine cable and a preparation method of the cable material. The cable material comprises the following raw materials: fluorosilicone rubber, methyl vinyl silicone rubber, precipitation-method white carbon black, light calcium carbonate, zinc oxide, magnesium oxide, stearic acid, an accelerator N, N-tetramethylthiuram disulfide, an antiager-2-mercapto benzimidazole, a vulcanizer-2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane, a flame retardant-ammonium polyphosphate, diphenyl silanediol, talcum powder and vaseline. According to the cable material, the advantages of the fluorosilicone rubber and the methyl vinyl silicone rubber as raw materials are combined, the performance of a conventional fluorosilicone rubber cable material is improved, the cable material has excellent performances such as friction and collision resistance, high and low temperature resistance, medium resistance, ageing resistance, flame retardance, waterproof and moistureproof properties, long service life and the like, the requirement of safety use in a coal mine in a special environment is met, and the preparation method of the cable material is simple in process and free of environmental pollution and three-waste emission.

Owner:WUXI HUAMEI CABLE

Anti-aging fishing net

InactiveCN103724767AImprove anti-agingImprove thermal stabilityMonocomponent polyolefin artificial filamentArtifical filament manufacturePhenyl groupP-Phenylenediamine

The invention discloses an anti-aging fishing net. The anti-aging fishing net comprises the following raw materials in parts by weight: 97-100 parts of UHMWPE, 3-4 parts of EVA resin, 0.1-0.2 part of N-cyclohexyl-N'-phenyl p-phenylenediamine, 1-2 parts of tetrachloroisophthalonitrile, 3-4 parts of cis-1, 4-polyisoprene rubber, 0.2-0.4 part of 2-mercapto benzimidazole, and 3-4 parts of a modified plasticizer; according to the anti-aging fishing net provided by the invention, the N-cyclohexyl-N'-phenyl p-phenylenediamine and the 2-mercapto benzimidazole are adopted so as to improve the anti-aging function and the thermostability of the fishing net.

Owner:巢湖市瑞强渔具有限责任公司

Flame retardant insulation compositions having improved abrasion resistance

InactiveUS6998443B2Increase resistanceHigh densitySynthetic resin layered productsCellulosic plastic layered productsSilanesZinc

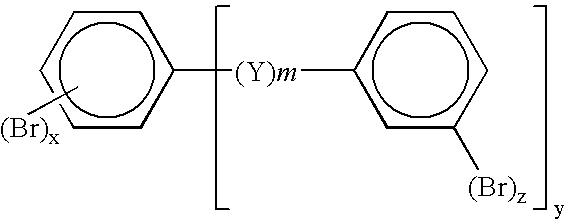

Moisture curable flame retardant insulation compositions for wire and cable having improved adhesion are provided. The compositions are comprised of an ethylene-silane copolymer, high density polyethylene resin, halogenated flame retardant, silanol condensation catalyst and stabilizer combination consisting of a zinc mercaptobenzimidazole and aromatic secondary amine.

Owner:EQUSR CHEM LP

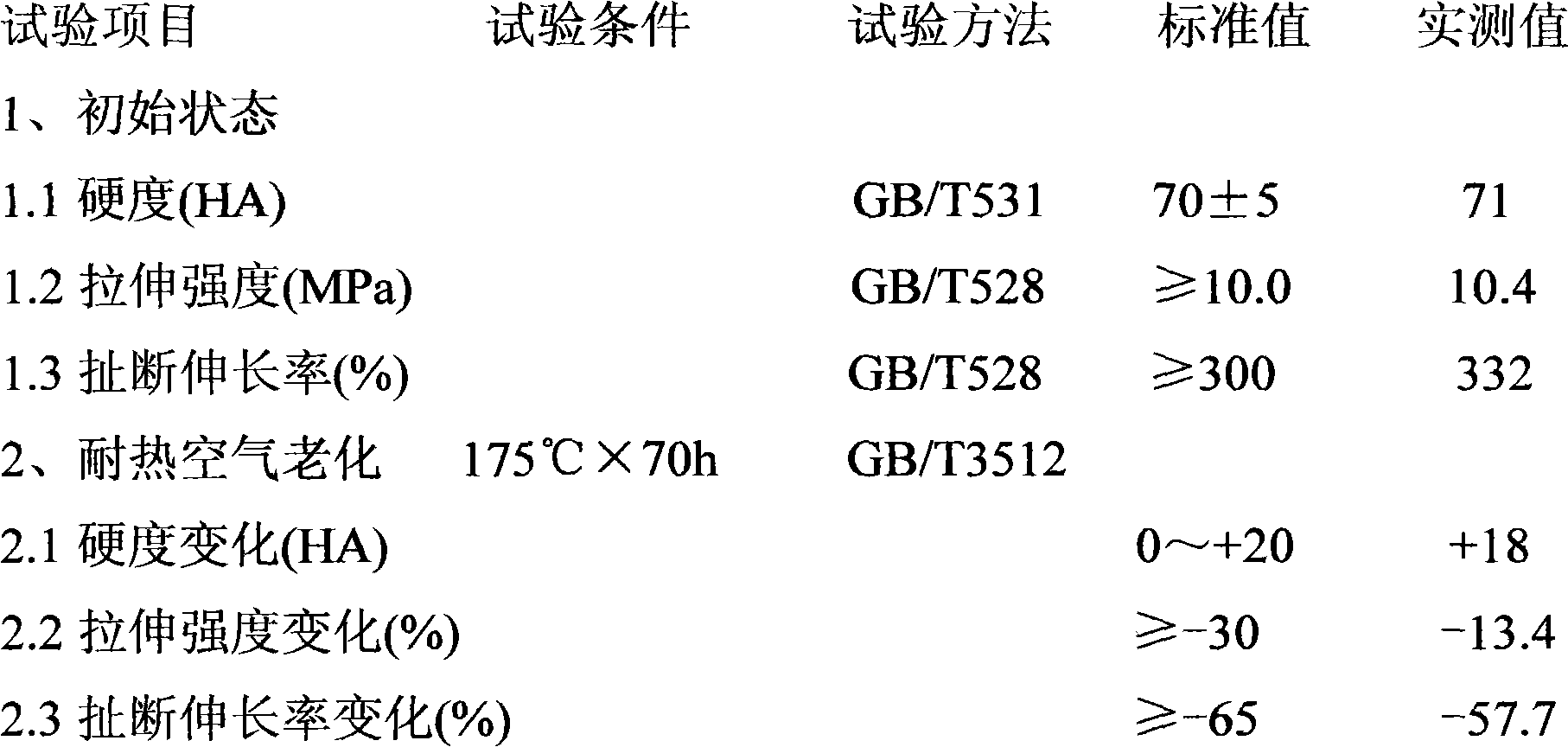

Preparation method for high-temperature-resistant rubber material of automobile radiating pipeline

InactiveCN102604238AImprove heat resistanceMeet heat resistance requirementsRubber materialPolymer science

The invention discloses a preparation method for a high-temperature-resistant rubber material of an automobile radiating pipeline. The method comprises a formula and a preparation process. In the method, an ethylene propylene diene monomer and chlorosulfonated polyethylene rubber are used together, dicumyl peroxide and a vulcanized system of N,N-m-phenylene bismaleimide are added into the formula, a 2,2,4-trimethyl-1,2-dihydroquinoline polymer and an anti-aging agent of 2-mercaptobenzimidazole are added into the formula, and magnesium oxide is added into the formula, so that the heat resistance of the material is improved; a technical scheme of a corresponding preparation process is matched for use, so that the defects of poor high temperature resistance and difficulty in meeting the increasing requirement of the automobile industry on the heat resistance of a rubber product existing in the prior art are overcome; and a rubber material which is resistant to the high temperature of 175 DEG C is prepared, so that the heat resistance of a prepared rubber product of the automobile radiating pipeline is improved, the increasing requirement of the automobile industry on the heat resistance of the rubber product is met, and the aim of meeting a high temperature resistance standard is fulfilled.

Owner:宁波市天普橡胶科技股份有限公司

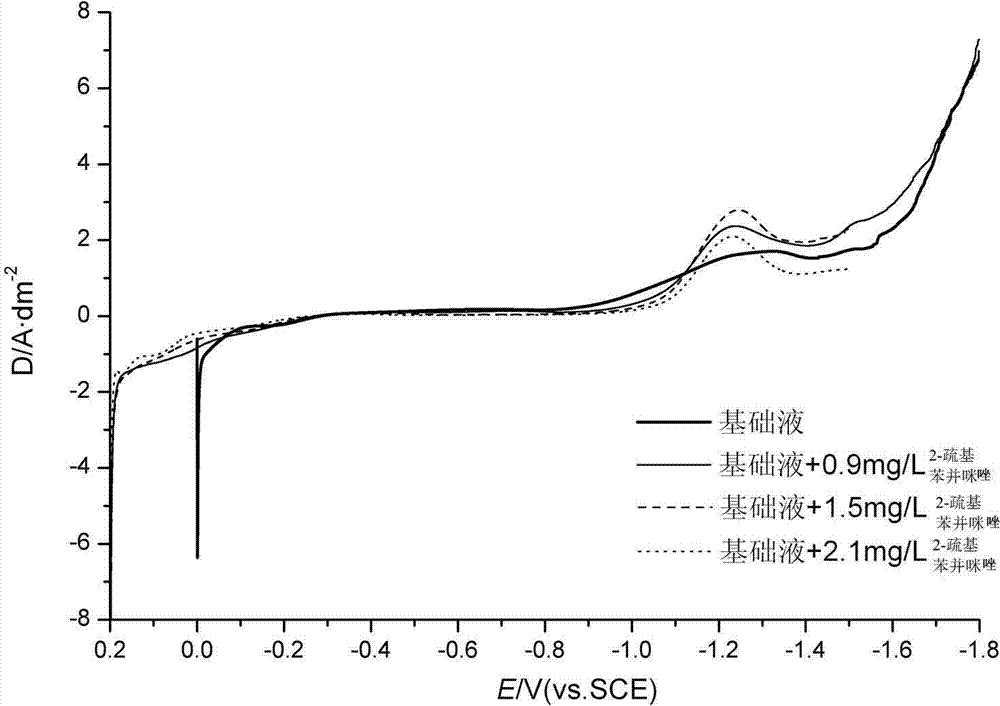

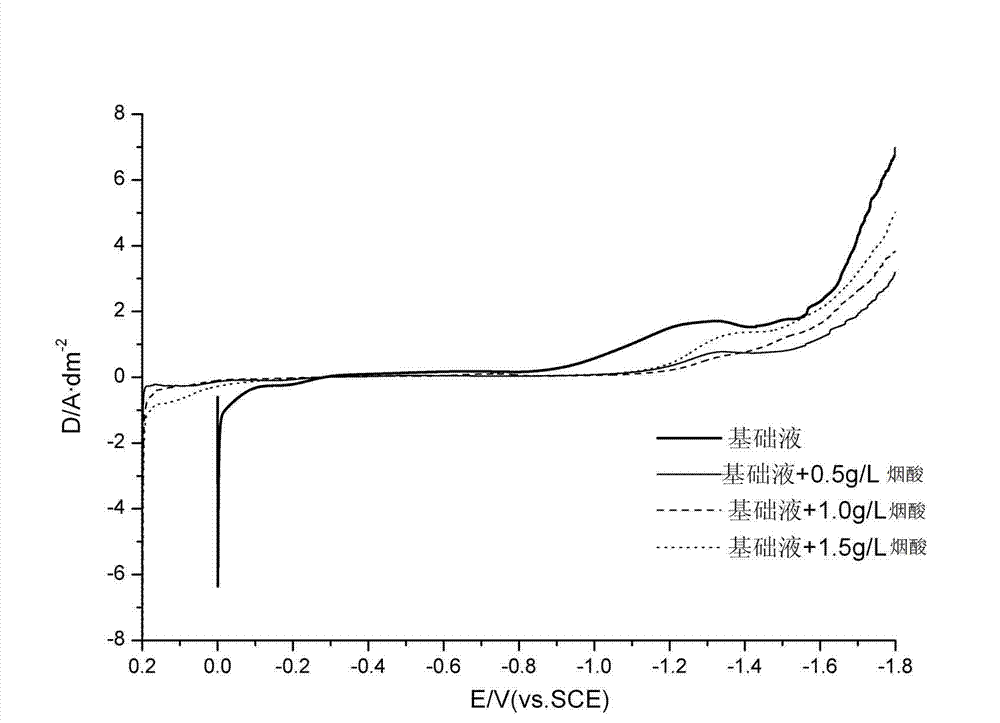

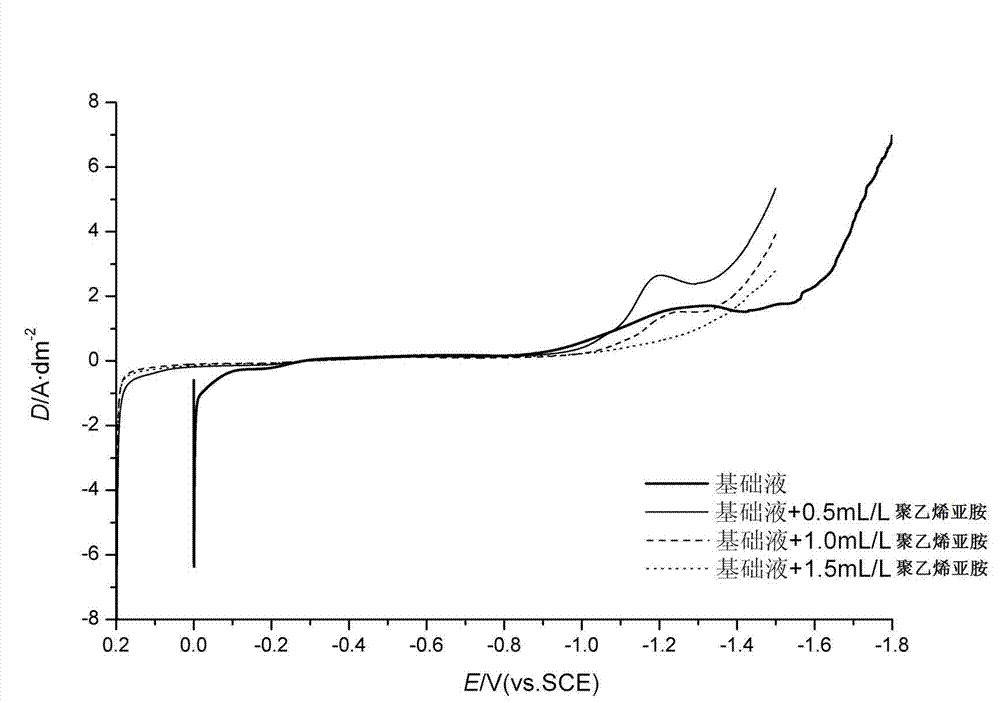

Citrate-tartrate dual-complexing non-cyanide alkaline copper-plating electrolyte on steel substrate

The invention discloses a citrate-tartrate dual-complexing non-cyanide alkaline copper-plating electrolyte on a steel substrate. The electrolyte per liter is prepared from the following raw materials by weight: 29-32g of copper sulfate, 110-147g of sodium citrate, 40-50g of sodium potassium tartrate, 6-8g of potassium nitrate, 8-12g of sodium bicarbonate, 0.5-1.5g of nicotinic acid, 0.1-0.2g of polyethylene glycol, 1-1.5ml of polyethyleneimine, 0.84-1.32mg of 2-mercapto benzimidazole and the balance of water. The electrolyte disclosed by the invention is good in dispersion capability, strong in coverage capability, high in stability, clean and environmentally-friendly in formula and suitable for wide working current density range; a plating coat of a plated part electroplated by the electrolyte is excellent in binding force, uniform in distribution and suitable for preparing a basic layer or a copper-plating layer in a medium thickness on a complex steel part.

Owner:HUBEI HENGXIN ELECTRO PLATING

Method for recovering nickel in chemical nickel-plating ageing liquid

ActiveCN102212842AImprove wettabilityConvenient and quick escapePhotography auxillary processesThioureaPolyethylene glycol

The invention discloses a method for recovering nickel in a chemical nickel-plating ageing liquid, and the method comprises the following steps: (1) adding 1100-1300 parts by weight of the chemical nickel-plating ageing liquid into an electrolytic cell, and regulating the pH value of the ageing liquid to 8-10 by use of solid sodium hydroxide; (2) dissolving 0.01-0.03 part by weight of polyethylene glycol, 0.01-0.02 part by weight of 2-mercapto benzimidazole, 0.03-0.06 part by weight of thiourea, 0.005-0.03 part by weight of hide glue and 0.3-0.5 part by weight of sodium hypophosphite into 40-70 parts by weight of water, adding the mixture into the electrolytic cell, and adding 1-3 parts by weight of 5mol / L hydrochloric acid solution; (3) at normal temperature, on the basis of taking a stainless steel plate as a cathode and a reticular plate plated with iridium oxide titanium alloy as an anode, reacting for 8-10 hours at constant reaction current of 0.6-1.0A, thus obtaining a recoveredmetal nickel on the cathode. The method has the advantages of high recovery rate, simple equipment, low cost and the like, works at normal temperature and is easy to realize.

Owner:WUXI ZHONGTIAN SOLID WASTE DISPOSAL CO LTD

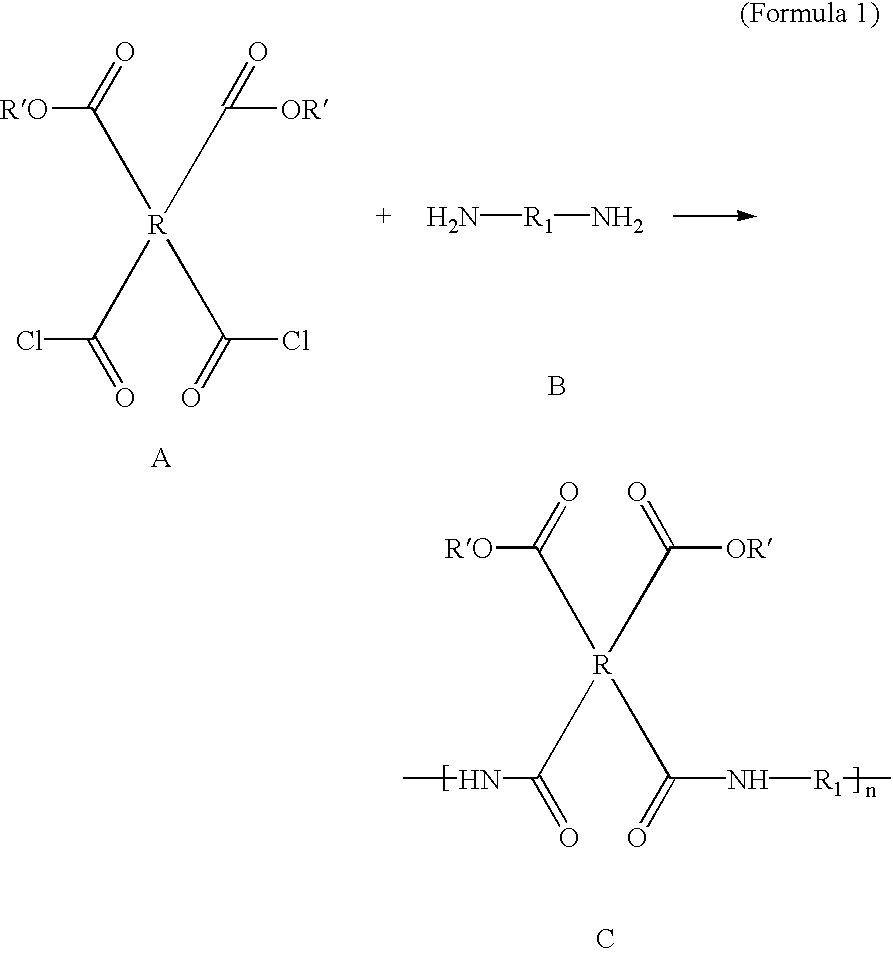

Vibration damping material of polyamides and mercaptobenzoimidazoles

The polyamide resin composition of the present invention is useful as a sound dampening material and includes (1) 30-97 wt % polyamide selected from (a) crystalline polyamide, (b) amorphous polyamide, or a mixture of (a) and (b), and (2) 1-30 wt % of a mercaptobenzoimidazole The polyamide resin composition of the present invention can further include a plasticizer or an inorganic filler.

Owner:SHISHIAI KK

Aluminium wiredrawing lubricant and preparation method thereof

The invention provides an aluminium wiredrawing lubricant and a preparation method thereof. The lubricant is characterized by comprising the following raw materials by weight parts: 0.3-0.4 parts of monoethanolamine, 0.6-0.8 parts of triethanolamine, 0.2-0.3 parts of mercapto benzimidazole, 1-2 parts of caprylic-capric acid blend, 1-2 parts of sodium dodecyl sulfate, 1-2 parts of dibutyltin dilaurate, 1-2 parts of zinc acetate, 1-2 parts of tung oil, 2-3 parts of methyl trimethoxy silane, 3-4 parts of a film forming auxiliary agent and 150-160 parts of water. According to the invention, the tung oil is added to promote lubricity, water base is used to play a relatively good heat dissipating effect, the triethanolamine is added to improve an anti-corrosion effect, and the methyl trimethoxy silane is combined with the mercapto benzimidazole, the caprylic-capric acid blend and the film forming agent to improve a film forming performance and prolong an anti-corrosion time of the aluminium conductor after the wiredrawing.

Owner:安徽富华电子集团有限公司

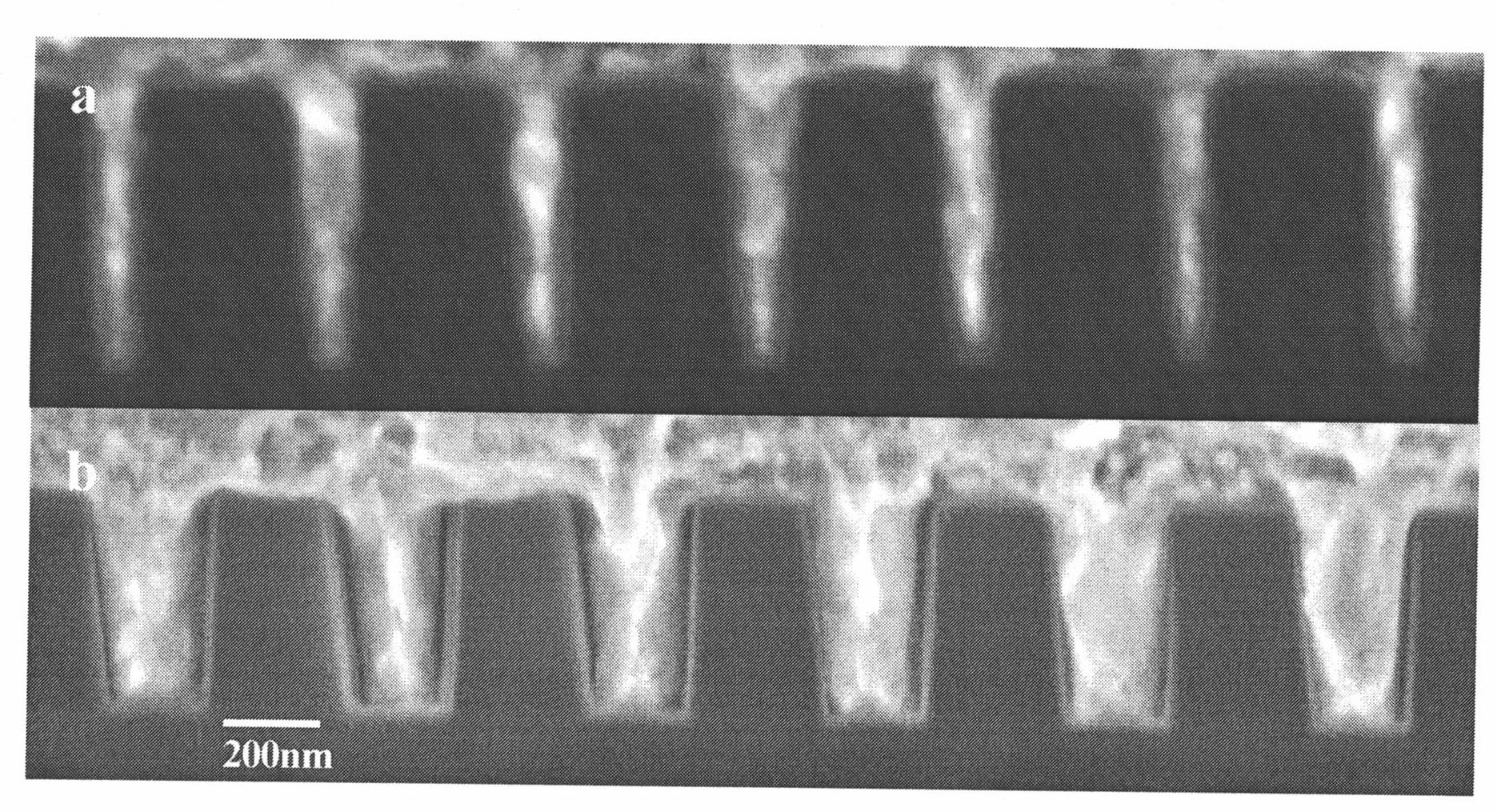

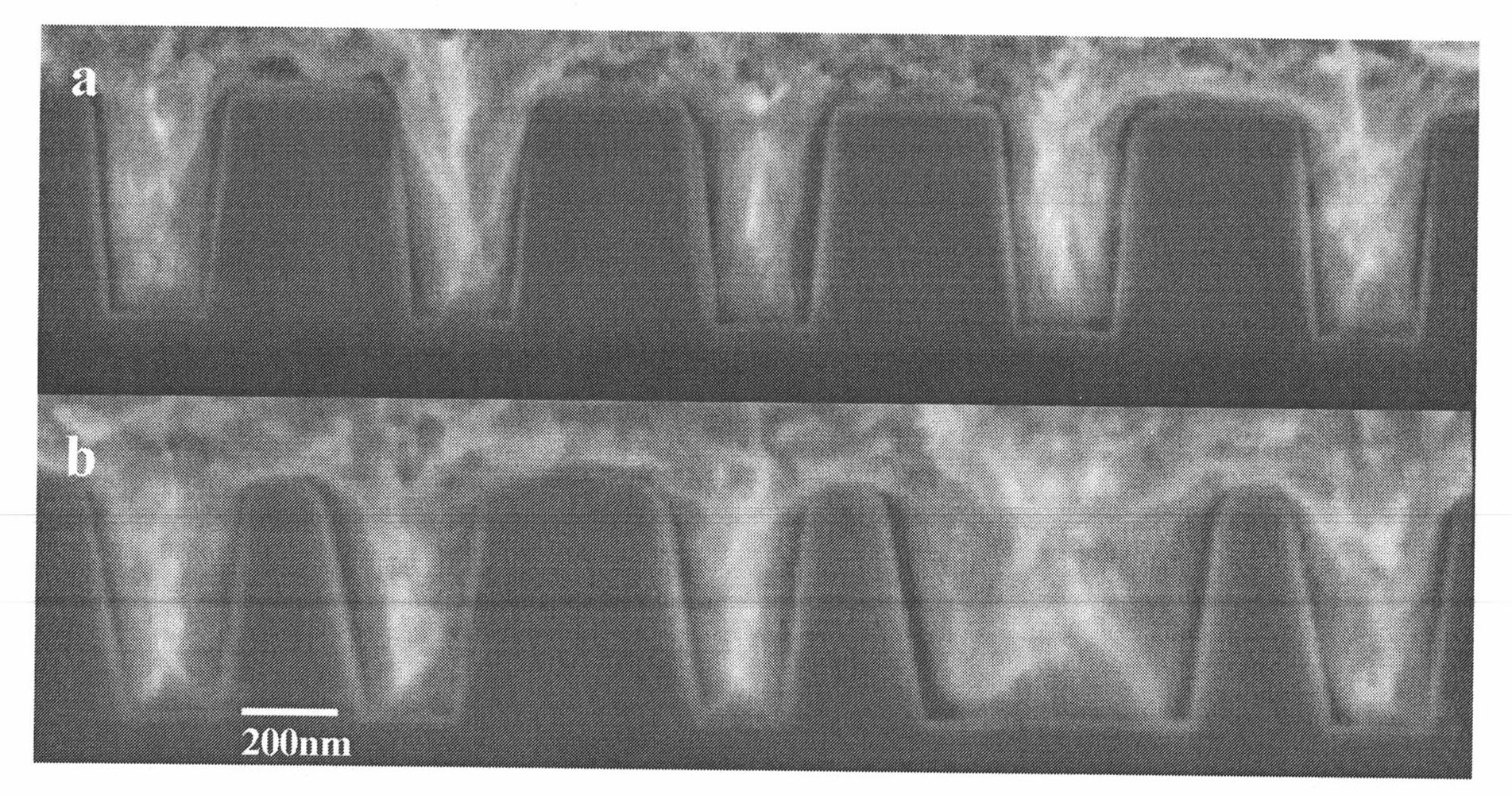

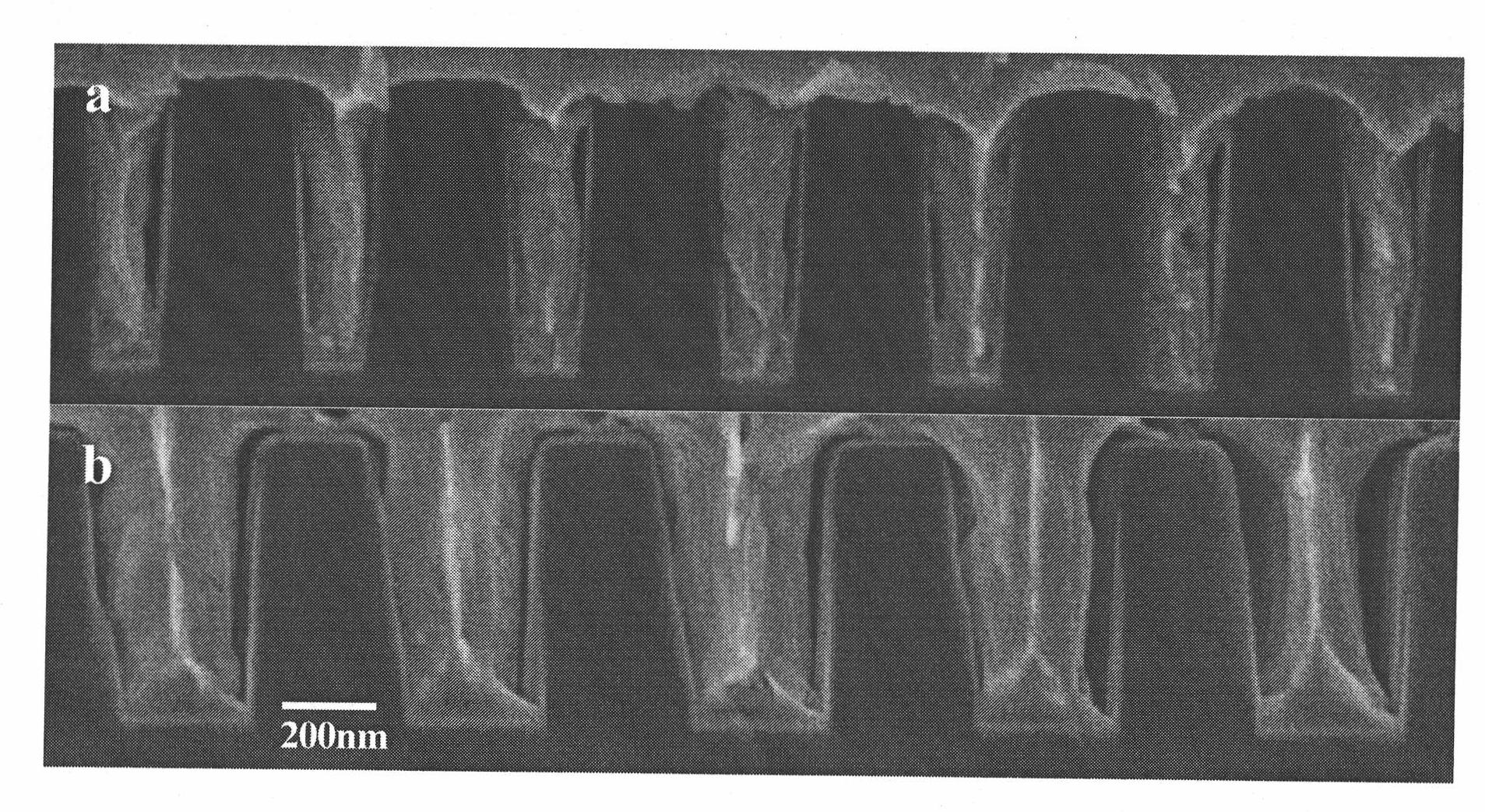

Electroless Copper Plating Solutions for Microvia Filling

InactiveCN102277567ANo holesSeamlessSemiconductor/solid-state device manufacturingLiquid/solution decomposition chemical coatingBenzoxazoleCopper plating

A chemical copper plating solution for micropore filling. 1 L of the chemical copper plating solution comprises 5-20 g of copper sulfate pentahydrate, 10-50 g of disodium ethylene diamine tetraacetate, 1.0-1.5 g of formaldehyde or glyoxylic acid, 0.001-0.02 g of mercapto heterocyclic compounds, 0.02-0.04 g of polyether with an average molecular weight of 3650, 1.5-3.5 g of NaOH, and the balance of distilled water; the mercapto heterocyclic compounds are 2-mercapto benzimidazole, 2- mercapto benzoxazole, 1-phenyl-5-mercapto-tetrazole or 2-mercapto benzothiazole. By simultaneously adding mercapto heterocyclic compounds and polyether with an average molecular weight of 3650 into the chemical copper plating solution, the invention realizes no cavity, no gap of micropores, and perfect chemicalcopper filling; the chemical copper plating solution is stable; and the deposited copper film has good quality.

Owner:SHAANXI NORMAL UNIV

Halogen-free low-smoke flame retardant double-layer insulating outer layer material for area-1 cable of AP1000 nuclear power station and preparation method thereof

ActiveCN103275401AImprove radiation resistanceImprove flame retardant performanceRubber insulatorsEthylene propylene rubberMaterials science

The invention discloses a halogen-free low-smoke flame retardant double-layer insulating outer layer material for an area-1 cable of an AP1000 nuclear power station and a preparation method thereof, belonging to the technical field of cables. The material comprises a base body consisting of ethylene propylene diene monomer, ethylene propylene monomer and ethylene vinyl acetate copolymer rubber, a halogen-free flame retardant smoke suppression system consisting of magnesium hydroxide, aluminum hydroxide, zinc borate pentahydrate, microcapsule-coated ammonium polyphosphate and siloxane, an anti-radiation system consisting of nano cerium dioxide and lead monoxide, a vulcanization system consisting of 98% bis(tert-butylperoxyisopropyl)benzene and N,N'-m-phenylene dimaleimide, a protection system consisting of 2-mercapto benzimidazole zinc salt, para, para'-diisopropylphenyl diphenylamine and nano zinc oxide, a coupling agent composed of vinyltri(beta-methoxyethyoxy)silane, and a lubricating and softening system consisting of stearic acid and microcrystalline wax. The material disclosed by the invention has the advantages of good radiation resistance, excellent mechanical properties and good electrical insulation properties; and the service life of the material reaches 60 years.

Owner:BAOSHENG SCI & TECH INNOVATION

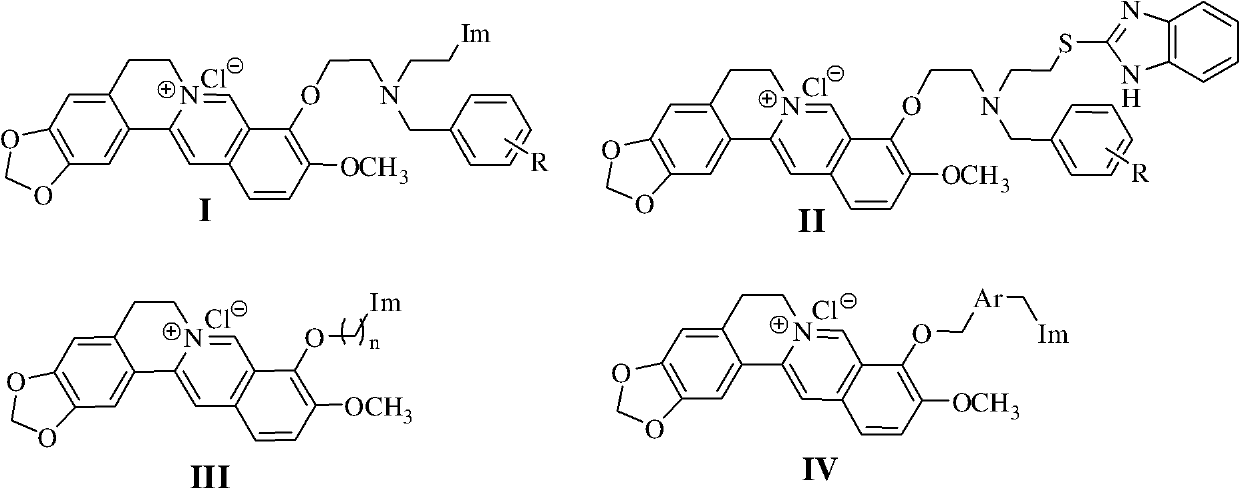

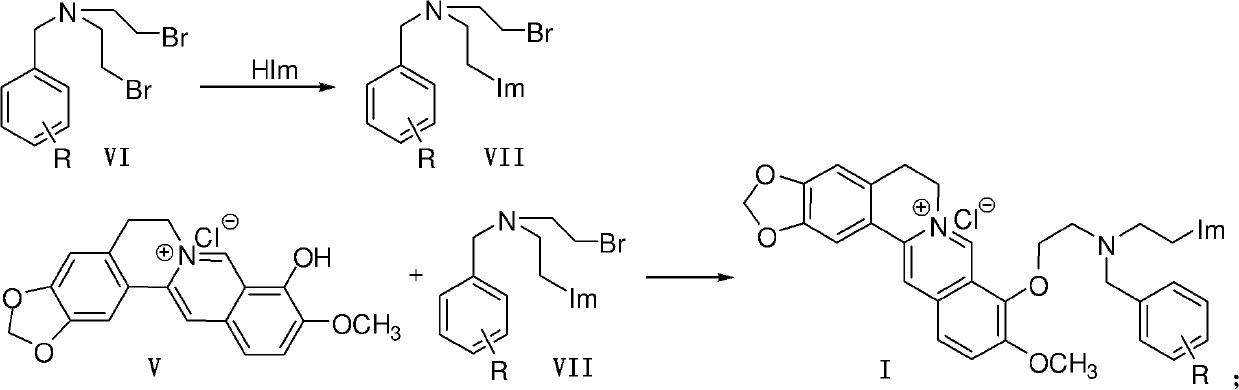

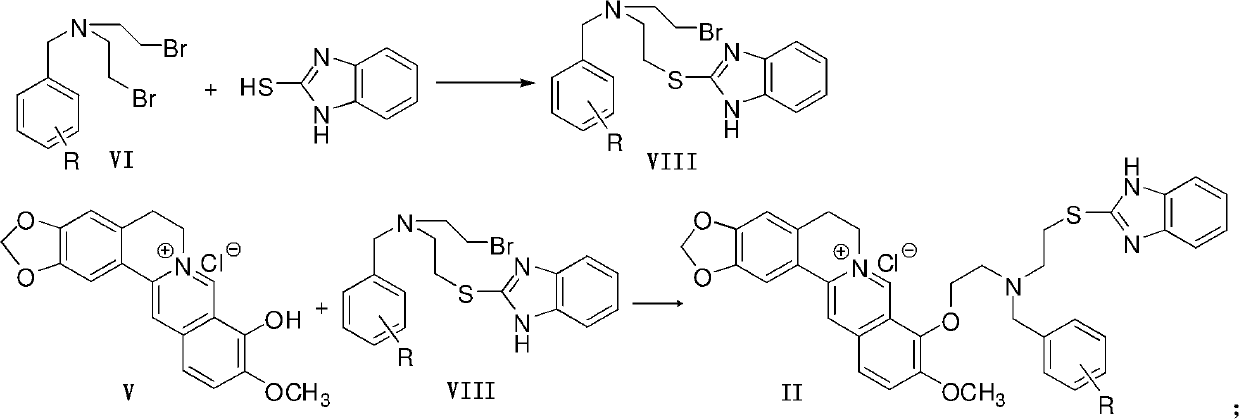

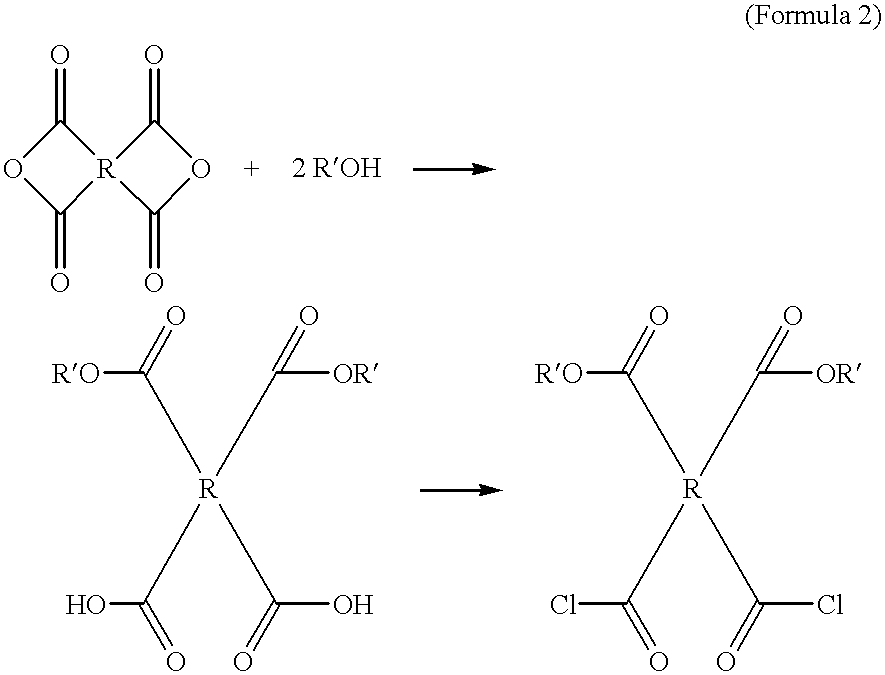

Berberine azole compound and preparation method and application thereof

ActiveCN102516242AEasy to prepareRaw materials are easy to getAntibacterial agentsOrganic active ingredientsBerberineFluconazole

The invention discloses a berberine azole compound shown in general formulas such as I-IV, and a pharmaceutically acceptable salt thereof, and also discloses a preparation method of the compound, which comprises the following steps that: a compound VI and an azole compound HIm or 1H-2-mercaptobenzimidazole are reacted to obtain an intermediate VII or VIII, and then the obtained intermediate is reacted with a compound V to obtain the berberine azole compound shown in general formulas such as I or II; and the compound V and a compound IX or XI are reacted to obtain an intermediate X or XII, and then the obtained intermediate is reacted with the azole compound Him to obtain the berberine azole compound shown in general formulas such as III or IV. The berberine azole compound has a certain inhibitory activity on Gram-positive bacteria, Gram-negative bacteria and fungi, the anti-bacterial activity of part of the compounds is equal to or even stronger than that of chloramphenicol or norfloxacin, the antifungal activity of part of the compounds is equal to or even stronger than that of fluconazole, and the berberine azole compound can be used for preparing anti-microbial drugs.

Owner:SOUTHWEST UNIVERSITY

Moistureproof insulation material for electrical engineering

InactiveCN104592704AHigh strengthImprove insulation performancePlastic/resin/waxes insulatorsPolyureas/polyurethane adhesivesEpoxyElectrical engineering technology

The invention discloses a moistureproof insulation material for electrical engineering. The material comprises an inner layer and an outer layer. The inner layer is prepared from the following raw materials in parts by weight: 10-16 parts of quartz sand, 16-22 parts of aluminum oxide, 16-22 parts of polyallylamine resin, 3-9 parts of dimethylformamide, 1-4 parts of butyl rubber and 3-9 parts of nano silicon dioxide. The outer layer is prepared from the following raw materials in parts by weight: 15-22 parts of epoxy resin, 10-17 parts of polyamide resin, 20-28 parts of glass fiber, 2-6 parts of ethylene propylene diene monomer rubber, 0.5-1.2 parts of 2-mercaptobenzimidazole, 1-4 parts of nano zinc oxide, 10-18 parts of silicon nitride, 2-9 parts of hydrogenated nitrile-butadiene rubber, 5-11 parts of aluminum nitride and 5-11 parts of polyethylene. The moistureproof insulation material is composed of the inner layer and outer layer; the outer layer achieves the moistureproof effect under the combined actions of the components; and the material has steady insulating property under the combined actions of the components of the inner layer.

Owner:WUJIANG HUACHENG COMPOSITE MATERIAL SCI & TECH

Wire and cable insulation

InactiveCN1496570AReduce or eliminate the needImprove convenienceRubber insulatorsPlastic/resin/waxes insulatorsPolypropyleneZinc sulphide

Wire or cable insulation comprising at least 30 %, preferably at least 40 %, of polypropylene homo- and / or co-polymer, and comprising at least 2 %, preferably at least 4 % zinc sulphide and / or at least 5 %, preferably at least 10 %, zinc oxide, percentages being by weight based on the whole insulation composition. Preferably, the insulation contains little or substantially zero hydrated flame-retardant fillers and substantially zero mercaptobenzimidazole, and a majority by weight or substantially all of any propylene copolymers present are copolymers of propylene with halogen-free co-monomers.

Owner:TYCO ELECTRONICS (UK) LTD

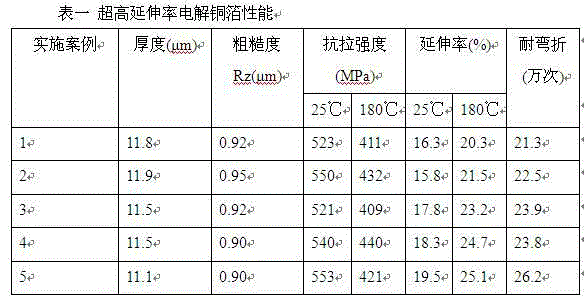

Compound additive for electrolytic copper foil

InactiveCN104651884AGood flexibilityImprove bending resistanceElectroforming processesSulfonateElectrolysis

Owner:雷磊

Radiation-resistant halogen-free flame-retardant cable material and preparation method thereof

InactiveCN103589076AConducive to subsequent molding processingImprove flame retardant performanceRubber insulatorsAluminium hydroxideQuinoline

The invention discloses a radiation-resistant halogen-free flame-retardant cable material and a preparation method thereof. The radiation-resistant halogen-free flame-retardant cable material is mainly prepared from the following components in parts by weight: 100 parts of EPDM (ethylene propylene diene monomer) rubber, 70-150 parts of metal hydroxide fire retardant, 5-15 parts of nanometer hydrotalcite, 2-10 parts of red phosphorus, 2-5 parts of surface treating agent, 4-8 parts of zinc oxide, 5-10 parts of boron nitride, 9-28 parts of macromolecular antiradiation agent, 0.5-2 parts of stearic acid, 0.5-3 parts of paraffin, 0.2-1.0 part of 2-mercapto benzimidazole, 3-6 parts of 1,1-di-tert-butyl peroxide-3,3,5-trimethyl cyclohexane, and 0.2-1.0 part of 2,2,4-trimethyl-1,2-dihydro quinoline. The radiation-resistant halogen-free flame-retardant cable material overcomes the defects such as poor radiation resistance and poor durability of the existing cable material; the nanometer hydrotalcite with aluminum hydroxide and magnesium hydroxide are integrated to serve as a composite flame retardant; the surface of the flame retardant is modified to promote the dispersibility in the cable material; the processability and the flame resistance of the cable material are improved.

Owner:JIANGSU UNIV +1

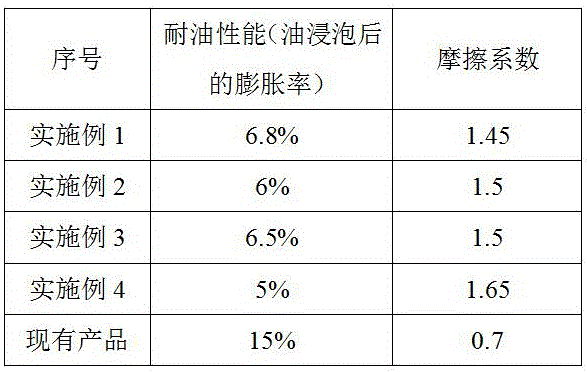

Oil-resistant and low-temperature-resistant material for shoe sole and method for preparing oil-resistant and low-temperature-resistant material

The invention discloses an oil-resistant and low-temperature-resistant material for shoe soles and a method for preparing the oil-resistant and low-temperature-resistant material. The oil-resistant and low-temperature-resistant material comprises, by weight, 60-80 parts of nitrile rubber, 40-50 parts of brominated butyl rubber, 5-8 parts of fluorine-based alkyl polyether-modified polysiloxane, 8-12 parts of zinc oxide, 20-25 parts of white carbon black, 3-5 parts of N, N'-bicyclo-caproyl-2-benzothiazole sulfonamide, 3-5 parts of tetramethyl thiuram disulfide, 2-4 parts of dioctyl phthalate, 6-12 parts of wood powder, 4-6 parts of 2-mercapto benzimidazole, 1-3 parts of sulfur, 1-3 parts of stearic acid and 1-2 parts of percarbamide. The oil-resistant and low-temperature-resistant material for the shoe soles and the method have the advantages that the oil-resistant and low-temperature-resistant material for the shoe soles is excellent in oil resistance, the oil resistance (the expansion rate of the oil-resistant and low-temperature-resistant material after the oil-resistant and low-temperature-resistant material is soaked in oil) can reach 5%-6.8%, the tensile strength of the oil-resistant and low-temperature-resistant material at the temperatures of minus 50 DEG C is 18-22 Mpa, the rebound rate of the oil-resistant and low-temperature-resistant material is 48-51%, the oil-resistant and low-temperature-resistant material is excellent in abrasion resistance, and a friction coefficient of the oil-resistant and low-temperature-resistant material is 1.45-1.65.

Owner:PUTIAN XIESHUN SHOES IND CO LTD

Method for suppressing discoloration over time of adhesive preparation containing donepezil

InactiveUS20100048628A1Sufficient effectImprove stabilityBiocideNervous disorderPropanoic acidDonepezil

[Object] Discoloration, over time, of a donepezil-containing adhesive preparation is suppressed.[Solution] At least one species of stabilizer selected from the group consisting of ascorbic acid, a metal salt or an ester thereof, isoascorbic acid or a metal salt thereof, ethylenediamine tetraacetic acid or a metal salt thereof, 2-mercaptobenzimidazole, 3(2)-t-butyl-4-hydroxyanisole, 2,6-di-t-butyl-4-methylphenol, tetrakis[3-(3′,5′-di-t-butyl-4′-hydroxyphenyl)propionic acid]pentaerythritol, (±)-α-tocopherol, (±)-α-tocopherol acetate, rutin, hypophosphorous acid, a metal metabisulfite salt and a metal salt of hydroxymethanesulfinic acid, is blended in a pressure-sensitive adhesive layer containing a pressure-sensitive adhesive and donepezil.

Owner:NITTO DENKO CORP +1

Oxido-reduction responsive metal gel and chitosan composite magnetic microsphere as well as preparation method and application thereof

InactiveCN104353428AGood redox propertiesEfficient regenerationOther chemical processesWater contaminantsMicrosphereMagnetite Nanoparticles

The invention relates to a Cu(I) metal gel and chitosan composite magnetic microsphere adsorption agent with good acid resistance and oxido-reduction responsiveness as well as a preparation method and application of the adsorption agent. The method comprises the following steps: (1), preparing Cu(I)-2-mercapto benzimidazole (Cu(I)-2-MBIm) metal gel powder; (2), preparing single-coated magnetic SiO2 nano-particles; (3), preparing the magnetic SiO2 nano-particle and Cu(I)-2-MBIm gel powder coated chitosan microsphere. The preparation method provided by the invention is simple in process and mild in condition and is very suitable for large-scale commercialized production; besides, prepared magnetic composite not only has good acid resistance. but also has good detoxicating and removing property to Cr(VI) ions; the used adsorption agent can be effectively regenerated by an ascorbic acid solution very easily.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Latex film compound with improved tear resistance

InactiveUS20030088002A1Good effectDeterioration of propertyGranular deliverySolid ballsPolymer scienceAntioxidant

The invention relates to a method of enhancing the tear resistance, tensile strength, and the aging properties of a latex product by adding an antioxidant synergist with an antioxidant to a latex compound comprising of a polymer, a stabilizing system, a film surface conditioner and a curing system comprised of an activator, crosslinker and accelerator and to the latex products formed therefrom. Antioxidant synergists which can be used with the present invention include 2-mercaptobenzimidazole (MBI), 2-mercaptotoluimidazole (MTI), zinc 2-mercaptobenzimidazole (ZMBI) and zinc 2-mercaptotoluimidazole (ZMTI). The latex products formed may be gloves but can also include threads, balloons and other latex-related products.

Owner:VANDERBILT CHEM LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com