Citrate-tartrate dual-complexing non-cyanide alkaline copper-plating electrolyte on steel substrate

A technology of citrate and tartrate, which is applied in the field of cyanide-free copper plating, can solve the problems of short plating time, high chemical oxygen consumption, and narrow current density, and achieves convenient control, simple process operation, and wide working current density range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Prepare 250ml containing copper sulfate 30 g / L, sodium citrate 147 g / L, potassium sodium tartrate 45 g / L, potassium nitrate 8 g / L, sodium bicarbonate 10 g / L, niacin 1 g / L, polyethylene glycol Electrolyte of amine 1 ml / L, polyethylene glycol 0.1 g / L, 2-mercaptobenzimidazole 1.2 mg / L: weigh 7.5 g of copper sulfate, 36.75 g of sodium citrate, 11.25 g of potassium sodium tartrate, and potassium nitrate Add 2g, 2.5g of sodium bicarbonate, 0.25g of niacin, 0.25ml of polyethyleneimine, 0.0250g of polyethylene glycol, and 0.3mg of 2-mercaptobenzimidazole into 160ml of tap water, stir to dissolve, and adjust the pH value to 7-8 , and then add tap water until the volume of the solution is 250ml, and adjust the pH value to 9. The electrolyte solution was heated to 50°C for later use.

[0054] Preparation of chemical degreasing liquid: prepare sodium hydroxide 20-40g / L, sodium carbonate 20-30 g / L, trisodium phosphate 5-10g / L, sodium silicate 5-15 g / L, OP emulsification according t...

Embodiment 2

[0059] According to the method described in Example 1, 250ml of copper sulfate 30 g / L, sodium citrate 147 g / L, potassium sodium tartrate 45 g / L, potassium nitrate 8 g / L, sodium bicarbonate 10 g / L, tobacco An electrolyte solution of 1 g / L acid, 1 ml / L polyethyleneimine, 0.2 g / L polyethylene glycol, and 0.9 mg / L 2-mercaptobenzimidazole was preheated to 50°C.

[0060] According to the scheme of Example 1, after the steel test piece is pickled, degreased and washed with water, it is placed in the Hull cell equipped with the above electrolyte, and the cathode current density is set to be 4A / dm 2 , under bubbling and stirring, electroplating for 10 minutes, using a scanning electron microscope to observe the microscopic morphology of the coating, the copper crystals are relatively uniform in size, and the distribution in rows is relatively uniform, see Image 6 .

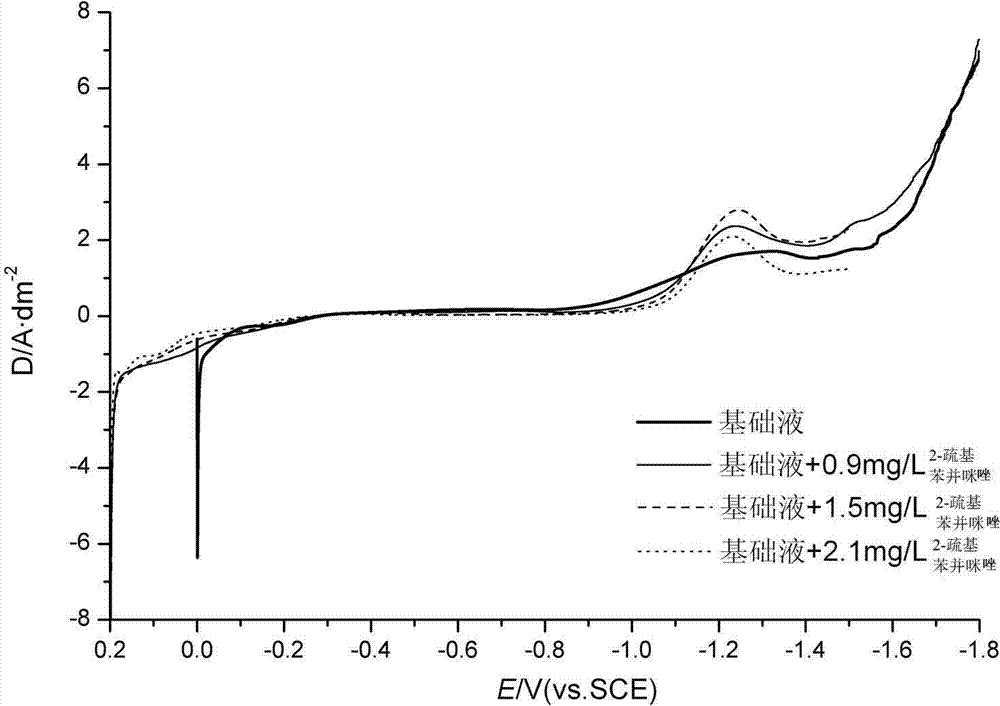

[0061] In this embodiment, the content of other components in the electrolyte is kept constant, the content of 2-merc...

Embodiment 3

[0063] According to the method described in Example 1, 250ml of copper sulfate 30 g / L, sodium citrate 147 g / L, potassium sodium tartrate 45 g / L, potassium nitrate 8 g / L, sodium bicarbonate 10 g / L, tobacco Electrolyte with 0.5 g / L acid, 1 ml / L polyethyleneimine, 0.2 g / L polyethylene glycol, and 1.2 mg / L 2-mercaptobenzimidazole, preheated to 50°C.

[0064] According to the scheme of Example 1, after the steel test piece is pickled, degreased and washed with water, it is placed in the Hull cell equipped with the above electrolyte, and the cathode current density is set to be 4A / dm 2 , under bubbling and stirring, electroplating for 10 minutes, using a scanning electron microscope to observe the microscopic morphology of the coating, the copper crystals are relatively uniform in size, and the distribution in rows is relatively uniform, see Figure 7 .

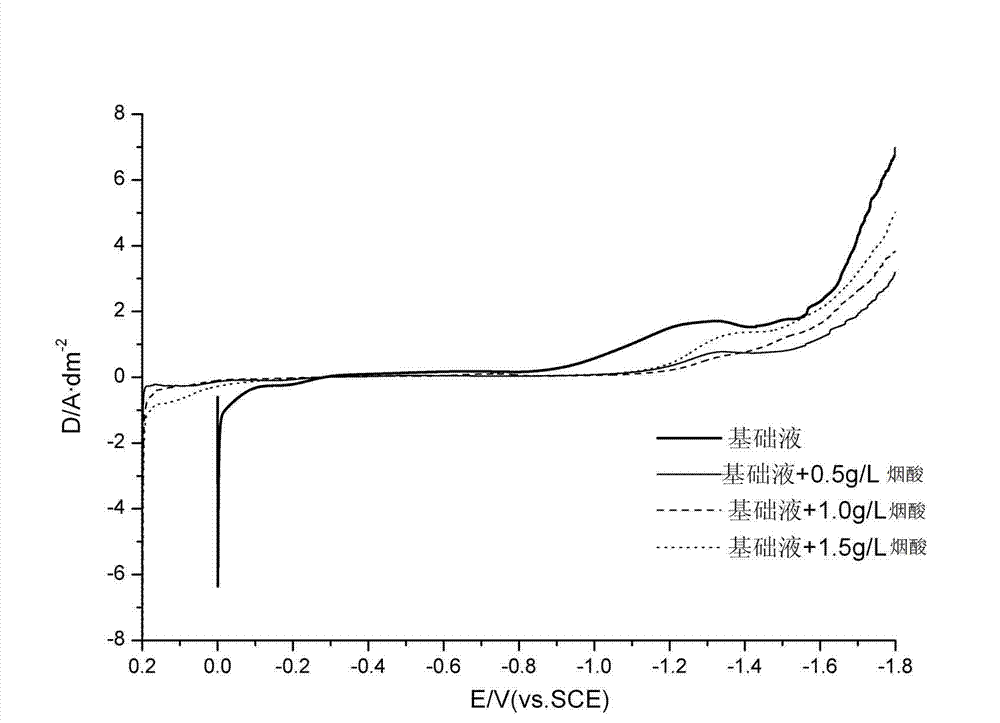

[0065] In this example, keep the content of other components in the electrolyte constant, adjust the content of nicotinic acid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com