Preparation method for high-temperature-resistant rubber material of automobile radiating pipeline

A heat dissipation pipeline and rubber material technology, which is applied in the field of rubber material preparation, can solve the problems of low high temperature resistance and achieve the effect of improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

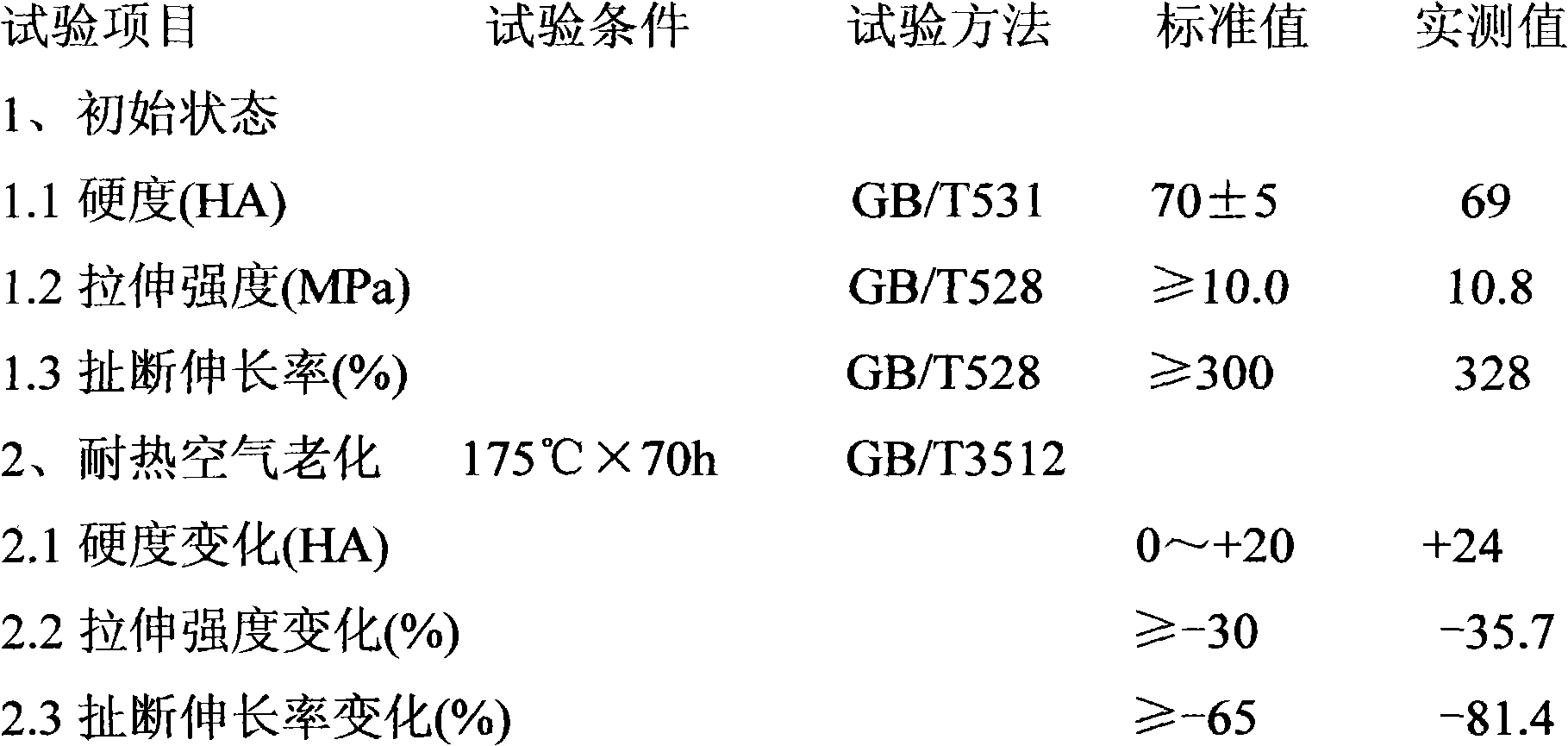

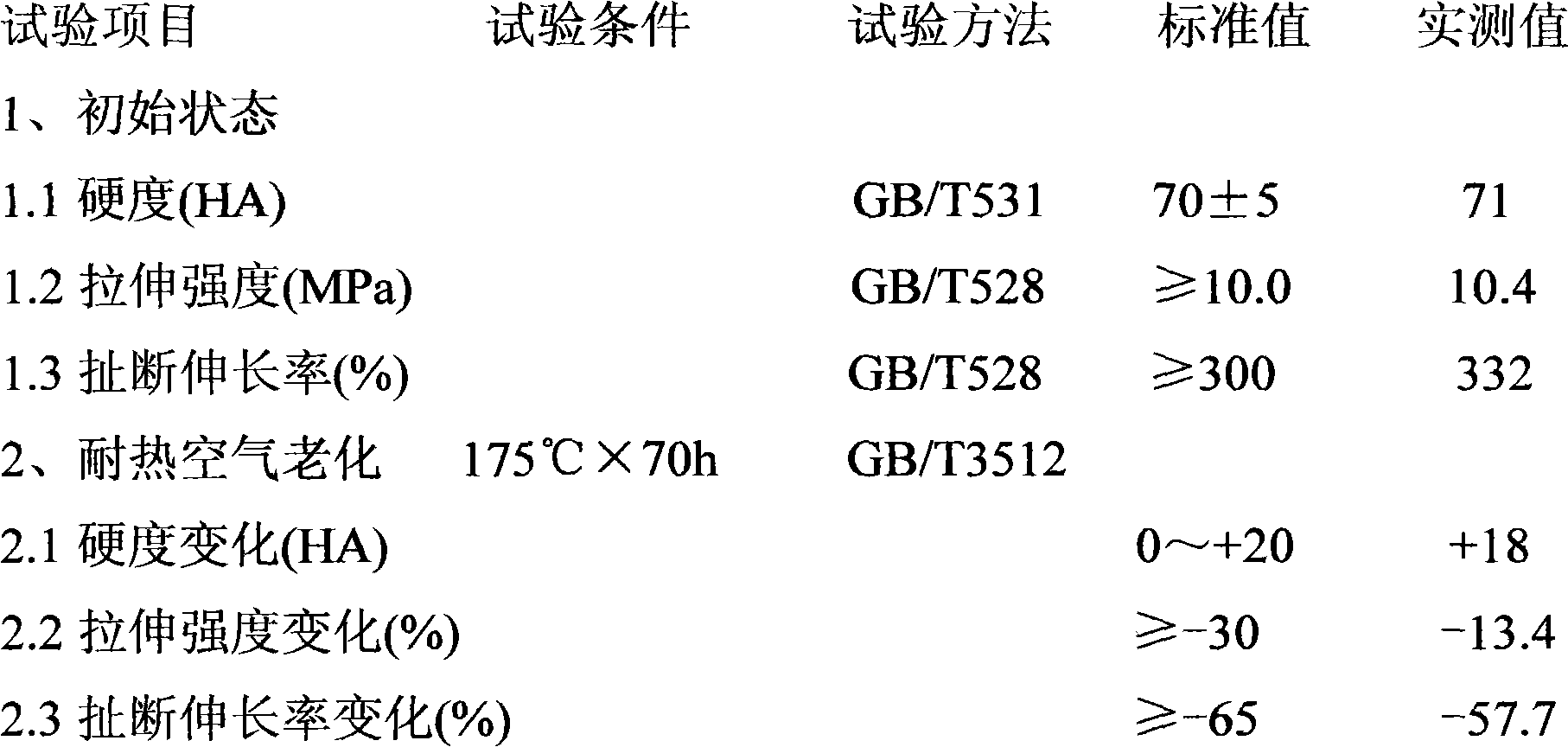

[0026] Product name: 175°C high-temperature resistant rubber material for automobile cooling pipes

[0027] Formula: formula unit is percentage by weight;

[0028] Rubber raw materials: EPDM rubber, 47.33%; chlorosulfonated polyethylene rubber, 4.73%;

[0029] Reinforcing agent: high wear-resistant furnace black, 14.20%; fast extrusion furnace black, 9.46%; white carbon black, 7.10%;

[0030] Plasticizer: paraffin oil, 2.37%;

[0031] Active agents: magnesium oxide, 9.47%; stearic acid, 0.47%;

[0032] Vulcanizing agent: dicumyl peroxide, 3.08%; N, N'-m-phenylene bismaleimide, 0.14%;

[0033] Antiaging agent: 2,2,4-trimethyl-1,2-dihydroquinoline polymer, 1.18%; 2-mercaptobenzimidazole, 0.47%;

[0034] preparation:

[0035] Preparation conditions, equipment

[0036] Ambient air pressure: one atmosphere;

[0037] Ambient temperature: room temperature;

[0038] Preparation equipment: open mill at 18 o'clock, 55L pressurized internal mixer;

[0039] Preparation process: m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com