Electroless copper plating solution

An electroless copper plating and solution technology, applied in liquid chemical plating, metal material coating process, coating, etc., can solve the problems of dim color, slow plating speed, stagnation and other problems of the plating layer, and achieve bright appearance and faster plating speed , Improve the effect of thickness

Inactive Publication Date: 2011-05-11

深圳市新合富力科技有限公司

View PDF0 Cites 33 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The coating color obtained by the existing electroless copper plating solution is dull, even without coating, and contains more cuprous oxide impurities, and the plating speed is extremely slow or even stagnant when the coating reaches 3-4 microns, and it is difficult to meet the requirements of the circuit board for the thickness of the coating. Require

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

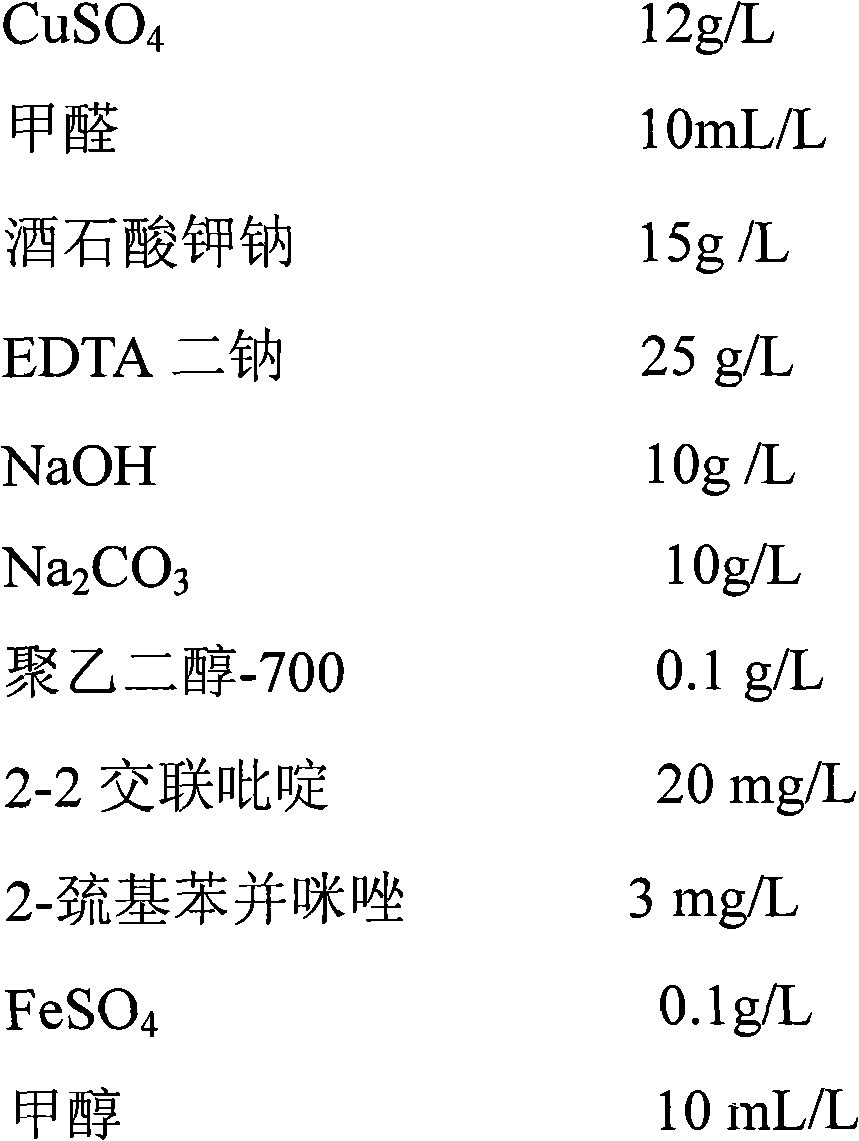

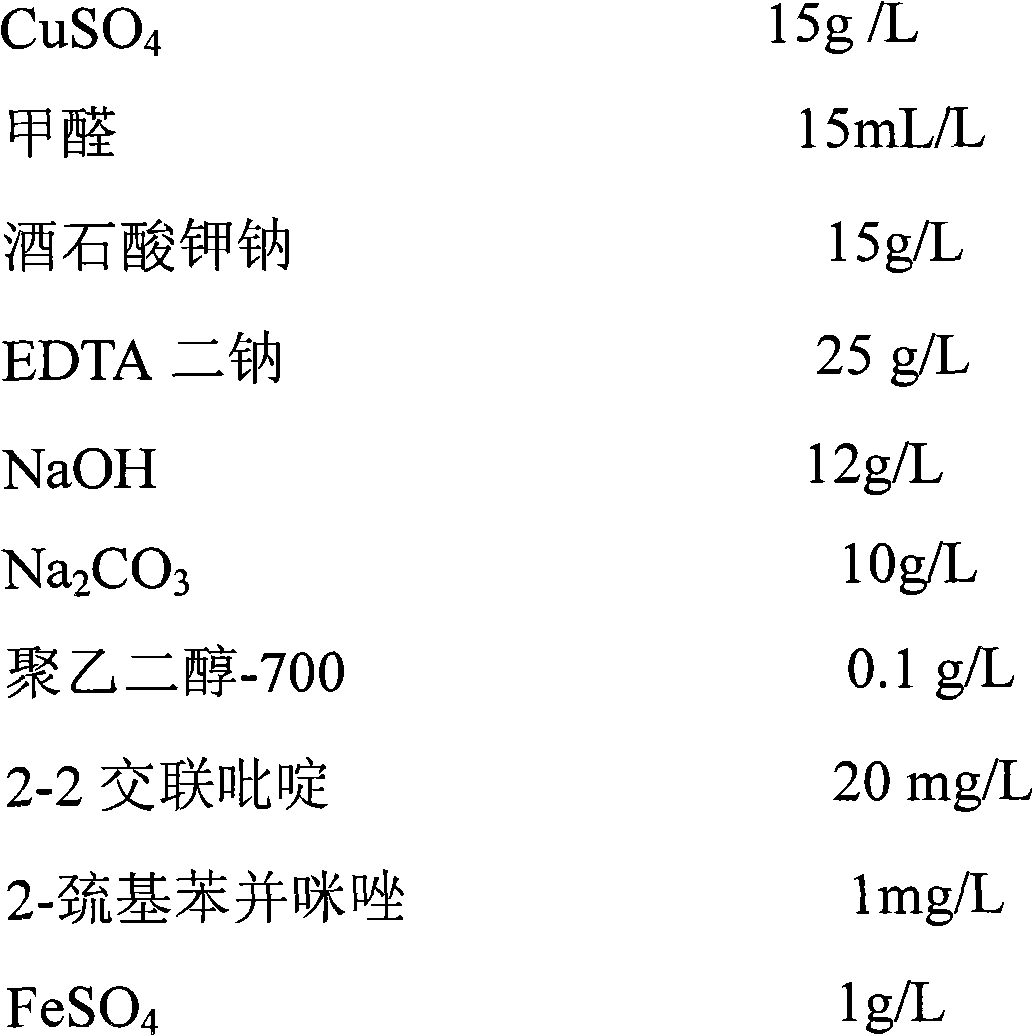

The invention belongs to the field of electroless copper plating, in particular to electroless copper plating solution. The electroless copper plating solution comprises the following components in concentration: 5 to 20 grams per liter of copper salt, 5 to 15 milliliters per liter of formaldehyde, 25 to 65 grams per liter of complexing agent, 8 to 20 grams per liter of pH regulator, 5 to 20 grams per liter of pH buffer, 0.05 to 1 gram per liter of polyethylene glycol, 10 to 60 milligrams of 2-2 cross-linked pyridinoline, 1 to 20 milligrams per liter of 2-mercapto benzimidazole, 0.05 to 1 gram per liter of ferrite and 5 to 50 milliliters per liter of methanol. The electroless copper plating solution provided by the invention is used in an electroless copper plating process for directly metalizing a circuit board, and the formed plating has a bright appearance color and a low impurity content. The thickness of the plating is improved greatly to over 20 micrometers. The electroless copper plating solution can accelerate plating speed to over 10 micrometers per hour.

Description

technical field [0001] The invention belongs to the field of electroless copper plating, in particular to an electroless copper plating solution. Background technique [0002] Electroless plating copper, commonly known as sinking copper. It is a self-catalyzed redox reaction. During the electroless copper plating process, Cu 2+ The ions get electrons and are reduced to metal copper, and the reducing agent releases electrons to be oxidized itself. [0003] Electroless copper plating has no external power supply, and there is no resistance drop loss during electrolysis. Therefore, electroless copper plating is a very energy-efficient and efficient copper deposition process. In addition, electroless copper plating can be deposited on any non-conductive substrate. Based on the above benefits, electroless copper plating has been widely used in the field of circuit board manufacturing. [0004] At present, the development trend of circuit board production is the electroless ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C23C18/40

Inventor 唐发德

Owner 深圳市新合富力科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com