Compound additive for electrolytic copper foil

A technology of compounding additives and electrolytic copper foil, which is applied in electrolytic process, electroforming, etc., and can solve the problems of lack of high-grade copper foil products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

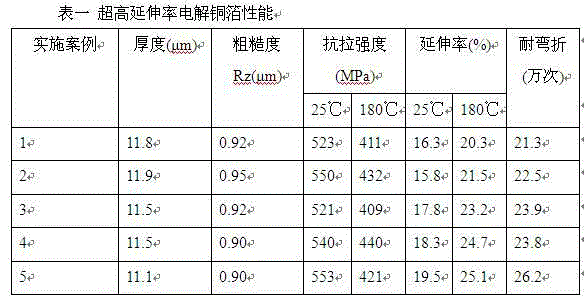

Embodiment example 1

[0017] Implementation case 1: A compound additive that can be used to manufacture ultra-high elongation electrolytic copper foil. Each liter of electrolytic copper foil electrolyte contains 20 mg of sodium polydisulfide dipropane sulfonate, 30 mg of triglycerin, and 5 mg of 2-mercaptobenzene And imidazole, 50mg hydrolyzed gelatin, 5mg rare earth sulfate.

Embodiment example 2

[0018] Example 2: A compound additive that can be used to manufacture ultra-high elongation electrolytic copper foil. Each liter of electrolytic copper foil electrolyte contains 20 mg sodium polydisulfide dipropane sulfonate, 50 mg triglycerin, and 5 mg 2-mercaptobenzene And imidazole, 50mg hydrolyzed gelatin, 5mg rare earth sulfate.

Embodiment example 3

[0019] Example 3: A compound additive that can be used to manufacture ultra-high elongation electrolytic copper foil, containing 20 mg sodium polydithiodipropane sulfonate, 75 mg triglycerin, and 5 mg 2-mercaptobenzene per liter of electrolytic copper foil electrolyte And imidazole, 50mg hydrolyzed gelatin, 2mg rare earth sulfate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com