Oil-resistant and low-temperature-resistant material for shoe sole and method for preparing oil-resistant and low-temperature-resistant material

A technology for anti-low temperature and shoe soles, applied in shoe soles, applications, footwear, etc., can solve the problems of nitrile rubber such as poor low temperature resistance, poor insulation performance, and poor ozone resistance, and achieve enhanced oil resistance, low cost, and wear resistance The effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

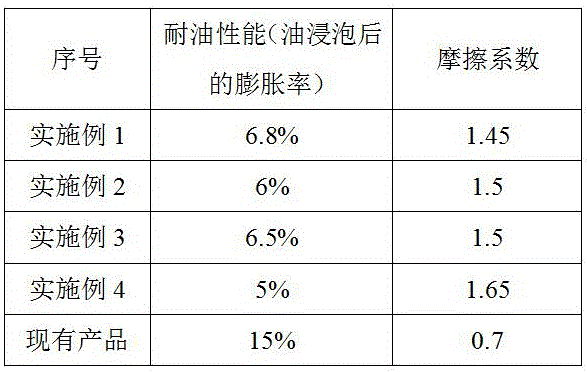

Examples

Embodiment 1

[0046] An oil-resistant and low-temperature-resistant material for shoe soles, the raw materials of which are composed of:

[0047] Nitrile rubber: 60 parts;

[0048] Bromobutyl rubber: 40 parts;

[0049] Fluoroalkyl polyether modified polysiloxane: 5 parts;

[0051] White carbon black: 20 parts;

[0052] N,N'-dicyclohexyl-2-benzothiazole sulfenamide: 3 parts;

[0053] Tetramethylthiuram disulfide: 3 parts;

[0054] Dioctyl phthalate: 2 parts;

[0055] Wood flour: 6 parts;

[0056] 2-Mercaptobenzimidazole: 4 parts;

[0057] Sulfur: 1 part;

[0058] Stearic acid: 1 part;

[0059] Percarbamide: 1 part.

[0060] The content of acrylonitrile in the nitrile rubber is 40wt%.

[0061] The preparation method of the oil-resistant and low-temperature-resistant material for shoe soles comprises the following steps:

[0062] (1) Internal mixing: put nitrile rubber, bromobutyl rubber and percarbamide together into the internal mixing chamber for in...

Embodiment 2

[0067] An oil-resistant and low-temperature-resistant material for shoe soles, the raw materials of which are composed of:

[0068] Nitrile rubber: 80 parts;

[0069] Bromobutyl rubber: 50 parts;

[0070] Fluoroalkyl polyether modified polysiloxane: 8 parts;

[0072] White carbon black: 25 parts;

[0073] N,N'-dicyclohexyl-2-benzothiazole sulfenamide: 5 parts;

[0074] Tetramethylthiuram disulfide: 5 parts;

[0075] Dioctyl phthalate: 4 parts;

[0076] Wood flour: 12 parts;

[0077] 2-mercaptobenzimidazole: 6 parts;

[0078] Sulfur: 3 parts;

[0079] Stearic acid: 3 parts;

[0080] Percarbamide: 2 parts.

[0081] The content of acrylonitrile in the nitrile rubber is 42wt%.

[0082] The preparation method of the oil-resistant and low-temperature-resistant material for shoe soles comprises the following steps:

[0083] (1) Internal mixing: put nitrile rubber, bromobutyl rubber and percarbamide together into the internal mixing chamber for...

Embodiment 3

[0088] An oil-resistant and low-temperature-resistant material for shoe soles, the raw materials of which are composed of:

[0089] Nitrile rubber: 70 parts;

[0090] Bromobutyl rubber: 45 parts;

[0091] Fluoroalkyl polyether modified polysiloxane: 7 parts;

[0092] Zinc oxide: 10 parts;

[0093] White carbon black: 23 parts;

[0094] N,N'-dicyclohexyl-2-benzothiazole sulfenamide: 4 parts;

[0095] Tetramethylthiuram disulfide: 4 parts;

[0096] Dioctyl phthalate: 3 parts;

[0097] Wood flour: 8 parts;

[0098] 2-mercaptobenzimidazole: 5 parts;

[0099] Sulfur: 2 parts;

[0100] Stearic acid: 2 parts;

[0101] Percarbamide: 1.5.

[0102] The content of acrylonitrile in the nitrile rubber is 41wt%.

[0103] The preparation method of the oil-resistant and low-temperature-resistant material for shoe soles comprises the following steps:

[0104] (1) Internal mixing: Put nitrile rubber, bromobutyl rubber and percarbamide together into the internal mixing chamber for in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic recovery rate | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com