Mixing mode expanded adsorbent bed medium and method for producing the same

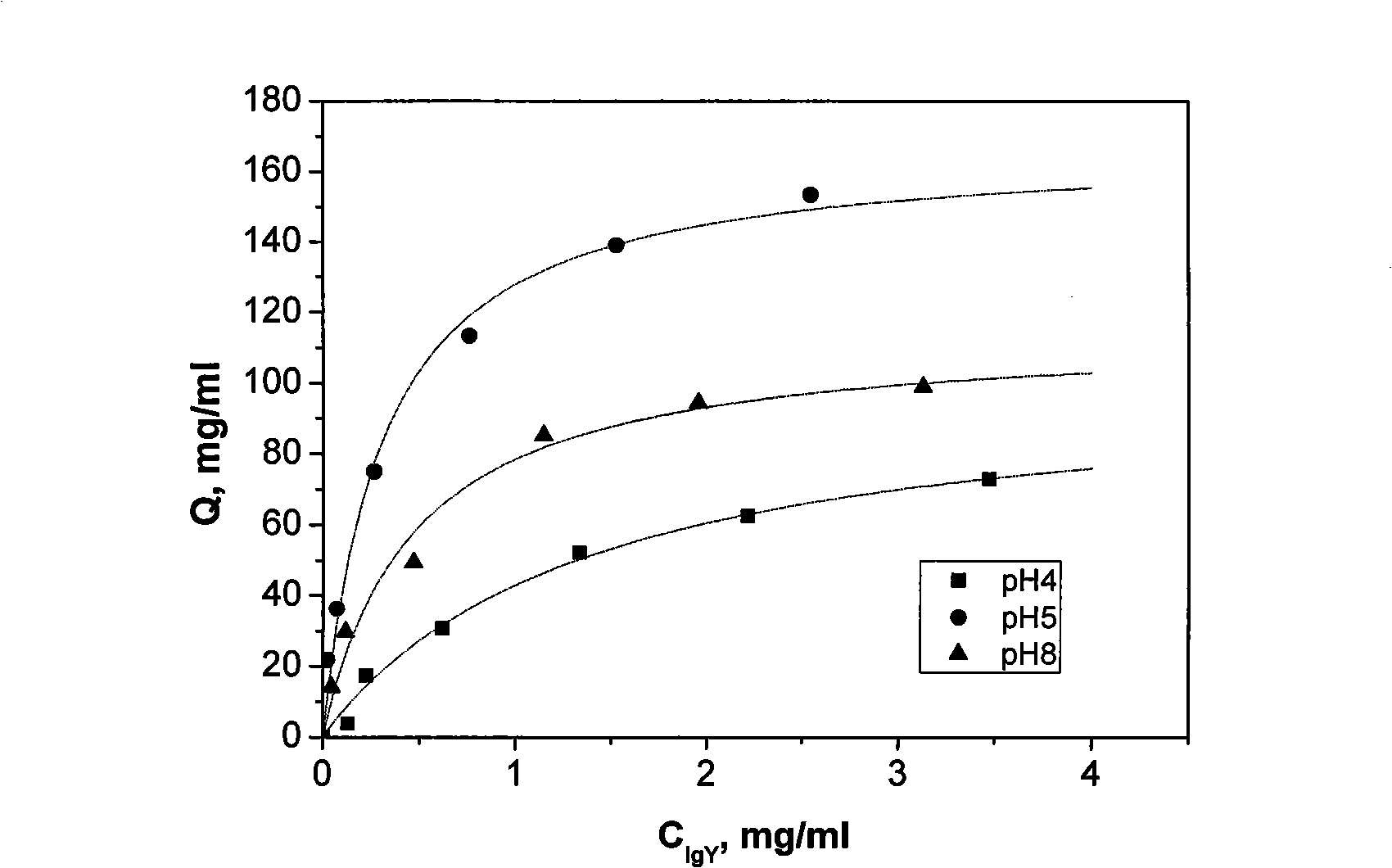

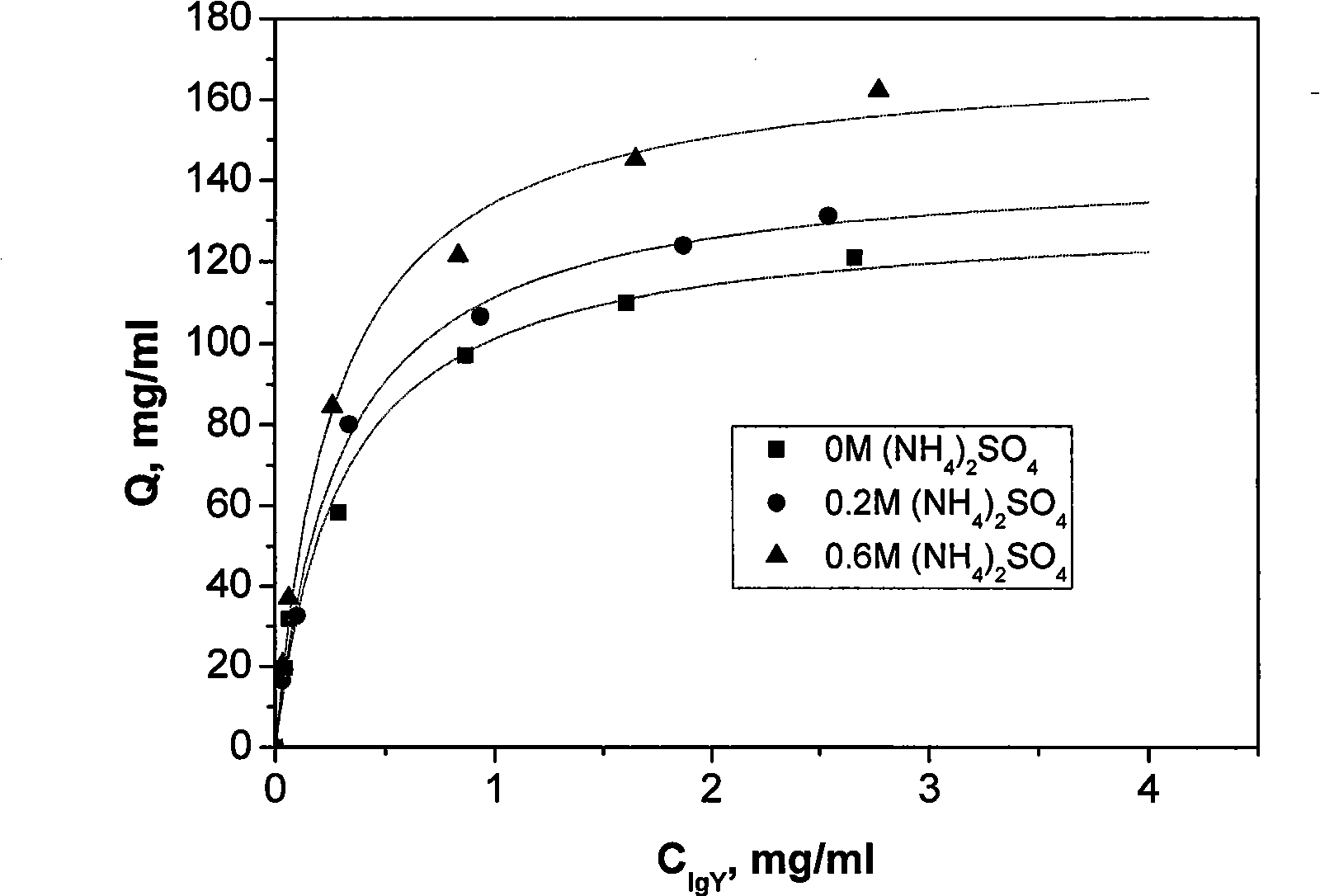

A technology of mixed mode and adsorption medium, which is applied in the field of expanded bed adsorption and separation of proteins in chromatographic separation, to achieve the effect of large adsorption capacity, high selectivity, and efficient separation and purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

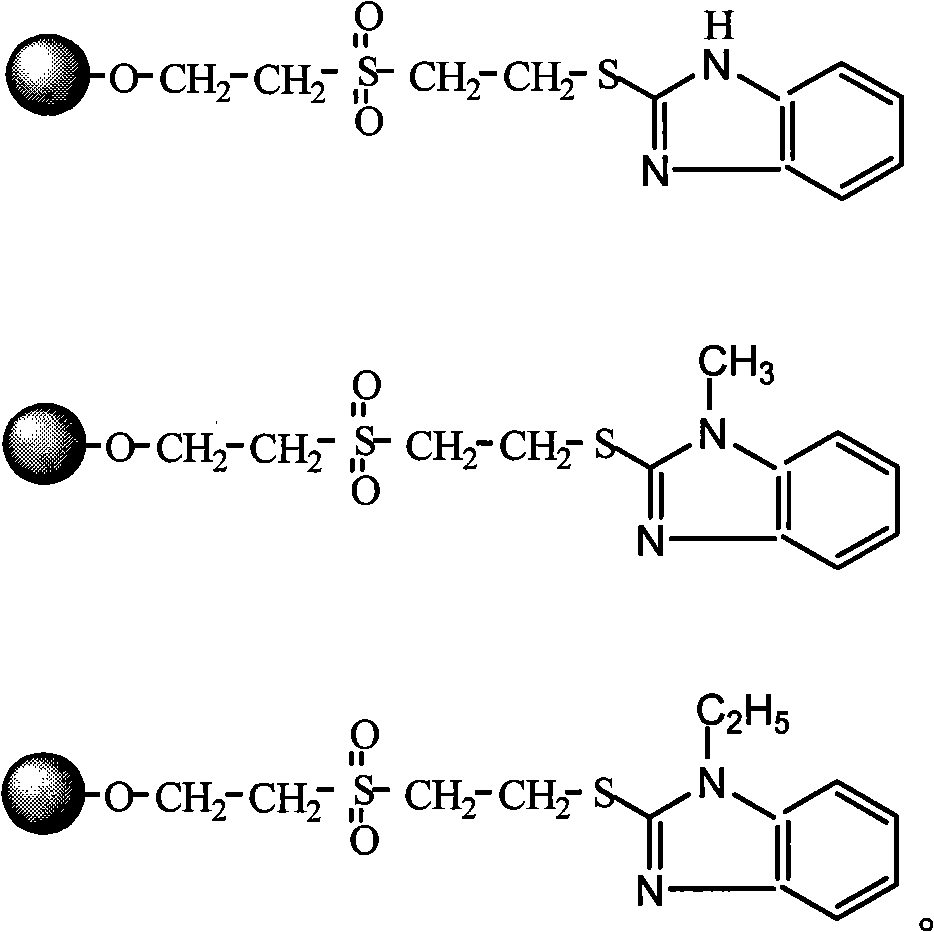

Embodiment 1

[0016] Stir 50g of cellulose viscose and 40g of tungsten carbide powder in a 500ml round-bottomed flask at 300rpm, add 300g of pump oil, rotate at 700rpm, inversely suspend and regenerate to make balls, wash with boiling water and deionized water for 3 to 5 times, Screen cellulose / inorganic weighting agent composite microspheres with a particle size of 50-250 μm as the matrix; 10ml of drained composite microspheres, 3.6ml of divinyl sulfone, 9ml of 0.25M pH12 sodium carbonate buffer and 1.5ml of bismuth Methyl sulfoxide was added into the Erlenmeyer flask, activated in a shaker at 180 rpm at 25°C for 4 hours, the mixed solution was removed by suction filtration, washed with deionized water, and sucked dry. Add 2-mercaptobenzimidazole with 3 times the molar amount of double bonds and 10ml of 0.5M sodium hydroxide solution containing 25mg / ml ammonium persulfate, perform coupling reaction in a shaker at 180rpm at 60°C for 8 hours, and remove the mixed solution by suction filtratio...

Embodiment 2

[0018] Stir 50g of cellulose viscose and 40g of tungsten carbide powder in a 500ml round-bottomed flask at 300rpm, add 300g of pump oil, rotate at 700rpm, inversely suspend and regenerate to make balls, wash with boiling water and deionized water for 3 to 5 times, Screen cellulose / inorganic weighting agent composite microspheres with a particle size of 50-250 μm as the matrix; 10ml of drained composite microspheres, 0.9ml of divinyl sulfone, 9ml of 0.5M pH12 sodium carbonate buffer and 1.5ml of bismuth Methyl sulfoxide was added into the Erlenmeyer flask, activated in a shaker at 180 rpm at 25°C for 4 hours, the mixed solution was removed by suction filtration, washed with deionized water, and sucked dry. Add 2-mercaptobenzimidazole with 3 times the molar amount of double bonds and 10ml of 0.7M sodium hydroxide solution containing 25mg / ml ammonium persulfate, perform coupling reaction in a shaker at 180rpm at 60°C for 8 hours, and remove the mixed solution by suction filtration...

Embodiment 3

[0020] Stir 50g of cellulose viscose and 80g of tungsten carbide powder in a 500ml round-bottomed flask at 300rpm, add 310g of pump oil, rotate at 800rpm, inversely suspend and thermally regenerate to make balls, wash with boiling water and deionized water for 3 to 5 times, Screen cellulose / inorganic weighting agent composite microspheres with a particle size of 50-250 μm as the matrix; 10ml of drained composite microspheres, 1.8ml of divinyl sulfone, 9ml of 0.1M pH12 sodium carbonate buffer and 1.5ml of bismuth Methyl sulfoxide was added into the Erlenmeyer flask, activated in a shaker at 180 rpm at 25°C for 4 hours, the mixed solution was removed by suction filtration, washed with deionized water, and sucked dry. Add 2-mercaptobenzimidazole with 3 times the molar amount of double bonds and 10ml of 0.2M sodium hydroxide solution containing 25mg / ml ammonium persulfate, perform coupling reaction in a shaker at 180rpm at 60°C for 8 hours, and remove the mixed solution by suction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturated adsorption capacity | aaaaa | aaaaa |

| Saturated adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com