Radiation-resistant halogen-free low smoke flame retardant insulating material for cables of nuclear power plants and preparation method

A nuclear power plant cable, low-smoke flame-retardant technology, applied to rubber insulators, organic insulators, etc., can solve the problem of rare production of containment cables, and achieve excellent radiation resistance, scientific and reasonable proportioning, and advanced technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

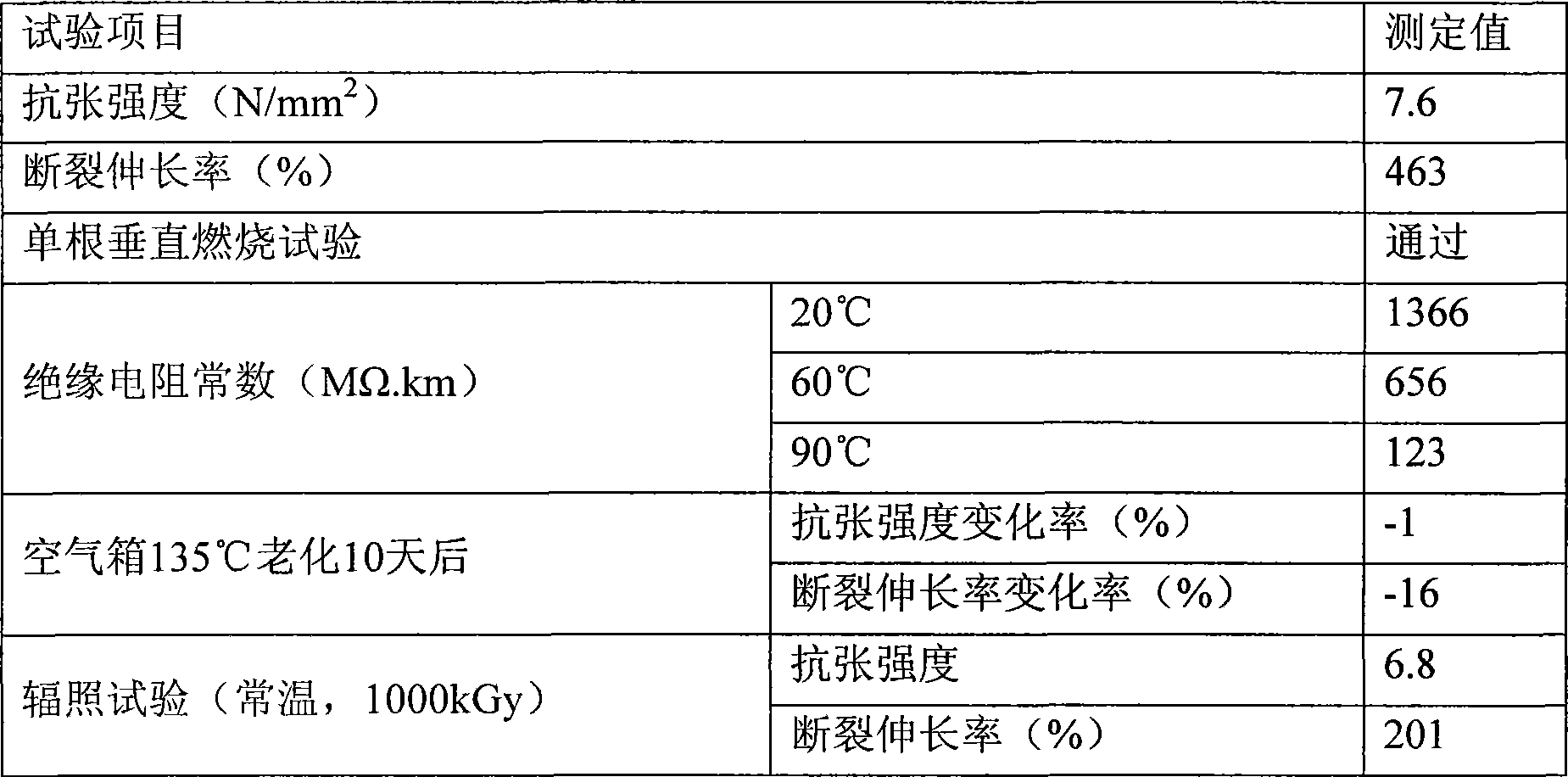

Examples

Embodiment 1

[0030] Insulation materials for radiation-resistant, halogen-free, low-smoke, flame-retardant cables for nuclear power plants. The raw materials include: a matrix composed of EPDM rubber-phenyl silicone rubber (60-40-100-0), magnesium hydroxide, hydroxide Flame retardant system composed of aluminum and zinc borate, reinforcing agent composed of white carbon black, anti-radiation agent composed of nano ceria and phenyl silicone rubber, bis-tert-butylperoxycumene, triallyl Vulcanization system composed of cyanurate and zinc oxide, protective system composed of 2-mercaptobenzimidazole and 2,2,4-trimethyl-1,2-dihydroquinoline, composed of vinyl tri(β - a coupling agent composed of methoxyethoxy) silane, a dispersion system composed of stearic acid and Rhine powder A-25, and a softening agent composed of paraffin oil. The raw materials of the above-mentioned cable insulation materials include the following components and contents (parts by weight):

[0031] EPDM 60~100

[0032] P...

Embodiment 2

[0049] The insulation material for radiation-resistant, halogen-free, low-smoke, flame-retardant cables for nuclear power plants includes the following components and contents (parts by weight):

[0050] EPDM 60

[0051] Phenyl silicone rubber 40

[0053] Aluminum hydroxide 100

[0054] Zinc borate 5

[0055] Silica 15

[0056] Ceria 5

[0058] Di-tert-butylperoxycumene 1

[0059] Triallyl cyanurate 5

[0060] 2-Mercaptobenzimidazole 1

[0061] 2,2,4-Trimethyl-1,2-dihydroquinoline 4

[0062] Rhine Powder A-25 1

[0063] stearic acid 3

[0064] Vinyltris(β-methoxyethoxy)silane 1

[0065] paraffin oil 5

[0066] First, raw materials other than magnesium hydroxide, aluminum hydroxide, vinyl tris(β-methoxyethoxy)silane, bis-tert-butylperoxycumene and paraffin oil are sent into the internal mixer according to the proportion, and mixed 2~4min, when the temperature rises to 85~95℃, add magnesium hydroxide, aluminum h...

Embodiment 3

[0068] The insulation material for radiation-resistant, halogen-free, low-smoke, flame-retardant cables for nuclear power plants includes the following components and contents (parts by weight):

[0069] EPDM 90

[0070] Phenyl silicone rubber 10

[0071] Magnesium Hydroxide 100

[0072] Aluminum hydroxide 50

[0073] Zinc borate 20

[0074] Silica 5

[0075] Ceria 20

[0076] Zinc oxide 8

[0077] Di-tert-butylperoxycumene 5

[0078] Triallyl cyanurate 1

[0079] 2-Mercaptobenzimidazole 4

[0080] 2,2,4-Trimethyl-1,2-dihydroquinoline 1

[0081] Rhine Powder A-25 5

[0082] stearic acid 1

[0083] Vinyltris(β-methoxyethoxy)silane 5

[0084] paraffin oil 15

[0085] First, raw materials other than magnesium hydroxide, aluminum hydroxide, vinyl tris(β-methoxyethoxy)silane, bis-tert-butylperoxycumene and paraffin oil are sent into the internal mixer according to the proportion, and mixed 2~4min, when the temperature rises to 85~95℃, add magnesium hydroxide, aluminum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com