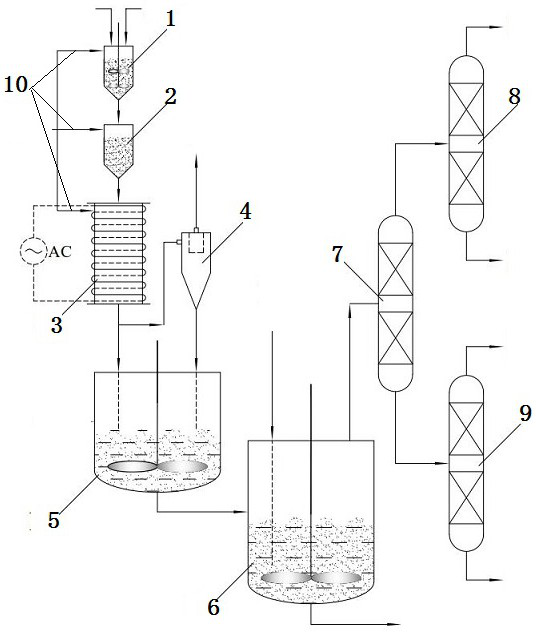

Method and reaction system for continuously producing disilane

A reaction system, the technology of disilane, applied in chemical instruments and methods, silicon hydride, silicon compounds, etc., can solve the problems of difficult to fully react powder, low production efficiency, hindered reaction, etc., to improve stability and safety, The effect of realizing continuous production and reducing overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031]An inductively coupled plasma generator with a power of 60kW is used as a thermal plasma generator, the system pressure is adjusted to 0.09MPa, the discharge gas is hydrogen, the feeding rate of silicon powder is 250 grams per hour, and the feeding rate of iron powder is 200 grams per hour. The feeding rate of magnesium powder is 85 grams per hour, the feeding rate of aluminum powder is 30 grams per hour, the feeding rate of strong acid hydrogen chloride is 2600 grams per hour, with ethylene glycol as solvent, the reaction temperature is 25 ℃, continuous reaction for 24 hours; after separation After the system is separated, the result is as follows:

[0032] Disilane output: 2122 grams; disilane mass yield: 31.9%

[0033] Monosilane output: 3446 grams; Monosilane mass yield: 50.3%

[0034] Trisilane output: 203 grams, trisilane mass yield: 3.1%

[0035] The total mass yield of silane: 85.3%.

Embodiment 2

[0037] An inductively coupled plasma generator with a power of 60kW is used as a thermal plasma generator, the system pressure is adjusted to 0.08MPa, the discharge gas is hydrogen with a volume fraction of 70% and argon with a volume fraction of 30%, and the feeding rate of silicon powder is 250 grams per hour. , the iron powder feeding rate is 250 grams per hour, the aluminum powder feeding rate is 15 grams per hour, the nickel powder feeding rate is 15 grams per hour, the strong acid hydrogen bromide feeding rate is 5700 grams per hour, with hydrazine as solvent, the reaction temperature 45°C, continuous reaction for 24 hours; after separation by the separation system, the results are as follows:

[0038] Disilane output: 2679 grams; disilane mass yield: 40.3%

[0039] Monosilane yield: 1857 grams; Monosilane mass yield: 27.1%

[0040] Trisilane output: 404 grams, trisilane mass yield: 6.1%

[0041] The total mass yield of silane: 73.5%.

Embodiment 3

[0043] An inductively coupled plasma generator with a power of 60kW is used as a thermal plasma generator, the system pressure is adjusted to 0.07MPa, the discharge gas is argon, the feeding rate of silicon powder is 250 grams per hour, and the feeding rate of iron powder is 250 grams per hour. , The feeding rate of magnesium powder is 15 grams per hour, the feeding rate of nickel powder is 15 grams per hour, the feeding rate of strong acid trichloroacetic acid is 11 kg per hour, with isobutanol as solvent, the reaction temperature is 50 ° C, continuous reaction for 24 hours ; After being separated by the separation system, the results are as follows:

[0044] Disilane output: 1686 grams; disilane mass yield: 25.4%

[0045] Monosilane yield: 2364 grams; Monosilane mass yield: 34.5%

[0046] Trisilane output: 629 grams, trisilane mass yield: 9.6%

[0047] The total mass yield of silane: 69.5%.

[0048] In the above examples, the process of using thermal plasma to assist the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com