Method for preparing 4-alkylphenol by self-forming hydrogenolysis of lignin or lignin oil

A technology of alkylphenol and lignin, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of difficult purification, high consumption of hydrogen or oxygen, and high production cost, and achieve low cost and dangerous The effect of small sex and increasing added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

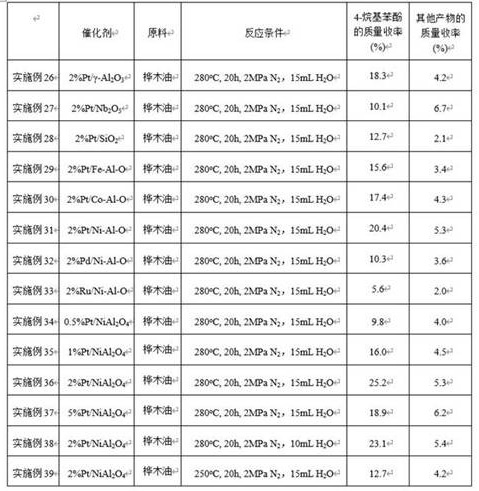

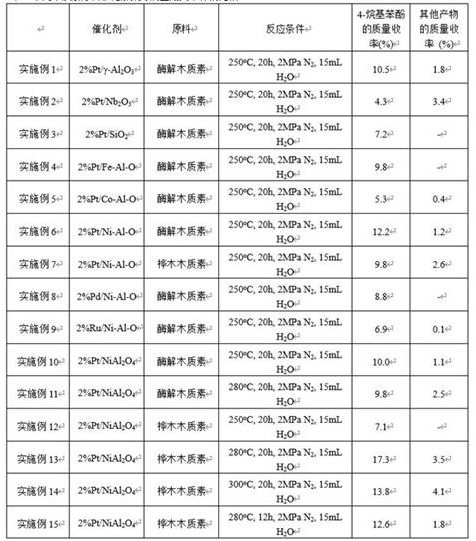

Examples

Embodiment Construction

[0020] specific implementation plan

[0021] Using lignin as raw material to prepare 4-alkylphenols includes the following process: self-reforming, depolymerization and upgrading of lignin under the action of a metal catalyst supported by a nickel-aluminum composite material to obtain 4-alkylphenols mixture.

[0022] The preparation of the nickel-aluminum composite material adopts the ammonia water co-precipitation method, specifically: 40mmol nickel nitrate hexahydrate and 80mmol aluminum nitrate nonahydrate are dissolved in 200mL deionized water and stirred thoroughly, and the ammonia solution is added dropwise to pH=9, and the stirring is continued for 2h, and then Aging at room temperature for 10h. Suction filtration and washing until the pH of the washing solution is 7, and the filter cake is placed in an oven at 100ºC to dry overnight. Finally, the catalyst precursor was placed in a muffle furnace at 450 o C under roasting 4h promptly obtains the nickel-aluminum compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com