Method for preparing levulinic acid and furfural by hydrolyzing biomass

A technology of levulinic acid and biomass, applied in chemical instruments and methods, preparation of organic compounds, preparation of carboxylate, etc., can solve the problems of many by-products, low yield, long reaction time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

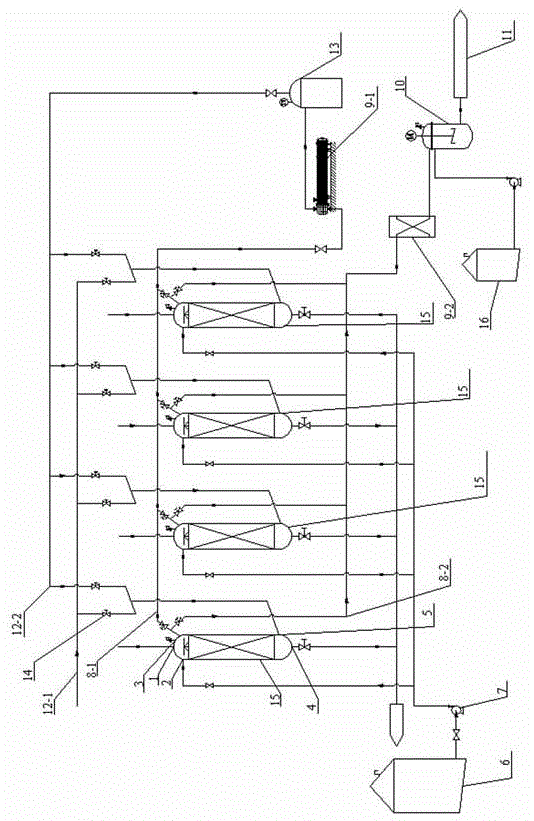

Image

Examples

Embodiment 1

[0032] A method for preparing levulinic acid and furfural by hydrolysis of biomass, comprising the following steps:

[0033] 1) After crushing 230kg of corn stalks with a moisture content of 11% (the main components are: 25% hemicellulose, 33% cellulose, and 16% lignin) into 15mm, fill it into the reactor, and add 170kg of catalyst (concentration 5% dilute sulfuric acid and 0.5% FeCl 3 ), at a speed of 0.6t / h, 170°C, 0.6MPa water vapor is introduced to undergo primary hydrolysis. When the temperature of the biomass and catalyst reaches 160°C, the gas phase of the primary hydrolysis is discharged until the primary hydrolysis is completed, and the gas phase of the primary hydrolysis passes through Condensation to obtain an aqueous solution containing furfural, the reaction time for a hydrolysis is 1h;

[0034] 2) Introduce steam at 210°C and 2.0MPa at a rate of 0.5t / h into the reactor after the primary hydrolysis in step 1) for secondary hydrolysis. When the biomass temperature...

Embodiment 2

[0043] A method for preparing levulinic acid and furfural by hydrolysis of biomass, comprising the following steps:

[0044] 1) After crushing 280kg corncobs with a moisture content of 7% (the main components are: 36% hemicellulose, 32% cellulose, and 15% lignin) into 20mm, fill it into the reactor, and add 190kg of catalyst (concentration: 3% dilute sulfuric acid and 0.3% FeCl 3 ), at a speed of 0.7t / h, 170°C, 0.6MPa water vapor is introduced to undergo primary hydrolysis. When the temperature of the biomass and catalyst reaches 160°C, the gas phase of the primary hydrolysis is discharged until the primary hydrolysis is completed, and the gas phase of the primary hydrolysis passes through Condensation to obtain an aqueous solution containing furfural, the reaction time for a hydrolysis is 1h;

[0045] 2) Introduce steam at 210°C and 2.0MPa at a rate of 0.56t / h into the reaction kettle after the primary hydrolysis in step 1) for secondary hydrolysis. When the biomass temperat...

Embodiment 3

[0052] A method for preparing levulinic acid and furfural by hydrolysis of biomass, comprising the following steps:

[0053] 1) After crushing 300kg of wood chips with a moisture content of 11% (the main components are: 50% hemicellulose, 30% cellulose, and 25% lignin) into 10mm, fill it into the reactor, and add 300kg of catalyst (concentration: 5% dilute sulfuric acid and 0.5% FeCl 3 ), at a speed of 0.8t / h, 180°C, 1MPa water vapor is introduced to undergo primary hydrolysis. When the temperature of the biomass and catalyst reaches 170°C, the gas phase of the primary hydrolysis is discharged until the primary hydrolysis is completed, and the gas phase of the primary hydrolysis is condensed To obtain an aqueous solution containing furfural, the reaction time for one hydrolysis is 1.1h;

[0054] 2) Introduce steam at 223°C and 2.5MPa at a rate of 0.6t / h into the reactor after the primary hydrolysis in step 1) for secondary hydrolysis. When the biomass temperature reaches 200°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com