A continuous reaction process and reactor for methanol conversion to produce hydrocarbon mixture

A hydrocarbon mixture and methanol conversion technology, applied in the direction of hydrocarbon production from oxygen-containing organic compounds, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of frequent reactor switching, deactivation, and carbon deposition of molecular sieve catalysts. Achieve the effect of avoiding the reduction of the yield of the target product, reducing the contact time, and avoiding the reduction of the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

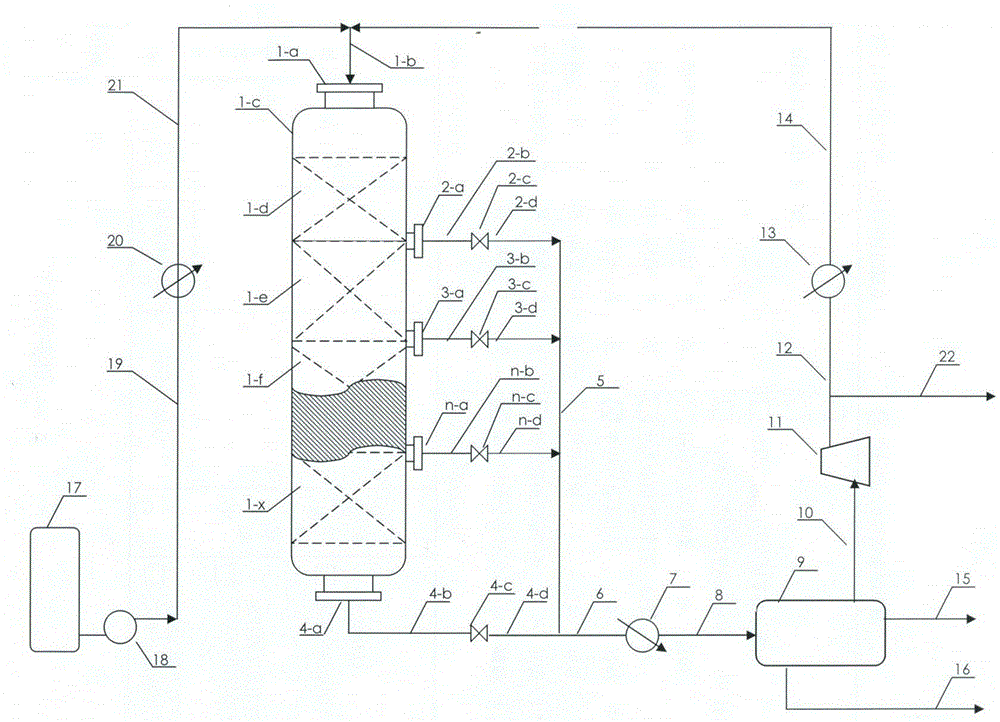

[0067] The technological process schematic diagram of embodiment 1 is with reference to appendix image 3 .

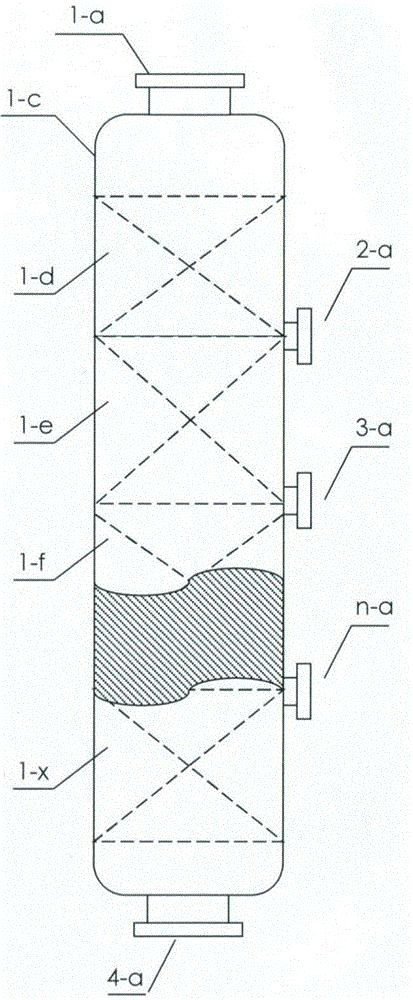

[0068] The fixed-bed adiabatic reactor is made of stainless steel with an inner diameter of 3600 mm. There is one nozzle on the top and bottom of the shell, and three nozzles on the side wall of the reactor shell. The catalyst bed in the reactor is virtually divided. The reactor is continuously filled with 93.17 tons of ZSM-5 molecular sieve catalyst, the total height of the catalyst bed is 14309mm, and the aspect ratio of the total catalyst bed is 3.97. The distance between the nozzles on the side wall of the reactor is 3577 mm, and the continuously loaded catalyst bed is equally divided into 4 catalyst sub-beds, the height of the sub-beds is 3577 mm, and the height-to-diameter ratio of the sub-beds is 0.99;

[0069] The inlet pressure of the fixed bed adiabatic reactor is 1.8MPa. Valve 2-c is open and valves 3-c, n-c, 4-c are closed. The system establishes nitrog...

Embodiment 2

[0097] Same as Example 1, using the same catalyst, but the catalyst loading increased by 25%, that is, the catalyst loading quality is 116.46 tons, the inner diameter of the fixed bed adiabatic reactor is 3600mm, the total catalyst bed height is 17887mm, and the total aspect ratio is 4.97. Three nozzles are arranged on the side wall of the reactor, and the distance between the nozzles is 4472 mm. The continuously loaded catalyst is divided into 4 catalyst sub-beds. The height of each sub-bed is 4472 mm, and the height-to-diameter ratio of the sub-beds is 1.24.

[0098] The operation method is the same as in Example 1, the operating pressure is 1.80MPa, the mass flow rate of methanol is 35.71t / h, and the mass space velocity of methanol relative to all catalysts is 0.31h -1 , relative to the mass space velocity of the catalyst sub-bed is 1.23h -1 , the standard volume flow rate of circulating gas is 180000Nm 3 / h, the volume circulation ratio is 7.2. The reactor inlet tempera...

Embodiment 3

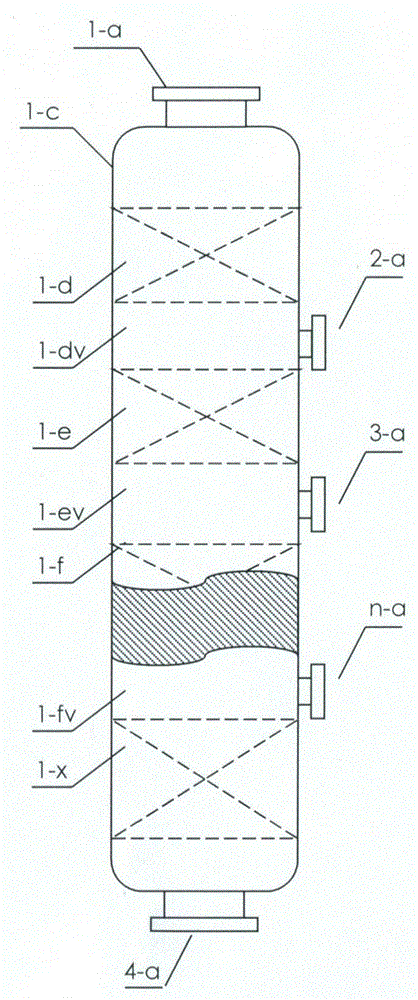

[0104] As in Example 1, the same catalyst is used, but the catalyst bed is actually divided. The fixed bed adiabatic reactor is made of stainless steel with an inner diameter of 3600mm. There are 1 nozzle on the top and bottom of the shell, 3 nozzles on the side wall of the reactor shell, and the reactor is installed at a position parallel to each nozzle. The grid used to carry the catalyst, the distance between the nozzles is 4577mm. When loading the catalyst, start loading from the bottom layer first, install the bottom grid first, lay wire mesh on the grid, and load 23.29 tons of catalyst. The actual filling height of the catalyst is 3577mm, and the thickness of the refilling on the catalyst is 200mm inert alumina pellets to compact the catalyst bed. After the alumina pellets are filled, install a layer of grid, and fill the catalyst and alumina pellets in the same way. A total of 4 layers of catalysts were loaded, with a total loading of 93.17 tons. The heights of the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com