2-chloropyridine synthetic method

A synthetic method, the technology of chloropyridine, applied in the direction of organic chemistry, etc., can solve the problems of reducing production costs, and achieve the effects of low cost, safe operation and mild reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

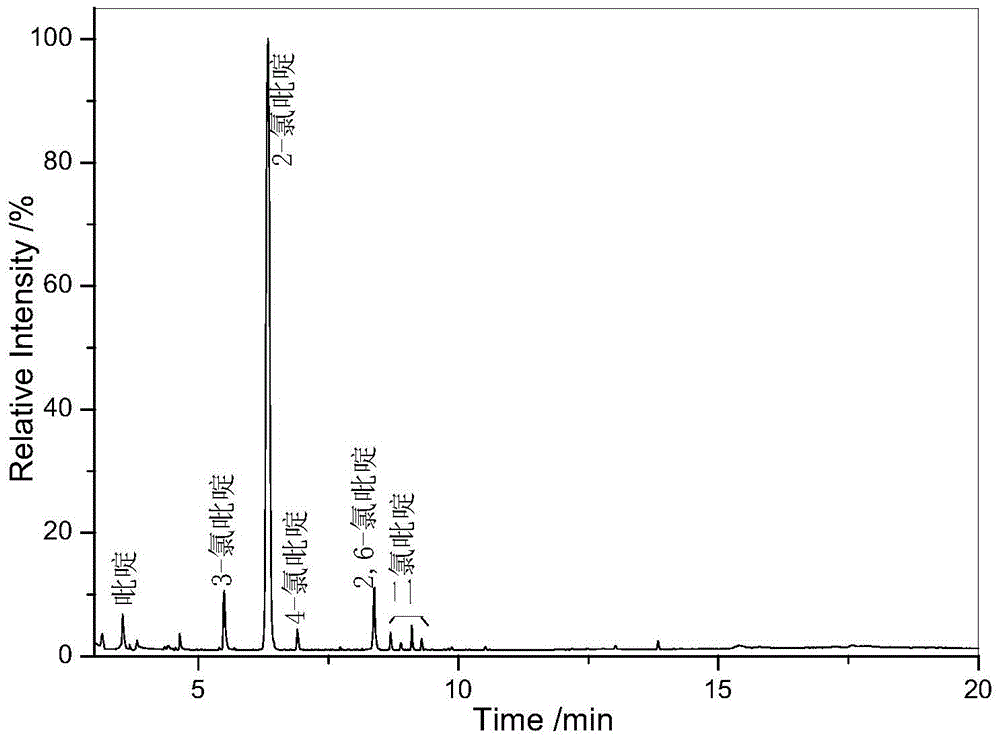

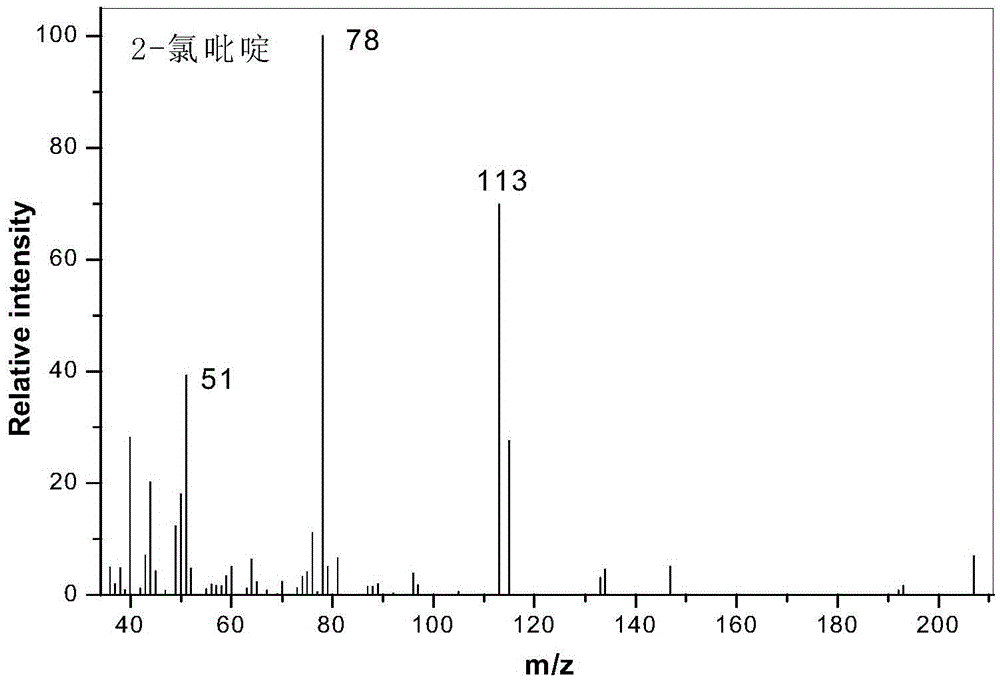

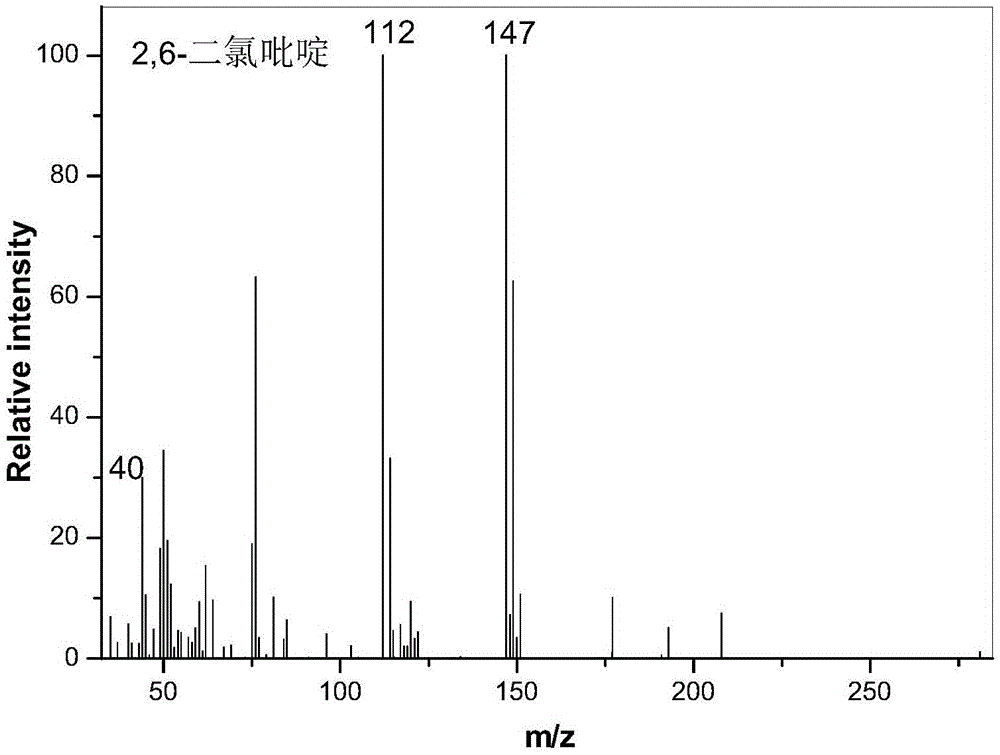

[0018] Add 120ml of sodium hypochlorite solution (13% available chlorine) into a 500mL flask, add 15g of pyridine under constant stirring, and mix well. 70ml of 20% hydrochloric acid was slowly added dropwise through the dropping funnel, and stirred at room temperature for 1h. Then, it was heated to 60°C and the reaction was continued for 2h. After the reaction is completed, a certain amount of NaOH solution is added to neutralize the pH to 9-11, and the reactant is extracted three times with 500 ml of chloroform. The obtained extract phase was distilled to remove the solvent chloroform sequentially, and unreacted pyridine (10.1 g) was recovered to finally obtain 6.9 g of chloropyridine product, and the mass yield of chloropyridine was 141%. The chloropyridine product is analyzed by GC-MS, mainly including 2-chloropyridine and a small amount of other dichloropyridines such as 2,6-dichloropyridine, 3-chloropyridine, 4-chloropyridine and 2,5-dichloropyridine . Among them, the...

Embodiment 2

[0020] Add 180ml of sodium hypochlorite solution (8% available chlorine) in a 500mL flask, add 15g of pyridine under constant stirring, and mix well. 80ml of 20% hydrochloric acid was slowly added dropwise through the dropping funnel, and stirred at room temperature for 2h. Then, it was heated to 80°C and the reaction was continued for 2h. After the reaction is completed, a certain amount of NaOH solution is added to neutralize the pH to 9-11, and the reactant is extracted three times with 500 ml of chloroform. The obtained extract phase was distilled to remove the solvent chloroform sequentially, and unreacted pyridine (10.3 g) was recovered to finally obtain 6.5 g of chloropyridine product, and the mass yield of chloropyridine was 138%. The chloropyridine product is analyzed by GC-MS, mainly including 2-chloropyridine and a small amount of other dichloropyridines such as 2,6-dichloropyridine, 3-chloropyridine, 4-chloropyridine and 2,5-dichloropyridine . Among them, the se...

Embodiment 3

[0022] Add 120ml of sodium hypochlorite solution (13% available chlorine) into a 500mL flask, add 15g of pyridine under constant stirring, and mix well. 60ml of 25% hydrochloric acid was slowly added dropwise through the dropping funnel, and stirred at room temperature for 1h. Then, it was heated to 60° C. and the reaction was continued for 1 h. After the reaction is completed, a certain amount of NaOH solution is added to neutralize the pH to 9-11, and the reactant is extracted three times with 500 ml of chloroform. The obtained extract phase was distilled to remove the solvent chloroform sequentially, and unreacted pyridine (10.8 g) was recovered to finally obtain 5.8 g of chloropyridine product, and the mass yield of chloropyridine was 138%. The chloropyridine product is analyzed by GC-MS, mainly including 2-chloropyridine and a small amount of other dichloropyridines such as 2,6-dichloropyridine, 3-chloropyridine, 4-chloropyridine and 2,5-dichloropyridine . Among them, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com