Combination process of residual oil hydrotreating and bright oil production

A combined process and residual oil hydrogenation technology, which is applied in the direction of hydrotreating process, hydrocarbon oil treatment products, hydrocarbon oil treatment, etc., can solve the problems of lower base oil yield, viscosity loss, restriction, etc., and achieve improved color and oxidation Stability, lower pour point, color improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

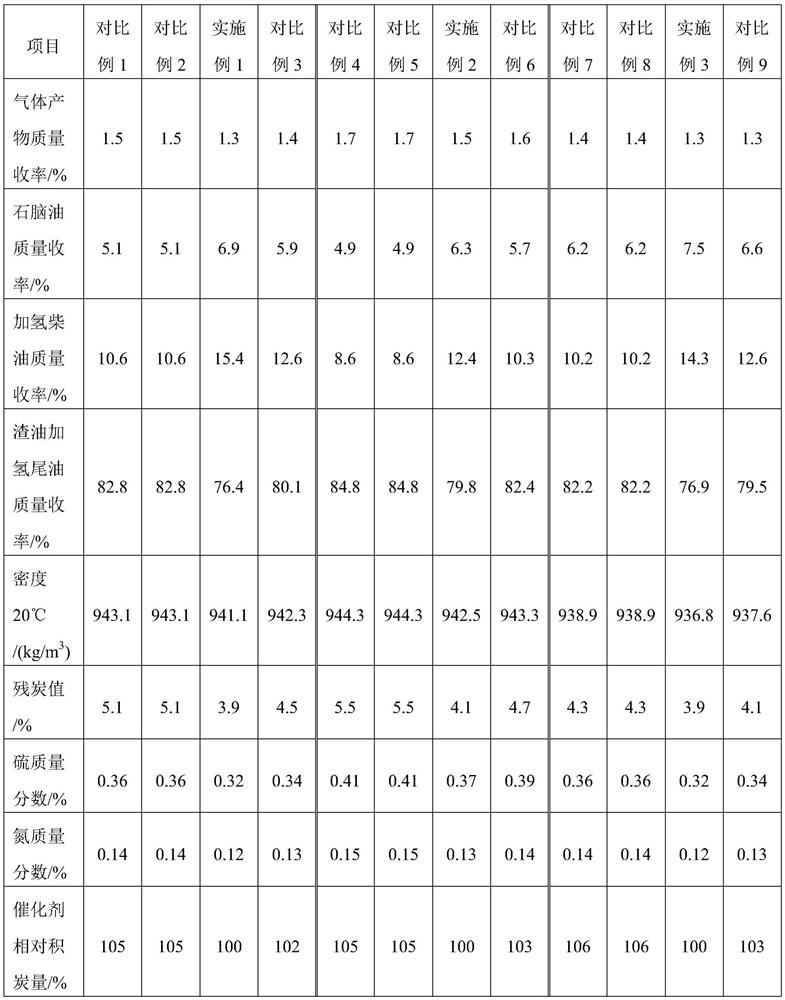

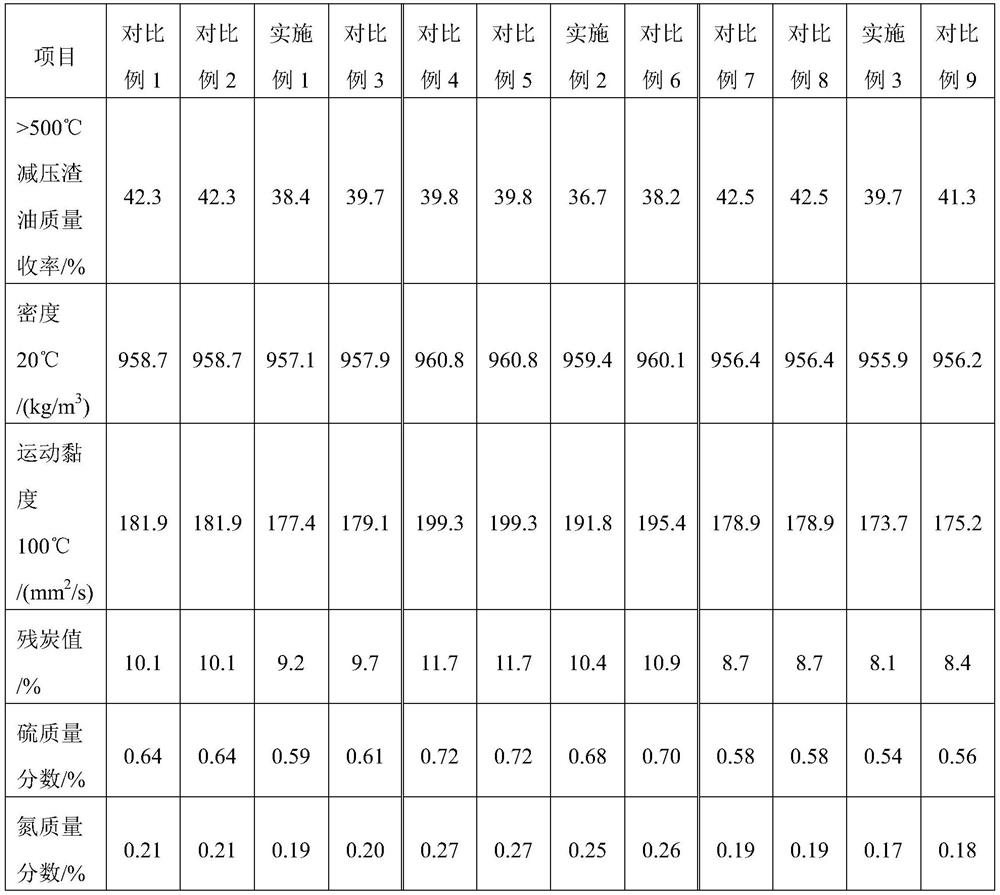

Embodiment 1

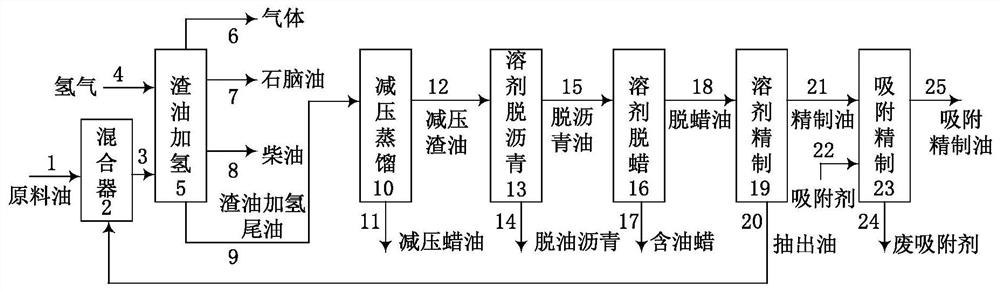

[0093] This example is used to illustrate the hydrogenation of residual oil and bright stock production method provided by the present invention.

[0094] Using the same raw materials and conditions as Comparative Example 1 to carry out residual oil hydrogenation and produce bright oil, the difference is that according to figure 1 The process of solvent deasphalting-solvent dewaxing-solvent refining-clay supplementary refining process is used to produce lubricating oil base oil, the mass ratio of solvent refining oil to oil is 5.5:1, the solvent dewaxing temperature is -24°C, and the pumping out of the solvent refining unit The oil is recycled back to the residual oil hydrogenation unit for use as co-solvent. The mass ratio of co-solvent to residual oil is 0.05:1, and the mass fraction of aromatic colloids in co-solvent is 67.4%.

[0095] At the initial stage of the test, pure residual oil was used for residual oil hydrogenation test, and the extracted oil was recycled to the...

Embodiment 2

[0113] This example is used to illustrate the hydrogenation of residual oil and bright stock production method provided by the present invention.

[0114] Using the same raw materials and conditions as Comparative Example 4 to carry out residual oil hydrogenation and produce bright oil, the difference is that according to figure 1 The process of solvent deasphalting-solvent dewaxing-solvent refining-clay supplementary refining process is used to produce lubricating oil base oil, the mass ratio of solvent refining oil to oil is 4.5:1, the temperature of solvent dewaxing is -27℃, and the extraction of solvent refining unit The oil is recycled back to the residual oil hydrogenation unit for use as co-solvent. The mass ratio of co-solvent to residual oil is 0.06:1, and the mass fraction of aromatic colloids in co-solvent is 84.8%.

[0115] At the initial stage of the test, pure residual oil was used for residual oil hydrogenation test, and the extracted oil was recycled to the re...

Embodiment 3

[0133] This example is used to illustrate the hydrogenation of residual oil and bright stock production method provided by the present invention.

[0134] Using the same raw materials and conditions as Comparative Example 7 to carry out residual oil hydrogenation and produce bright oil, the difference is that according to figure 1 The process of solvent deasphalting-solvent dewaxing-solvent refining-clay supplementary refining process is used to produce lubricating oil base oil, the mass ratio of solvent refining to oil is 2.5:1, the temperature of solvent dewaxing is -28℃, and the extraction of solvent refining unit The oil is recycled back to the residual oil hydrogenation unit for use as co-solvent. The mass ratio of co-solvent to residual oil is 0.03:1, and the mass fraction of aromatic colloids in co-solvent is 76.2%.

[0135]At the initial stage of the test, pure residual oil was used for residual oil hydrogenation test, and the extracted oil was recycled to the residua...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com