Method for preparing alkylphenol and alkyl diphenol from lignin oil

A technology for alkyl phenols and alkyl diphenols, which is applied in the field of preparation of alkyl phenols and alkyl diphenols from lignin oil, can solve the problems of product added value reduction, product quality yield reduction, product quality yield reduction, etc., and achieve Cost-saving, wide-ranging sources, and low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

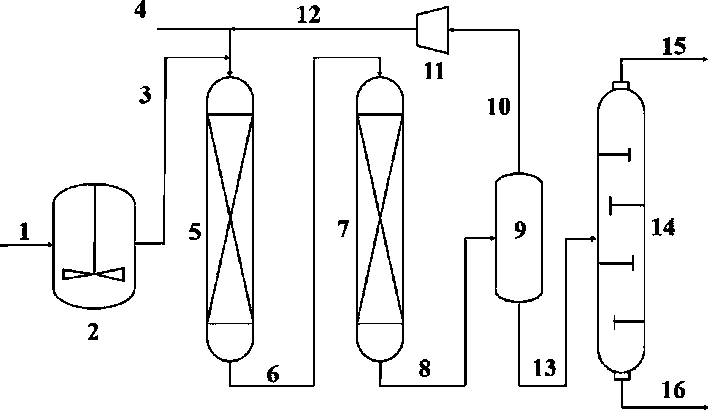

Image

Examples

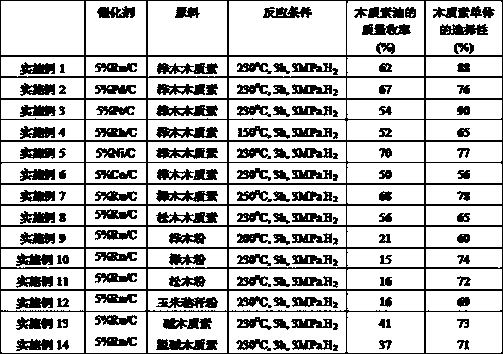

Embodiment 1-14

[0025] The preparation steps of lignin oil are as follows: In a 50mL small autoclave, add 0.1g of metal catalyst supported by activated carbon, 1.0g of lignin or lignin-containing biomass raw material and 20mL of methanol, under hydrogen partial pressure of 2.5~3.5MPa, temperature for 150 o C~250 o C under the condition of reaction for 2 to 5 hours. The product was rotary evaporated to remove the methanol solvent to obtain lignin oil and its components were analyzed. The reaction product was qualitatively analyzed by gas chromatography-mass chromatography (GC-MS Agilent 7890A-5975C) and quantitatively analyzed by gas chromatography (GC Agilent 7890A). HP-5 chromatographic column was used, and the temperature program temperature condition of the chromatographic column was: 50 o C maintain 10mins, with 10 o C / min heating rate increased to 250 o C, and at 250 o C maintained for 5mins.

[0026] Wherein, the calculation formula of yield is: mass yield of lignin oil=(quality o...

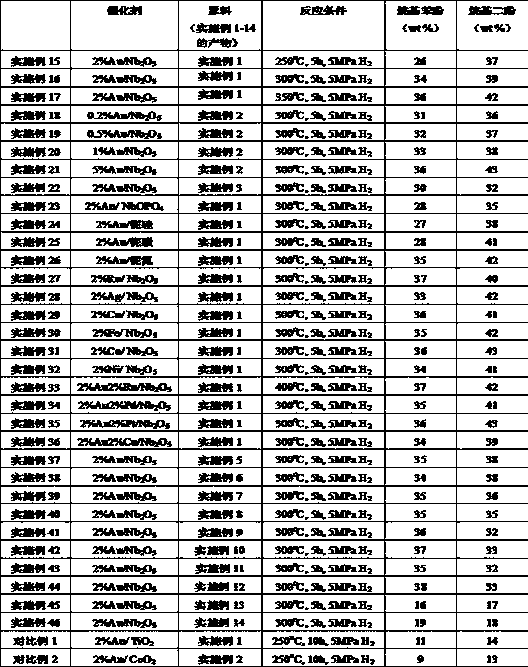

Embodiment 15-46

[0033] The steps of the batch reactor are as follows: 0.1g lignin oil (the product of Example 1-14), 0.05g catalyst and 20mL deionized water are added to a 50mL batch reactor, and the hydrogen partial pressure is 4~6MPa, the temperature for 250 o C~400 o C under the conditions of reaction for 5 to 10 hours. The reaction product was qualitatively analyzed by gas chromatography-mass chromatography (GC-MS Agilent 7890A-5975C) and quantitatively analyzed by gas chromatography (GC Agilent 7890A). HP-5 chromatographic column was used, and the temperature program temperature condition of the chromatographic column was: 50 o C maintain 10mins, with 10 o C / min heating rate increased to 250 o C, and at 250 o C maintained for 5mins. The analysis results are shown in Table 2.

[0034] Wherein, the calculation formula of yield is: mass yield of alkylphenol mixture (%)=(mass of alkylphenol mixture in product / mass of lignin oil before reaction)´100%.

[0035] The preparation of niobiu...

Embodiment 47-77

[0047] Examples 47-77

[0048] The steps of continuous fixed bed are as follows: 0.075g catalyst, the feed rate of lignin oil (the product of embodiment 1-14) is 3mmol / h, and hydrogen flow rate is 20-50mL / h, and temperature is 250 o C~450 o c. The reaction product was qualitatively analyzed by gas chromatography-mass chromatography (GC-MS Agilent 7890A-5975C) and quantitatively analyzed by gas chromatography (GC Agilent 7890A). HP-5 chromatographic column was used, and the temperature program temperature condition of the chromatographic column was: 50 o C maintain 10mins, with 10 o C / min heating rate increased to 250 o C, and at 250 o C maintained for 5mins. The analysis results are shown in Table 3.

[0049] Wherein, the calculation formula of yield is: mass yield of alkylphenol mixture (%)=(mass of alkylphenol mixture in product / mass of lignin oil before reaction)´100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com