Coated hollow three-dimensional material preparation method and product and application thereof

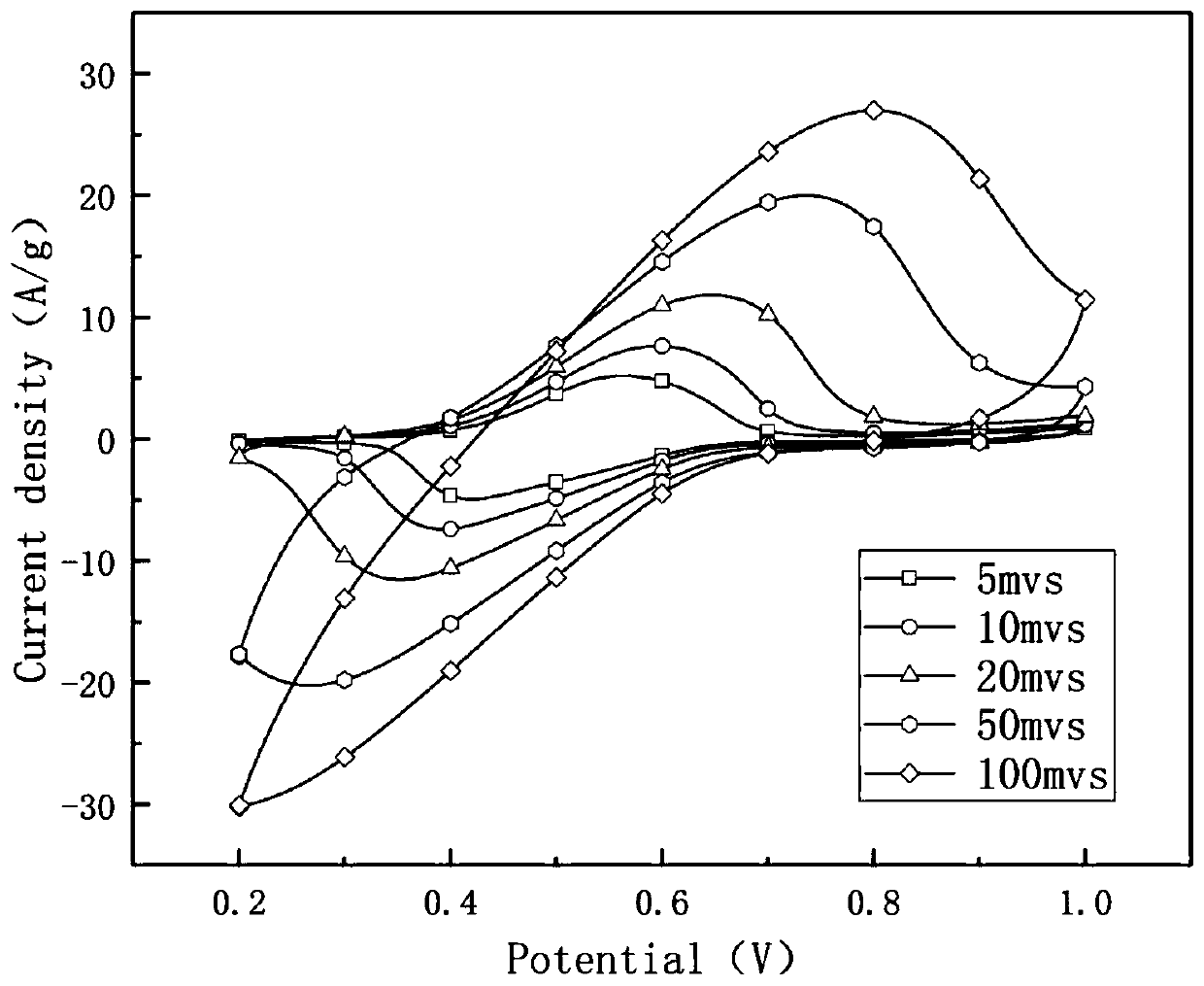

A hollow, three-dimensional technology, applied in the field of coating hollow three-dimensional materials, can solve the problems of poor electrical conductivity, poor cycle performance, etc., and achieve the effect of increasing specific capacity, excellent electrochemical performance, and improving specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] This embodiment provides a method for preparing poly-3,4-ethylenedioxythiophene-coated ferromanganese Prussian blue analogs, which includes the following steps (wherein the centrifugation conditions described in each step are 10000r / min centrifugation for 10 minutes , the washing conditions are all 50vol% ethanol solution): step 1, get 4mmol manganese chloride and 8mmol sodium citrate and dissolve them in 100mL deionized water, and record it as solution ①; dissolve 2mmol sodium ferricyanide in 100mL deionized water , recorded as solution ②, under the condition of rapid stirring of solution ①, slowly drop solution ② into it, stir at room temperature (25°C) for 0.5 hours, age and stand for 24 hours, then centrifuge, and use ethanol solution to dissolve the precipitate obtained by centrifugation Washing, centrifuging the precipitate after washing and drying the solid matter in a 40°C oven for 24 hours to obtain ferromanganese Prussian blue analog nanocube material;

[0023...

Embodiment 2

[0027] This embodiment provides a method for preparing poly-3,4-ethylenedioxythiophene-coated ferromanganese Prussian blue analogs, which includes the following steps (wherein the centrifugation conditions described in each step are 10000r / min centrifugation for 20 minutes , the washing conditions are all 50vol% ethanol solution): step 1, get 3mmol manganese chloride and 6mmol sodium citrate and dissolve them in 100mL deionized water, and record it as solution ①; dissolve 2mmol sodium ferricyanide in 100mL deionized water , recorded as solution ②, under the condition of rapid stirring of solution ①, slowly drop solution ② into it, stir at room temperature (25°C) for 1 hour, age and stand for 12 hours, then centrifuge, and use ethanol solution to remove the precipitate obtained by centrifugation Washing, centrifuging the precipitate after washing and drying the solid matter in a 40°C oven for 24 hours to obtain ferromanganese Prussian blue analog nanocube material;

[0028] Ste...

Embodiment 3

[0031]This embodiment provides a preparation method of poly-3,4-ethylenedioxythiophene-coated ferromanganese Prussian blue analogue, which includes the following steps (wherein the centrifugation conditions described in each step are 9000r / min centrifugation for 10 minutes , the washing conditions are all 75vol% ethanol solution): step 1, get 4mmol manganese chloride and 10mmol sodium citrate and dissolve them in 100mL deionized water, which is recorded as solution ①; 3mmol sodium ferricyanide is dissolved in 100mL deionized water , recorded as solution ②, under the condition of rapid stirring of solution ①, slowly drop solution ② into it, stir at room temperature (25°C) for 0.5 hours, age and stand still for 24 hours, and centrifuge, and wash the precipitate obtained by centrifugation with ethanol solution, The solid matter obtained by centrifuging the precipitate after washing is placed in a 40°C oven and dried for 24 hours to obtain the ferromanganese Prussian blue analog na...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com