Amino-modifying interpenetrating resin adsorbent and preparing method thereof

A resin adsorption, amino modification technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of high investment and operation cost, easy blockage of pore size, slow adsorption rate, etc., achieve high adsorption capacity, reduce chloromethylation Steps, the effect of reducing the equilibration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

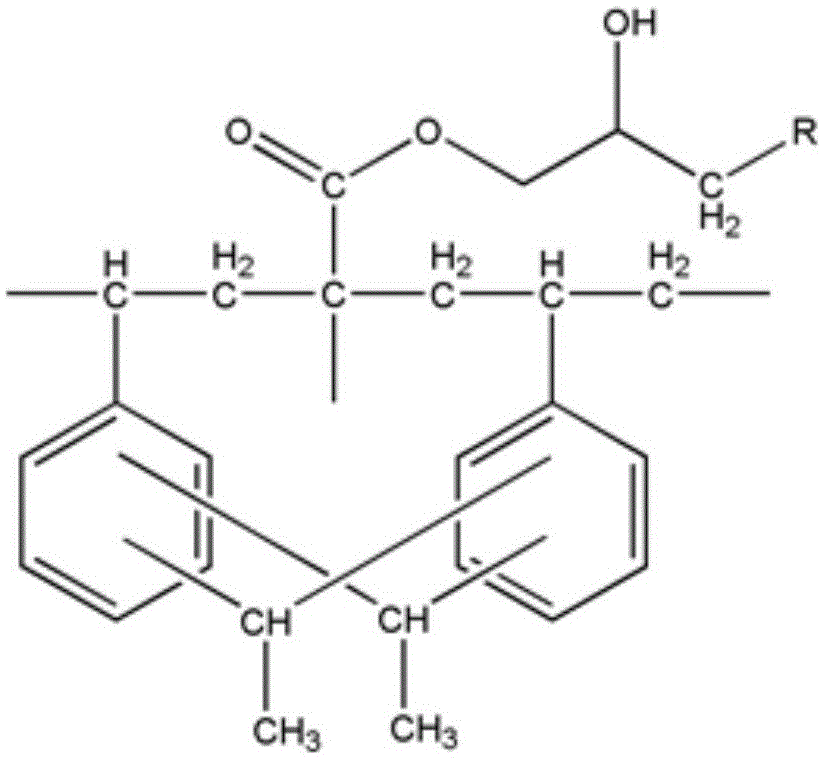

[0043] Taking 10g of resin white balls as an example, use 25mL of amino interpenetrating resin adsorbent beads (basic structure such as figure 1 shown)

[0044] The preparation method is as follows:

[0045] Dissolve 2g of gelatin, 1.05g of trisodium phosphate, 4.2g of disodium hydrogen phosphate and 32.5g of sodium chloride in 250mL of deionized water, heat to 55°C to dissolve it completely, then add 12.5g of divinylbenzene, 12.5g Glycidyl methacrylate, 0.5g benzoyl peroxide, 0.5g azobisisobutyronitrile and 62.5g oil phase of toluene, heated to 70°C to start the reaction, reacted at 75°C for 2h, heated to 80°C to react 2h, and then heated to 90°C for 10h to complete the reaction to obtain white resin balls, which were washed with deionized water and acetone at 65°C to remove impurities.

[0046] Take 10 g of cleaned resin white balls and add them to the reaction device, use 100 mL of ethanol to swell for 1 hour, then extract excess ethanol, add 25 mL of dimethylamine soluti...

Embodiment 2

[0051] Taking 20g of resin white balls as an example, use 75mL of amino interpenetrating resin adsorbent beads modified with a dimethylamine solution with a concentration of 5mol / L

[0052] The preparation method is as follows:

[0053] Take 2.5g of gelatin, 1.05g of trisodium phosphate, 4.2g of disodium hydrogen phosphate and 32.5g of sodium chloride and dissolve them in 250mL of deionized water, heat to 53°C to dissolve them completely, then add 12.5g of divinylbenzene, 12.5 g glycidyl methacrylate, 0.5g benzoyl peroxide, 0.5g azobisisobutyronitrile and 45g oil phase of toluene, heated to 70°C to start the reaction, reacted at 75°C for 1.5h, heated to 80°C React for 1.5 hours, then heat to 95° C. and react for 11 hours to obtain white resin balls. Use 75° C. deionized water and ethanol to wash away impurities.

[0054] Take 20g of cleaned resin white balls and add them to the reaction device, use 100mL of ethanol to swell for 1 hour, then extract excess ethanol, add 75mL of...

Embodiment 3

[0059] Taking 30g of resin white balls as an example, use 160mL of dimethylamine solution with a concentration of 5mol / L to modify the amino interpenetrating resin adsorbent beads

[0060] The preparation method is as follows:

[0061] Dissolve 3g of gelatin, 1.05g of trisodium phosphate, 4.2g of disodium hydrogen phosphate and 32.5g of sodium chloride in 250mL of deionized water, heat to 51°C to dissolve completely, then add 12.5g of divinylbenzene, 12.5g Glycidyl methacrylate, 0.5g benzoyl peroxide, 0.5g azobisisobutyronitrile and 40g toluene oil phase, heated to 70°C to start the reaction, reacted at 75°C for 1.5h, heated to 80°C to react After 1.5 hours, heat to 95° C. and react for 13.5 hours to obtain white resin balls. Use 72° C. deionized water and ethanol to wash away impurities.

[0062] Take 20g of cleaned resin white balls and add them to the reaction device, use 100mL of ethanol to swell for 1 hour, extract excess ethanol, add 150mL of dimethylamine solution with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com