Catalyst for preparing light olefins through Fischer-Tropsch synthesis as well as preparation method and application of catalyst

A technology for Fischer-Tropsch synthesis and low-carbon olefins, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxides/metal hydroxide catalysts, etc., can solve the problem that the selectivity of target products is not too large Improvement, target product yield reduction, CO conversion rate decline, etc., to achieve good thermal stability and chemical stability, wide selection of raw materials, and moderate combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] The purpose of this embodiment is to provide 10Fe·1.4K·3Mn·85.6 (50MgO·50Al 2 o 3 ) Catalyst preparation.

[0075] a) Accurately weigh 7.222g of magnesium nitrate hexahydrate [Mg(NO 3 ) 2 ·6H 2 O] and 21.146g of aluminum nitrate nonahydrate [Al(NO 3 ) 3 9H 2 O], add a certain amount of deionized water after mixing, and stir until completely dissolved at 60°C;

[0076] b) Accurately weigh 26.800 g of complexing agent ethylenediaminetetraacetic acid (EDTA) at room temperature, add an appropriate amount of deionized water and stir at 60°C, add ammonia water drop by drop until the powder is completely dissolved, and continue stirring;

[0077] c) Slowly add the solution in step a) into the solution in step b) at a constant temperature of 60°C, and keep stirring, raise the temperature of the mixture system to 80°C, and continue stirring until it becomes viscous and a small amount of solid insoluble matter appears;

[0078] d) Dry the mixture in an oven at 100-140°C o...

Embodiment 2-23

[0087] The purpose of this embodiment is to provide 10Fe·1.4K·3Mn·85.6 (50MgO·50Al 2 o 3 ) Catalyst preparation.

[0088] According to the conditions of each step in Example 1, only the catalyst carrier magnesium source, aluminum source, and complexing agent were changed. The specific reagents used are shown in Table 1.

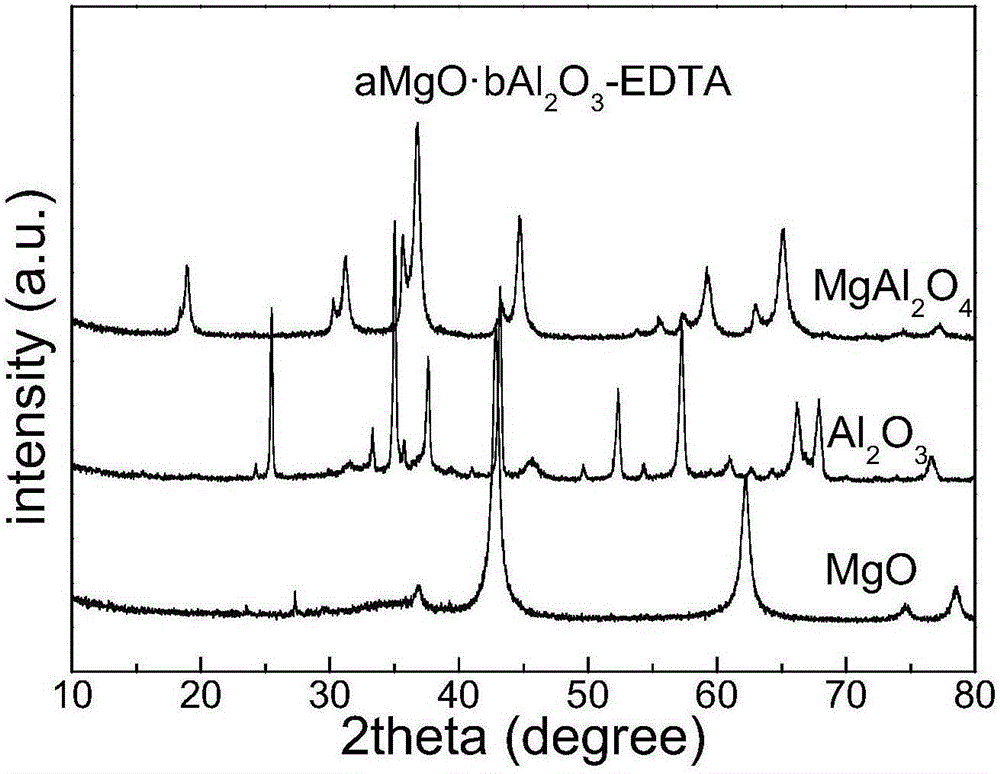

[0089] Wherein, the X-ray powder diffraction pattern of the catalyst carrier prepared in embodiment 7, such as figure 2 shown.

[0090] Table 1 Example 2-23 Reagents used

[0091] Example

[0092] 17

Embodiment 24-42

[0094] The purpose of this embodiment is to provide 10Fe·1.4K·3Mn·85.6 (50MgO·50Al 2 o 3 ) Catalyst preparation.

[0095] According to the conditions of each step in Example 1, only the iron source, potassium source, and manganese source required for the preparation of the catalyst were changed. The specific reagents used are shown in Table 2.

[0096] Table 2 embodiment 24-42 uses reagent

[0097] Example

[0098] 39

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com