Preparation method of micron spherical silicon oxide

A technology of spherical silica and silica powder, which is applied in the chemical industry, can solve problems such as poor density, high energy consumption, and serious agglomeration, and achieve the effects of high mechanical strength and high water absorption of the carrier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1-1) Weigh an average of 100 mesh SiO 2 21g of powder, 15ml of concentrated hydrochloric acid, 126g of 30%wt alkaline silica sol (wherein the average particle size of silicon oxide is 25nm) and 10ml of methanol are fully mixed to obtain a slurry, and then 15g of hexamethylenetetramine is added to the slurry, fully dissolve.

[0029] (1-2) Select a nozzle with an aperture of 0.25mm and install it on the jet generator, inject the slurry obtained in (1-1) into 25# transformer oil at 95°C at a speed of 5m / s, and let it stand for aging for 4 After hours, the shaped pellets were separated from the oil and dried under vacuum at 80°C for 12 hours.

[0030] (1-3) The obtained product was washed until neutral, then dried at 140°C for 10 hours, and calcined at 550°C for 12 hours to obtain micron spherical silicon oxide particles.

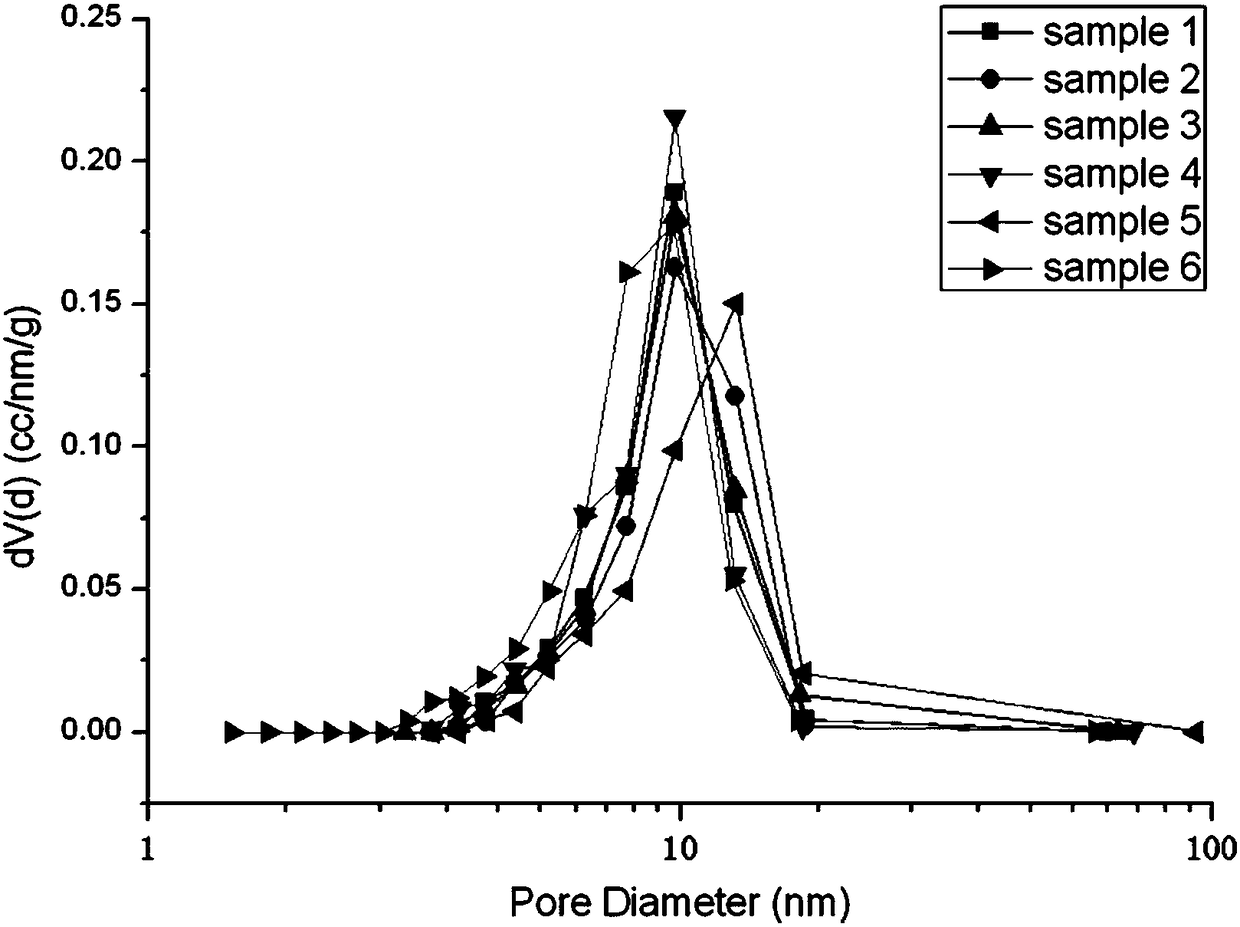

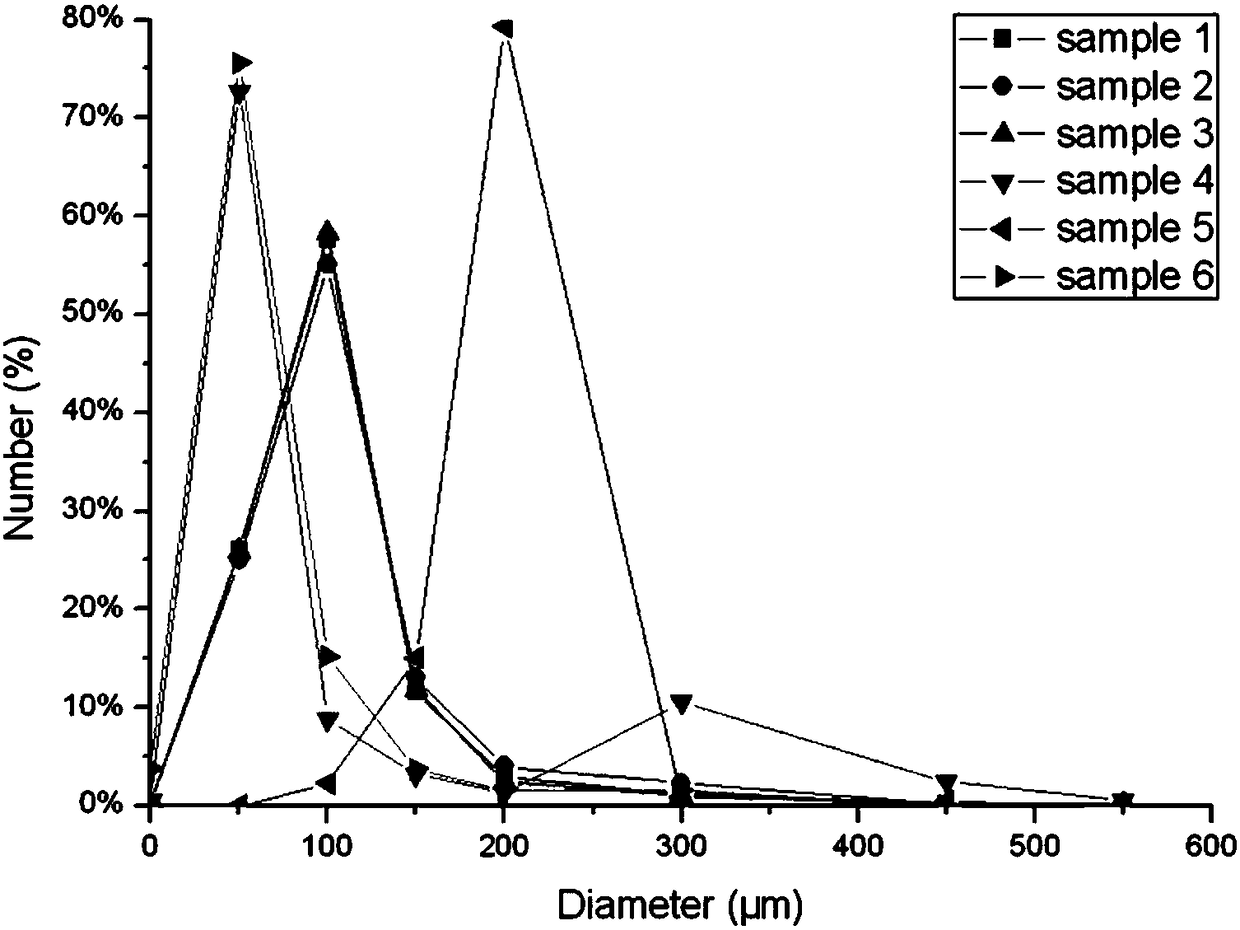

[0031] After characterization, the BET specific surface area of Example 1 is 394.1m 2 / g, the pore volume is 0.949cm 3 / g, the average pore diam...

Embodiment 2

[0033] (2-1) Weigh an average of 100 mesh SiO 2 21g of powder, 5ml of concentrated nitric acid, 126g of 30%wt alkaline silica sol (the average particle size of silicon oxide is 25nm) and 10ml of ethanol are fully mixed to obtain a slurry, and then 2g of wollastonite (300 mesh) and hexamethylene Tetramine 15g is added in the slurry, fully dissolved.

[0034] (2-2) Select a nozzle with an aperture of 0.25mm and install it on the jet generator, inject the slurry obtained in (2-1) into 25# transformer oil at 90°C at a speed of 5m / s, and separate it from the oil The formed pellets were vacuum-dried at 60° C. for 24 hours.

[0035] (2-3) The obtained product was washed until neutral, then dried at 140°C for 10 hours, and calcined at 550°C for 12 hours to obtain micron spherical silicon oxide particles.

[0036] After characterization, the BET specific surface area of embodiment 2 is 393.5m 2 / g, the pore volume is 0.993cm 3 / g, the average pore diameter is 9.726nm, and the bul...

Embodiment 3

[0038] (3-1) Weigh an average of 100 mesh SiO 2 31g of powder, 10ml of concentrated phosphoric acid, 126g of 30%wt alkaline silica sol (the average particle size of silicon oxide is 25nm) and 8ml of polyethylene glycol are fully mixed to obtain a mixed slurry, and then 2.5g of silicon carbide fiber (500 mesh) and hexamethylenetetramine 14g are added in the slurry, fully dissolved.

[0039] (3-2) Select a nozzle with an aperture of 0.35mm and install it on the jet generator, inject the slurry obtained in (3-1) into 25# transformer oil at 90°C at a speed of 5m / s, and form it from the oil The formed pellets were isolated and dried under vacuum at 80°C for 16 hours.

[0040] (3-3) The obtained product was washed until neutral, then dried at 140°C for 10 hours, and calcined at 550°C for 12 hours to obtain micron spherical silicon oxide particles.

[0041] After characterization, the BET specific surface area of embodiment 3 is 400.6m 2 / g, the pore volume is 0.987cm 3 / g, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com