Preparation method of synthetic 1,4-butynediol catalyst

The technology of butynediol and catalyst is applied in the field of preparation of catalyst for producing 1,4-butynediol, and can solve the problems of poor wear resistance and stability of catalyst, unsuitable particle size of catalyst, complicated preparation process of carrier and the like, To achieve the effect of easy separation, concentrated distribution and uniform catalyst particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

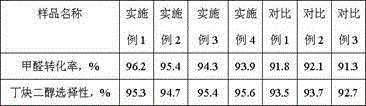

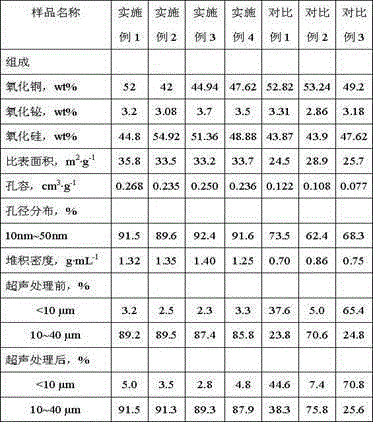

Examples

Embodiment 1

[0034] (1) Weigh 96.64g Cu(NO 3 ) 2 .3H 2 O and 229.6g 30% silica sol, prepare 400ml copper-silicon mixed solution; Take by weighing 144.96g Cu(NO 3 ) 2 .3H 2 O and 10.24g Bi(NO 3 ) 3 .5H 2 O, prepare 600ml copper-bismuth mixed solution, adjust the pH of the solution to be 2 with nitric acid to fully dissolve the bismuth salt; prepare 3mol / L and 1mol / L Na 2 CO 3 The solution is ready for use.

[0035] (2) Heat 400ml of copper-silicon mixed solution prepared in step (1) to 60°C, add 3mol / L Na 2 CO 3 The solution was dropped into the copper-silicon mixed solution, the reaction temperature was controlled to be 60° C., and the pH at the end of the reaction was 6. After the reaction was completed, the reaction temperature and pH were maintained, and stirring was continued for 30 min.

[0036] (3) Add 600ml of the copper-bismuth mixed solution prepared in step (1) to the copper-silicon precipitate slurry obtained in step (2).

[0037] (4) The 1mol / L Na prepared in step ...

Embodiment 2

[0041] (1) Weigh 120.8g Cu(NO 3 ) 2 .3H 2 O and 348.8g 30% silica sol, prepare 500ml copper-silicon mixed solution; Take by weighing 120.8g Cu(NO 3 ) 2 .3H 2 O and 12.49g Bi(NO 3 ) 3 .5H 2 O, prepare 500ml copper-bismuth mixed solution, adjust the pH of the solution to be 2 with nitric acid to fully dissolve the bismuth salt; prepare 4mol / L NaOH solution and 1mol / L NaOH solution 2 CO 3 The solution is ready for use.

[0042] (2) Heat 500ml of the copper-silicon mixed solution prepared in step (1) to 65°C, drop 4mol / L NaOH solution into the copper-silicon mixed solution, control the reaction temperature to 65°C, and the pH at the end of the reaction to be 5.5. After the reaction was completed, the reaction temperature and pH were maintained, and stirring was continued for 30 min.

[0043] (3) Add 500ml of the copper-bismuth mixed solution prepared in step (1) to the copper-silicon precipitate slurry obtained in step (2).

[0044] (4) The 1mol / L Na prepared in step (1...

Embodiment 3

[0048] (1) Weigh 144.96g Cu(NO 3 ) 2 .3H 2 O and 304.7g 30% silica sol, prepare 600ml copper-silicon mixed solution; Take by weighing 96.64g Cu(NO 3 ) 2 .3H 2 O and 13.71g Bi(NO 3 ) 3 .5H 2 O, prepare 500ml of copper-bismuth mixed solution, adjust the pH of the solution to be 2 with nitric acid to fully dissolve the bismuth salt; prepare 4.4mol / L ammonia solution and 1.5mol / L Na 2 CO 3 The solution is ready for use.

[0049] (2) Heat 600ml of the copper-silicon mixed solution prepared in step (1) to 70°C, drop 4.4mol / L ammonia solution into the copper-silicon mixed solution, control the reaction temperature to 70°C, and the pH at the end of the reaction to be 5.5 . After the reaction was completed, the reaction temperature and pH were maintained, and stirring was continued for 30 min.

[0050] (3) Add 500ml of the copper-bismuth mixed solution prepared in step (1) to the copper-silicon precipitate slurry obtained in step (2).

[0051] (4) Add 1.5mol / L of Na prepare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com