Method for extracting ganoderma triterpene and ganoderma lucidum polysaccharide from ganoderma lucidum

A technology for Ganoderma lucidum triterpenes and Ganoderma lucidum polysaccharides is applied in the field of extracting Ganoderma lucidum triterpenes and Ganoderma lucidum polysaccharides, which can solve the problems of low extraction rate, high operation difficulty, human body and environmental impact, etc. The effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

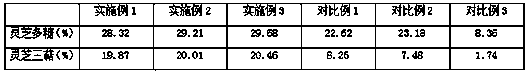

Embodiment 1

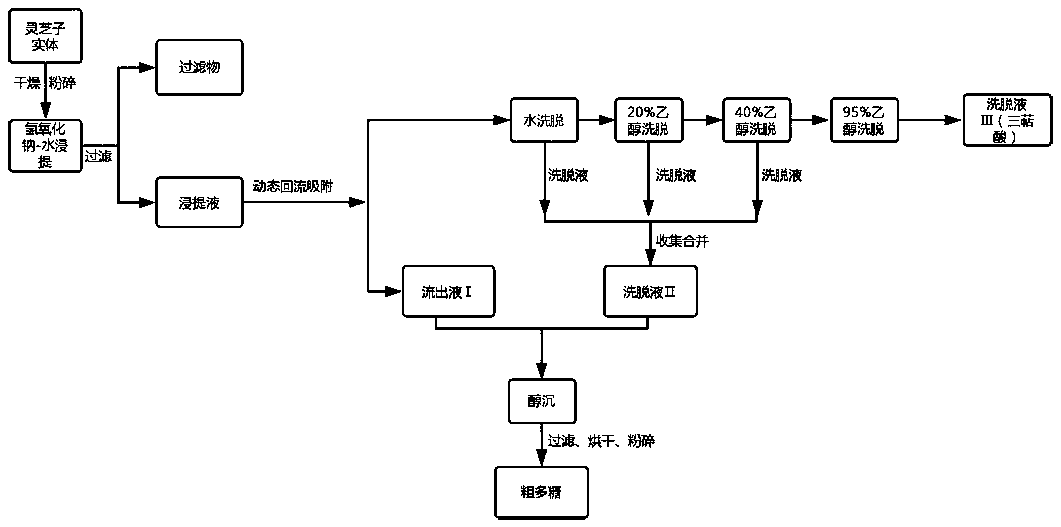

[0044] A method for extracting ganoderma triterpenes and ganoderma polysaccharides from ganoderma mainly comprises the following steps:

[0045] A. Pretreatment of raw materials: after drying and ultrafine grinding of the fruiting body of Ganoderma lucidum, put the crushed fruiting body of Ganoderma lucidum in 0.2wt% sodium hydroxide-distilled aqueous solution and extract at 50°C, the fruiting body of Ganoderma lucidum and The weight ratio of sodium hydroxide-distilled aqueous solution is 1:20, and filtered after ultrasonic treatment, the ultrasonic conditions are: power 100w, time 20min, to obtain filtrate and extract;

[0046] B. adjust pH: adjust the pH of the extract with high-purity hydrochloric acid to be 2.0;

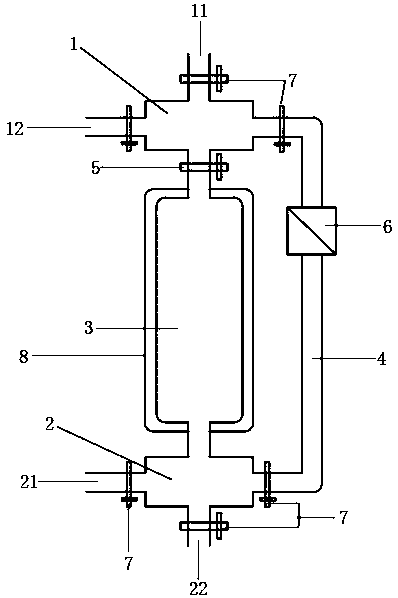

[0047] C. Dynamic reflux adsorption: inject the extract obtained in step B into the liquid inlet 1 through the pipeline 11, adjust the flow rate of the flow valve to 20ml / min, the extract enters the resin column at a predetermined flow rate, and open the liquid i...

Embodiment 2

[0052] A method for extracting ganoderma triterpenes and ganoderma polysaccharides from ganoderma mainly comprises the following steps:

[0053] A. Pretreatment of raw materials: after drying and ultrafine grinding of the fruiting body of Ganoderma lucidum, put the crushed fruiting body of Ganoderma lucidum in 0.5wt% sodium hydroxide-purified aqueous solution and extract at 60°C, the fruiting body of Ganoderma lucidum and The weight ratio of sodium hydroxide-purified aqueous solution is 1:25, filtered after ultrasonic treatment, the ultrasonic conditions are: power 200w, time 25min, to obtain filtrate and extract;

[0054] B. adjust pH: adjust the pH of the extract with high-purity hydrochloric acid to be 3.0;

[0055] C. Dynamic reflux adsorption: inject the extract obtained in step B into the liquid inlet 1 through the pipeline 11, adjust the flow rate of the flow valve to 35ml / min, the extract enters the resin column at a predetermined flow rate, and open the liquid inlet 1...

Embodiment 3

[0060] A method for extracting ganoderma triterpenes and ganoderma polysaccharides from ganoderma mainly comprises the following steps:

[0061] A. Pretreatment of raw materials: after drying and ultrafine grinding of the fruiting body of Ganoderma lucidum, put the crushed fruiting body of Ganoderma lucidum in 1.0wt% sodium hydroxide-purified aqueous solution and extract at 75°C, the fruiting body of Ganoderma lucidum and The weight ratio of sodium hydroxide-purified aqueous solution is 1:30, filtered after ultrasonic treatment, the ultrasonic conditions are: power 250w, time 30min, to obtain filtrate and extract;

[0062] B. adjust pH: adjust the pH of the extract with high-purity hydrochloric acid to be 4.5;

[0063] C. Dynamic reflux adsorption: inject the extract obtained in step B into the liquid inlet 1 through the pipeline 11, adjust the flow rate of the flow valve to 50ml / min, the extract enters the resin column at a predetermined flow rate, and open the liquid inlet 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com