Secondary battery and anode active substance

A positive active material, secondary battery technology, applied in the direction of active material electrodes, secondary battery manufacturing, battery electrodes, etc., can solve the problems of reduced utilization efficiency, reduced capacity, etc., and achieve the effect of good capacity, not easy to peel or defect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Hereinafter, in the present embodiment, a Li secondary battery will be described as the secondary battery. In the present embodiment, lithium manganese oxide, lithium nickel oxide, lithium cobalt oxide, manganese oxide, and the like can be used as the metal oxide constituting the main body of the positive electrode active material.

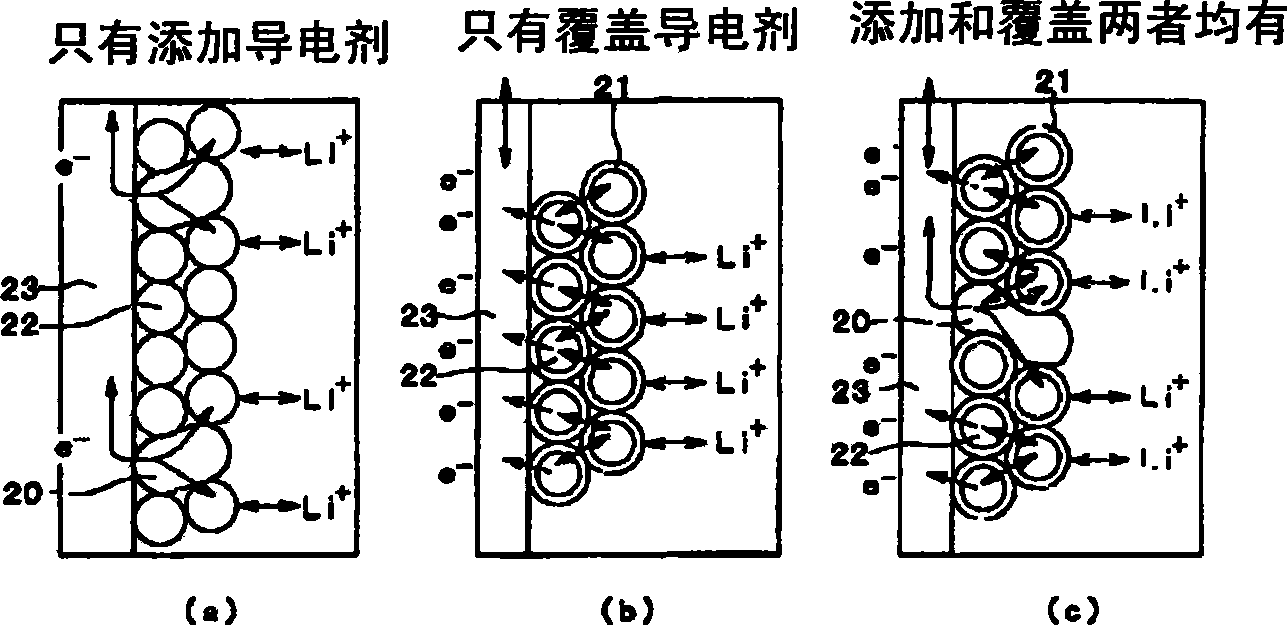

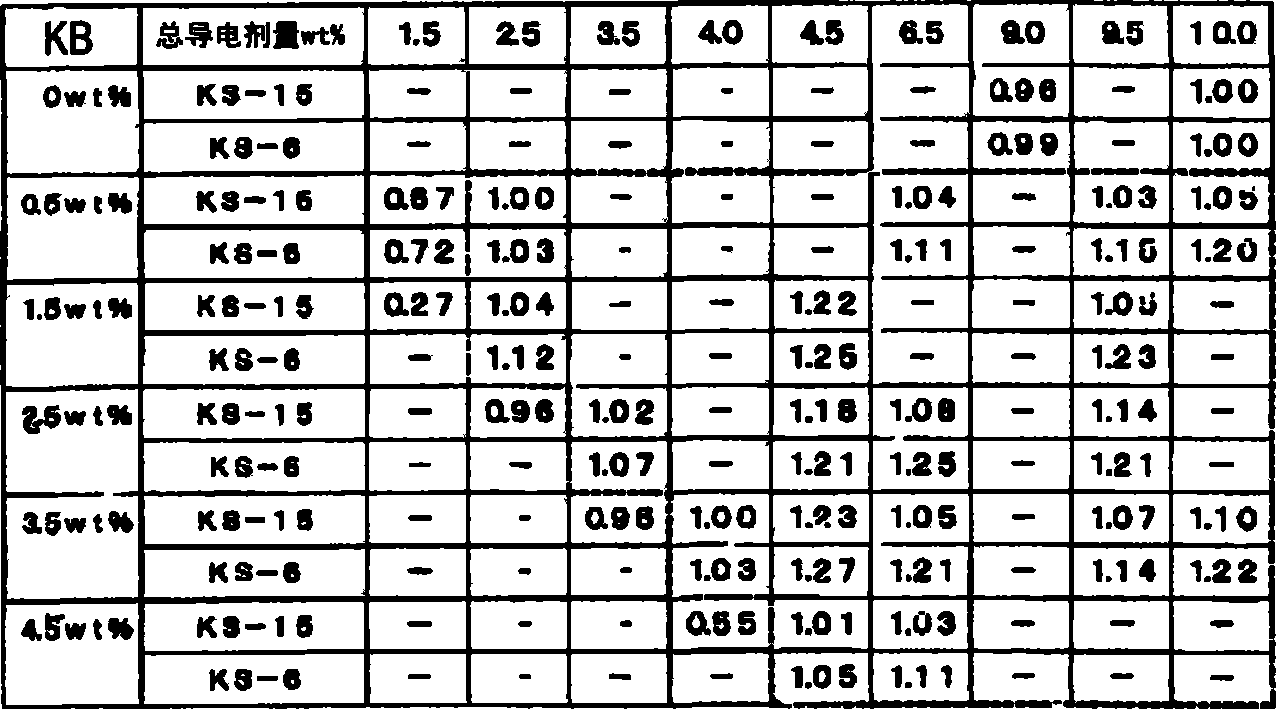

[0034]As a coating conductive agent (first conductive agent) that covers the surface of each particle of the metal oxide and makes the conductivity of electrons uniform in the metal oxide, a specific surface area of 250m can be used. 2 / g~1500m 2 / g Ketjen black or acetylene black, etc. Also, in order to increase the capacity more, it is more preferable that the specific surface area is 1000m 2 / g~1500m 2 / g (refer to Japanese Patent Application Publication No. 9-92265 Figure 4 ).

[0035] In addition, as an additional conductive agent (second conductive agent) further added to the covered metal oxide, it intervenes between the part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com