High water absorptive resin for sanitary material

A technology of superabsorbent resin and hygienic materials, applied in the field of superabsorbent resin, can solve problems such as gel strength, dryness, breathability, unsatisfactory water retention, failure to meet high requirements for hygienic materials, and slow liquid absorption speed. The production process is simple and easy to control, the water retention performance is good, and the gel strength is strong

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1. Dissolve 130g of sodium hydroxide and 0.2g of silicon dioxide in 400g of water, add 300g of acrylic acid and 0.5g of hydroxyethyl acrylate dropwise, raise the temperature to 40-60°C for neutralization reaction, and then add 0.5-1% of N', N-methylenebisacrylamide solution 4g to obtain a reaction solution.

[0019] 2. Take 350 g of the reaction solution, add 100 g of 0.5-1% potassium persulfate solution, 100 g of 0.5-1% sodium bisulfite solution, heat to 75-85° C. Half an hour later, the polymerization product was dried to obtain the product resin.

[0020] 3. 100g of product resin is post-treated with 18g of surface treatment agent, and dried to obtain a super fast liquid-absorbing superabsorbent resin.

[0021] The product absorbs 0.9% salt water with a water absorption rate of 60g / g, absorbs 0.9% salt water for 75 seconds, and absorbs 0.9% salt water with a pressurized water absorption of 40g / g.

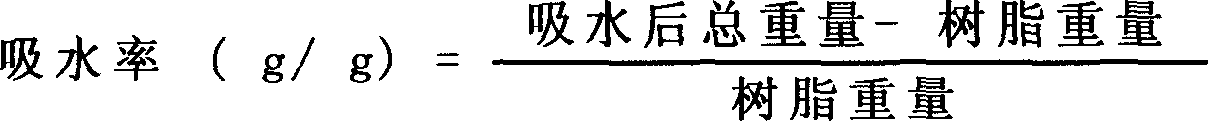

[0022] Among them, the water absorption rate is calculated by the f...

Embodiment 2

[0025] 1. Dissolve 150g of sodium hydroxide and 0.2g of silicon dioxide in 420g of water, add dropwise 320g of acrylic acid and 0.35g of hydroxyethyl acrylate, raise the temperature to 40-60°C for neutralization, and then add 0.5-1% of N', N-methylenebisacrylamide solution 6g to obtain a reaction solution.

[0026] 2. Take 380g of the reaction solution, add 100g of ammonium persulfate solution with a concentration of 0.5-1%, 100g of a sodium bisulfite solution with a concentration of 0.5-1%, and heat to 75-85°C for polymerization, and detonation occurs. Half an hour later, the polymerization product was dried to obtain the product resin.

[0027] 3. 100g of product resin is post-treated with 18g of surface treatment agent, and dried to obtain a super fast liquid-absorbing superabsorbent resin.

[0028] The product absorbs 0.9% salt water with a water absorption rate of 55g / g, absorbs 0.9% salt water for 75 seconds, and absorbs 0.9% salt water with a pressurized water absorpti...

Embodiment 3

[0030] 1. Dissolve 130g of sodium hydroxide and 0.2g of silicon dioxide in 410g of water, add 320g of acrylic acid and 0.32g of hydroxyethyl acrylate dropwise, raise the temperature to 40-60°C for neutralization reaction, and then add 0.5-1% of N', 4 g of N-methylenebisacrylamide solution, 2 g of diethylene glycol with a concentration of 0.5-1% to obtain a reaction liquid.

[0031] 2. Take 380g of the reaction solution, add 95g of potassium persulfate solution with a concentration of 0.5-1%, and 95g of sodium sulfite solution with a concentration of 0.5-1%, and heat to 75-85°C for polymerization, and implosion occurs. Half an hour later, the polymerization product was dried to obtain the product resin.

[0032] 3. 100g of product resin is post-treated with 18g of surface treatment agent, and dried to obtain a super fast liquid-absorbing superabsorbent resin.

[0033] The product absorbs 0.9% saline water with a water absorption rate of 50g / g, absorbs 0.9% saline water for 78s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com