Preparation method of gray track resistance KTiOPO (GTR-KTP) crystals

A crystal, KH2PO4 technology, applied in crystal growth, chemical instruments and methods, single crystal growth, etc., can solve the problems of laser output power drop, KTP crystal unrecoverable, frequency doubling efficiency reduction, etc., to improve the internal quality of the crystal, good Anti-gray effect, effect of reducing conductivity and absorption coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Raw materialKH 2 PO 4 Dissolve in distilled water first, with a mass concentration of 55%, filter with an ultra-fine membrane filtration device, and grow high-purity KH through a low-temperature solution method 2 PO 4 Crystal material, reducing the content of impurity ions in raw materials.

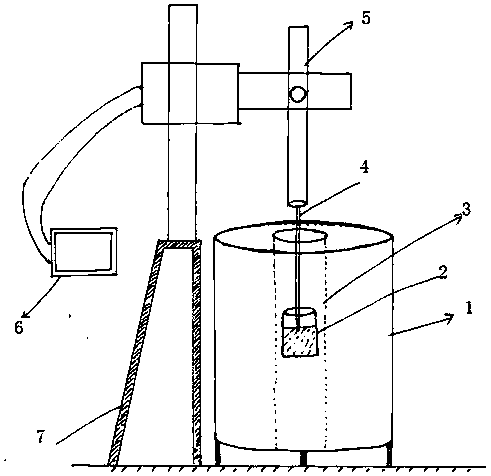

[0028] Make a platinum crucible container with a diameter of 10cm and a height of 14cm, and the raw material KH 2 PO 4 , K 2 CO 3 , Ti0 2 After mixing according to the mass ratio of 8:1:1, stir evenly and put it into a platinum crucible, heat up to 1000°C to melt the raw materials for reaction, the solution height is about 9cm, heat up to 1100°C and burn for 24h, then stir at constant temperature for 48h to form a uniform Stable high temperature solution.

[0029] The reaction produces the chemical equation of K6 co-solvent and KTP:

[0030] K6 co-solvent: 4KH 2 PO 4 +K 2 CO 3 —K 6 P 4 o 13 +4H 2 O↑+CO 2 ↑

[0031] KTP:KH 2 PO 4 +TiO 2 —KTiOPO 4 +H 2 O↑

[...

Embodiment 2

[0038] Raw materialKH 2 PO 4 Dissolve in distilled water first, with a mass concentration of 50%, filter with an ultra-fine membrane filtration device, and grow high-purity KH through a low-temperature solution method 2 PO 4 Crystal material, reducing the content of impurity ions in raw materials.

[0039] Make a platinum crucible container with a diameter of 10cm and a height of 14cm, and the raw material KH 2 PO 4 、K 2 CO 3 , TiO 2 After mixing according to the mass ratio of 8:1:1, stir evenly and put it into a platinum crucible, heat up to 1000°C to melt the raw materials for reaction, the solution height is about 9cm, heat up to 1100°C and burn for 24h, then stir at constant temperature for 48h to form a uniform Stable high temperature solution.

[0040] The reaction produces the chemical equation of K6 co-solvent and KTP:

[0041] K6 co-solvent: 4KH 2 PO 4 +K 2 CO 3 —K 6 P 4 o 13 +4H 2 O↑+CO 2 ↑

[0042] KTP:KH 2 PO 4 +TiO 2 —KTiOPO 4 +H 2 O↑

[0...

Embodiment 3

[0048] Raw materialKH 2 PO 4 Dissolve in distilled water first, with a mass concentration of 60%, filter with an ultra-fine membrane filtration device, and grow high-purity KH through a low-temperature solution method 2 PO 4 Crystal material, reducing the content of impurity ions in raw materials.

[0049] Make a platinum crucible container with a diameter of 10cm and a height of 14cm, and the raw material KH 2 PO 4 ,K 2 CO 3 , TiO 2 After mixing according to the mass ratio of 8:1:1, stir evenly and put it into a platinum crucible, heat up to 1000°C to melt the raw materials for reaction, the solution height is about 9cm, heat up to 1100°C and burn for 24h, then stir at constant temperature for 48h to form a uniform Stable high temperature solution.

[0050] The reaction produces the chemical equation of K6 co-solvent and KTP:

[0051] K6 co-solvent: 4KH 2 PO 4 +K 2 CO 3 —K 6 P 4 o 13 +4H 2 O↑+CO 2 ↑

[0052] KTP:KH 2 PO 4 +TiO 2 —KTiOPO 4 +H 2 O↑

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com