Method and system device for removing nitrate in water based on S-Fe collaborative autotrophic denitrification

An autotrophic denitrification and system device technology, applied in the field of high-efficiency autotrophic denitrification, can solve the problems of excessive sulfate radicals in effluent, danger, and high usage costs, and achieve the effects of reducing carbon dioxide emissions, small footprint, and avoiding consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

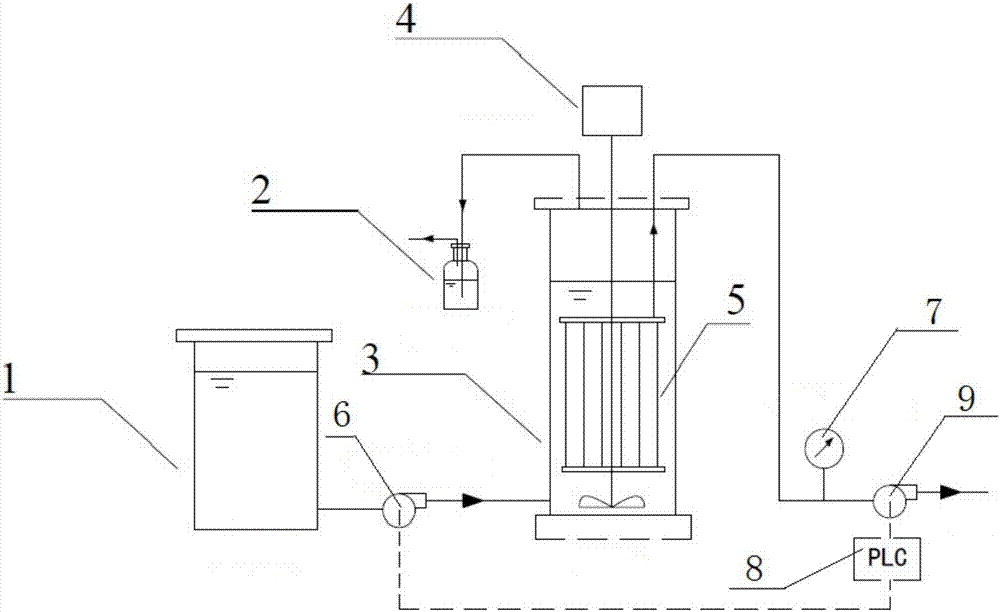

[0047] A system device based on S-Fe synergistic autotrophic denitrification to remove nitrate in water, its structure diagram is as follows figure 1 As shown, it mainly includes: an airtight anaerobic / anoxic reactor 3, a water tank 1 and a liquid seal device 2; an electric mixer 4 and a membrane module 5 are arranged in the airtight anaerobic / anoxic reactor 3; The waste water containing sulfate is pumped into the closed anaerobic / anoxic reactor 3 through the pipeline through the water inlet peristaltic pump 6 for treatment, and then pumped out through the water outlet peristaltic pump 9; a vacuum pressure is provided between the water outlet and the water outlet peristaltic pump 9 Table 7: The gas generated in the closed anaerobic / anoxic reactor 3 is discharged through the liquid seal device 2 through the gas outlet pipe.

[0048] The device also includes a PCL automatic control system 8, and the water inlet and outlet of the device are controlled by the PCL automatic control...

Embodiment 2

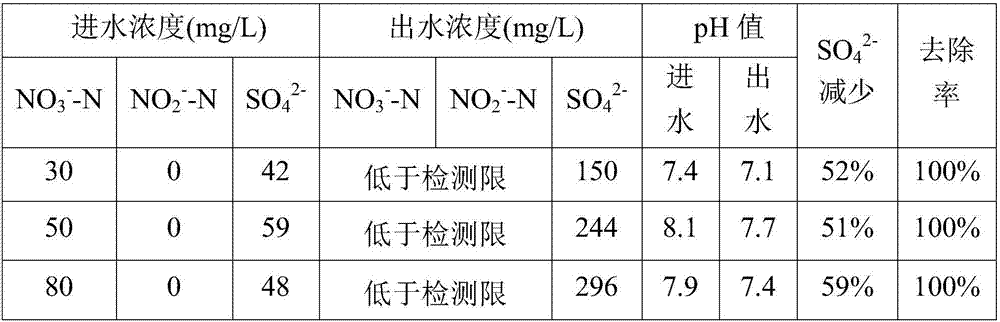

[0059] Adopt the system device of embodiment 1 to process nitrate waste water, its process parameter control is as follows: in the reactor that effective volume is 3.2L, add the sulfur that particle diameter is 0.5-20mm and each 150g of iron, treated raw water is configured by potassium nitrate, The concentration of nitrate nitrogen in the water is 30, 50 and 80mg / L, and the hydraulic retention time is set at 20min-1h. The water quality after treatment is shown in Table 1.

[0060] Table 1

[0061]

Embodiment 3

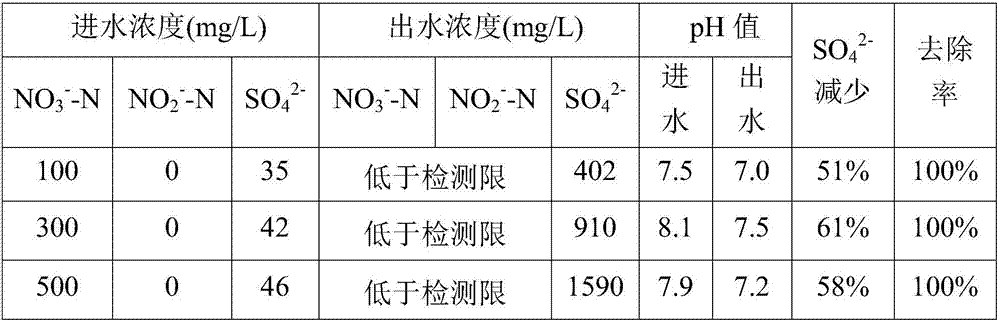

[0063] The system device of Example 1 is used to treat nitrate wastewater, and its process parameters are controlled as follows: add 0.5-20mm sulfur and 150g iron each in a reactor with an effective volume of 3.2L, and the raw water to be treated is configured by potassium nitrate, and the nitrate in the water is The nitrogen concentration is 100, 300 and 500mg / L, and the hydraulic retention time is set at 1.5h-4.0h. The water quality after treatment is shown in Table 2.

[0064] Table 2

[0065]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com