Low-smoke low-toxicity halogen-free flame-retardant resin as well as preparation method and application thereof

A technology of flame retardant resin and flame retardant, which is applied in the field of low-smoke, low-toxicity, halogen-free flame retardant resin and its preparation, can solve the problems of poor long-term flame retardant performance and mechanical properties, large smoke and high toxicity, and achieve Good RTM process practicability, improve thermal denaturation stability, and ensure the effect of anti-oxidative aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] In some preferred embodiments, the preparation method of the matrix resin comprises the following steps: (1) put the weighed glycol, saturated dibasic acid or acid anhydride into the reactor, and rapidly heat up to 160-200°C; (2) Then increase to 200-220°C at a rate of 2-3°C per 10 minutes, cool down to 60-90°C after the material is transparent, add unsaturated acid anhydride, and heat up to 200-200°C after the material is exothermic 220°C, maintain for a certain period of time, then cool down to 70-80°C, slowly add styrene and additives; (3) Then increase nitrogen, stir the reaction to a suitable acid value, cool down and stop.

[0034] In some preferred embodiments, the dihydric alcohol is at least one of ethylene glycol, propylene glycol, pentanediol, and dipropylene glycol; the unsaturated acid anhydride is maleic anhydride, fumaric anhydride at least one of; the saturated dibasic acid or acid anhydride is at least one of phthalic acid, isophthalic acid, terephthalic ...

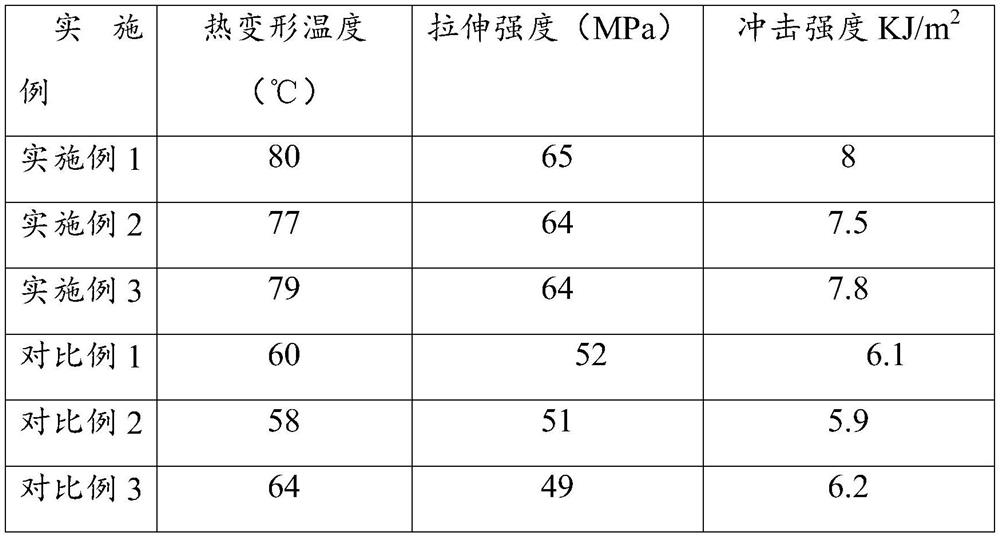

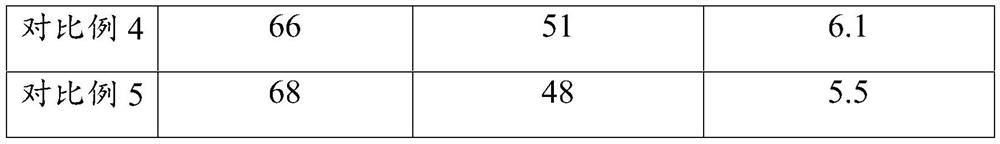

Embodiment 1

[0055] Embodiment 1 The first aspect provides a low-smoke, low-toxicity, halogen-free flame-retardant resin, the raw materials include the following parts by weight: 100 parts of matrix resin, 0.1 part of cobalt isooctanoate, 0.01 part of p-tert-butylcatechol, diethylphosphoric acid di 15 parts of ethyl ester.

[0056] In the present embodiment, the raw material of base resin comprises the following parts by weight: 25 parts of ethylene glycol, 171 parts of propylene glycol, 97 parts of maleic anhydride, 152 parts of phthalic anhydride, 205 parts of styrene, 30 parts of additives ( Hydroquinone and diphenylamine, weight ratio 2:1).

[0057] In the present embodiment, the preparation method of matrix resin comprises the following steps: (1) 25 parts of ethylene glycol that weighs, 171 parts of propylene glycol, 152 parts of phthalic anhydrides are put into reaction kettle, under nitrogen protection, quickly Raise the temperature to 175°C; (2) then raise the temperature to 210°...

Embodiment 2

[0063] The specific implementation method of the present embodiment is the same as that of Example 1, except that the propylene glycol is 150 parts.

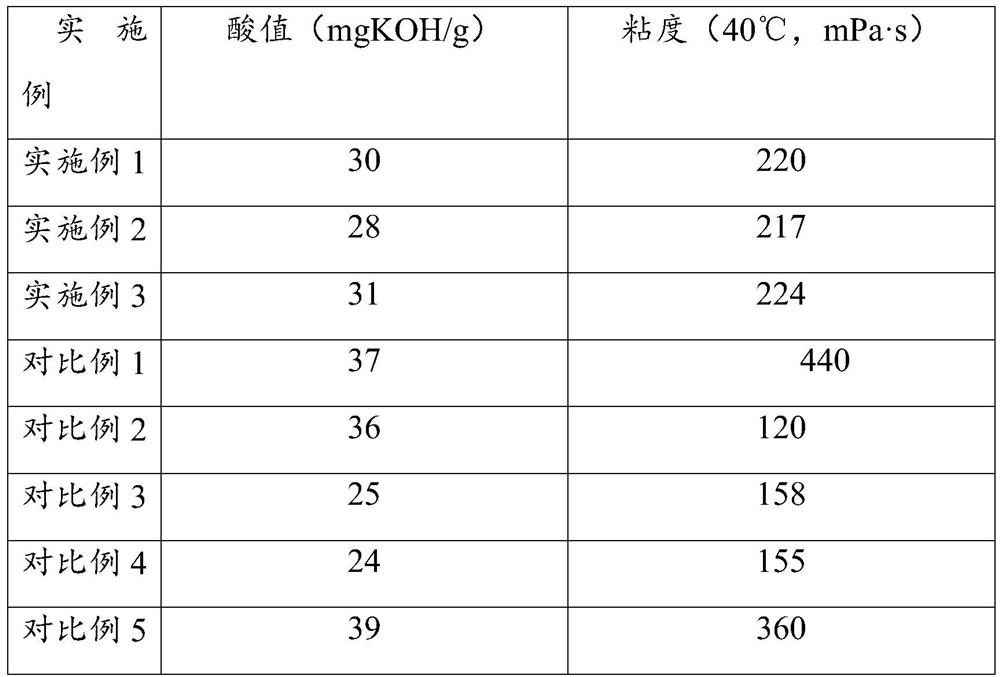

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com