Internal vaporizing expansion method for regenerating modified FCC waste catalyst and application thereof

A technology of internal vaporization and waste catalyst, which is applied in the fields of chemical modification of natural resin, catalyst regeneration/reactivation, chemical instruments and methods, etc. It can solve the problems of complex regeneration process and high energy consumption of FCC waste catalyst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Take 10kg of FCC waste catalyst, add 10kg of ether to infiltrate according to the solid-to-liquid ratio of FCC waste catalyst to organic solvent 1:1, soak for 120min, and then put it in an oven at 80°C to instantly vaporize the ether infiltrated into the FCC waste catalyst Expansion, to achieve the purpose of removing the carbon deposits and impurities in the channels of the FCC waste catalyst; then put the FCC waste catalyst after the internal vaporization and expansion treatment in the muffle furnace, and use the high-temperature roasting air oxidation method to roast at 300 ° C for 1 hour, and the roasted FCC waste catalyst is used as a carrier, and the FCC catalyst after roasting and the sulfuric acid with a mass concentration of 5% are added in the reaction kettle with agitator, thermometer and reflux condenser to impregnate, and the sulfuric acid added and the roasted FCC waste catalyst after adding The liquid-solid ratio is 2:1, that is, the mass of sulfuric acid ...

Embodiment 2

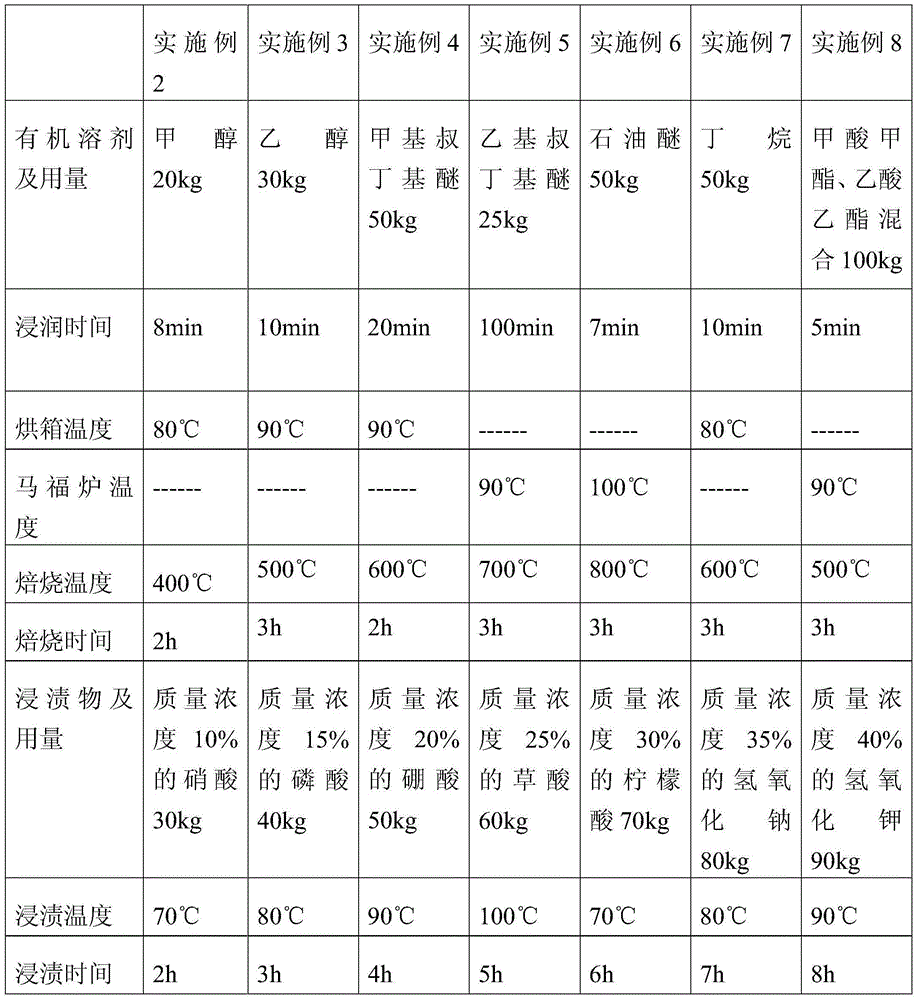

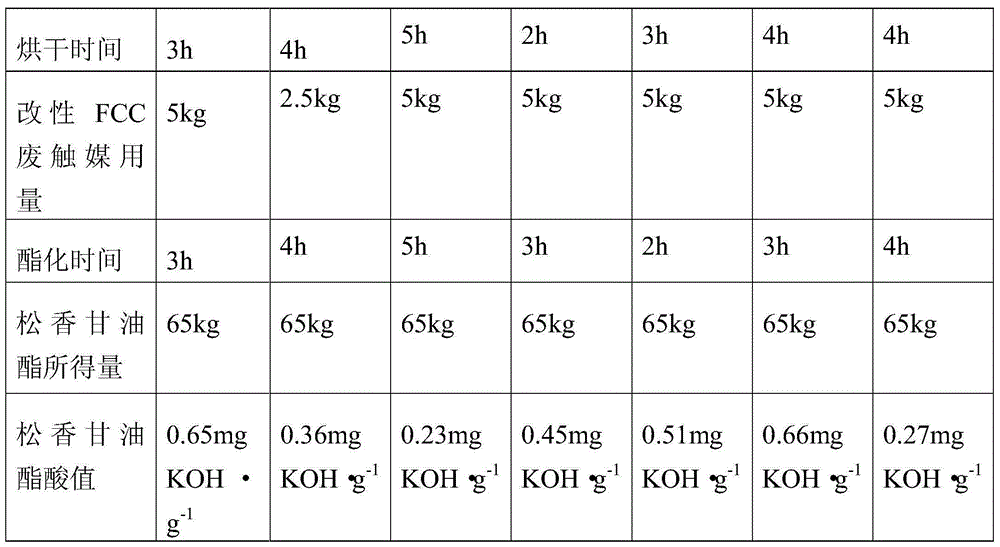

[0033] The method steps of Example 1 were repeated with the components and process parameters specified in Table 1 below. Other parameters appearing in Example 1 that are not mentioned in Table 1 are all carried out according to the parameters described in Example 1.

Embodiment 3

[0035] The method steps of Example 1 were repeated with the components and process parameters specified in Table 1 below. Other parameters appearing in Example 1 that are not mentioned in Table 1 are all carried out according to the parameters described in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com