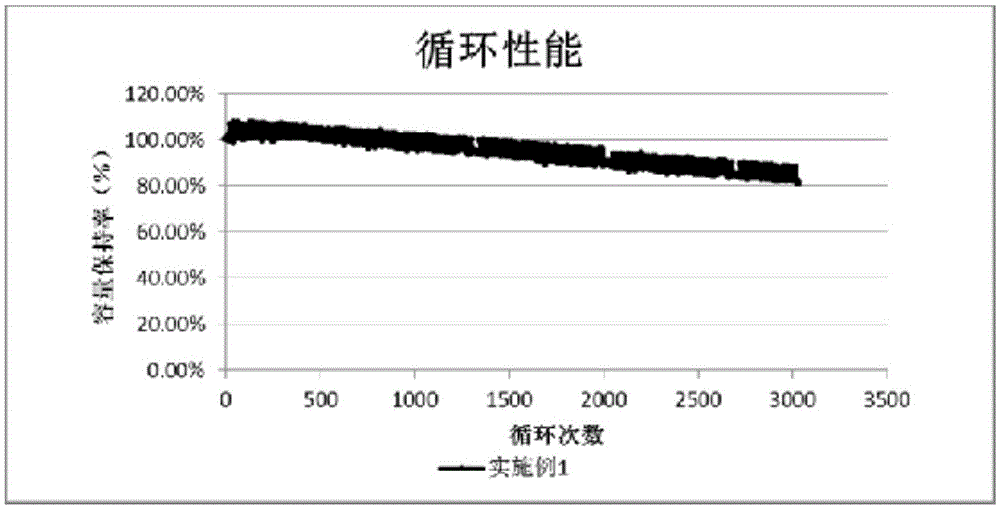

Industrial production method of nickel cobalt lithium manganite ternary positive electrode material with cycle life more than 3000 times

A technology of nickel-cobalt lithium manganese oxide and cycle life, which is applied in the production field of lithium-ion battery cathode materials, can solve the problems of reduced specific capacity, increased processing costs, and poor cycle performance of materials, and achieves the goal of reducing polarization and reducing charge transfer resistance Increase and improve the effect of crystal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

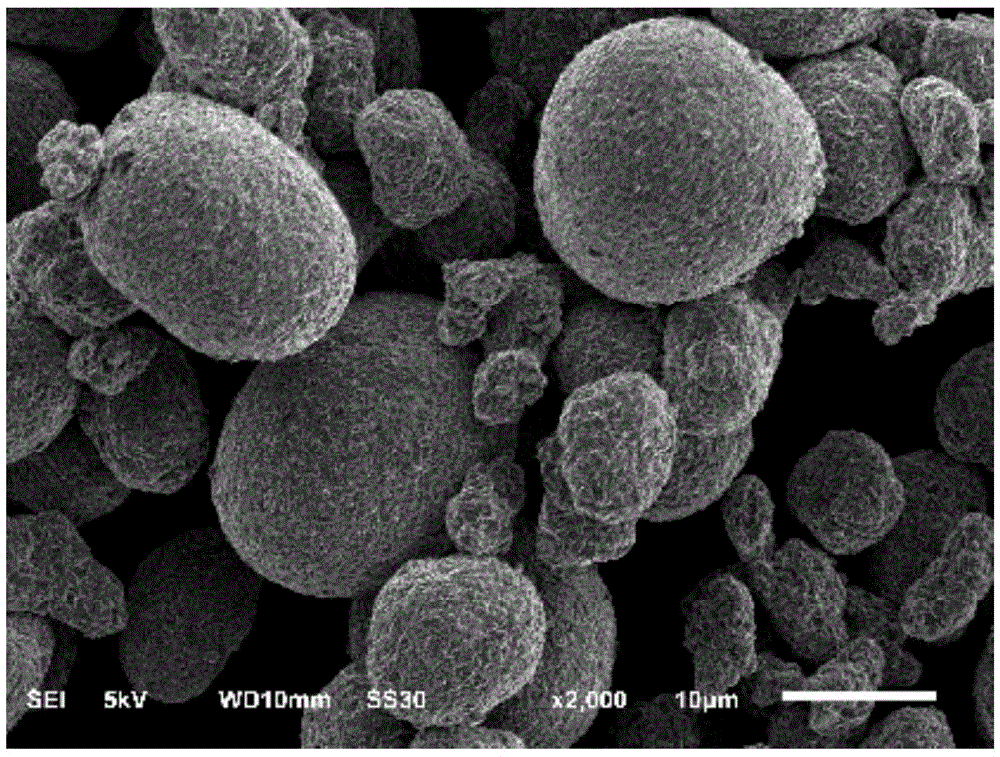

[0038] 1) Accurately weigh the nickel-cobalt-manganese hydroxide precursor with a D50 of 10.0-12.0 μm, about 2 tons in total, and add it to the high-efficiency mixer. At the same time, according to Li / Me=1.04, accurately weigh about 0.8 tons of lithium carbonate and add High-efficiency mixer mixes evenly;

[0039] 2) Put the mixture prepared in step 1 into the roller kiln at a certain speed, raise the temperature to 880°C at a certain rate of 1.5°C / min, and keep it warm for 15 hours. After the material enters the cooling zone, it is cooled by air cooling and water cooling. The cooling rate is 2.0-5.0°C / min, and the air intake volume is precisely controlled to be 10.0-50.0m 3 / h, displacement 1000~3500m 3 / h; After being out of the furnace, LiNi with a D50 of 11.0-14.0 μm can be obtained through coarse crushing and fine crushing. x co y mn 1-x-y o 2 , 0.45≤x≤0.55, 0.15≤y≤0.25.

Embodiment 2

[0041] 1) Accurately weigh the nickel-cobalt-manganese hydroxide precursor with a D50 of 10.0-12.0 μm, about 2 tons in total, and add it to the high-efficiency mixer. At the same time, according to Li / Me=1.02, accurately weigh about 0.95 tons of lithium hydroxide Add high-efficiency mixer and mix evenly;

[0042] 2) Put the mixture prepared in step 1 into the roller kiln at a certain speed in a sagger, raise the temperature to 900°C at a certain rate of 3°C / min, and keep it warm for 10 hours. After the material enters the cooling zone, it is cooled by air cooling and water cooling. The cooling rate is 2.0-5.0°C / min, and the air intake volume is precisely controlled to be 10.0-50.0m 3 / h, displacement 1000~3500m 3 / h; After being out of the furnace, LiNi with a D50 of 11.0-14.0 μm can be obtained through coarse crushing and fine crushing. x co y mn 1-x-y o 2 , 0.45≤x≤0.55, 0.15≤y≤0.25.

Embodiment 3

[0044] 1) Accurately weigh the nickel-cobalt-manganese hydroxide precursor with a D50 of 10.0-12.0 μm, about 2 tons in total, and add it to the high-efficiency mixer. At the same time, according to Li / Me=1.05, accurately weigh about 0.8 tons of lithium carbonate, Add the high-efficiency mixer and mix evenly;

[0045] 2) Put the mixture prepared in step 1 into the roller kiln at a certain speed, raise the temperature to 920°C at a certain rate of 1.0°C / min, and keep it warm for 15 hours. After entering the cooling zone, the material is cooled by air cooling and water cooling. The cooling rate is 2.0-5.0°C / min, and the air intake volume is precisely controlled to be 10.0-50.0m 3 / h, displacement 1000~3500m 3 / h; After being out of the furnace, LiNi with a D50 of 11.0-14.0 μm can be obtained through coarse crushing and fine crushing. x co y mn 1-x-y o 2 , 0.45≤x≤0.55, 0.15≤y≤0.25.

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com