Solution method for synthesizing butyl rubber

A technology of butyl rubber and solution method, which is applied in the field of butyl rubber synthesis by solution method, can solve the problems of insoluble aluminum trichloride, complicated preparation process, and difficult catalyst dispersion, and achieve good control of polymerization reaction and narrow molecular weight distribution , the effect of high number average molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

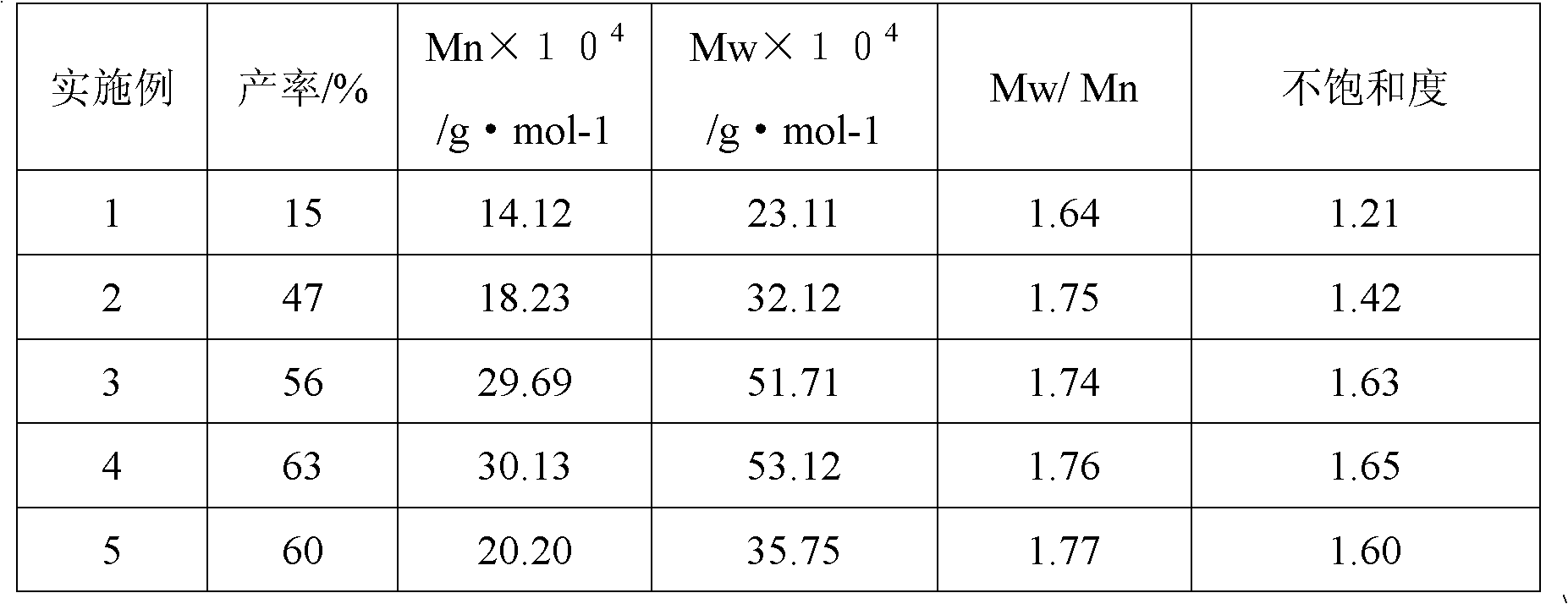

Examples

Embodiment 1

[0026] Mix 131ml of hexane with 54ml of methyl chloride, 124ml of isobutylene and 4.4ml of isoprene, take 33μL of water, add 6ml of sesqui-aluminum and dilute with 13ml of hexane to prepare an initiator system and age it for 15min. The prepared initiator system contains a large amount of white precipitation. After the initiation system was added to the polymerization at -80°C for 40 minutes, 10 ml of pre-cooled methanol solution was added to terminate. Precipitate by methanol solution, wash, and dry the product in vacuum.

Embodiment 2

[0028] Mix 131ml of hexane with 54ml of methyl chloride, 124ml of isobutene and 4.4ml of isoprene, then add to 0.3ml of CH 2 Cl 2 (Water content: 1600μg / g) was added 0.8ml of ethylaluminum dichloride and diluted with 9ml of hexane to prepare the trigger system and aged for 15min, the trigger system was light yellow, clear and free of white precipitate. After the initiation system was added to the polymerization at -80°C for 50 minutes, 10 ml of pre-cooled methanol solution was added to terminate it. Precipitate by methanol solution, wash, and dry the product in vacuum.

Embodiment 3

[0030] Mix 131ml of hexane with 54ml of methyl chloride, 124ml of isobutene and 4.4ml of isoprene, then mix 0.1ml of N,N-dimethylethanolamine with 0.3ml of CH 2 Cl 2 (water content: 1600μg / g) mixed, add 0.8ml of dichloroethylaluminum and dilute with 9ml of hexane to prepare the initiator system to age for 15min, add the initiator system to polymerization at -80°C for 50min, then add 10ml of pre-cooled methanol solution termination. Precipitate by methanol solution, wash, and dry the product in vacuum.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com