Preparation method of ultra-high molecular weight anionic polyacrylamide

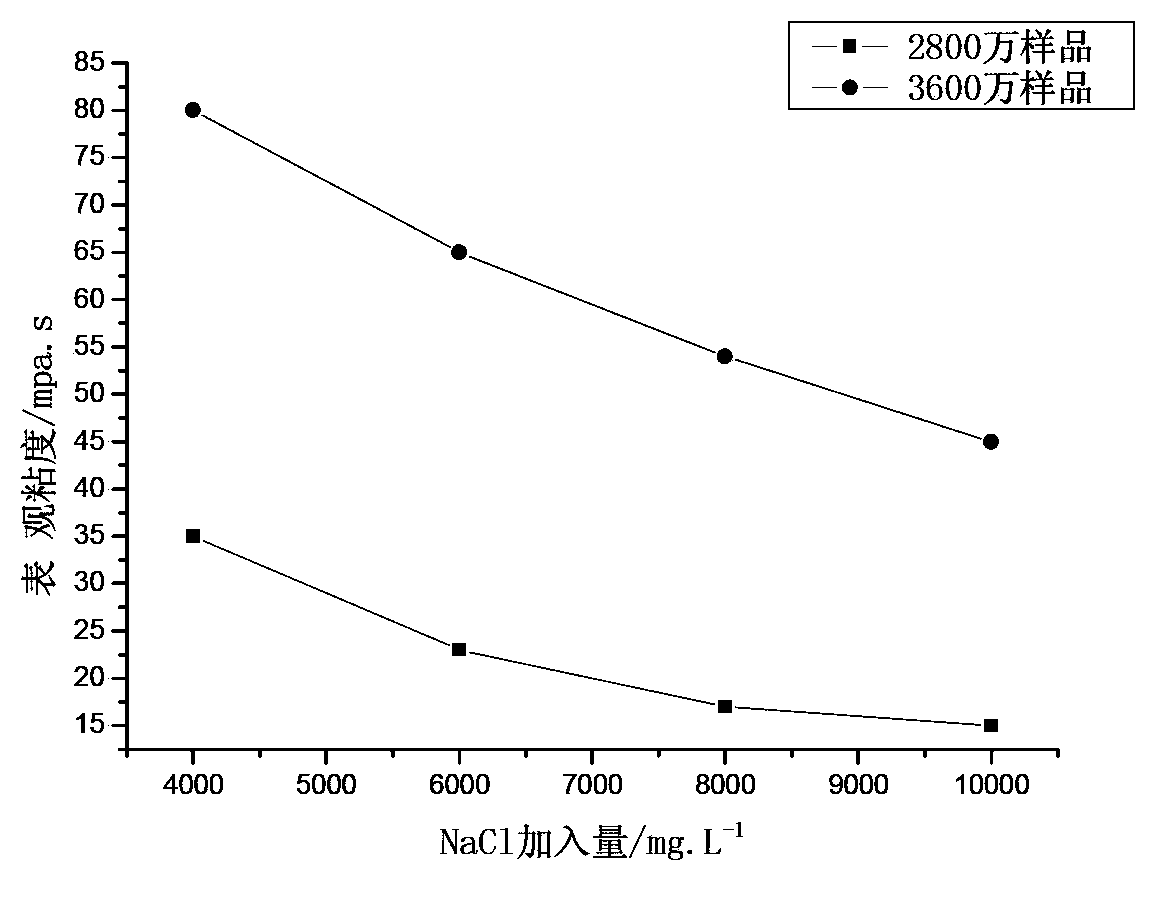

A polyacrylamide and ultra-high molecular weight technology, which is applied in the field of polymer compound preparation, can solve the problems of complicated operation process, inability to obtain molecular weight products, etc., and achieves the effects of good product solubility, easy large-scale industrial production and simple production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Add 100g of deionized water into the polymerization container, add 500g of 30% acrylamide, 40g of sodium carbonate, 4.8g of urea and 0.09g of sodium formate in turn under stirring, and feed nitrogen to remove dissolved oxygen in the reaction system, and at the same time adjust the system to initiate When the temperature reaches 10°C, place 0.01g of azobisisobutyrimidine hydrochloride and 0.01g of azobisisobutyrimidine hydrochloride at 60°C for 5 minutes, and add the initiator after passing nitrogen through the system for 15 minutes. After 3 minutes, the polymerization system started to become viscous, and the temperature began to rise. After 2 hours, the temperature of the polymerization system reached 70°C. After the system temperature began to drop, it was hydrolyzed in an oven at 90°C for 4 hours, and then granulated, dried, and crushed to obtain polyacrylamide with a molecular weight of 35.4 million. (HPAM).

Embodiment 2

[0028] According to the method and steps of Example 1, the difference is that the initiation temperature of the system in Example 2 is 5° C., and the molecular weight of the obtained HPAM is 37.14 million.

Embodiment 3

[0030] According to the method and steps of Example 1, the difference is that the initiation temperature of the system in Example 3 is 15° C., and the molecular weight of the obtained HPAM is 35.31 million.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com